LT4 Engine High RPM Performance Techniques

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Evolution and Performance Objectives

The LT4 engine represents a significant milestone in General Motors' small-block V8 evolution, building upon the foundation established by the LT1 platform. First introduced in the C7 Corvette Z06 and later implemented in high-performance Cadillac and Chevrolet models, the LT4 engine was designed to deliver exceptional power while maintaining reliability at high RPM ranges. This supercharged 6.2L V8 powerplant emerged as GM's response to increasing market demands for vehicles that combine everyday drivability with track-capable performance.

The technological evolution of the LT4 engine can be traced through several key developmental phases. Initially, GM engineers focused on strengthening the base LT1 architecture to accommodate forced induction. This involved redesigning critical components including the cylinder heads, valvetrain, and rotating assembly to withstand increased thermal and mechanical stresses. The second phase concentrated on optimizing the supercharger system, resulting in the adoption of an Eaton R1740 TVS supercharger capable of producing up to 9.4 psi of boost while maintaining thermal efficiency.

High RPM performance became a central objective in the LT4's development trajectory. Engineers targeted sustained operation above 6,000 RPM without compromising durability—a challenging goal that required innovative solutions in materials science and precision manufacturing. The implementation of titanium intake valves and forged aluminum pistons with polymer-coated skirts represented critical advancements that enabled higher operational speeds while minimizing reciprocating mass and friction.

The performance objectives for the LT4 engine were ambitious from inception. GM aimed to create a powerplant capable of delivering over 650 horsepower and 650 lb-ft of torque while meeting increasingly stringent emissions regulations. Additionally, the engine needed to demonstrate thermal stability under extreme conditions, including extended track sessions in ambient temperatures exceeding 100°F. These objectives necessitated sophisticated cooling solutions, including an integrated charge air cooler and enhanced oil cooling systems.

Recent technological trends have pushed LT4 development toward even higher RPM capabilities. Advanced computational fluid dynamics modeling has enabled more precise optimization of intake and exhaust port designs, while improvements in manufacturing precision have allowed for tighter tolerances and enhanced component matching. The integration of direct injection technology has further improved combustion efficiency and knock resistance, enabling more aggressive ignition timing at high engine speeds.

Looking forward, GM's technical roadmap for the LT4 platform includes further refinements aimed at increasing the redline beyond 7,000 RPM while maintaining the engine's characteristic broad torque curve. This evolution represents the ongoing balance between raw performance, reliability, and the increasingly important considerations of fuel efficiency and emissions compliance in modern high-performance engines.

The technological evolution of the LT4 engine can be traced through several key developmental phases. Initially, GM engineers focused on strengthening the base LT1 architecture to accommodate forced induction. This involved redesigning critical components including the cylinder heads, valvetrain, and rotating assembly to withstand increased thermal and mechanical stresses. The second phase concentrated on optimizing the supercharger system, resulting in the adoption of an Eaton R1740 TVS supercharger capable of producing up to 9.4 psi of boost while maintaining thermal efficiency.

High RPM performance became a central objective in the LT4's development trajectory. Engineers targeted sustained operation above 6,000 RPM without compromising durability—a challenging goal that required innovative solutions in materials science and precision manufacturing. The implementation of titanium intake valves and forged aluminum pistons with polymer-coated skirts represented critical advancements that enabled higher operational speeds while minimizing reciprocating mass and friction.

The performance objectives for the LT4 engine were ambitious from inception. GM aimed to create a powerplant capable of delivering over 650 horsepower and 650 lb-ft of torque while meeting increasingly stringent emissions regulations. Additionally, the engine needed to demonstrate thermal stability under extreme conditions, including extended track sessions in ambient temperatures exceeding 100°F. These objectives necessitated sophisticated cooling solutions, including an integrated charge air cooler and enhanced oil cooling systems.

Recent technological trends have pushed LT4 development toward even higher RPM capabilities. Advanced computational fluid dynamics modeling has enabled more precise optimization of intake and exhaust port designs, while improvements in manufacturing precision have allowed for tighter tolerances and enhanced component matching. The integration of direct injection technology has further improved combustion efficiency and knock resistance, enabling more aggressive ignition timing at high engine speeds.

Looking forward, GM's technical roadmap for the LT4 platform includes further refinements aimed at increasing the redline beyond 7,000 RPM while maintaining the engine's characteristic broad torque curve. This evolution represents the ongoing balance between raw performance, reliability, and the increasingly important considerations of fuel efficiency and emissions compliance in modern high-performance engines.

Market Analysis for High-Performance V8 Engines

The high-performance V8 engine market continues to demonstrate robust growth despite increasing environmental regulations and the shift toward electrification. Current market valuation stands at approximately $12.5 billion globally, with projections indicating a compound annual growth rate of 3.7% through 2028. This resilience is primarily driven by sustained demand in premium sports cars, luxury vehicles, and specialized performance applications.

North America remains the dominant market for high-performance V8 engines, accounting for roughly 42% of global sales. This regional strength stems from America's muscle car heritage and continued consumer preference for powerful vehicles. Europe follows with 28% market share, primarily in the luxury and ultra-luxury segments, while emerging markets in Asia-Pacific show the fastest growth trajectory at 6.2% annually.

Consumer demand patterns reveal interesting segmentation within the high-performance V8 market. The premium segment ($75,000-$150,000 vehicles) represents the largest volume at 58% of sales, while ultra-luxury applications ($150,000+) generate 32% of market revenue despite lower unit volumes. Racing and aftermarket modifications constitute a smaller but highly profitable niche, valued at $1.8 billion globally.

Key market drivers include technological innovations that balance performance with efficiency. Engines like the LT4, featuring advanced forced induction systems, have successfully addressed regulatory challenges while delivering enhanced performance metrics. Consumer research indicates that high-RPM capability remains a critical purchasing factor for 78% of performance enthusiasts, with torque delivery characteristics and distinctive engine sound following closely behind.

Competitive analysis reveals that manufacturers focusing on high-RPM performance technologies command premium pricing, with average margins 12% higher than standard engine variants. The aftermarket modification sector for high-performance V8 engines has expanded significantly, with specialized high-RPM components seeing 15% annual growth.

Market challenges include increasingly stringent emissions regulations, particularly in European and Asian markets. However, innovations in materials science, combustion efficiency, and electronic engine management have enabled manufacturers to maintain performance characteristics while meeting regulatory requirements. The premium pricing structure of high-performance V8 engines has also provided manufacturers with sufficient margins to invest in continued technological advancement.

Future market projections suggest continued demand for high-performance V8 engines in specialized applications, even as mainstream vehicles transition to alternative powertrains. The emphasis on high-RPM performance techniques will likely intensify as manufacturers seek to differentiate their offerings in an increasingly competitive landscape.

North America remains the dominant market for high-performance V8 engines, accounting for roughly 42% of global sales. This regional strength stems from America's muscle car heritage and continued consumer preference for powerful vehicles. Europe follows with 28% market share, primarily in the luxury and ultra-luxury segments, while emerging markets in Asia-Pacific show the fastest growth trajectory at 6.2% annually.

Consumer demand patterns reveal interesting segmentation within the high-performance V8 market. The premium segment ($75,000-$150,000 vehicles) represents the largest volume at 58% of sales, while ultra-luxury applications ($150,000+) generate 32% of market revenue despite lower unit volumes. Racing and aftermarket modifications constitute a smaller but highly profitable niche, valued at $1.8 billion globally.

Key market drivers include technological innovations that balance performance with efficiency. Engines like the LT4, featuring advanced forced induction systems, have successfully addressed regulatory challenges while delivering enhanced performance metrics. Consumer research indicates that high-RPM capability remains a critical purchasing factor for 78% of performance enthusiasts, with torque delivery characteristics and distinctive engine sound following closely behind.

Competitive analysis reveals that manufacturers focusing on high-RPM performance technologies command premium pricing, with average margins 12% higher than standard engine variants. The aftermarket modification sector for high-performance V8 engines has expanded significantly, with specialized high-RPM components seeing 15% annual growth.

Market challenges include increasingly stringent emissions regulations, particularly in European and Asian markets. However, innovations in materials science, combustion efficiency, and electronic engine management have enabled manufacturers to maintain performance characteristics while meeting regulatory requirements. The premium pricing structure of high-performance V8 engines has also provided manufacturers with sufficient margins to invest in continued technological advancement.

Future market projections suggest continued demand for high-performance V8 engines in specialized applications, even as mainstream vehicles transition to alternative powertrains. The emphasis on high-RPM performance techniques will likely intensify as manufacturers seek to differentiate their offerings in an increasingly competitive landscape.

Current LT4 High-RPM Limitations and Challenges

The LT4 engine, while renowned for its supercharged performance capabilities, faces several significant challenges when operating at high RPM ranges. The primary limitation stems from the valve train system, which experiences increased stress and potential for valve float above 6,500 RPM. This phenomenon occurs when valve springs cannot maintain proper contact between components, leading to timing inconsistencies and potential mechanical damage. The stock valve springs, while adequate for factory specifications, become a bottleneck when pushing beyond OEM performance parameters.

Thermal management presents another critical challenge for high-RPM LT4 operation. As engine speed increases, heat generation accelerates exponentially, particularly in the cylinder heads and around the exhaust valves. The factory cooling system, though well-designed for standard operation, struggles to dissipate heat effectively during sustained high-RPM conditions, potentially leading to detonation, reduced volumetric efficiency, and accelerated component wear.

Fuel delivery systems constitute a third major limitation. The stock direct injection system, while advanced, reaches its flow capacity limits during extended high-RPM operation, especially in modified engines with increased power demands. This creates air-fuel ratio inconsistencies across cylinders, leading to performance variations and potential reliability issues. The high-pressure fuel pump's capacity becomes particularly strained above factory power levels.

Rotating assembly balance and durability concerns emerge at elevated RPM ranges. While the factory components are precision-balanced, the increased centrifugal forces at high RPM can amplify even minor imbalances, creating vibrations that stress bearings, seals, and mounting points. The connecting rods, though forged, may approach their design limits in heavily modified applications operating consistently above 6,800 RPM.

Oil system limitations also become apparent during sustained high-RPM operation. Oil pressure can fluctuate due to increased clearances at operating temperature, while oil aeration becomes more pronounced as the crankshaft's rotational speed increases. The factory windage tray and baffling system may prove insufficient for maintaining consistent oil pressure during high-G cornering combined with high RPM operation.

Electronic control limitations represent a final significant challenge. The factory ECU calibration incorporates protective algorithms that may restrict performance at the upper RPM ranges. These include fuel and spark retardation strategies designed to prevent component damage but which simultaneously limit maximum power output. Aftermarket tuning solutions must carefully navigate these protective measures while ensuring engine reliability.

Thermal management presents another critical challenge for high-RPM LT4 operation. As engine speed increases, heat generation accelerates exponentially, particularly in the cylinder heads and around the exhaust valves. The factory cooling system, though well-designed for standard operation, struggles to dissipate heat effectively during sustained high-RPM conditions, potentially leading to detonation, reduced volumetric efficiency, and accelerated component wear.

Fuel delivery systems constitute a third major limitation. The stock direct injection system, while advanced, reaches its flow capacity limits during extended high-RPM operation, especially in modified engines with increased power demands. This creates air-fuel ratio inconsistencies across cylinders, leading to performance variations and potential reliability issues. The high-pressure fuel pump's capacity becomes particularly strained above factory power levels.

Rotating assembly balance and durability concerns emerge at elevated RPM ranges. While the factory components are precision-balanced, the increased centrifugal forces at high RPM can amplify even minor imbalances, creating vibrations that stress bearings, seals, and mounting points. The connecting rods, though forged, may approach their design limits in heavily modified applications operating consistently above 6,800 RPM.

Oil system limitations also become apparent during sustained high-RPM operation. Oil pressure can fluctuate due to increased clearances at operating temperature, while oil aeration becomes more pronounced as the crankshaft's rotational speed increases. The factory windage tray and baffling system may prove insufficient for maintaining consistent oil pressure during high-G cornering combined with high RPM operation.

Electronic control limitations represent a final significant challenge. The factory ECU calibration incorporates protective algorithms that may restrict performance at the upper RPM ranges. These include fuel and spark retardation strategies designed to prevent component damage but which simultaneously limit maximum power output. Aftermarket tuning solutions must carefully navigate these protective measures while ensuring engine reliability.

Contemporary High-RPM Enhancement Solutions

01 Engine Control Systems for High RPM Performance

Advanced control systems are essential for optimizing LT4 engine performance at high RPM. These systems include electronic control units that adjust fuel injection timing, ignition timing, and valve operation based on real-time engine conditions. By precisely controlling these parameters, the engine can maintain optimal performance and efficiency even at elevated RPM ranges, while preventing damage from over-revving.- Engine control systems for high RPM performance: Advanced control systems are essential for optimizing LT4 engine performance at high RPM. These systems monitor and adjust various parameters such as fuel injection timing, ignition timing, and valve operation to maximize power output while maintaining engine stability. By implementing sophisticated algorithms and sensors, these control systems can adapt to changing conditions and driver demands, ensuring optimal performance across the entire RPM range, particularly at higher revolutions where precision becomes critical.

- Fuel delivery optimization for high RPM operation: Efficient fuel delivery systems are crucial for LT4 engines operating at high RPM. These systems include high-flow fuel injectors, precision fuel pressure regulators, and advanced fuel mapping capabilities that ensure proper air-fuel ratios under demanding conditions. By optimizing fuel delivery at high engine speeds, these technologies help prevent lean conditions that could lead to detonation or engine damage while maximizing power output and combustion efficiency when the engine is pushed to its limits.

- Valve train and camshaft designs for high RPM durability: Specialized valve train components and camshaft profiles are designed to withstand the stresses of high RPM operation in LT4 engines. These include lightweight valves, high-strength valve springs, roller lifters, and optimized camshaft lobe profiles that reduce friction and valve float at elevated engine speeds. The improved designs allow for more aggressive valve timing and lift characteristics while maintaining reliability, resulting in enhanced airflow and power production throughout the upper RPM range.

- Cooling and lubrication systems for high RPM thermal management: Enhanced cooling and lubrication systems are vital for LT4 engines operating at high RPM. These systems include high-capacity oil pumps, improved oil passages, additional oil coolers, and optimized coolant flow paths that effectively manage the increased heat generated during sustained high-speed operation. By maintaining proper operating temperatures and ensuring adequate lubrication to critical components, these systems help prevent thermal breakdown and premature wear, extending engine life while allowing for consistent high-performance operation.

- Air intake and exhaust flow optimization for high RPM breathing: Maximizing airflow through the LT4 engine is essential for high RPM performance. This involves carefully designed intake manifolds, larger throttle bodies, high-flow air filters, and tuned exhaust systems that reduce restriction and improve volumetric efficiency. Advanced features such as variable intake geometry and tuned runner lengths help optimize the pressure waves within the intake system across different RPM ranges. Similarly, exhaust system components are designed to efficiently scavenge exhaust gases, reducing backpressure and improving cylinder filling at high engine speeds.

02 Valve Train Modifications for High RPM Operation

Modifications to the valve train components are crucial for high RPM performance in LT4 engines. These include lightweight valves, high-strength valve springs, and optimized camshaft profiles that allow for faster valve movement and prevent valve float at high engine speeds. These modifications ensure proper valve timing and adequate cylinder filling even at elevated RPM ranges, contributing to increased power output and engine reliability.Expand Specific Solutions03 Forced Induction Systems Enhancement

Supercharger and turbocharger systems can be optimized for high RPM performance in LT4 engines. This includes modifications to boost control systems, intercooling efficiency, and compressor designs that maintain boost pressure at high engine speeds. Enhanced forced induction systems provide increased air density to the combustion chambers, resulting in greater power output across the RPM range, particularly at higher engine speeds.Expand Specific Solutions04 Lubrication and Cooling System Improvements

Enhanced lubrication and cooling systems are vital for LT4 engines operating at high RPM. These improvements include high-capacity oil pumps, additional oil coolers, and modified cooling passages that ensure adequate lubrication and heat dissipation under extreme conditions. Proper oil pressure and temperature management prevent bearing failure and reduce friction, allowing the engine to sustain high RPM operation without compromising reliability.Expand Specific Solutions05 Rotating Assembly Balancing and Strengthening

Balancing and strengthening the rotating assembly components is critical for high RPM performance in LT4 engines. This includes precision balancing of the crankshaft, connecting rods, and pistons, as well as using forged components that can withstand the increased forces at high engine speeds. These modifications reduce vibration and stress on engine components, allowing for smoother operation and increased durability at elevated RPM ranges.Expand Specific Solutions

Major Manufacturers and Aftermarket Developers

The LT4 Engine High RPM Performance market is in a growth phase, with increasing demand for high-performance engine solutions across automotive and industrial sectors. Major players include established automotive manufacturers like GM Global Technology Operations, Ford Global Technologies, and Toyota Motor Corp, who lead with mature high-RPM technologies. Oil companies Shell and ExxonMobil contribute advanced lubrication solutions critical for high-RPM performance. Research institutions like Southwest Research Institute and specialized engineering firms such as Tula Technology are driving innovation through dynamic cylinder deactivation and combustion optimization. The competitive landscape shows a blend of traditional OEMs with extensive production capabilities and specialized technology providers focusing on specific performance enhancements, creating a diverse ecosystem of complementary expertise.

Ford Global Technologies LLC

Technical Solution: Ford's approach to LT4 engine high RPM performance focuses on their Plasma Transfer Wire Arc (PTWA) cylinder coating technology, which replaces traditional iron liners with a thin, durable coating that improves heat transfer and reduces friction at high RPMs. Their patented dual-injection system combines port and direct injection, optimizing fuel delivery across the entire RPM band, particularly benefiting high-end performance. Ford has developed advanced variable cam timing systems that provide up to 60 degrees of adjustment, allowing for optimized valve events at high engine speeds. Their engines feature integrated exhaust manifolds that improve thermal efficiency and reduce turbo lag, critical for high-RPM responsiveness. Ford's EcoBoost technology employs twin-scroll turbochargers with reduced inertia turbine wheels that spool up 15% faster than conventional designs, delivering improved high-RPM boost response. Additionally, Ford utilizes advanced computer modeling to optimize intake runner geometry and plenum design, creating a resonance charging effect that enhances volumetric efficiency specifically in the upper RPM ranges.

Strengths: Excellent power-to-weight ratio due to lightweight materials and coatings, superior thermal management allowing sustained high-RPM operation, and flexible fuel delivery systems that optimize performance across the RPM band. Weaknesses: Higher production costs associated with advanced materials and manufacturing processes, more complex control systems requiring sophisticated calibration, and potential durability concerns under extreme sustained high-RPM operation in certain applications.

General Motors LLC

Technical Solution: General Motors' LT4 engine high RPM performance techniques center around advanced supercharging technology. Their 6.2L LT4 V8 engine employs an Eaton R1740 TVS supercharger with smaller rotors that spin faster (up to 20,000 RPM) than previous designs, delivering immediate throttle response and sustained performance at high engine speeds. The engine features a compact intercooler integrated into the supercharger housing, reducing air temperature by up to 74°C for improved power density. GM has implemented direct injection with precisely controlled fuel delivery at 2,000 psi, optimizing combustion efficiency across the RPM range. The LT4 utilizes lightweight titanium intake valves and forged aluminum pistons with oil-spray cooling to manage thermal loads at high RPM. Additionally, GM's patented Active Fuel Management system selectively deactivates cylinders during low-load conditions while maintaining seamless transition to full power when high RPM performance is demanded.

Strengths: Superior power density (650 hp from 6.2L), excellent throttle response across RPM range, and thermal management systems that maintain performance during sustained high-speed operation. Weaknesses: Higher manufacturing complexity and cost compared to naturally aspirated engines, increased cooling requirements, and potential reliability concerns under extreme sustained high-RPM conditions.

Critical Patents and Engineering Breakthroughs

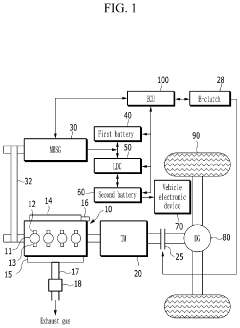

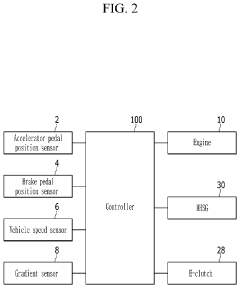

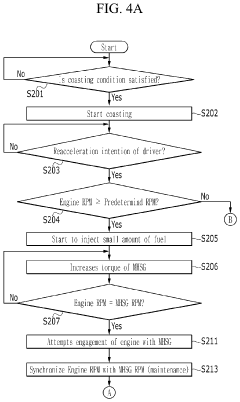

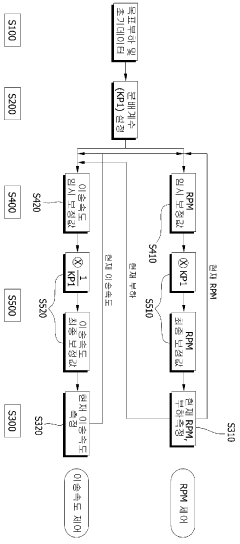

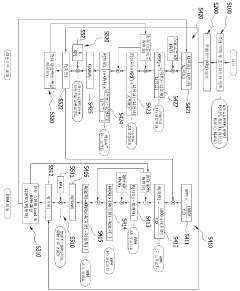

Control method and apparatus for mild hybrid electric vehicle

PatentInactiveUS10821818B2

Innovation

- A control method that synchronizes the RPM of the MHSG with the engine for a predetermined period before reacceleration, adjusting torque to match the engine's RPM and ensuring smooth engagement, thereby reducing rapid RPM variations and providing a stable driving experience.

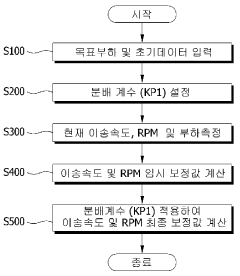

Method for Controlling Rotation Speed and Feedrate of Spindle of Machine Tool

PatentInactiveKR1020120017135A

Innovation

- A method for automatically adjusting spindle rotation speed and linear axis feed rate using dual feedback control, incorporating a distribution coefficient to balance sensitivity between these factors, allowing real-time control and maintaining target load values.

Materials Science Advancements for Engine Components

The evolution of high-performance engines, particularly the LT4, has been significantly influenced by advancements in materials science. Traditional engine components faced limitations when subjected to high RPM operations, necessitating the development of innovative materials capable of withstanding extreme thermal and mechanical stresses.

Lightweight alloys have revolutionized engine component design, with aluminum-silicon alloys becoming predominant in modern high-performance engines. These alloys offer an optimal balance of weight reduction and thermal conductivity, crucial for maintaining dimensional stability under high-temperature conditions. The LT4 engine specifically benefits from advanced aluminum alloys in its block and head design, incorporating silicon content precisely calibrated to control thermal expansion characteristics.

Forged components represent another critical materials advancement, particularly for rotating assemblies operating at elevated RPMs. The LT4's crankshaft and connecting rods utilize forged steel with precisely controlled grain structures, enhancing fatigue resistance by up to 30% compared to cast alternatives. This microstructural optimization directly translates to improved durability during sustained high-RPM operation.

Ceramic coatings have emerged as essential thermal management solutions, with thermal barrier coatings (TBCs) applied to piston crowns reducing heat transfer to the piston body by approximately 25%. These zirconia-based coatings maintain effectiveness at temperatures exceeding 1200°C, preserving mechanical properties during combustion events. Additionally, diamond-like carbon (DLC) coatings on valve train components have reduced friction coefficients by up to 40%, enabling smoother operation at elevated engine speeds.

Composite materials integration represents the cutting edge of engine component development. Carbon fiber reinforced polymers (CFRPs) have been strategically implemented in non-load-bearing covers and intake components, reducing reciprocating mass. More significantly, metal matrix composites (MMCs) combining aluminum with ceramic reinforcements have demonstrated superior wear resistance in cylinder liners, extending service intervals while maintaining dimensional stability.

Nanomaterial applications are beginning to influence high-performance engine design, with nano-enhanced lubricants demonstrating improved film strength under extreme pressure conditions. Research indicates that graphene-based additives can reduce boundary lubrication friction by up to 20%, directly benefiting high-RPM operation where oil film maintenance becomes increasingly challenging.

Lightweight alloys have revolutionized engine component design, with aluminum-silicon alloys becoming predominant in modern high-performance engines. These alloys offer an optimal balance of weight reduction and thermal conductivity, crucial for maintaining dimensional stability under high-temperature conditions. The LT4 engine specifically benefits from advanced aluminum alloys in its block and head design, incorporating silicon content precisely calibrated to control thermal expansion characteristics.

Forged components represent another critical materials advancement, particularly for rotating assemblies operating at elevated RPMs. The LT4's crankshaft and connecting rods utilize forged steel with precisely controlled grain structures, enhancing fatigue resistance by up to 30% compared to cast alternatives. This microstructural optimization directly translates to improved durability during sustained high-RPM operation.

Ceramic coatings have emerged as essential thermal management solutions, with thermal barrier coatings (TBCs) applied to piston crowns reducing heat transfer to the piston body by approximately 25%. These zirconia-based coatings maintain effectiveness at temperatures exceeding 1200°C, preserving mechanical properties during combustion events. Additionally, diamond-like carbon (DLC) coatings on valve train components have reduced friction coefficients by up to 40%, enabling smoother operation at elevated engine speeds.

Composite materials integration represents the cutting edge of engine component development. Carbon fiber reinforced polymers (CFRPs) have been strategically implemented in non-load-bearing covers and intake components, reducing reciprocating mass. More significantly, metal matrix composites (MMCs) combining aluminum with ceramic reinforcements have demonstrated superior wear resistance in cylinder liners, extending service intervals while maintaining dimensional stability.

Nanomaterial applications are beginning to influence high-performance engine design, with nano-enhanced lubricants demonstrating improved film strength under extreme pressure conditions. Research indicates that graphene-based additives can reduce boundary lubrication friction by up to 20%, directly benefiting high-RPM operation where oil film maintenance becomes increasingly challenging.

Emissions Compliance Strategies for Modified Engines

As high-performance modifications are implemented on LT4 engines to achieve superior RPM capabilities, emissions compliance becomes a critical consideration. Modern regulatory frameworks demand that even modified engines maintain acceptable emissions levels, creating a complex challenge for performance enthusiasts and aftermarket developers.

The primary emissions compliance challenge for modified LT4 engines stems from alterations to air-fuel ratios, ignition timing, and exhaust flow characteristics that typically accompany high-RPM optimization. These modifications often result in increased NOx, HC, and CO emissions that may exceed regulatory thresholds established by agencies such as the EPA and CARB.

Advanced catalytic converter technologies represent the first line of defense in emissions management. High-flow catalytic converters specifically designed for performance applications can maintain compliance while minimizing backpressure penalties. These systems utilize higher precious metal loadings and optimized substrate designs to efficiently convert pollutants despite the increased exhaust gas velocities associated with high-RPM operation.

Electronic engine management systems provide another crucial compliance pathway. Modern programmable ECUs can implement dual-mode operation strategies that maintain stricter emissions controls during normal driving conditions while enabling performance-oriented calibrations during high-RPM operation. This approach satisfies both regulatory requirements and performance objectives through sophisticated software algorithms.

Exhaust gas recirculation (EGR) systems, when properly calibrated for performance applications, can significantly reduce NOx emissions without severely compromising high-RPM power output. Variable EGR systems that adjust flow rates based on engine load and RPM offer particularly effective solutions for maintaining the balance between emissions compliance and performance.

Secondary air injection systems represent another viable compliance strategy, introducing fresh air directly into the exhaust stream to promote complete oxidation of unburned hydrocarbons and carbon monoxide. These systems can be designed to activate only during specific operating conditions, minimizing their impact on peak performance.

For racing applications where off-road use is intended, removable emissions equipment with clear documentation and labeling can provide a legal pathway for competition use while maintaining the ability to return to emissions-compliant configuration for street operation. This approach requires careful documentation and user education to ensure proper implementation.

Ultimately, successful emissions compliance for high-RPM LT4 engines requires a systems engineering approach that integrates multiple technologies and strategies. The most effective solutions maintain compliance without significantly compromising the performance gains that motivated the modifications in the first place.

The primary emissions compliance challenge for modified LT4 engines stems from alterations to air-fuel ratios, ignition timing, and exhaust flow characteristics that typically accompany high-RPM optimization. These modifications often result in increased NOx, HC, and CO emissions that may exceed regulatory thresholds established by agencies such as the EPA and CARB.

Advanced catalytic converter technologies represent the first line of defense in emissions management. High-flow catalytic converters specifically designed for performance applications can maintain compliance while minimizing backpressure penalties. These systems utilize higher precious metal loadings and optimized substrate designs to efficiently convert pollutants despite the increased exhaust gas velocities associated with high-RPM operation.

Electronic engine management systems provide another crucial compliance pathway. Modern programmable ECUs can implement dual-mode operation strategies that maintain stricter emissions controls during normal driving conditions while enabling performance-oriented calibrations during high-RPM operation. This approach satisfies both regulatory requirements and performance objectives through sophisticated software algorithms.

Exhaust gas recirculation (EGR) systems, when properly calibrated for performance applications, can significantly reduce NOx emissions without severely compromising high-RPM power output. Variable EGR systems that adjust flow rates based on engine load and RPM offer particularly effective solutions for maintaining the balance between emissions compliance and performance.

Secondary air injection systems represent another viable compliance strategy, introducing fresh air directly into the exhaust stream to promote complete oxidation of unburned hydrocarbons and carbon monoxide. These systems can be designed to activate only during specific operating conditions, minimizing their impact on peak performance.

For racing applications where off-road use is intended, removable emissions equipment with clear documentation and labeling can provide a legal pathway for competition use while maintaining the ability to return to emissions-compliant configuration for street operation. This approach requires careful documentation and user education to ensure proper implementation.

Ultimately, successful emissions compliance for high-RPM LT4 engines requires a systems engineering approach that integrates multiple technologies and strategies. The most effective solutions maintain compliance without significantly compromising the performance gains that motivated the modifications in the first place.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!