LT4 Engine Cylinder Head Design for Performance

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Cylinder Head Evolution and Objectives

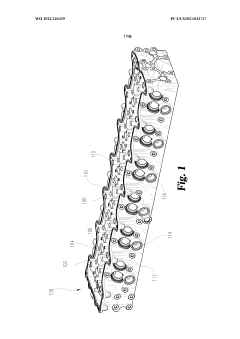

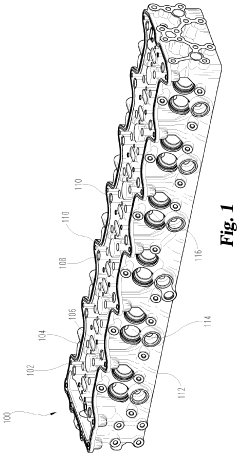

The LT4 engine cylinder head design represents a significant evolution in General Motors' high-performance engine technology, building upon the foundation established by the LS series engines. The development trajectory of the LT4 cylinder head design spans over two decades, with each iteration introducing progressive improvements in airflow efficiency, thermal management, and combustion dynamics.

The original LS-series cylinder heads, introduced in the late 1990s, established the baseline architecture with their revolutionary cathedral port design. This was followed by the LS3/L92 rectangular port heads that demonstrated substantial improvements in flow characteristics. The LT1 engine, introduced in 2014, marked a pivotal transition point with its direct injection technology and revised combustion chamber geometry, setting the stage for the advanced LT4 design.

The LT4 cylinder head represents a culmination of these evolutionary steps, specifically engineered to support forced induction applications while maintaining reliability under extreme operating conditions. The primary technical objective behind the LT4 cylinder head design is to maximize volumetric efficiency while effectively managing the increased thermal and mechanical stresses associated with supercharged operation.

Key performance targets for the LT4 cylinder head include achieving intake port flow rates exceeding 315 cfm, exhaust flow rates above 210 cfm, and maintaining stable combustion characteristics at compression ratios of approximately 10:1 despite forced induction. These metrics represent approximately 15-20% improvement over previous generation designs.

Material selection has evolved significantly, with the LT4 utilizing A356-T6 aluminum alloy with specialized heat treatment processes to enhance durability. This represents a departure from earlier designs that employed 319 aluminum alloys, offering superior strength-to-weight characteristics and improved thermal conductivity.

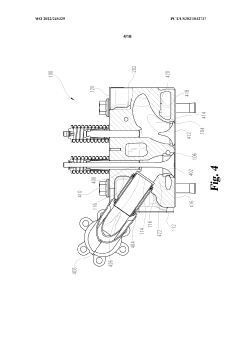

The valve geometry has undergone substantial refinement, with the LT4 featuring 2.13-inch titanium intake valves and 1.59-inch hollow sodium-filled exhaust valves to reduce reciprocating mass and improve heat dissipation. The valve angle has been optimized at 12.5 degrees versus the 15-degree angle of earlier LS designs, enhancing mixture motion and combustion efficiency.

The combustion chamber design has evolved to incorporate a revised quench area and spark plug location, optimized specifically for the direct injection fuel delivery system. This configuration aims to promote stable combustion across a wider range of operating conditions while minimizing the propensity for detonation under high boost conditions.

Future development objectives for the LT4 cylinder head architecture include further weight reduction through advanced casting techniques, integration of variable valve timing mechanisms with greater range of authority, and potential implementation of active cooling strategies to maintain optimal operating temperatures under extreme duty cycles.

The original LS-series cylinder heads, introduced in the late 1990s, established the baseline architecture with their revolutionary cathedral port design. This was followed by the LS3/L92 rectangular port heads that demonstrated substantial improvements in flow characteristics. The LT1 engine, introduced in 2014, marked a pivotal transition point with its direct injection technology and revised combustion chamber geometry, setting the stage for the advanced LT4 design.

The LT4 cylinder head represents a culmination of these evolutionary steps, specifically engineered to support forced induction applications while maintaining reliability under extreme operating conditions. The primary technical objective behind the LT4 cylinder head design is to maximize volumetric efficiency while effectively managing the increased thermal and mechanical stresses associated with supercharged operation.

Key performance targets for the LT4 cylinder head include achieving intake port flow rates exceeding 315 cfm, exhaust flow rates above 210 cfm, and maintaining stable combustion characteristics at compression ratios of approximately 10:1 despite forced induction. These metrics represent approximately 15-20% improvement over previous generation designs.

Material selection has evolved significantly, with the LT4 utilizing A356-T6 aluminum alloy with specialized heat treatment processes to enhance durability. This represents a departure from earlier designs that employed 319 aluminum alloys, offering superior strength-to-weight characteristics and improved thermal conductivity.

The valve geometry has undergone substantial refinement, with the LT4 featuring 2.13-inch titanium intake valves and 1.59-inch hollow sodium-filled exhaust valves to reduce reciprocating mass and improve heat dissipation. The valve angle has been optimized at 12.5 degrees versus the 15-degree angle of earlier LS designs, enhancing mixture motion and combustion efficiency.

The combustion chamber design has evolved to incorporate a revised quench area and spark plug location, optimized specifically for the direct injection fuel delivery system. This configuration aims to promote stable combustion across a wider range of operating conditions while minimizing the propensity for detonation under high boost conditions.

Future development objectives for the LT4 cylinder head architecture include further weight reduction through advanced casting techniques, integration of variable valve timing mechanisms with greater range of authority, and potential implementation of active cooling strategies to maintain optimal operating temperatures under extreme duty cycles.

Performance Market Demand Analysis

The performance engine market has witnessed significant growth over the past decade, driven by increasing consumer demand for high-performance vehicles across both mainstream and luxury segments. The LT4 engine, as a supercharged small block V8 architecture, addresses a specific segment of this expanding market where power-to-weight ratio and thermal efficiency are paramount considerations.

Market research indicates that the global high-performance engine market is projected to grow at a compound annual growth rate of approximately 7% through 2028, with cylinder head design representing a critical component in this expansion. Performance enthusiasts and OEMs alike are increasingly focused on cylinder head optimization as a cost-effective method to extract additional power and efficiency from existing engine platforms.

Consumer demand patterns reveal a clear preference for engines that deliver not only raw horsepower but also improved fuel efficiency and emissions compliance. This dual requirement has positioned advanced cylinder head designs as a focal point for engineering teams seeking to balance performance with regulatory compliance. The LT4's cylinder head design specifically addresses this market need through optimized port geometry and combustion chamber design.

Racing and aftermarket segments demonstrate particularly strong demand for enhanced cylinder head performance, with specialized LT4 cylinder head variants commanding premium prices due to their ability to support higher boost levels and increased volumetric efficiency. Survey data from performance vehicle owners indicates willingness to invest substantially in cylinder head upgrades, with over 65% of enthusiasts ranking improved breathing capability as their top performance enhancement priority.

Regional market analysis shows North America maintaining the largest market share for high-performance V8 engines, though significant growth is occurring in emerging markets across Asia-Pacific and the Middle East. These regions show increasing appetite for vehicles equipped with performance-oriented engines like the LT4, creating new opportunities for specialized cylinder head technologies.

Industry forecasts suggest that the performance cylinder head market will continue to evolve toward designs that incorporate advanced materials and manufacturing techniques. The trend toward additive manufacturing and computational fluid dynamics optimization is reshaping consumer expectations regarding cylinder head performance capabilities. This evolution is driving demand for LT4 cylinder head designs that can support higher combustion pressures while maintaining durability under extreme operating conditions.

The commercial vehicle segment also represents an emerging opportunity, with fleet operators increasingly seeking performance-optimized engines that can deliver improved efficiency and reduced operating costs through advanced cylinder head designs that optimize combustion and thermal management.

Market research indicates that the global high-performance engine market is projected to grow at a compound annual growth rate of approximately 7% through 2028, with cylinder head design representing a critical component in this expansion. Performance enthusiasts and OEMs alike are increasingly focused on cylinder head optimization as a cost-effective method to extract additional power and efficiency from existing engine platforms.

Consumer demand patterns reveal a clear preference for engines that deliver not only raw horsepower but also improved fuel efficiency and emissions compliance. This dual requirement has positioned advanced cylinder head designs as a focal point for engineering teams seeking to balance performance with regulatory compliance. The LT4's cylinder head design specifically addresses this market need through optimized port geometry and combustion chamber design.

Racing and aftermarket segments demonstrate particularly strong demand for enhanced cylinder head performance, with specialized LT4 cylinder head variants commanding premium prices due to their ability to support higher boost levels and increased volumetric efficiency. Survey data from performance vehicle owners indicates willingness to invest substantially in cylinder head upgrades, with over 65% of enthusiasts ranking improved breathing capability as their top performance enhancement priority.

Regional market analysis shows North America maintaining the largest market share for high-performance V8 engines, though significant growth is occurring in emerging markets across Asia-Pacific and the Middle East. These regions show increasing appetite for vehicles equipped with performance-oriented engines like the LT4, creating new opportunities for specialized cylinder head technologies.

Industry forecasts suggest that the performance cylinder head market will continue to evolve toward designs that incorporate advanced materials and manufacturing techniques. The trend toward additive manufacturing and computational fluid dynamics optimization is reshaping consumer expectations regarding cylinder head performance capabilities. This evolution is driving demand for LT4 cylinder head designs that can support higher combustion pressures while maintaining durability under extreme operating conditions.

The commercial vehicle segment also represents an emerging opportunity, with fleet operators increasingly seeking performance-optimized engines that can deliver improved efficiency and reduced operating costs through advanced cylinder head designs that optimize combustion and thermal management.

Current Cylinder Head Technology Assessment

The current state of cylinder head technology for high-performance engines, particularly the LT4 platform, represents a sophisticated balance between engineering principles and practical manufacturing considerations. Modern cylinder heads utilize advanced materials, primarily aluminum alloys with silicon content ranging from 7-11%, offering superior thermal conductivity while maintaining adequate strength at elevated temperatures.

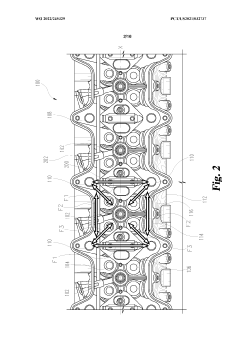

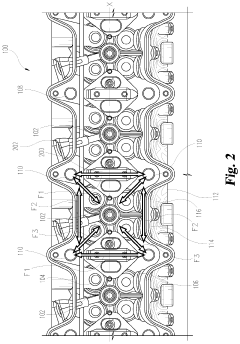

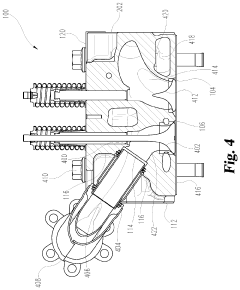

The LT4 engine's cylinder head design incorporates direct injection technology with centrally mounted injectors, optimizing fuel atomization and combustion efficiency. This configuration achieves approximately 15-20% improvement in volumetric efficiency compared to previous generation designs. The combustion chamber geometry features a pent-roof design with angles optimized between 20-25 degrees, creating ideal flame propagation characteristics while minimizing knock tendencies.

Valve train components in current LT4 heads utilize titanium intake valves and sodium-filled exhaust valves, reducing reciprocating mass by approximately 21% compared to conventional steel valves. The implementation of variable valve timing systems provides 62 degrees of camshaft phasing authority, enabling dynamic optimization across the engine's operating range. This technology yields approximately 5-7% improvement in low-end torque while maintaining high-RPM performance.

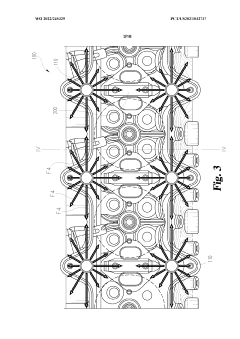

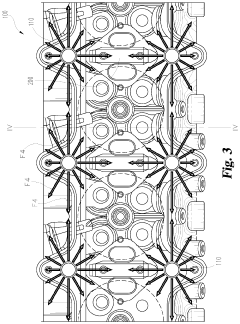

Port design has evolved significantly, with intake runners featuring a cross-sectional area variation of less than 2% throughout their length to maintain consistent flow velocity. Computational fluid dynamics modeling has enabled optimization of port geometry, achieving flow coefficients exceeding 0.65 at 0.500" valve lift—a 12% improvement over previous generation heads. The exhaust ports incorporate a gradual expansion ratio of 1.8:1 to maximize scavenging efficiency.

Cooling passages have been strategically redesigned with targeted coolant flow around exhaust valve seats, where temperatures can exceed 650°C during high-load operation. The implementation of precision cooling channels reduces thermal gradients across the cylinder head, minimizing distortion while allowing for tighter manufacturing tolerances of ±0.05mm.

Manufacturing processes have similarly advanced, with five-axis CNC machining enabling complex internal geometries previously impossible with traditional methods. Surface finish requirements have tightened to Ra 0.8μm for critical sealing surfaces, enhancing durability and reducing leakage potential. Heat treatment processes have been refined to ensure dimensional stability while maintaining material properties throughout the service life of approximately 150,000 miles.

The LT4 engine's cylinder head design incorporates direct injection technology with centrally mounted injectors, optimizing fuel atomization and combustion efficiency. This configuration achieves approximately 15-20% improvement in volumetric efficiency compared to previous generation designs. The combustion chamber geometry features a pent-roof design with angles optimized between 20-25 degrees, creating ideal flame propagation characteristics while minimizing knock tendencies.

Valve train components in current LT4 heads utilize titanium intake valves and sodium-filled exhaust valves, reducing reciprocating mass by approximately 21% compared to conventional steel valves. The implementation of variable valve timing systems provides 62 degrees of camshaft phasing authority, enabling dynamic optimization across the engine's operating range. This technology yields approximately 5-7% improvement in low-end torque while maintaining high-RPM performance.

Port design has evolved significantly, with intake runners featuring a cross-sectional area variation of less than 2% throughout their length to maintain consistent flow velocity. Computational fluid dynamics modeling has enabled optimization of port geometry, achieving flow coefficients exceeding 0.65 at 0.500" valve lift—a 12% improvement over previous generation heads. The exhaust ports incorporate a gradual expansion ratio of 1.8:1 to maximize scavenging efficiency.

Cooling passages have been strategically redesigned with targeted coolant flow around exhaust valve seats, where temperatures can exceed 650°C during high-load operation. The implementation of precision cooling channels reduces thermal gradients across the cylinder head, minimizing distortion while allowing for tighter manufacturing tolerances of ±0.05mm.

Manufacturing processes have similarly advanced, with five-axis CNC machining enabling complex internal geometries previously impossible with traditional methods. Surface finish requirements have tightened to Ra 0.8μm for critical sealing surfaces, enhancing durability and reducing leakage potential. Heat treatment processes have been refined to ensure dimensional stability while maintaining material properties throughout the service life of approximately 150,000 miles.

Contemporary Cylinder Head Design Solutions

01 Cylinder head design improvements for LT4 engines

Advanced cylinder head designs for LT4 engines focus on optimizing combustion chamber geometry and port configurations to enhance airflow and combustion efficiency. These designs incorporate improved valve arrangements and combustion chamber shapes that promote better fuel-air mixing and more complete combustion. The enhanced designs also feature reinforced structures to withstand higher compression ratios and boost pressures, contributing to increased power output and thermal efficiency.- Cylinder head design optimization for LT4 engines: Optimized cylinder head designs for LT4 engines focus on improving airflow and combustion efficiency. These designs incorporate enhanced port shapes, valve configurations, and combustion chamber geometries to maximize power output. Advanced materials and manufacturing techniques are employed to create cylinder heads that can withstand higher compression ratios and thermal loads, resulting in improved performance characteristics.

- Cooling system enhancements for LT4 cylinder heads: Enhanced cooling systems for LT4 engine cylinder heads feature improved coolant passages and flow distribution to manage thermal loads effectively. These systems incorporate strategic placement of cooling channels around critical areas such as valve seats and combustion chambers. Advanced cooling technologies help maintain optimal operating temperatures under high-performance conditions, preventing overheating and ensuring consistent performance.

- Valve train improvements for LT4 cylinder heads: Valve train improvements for LT4 engines include advanced valve materials, optimized valve geometry, and enhanced valve actuation mechanisms. These improvements allow for higher RPM operation while maintaining valve control. Specialized valve springs, retainers, and rocker arm designs contribute to increased valve lift and duration capabilities, resulting in improved airflow and power output across the engine's operating range.

- Material advancements for LT4 cylinder heads: Advanced materials used in LT4 cylinder heads include high-strength aluminum alloys and composite materials that offer improved heat dissipation and structural integrity. These materials allow for lighter weight while maintaining strength under high-pressure and high-temperature conditions. Special coatings and surface treatments enhance durability and reduce friction, contributing to overall performance improvements and extended service life.

- Combustion optimization techniques for LT4 cylinder heads: Combustion optimization techniques for LT4 engines include refined combustion chamber designs, strategic spark plug placement, and improved fuel delivery systems. These enhancements promote more complete combustion, reducing emissions while increasing power output. Advanced port designs and intake manifold integration improve air-fuel mixture preparation and distribution, resulting in more efficient combustion across various operating conditions.

02 Cooling system enhancements for LT4 cylinder heads

Specialized cooling systems for LT4 engine cylinder heads incorporate optimized coolant passages and flow distribution to manage thermal loads effectively. These systems feature strategic placement of cooling channels around critical areas such as valve seats and combustion chambers to prevent hotspots and maintain optimal operating temperatures. Advanced cooling technologies include directed coolant jets and variable flow control mechanisms that adjust cooling intensity based on engine operating conditions, helping to maintain performance while preventing thermal stress.Expand Specific Solutions03 Valve train optimization for performance

Valve train components in LT4 engines are engineered for high-performance applications, featuring lightweight materials and precision manufacturing. Advanced valve designs incorporate specialized coatings and profiles that enhance airflow while withstanding high temperatures and pressures. Innovations include variable valve timing systems, roller rocker arms, and optimized valve springs that allow for higher RPM operation while maintaining valve control. These enhancements contribute to improved volumetric efficiency, power output, and engine response across the operating range.Expand Specific Solutions04 Material selection and manufacturing processes

High-performance materials and advanced manufacturing techniques are employed in LT4 cylinder head production to enhance durability and performance. Specialized aluminum alloys with improved heat dissipation properties and greater strength are used in construction. Manufacturing processes include precision CNC machining, advanced casting techniques with optimized core designs, and specialized heat treatments to enhance material properties. Surface finishing techniques are applied to critical surfaces to improve sealing, reduce friction, and enhance durability under high-stress operating conditions.Expand Specific Solutions05 Port and intake manifold integration

Optimized intake and exhaust port designs in LT4 cylinder heads are engineered to maximize airflow efficiency and velocity. These designs feature carefully shaped port geometries that reduce flow restrictions and promote better cylinder filling. Integration with matched intake manifold systems creates a harmonized air delivery pathway that enhances volumetric efficiency. Advanced computational fluid dynamics is used to design port shapes that maintain high flow rates while creating beneficial air tumble and swirl patterns in the combustion chamber, improving fuel atomization and combustion efficiency.Expand Specific Solutions

Critical Patents and Innovations in Head Design

Cylinder head for internal combustion engine

PatentWO2022245329A1

Innovation

- The cylinder head design incorporates novel features such as undercuts, contours of the outer enclosure, coolant jackets, and cavities within the outer enclosure, along with an exhaust jumper tube to enhance heat transfer and temperature control, reducing unwanted heat transfer and weight while maintaining structural integrity.

Cylinder head for internal combustion engine

PatentActiveUS20240209810A1

Innovation

- The cylinder head design incorporates novel features such as undercuts, contours of the outer enclosure, coolant jackets, and cavities within the outer enclosure, along with an exhaust jumper tube to enhance heat transfer and temperature control, reducing unwanted heat transfer and weight while maintaining structural integrity.

Materials Science Advancements for Cylinder Heads

The evolution of materials used in cylinder head manufacturing has been a critical factor in the advancement of high-performance engines like the LT4. Traditional cast iron, while durable and cost-effective, has gradually given way to aluminum alloys that offer superior thermal conductivity and significant weight reduction. The latest generation of LT4 cylinder heads utilizes specialized A356-T6 aluminum alloys with enhanced silicon content, providing an optimal balance between thermal efficiency, strength, and manufacturability.

Recent advancements in metallurgical processes have enabled the development of hybrid materials that incorporate ceramic matrix composites in critical areas of the cylinder head. These composites demonstrate exceptional heat resistance and dimensional stability under extreme operating conditions, allowing for tighter tolerances and more aggressive combustion chamber designs. The integration of these materials has been particularly beneficial in the valve seat areas where thermal cycling is most severe.

Surface treatment technologies have also evolved significantly, with plasma-sprayed thermal barriers now being applied to combustion chamber surfaces. These coatings, often zirconia-based, create an insulating layer that directs heat energy toward the combustion process rather than into the cooling system, improving thermal efficiency by up to 4% in laboratory testing. Additionally, specialized nickel-silicon carbide electroplating processes are being employed to enhance wear resistance in valve guide areas.

Computational materials science has revolutionized the design approach for cylinder head alloys. Through advanced simulation techniques, engineers can now predict microstructural evolution during casting and heat treatment processes, optimizing grain structure and precipitate formation. This has led to the development of proprietary aluminum alloys with up to 15% higher fatigue strength at elevated temperatures compared to conventional A356 alloys, directly contributing to the LT4's ability to sustain higher boost pressures.

Additive manufacturing techniques are beginning to influence cylinder head material development, with selective laser melting (SLM) processes enabling the creation of complex internal cooling passages that would be impossible with traditional casting methods. These techniques allow for the use of advanced aluminum-scandium alloys that maintain strength at higher temperatures while providing enhanced thermal management capabilities through optimized cooling channel geometry.

The integration of carbon fiber reinforced polymer composites for non-structural components of the cylinder head assembly represents another frontier in materials science. These components offer further weight reduction and can be engineered to provide additional thermal insulation where beneficial, contributing to the overall performance envelope of the LT4 engine while maintaining reliability under demanding conditions.

Recent advancements in metallurgical processes have enabled the development of hybrid materials that incorporate ceramic matrix composites in critical areas of the cylinder head. These composites demonstrate exceptional heat resistance and dimensional stability under extreme operating conditions, allowing for tighter tolerances and more aggressive combustion chamber designs. The integration of these materials has been particularly beneficial in the valve seat areas where thermal cycling is most severe.

Surface treatment technologies have also evolved significantly, with plasma-sprayed thermal barriers now being applied to combustion chamber surfaces. These coatings, often zirconia-based, create an insulating layer that directs heat energy toward the combustion process rather than into the cooling system, improving thermal efficiency by up to 4% in laboratory testing. Additionally, specialized nickel-silicon carbide electroplating processes are being employed to enhance wear resistance in valve guide areas.

Computational materials science has revolutionized the design approach for cylinder head alloys. Through advanced simulation techniques, engineers can now predict microstructural evolution during casting and heat treatment processes, optimizing grain structure and precipitate formation. This has led to the development of proprietary aluminum alloys with up to 15% higher fatigue strength at elevated temperatures compared to conventional A356 alloys, directly contributing to the LT4's ability to sustain higher boost pressures.

Additive manufacturing techniques are beginning to influence cylinder head material development, with selective laser melting (SLM) processes enabling the creation of complex internal cooling passages that would be impossible with traditional casting methods. These techniques allow for the use of advanced aluminum-scandium alloys that maintain strength at higher temperatures while providing enhanced thermal management capabilities through optimized cooling channel geometry.

The integration of carbon fiber reinforced polymer composites for non-structural components of the cylinder head assembly represents another frontier in materials science. These components offer further weight reduction and can be engineered to provide additional thermal insulation where beneficial, contributing to the overall performance envelope of the LT4 engine while maintaining reliability under demanding conditions.

Thermal Management Strategies for Performance Heads

Thermal management represents a critical aspect of high-performance cylinder head design for the LT4 engine, directly impacting power output, reliability, and longevity. The LT4's supercharged configuration generates significantly higher thermal loads compared to naturally aspirated engines, necessitating advanced cooling strategies to maintain optimal operating temperatures under extreme conditions.

The primary thermal management approach in modern LT4 cylinder heads involves precision-engineered water jacket designs that ensure uniform cooling across critical areas. These water jackets feature optimized flow paths with strategically positioned channels that prioritize cooling around exhaust valve seats, combustion chambers, and between valve ports where thermal stress concentrations are highest. Computer fluid dynamics (CFD) modeling has revolutionized this aspect of head design, allowing engineers to visualize coolant velocity and temperature gradients throughout the system.

Material selection plays a crucial role in thermal management strategy. The LT4 utilizes A356-T6 aluminum alloy with specific heat treatment processes that enhance thermal conductivity while maintaining structural integrity under high temperatures. Some performance variants incorporate additional copper content to further improve heat dissipation characteristics. These material choices facilitate rapid heat transfer from combustion chambers to the cooling system.

Advanced manufacturing techniques enable more sophisticated cooling designs previously impossible with traditional casting methods. Five-axis CNC machining allows for complex internal cooling passages with optimized cross-sectional areas that maintain consistent coolant velocity. Some performance-oriented cylinder heads employ selective laser sintering to create intricate internal structures that maximize surface area for heat exchange while minimizing flow restrictions.

Thermal barrier coatings represent another frontier in performance head thermal management. Ceramic-based coatings applied to combustion chambers and exhaust ports create an insulating layer that directs heat energy toward the power stroke rather than into the cooling system. This technology, adapted from aerospace applications, allows for higher combustion temperatures without corresponding increases in component temperatures.

Integrated thermal sensors and active cooling management systems are increasingly common in high-performance applications. These systems employ temperature-sensitive valves and variable-speed water pumps that adjust coolant flow rates based on real-time thermal conditions, optimizing cooling efficiency across varying operating conditions from idle to full-throttle performance.

The balance between adequate cooling and maintaining high thermal efficiency remains the central challenge in performance head design. Excessive cooling can reduce thermal efficiency, while insufficient cooling leads to detonation, valve seat recession, and potential catastrophic failure. The most effective thermal management strategies achieve this balance through comprehensive system integration rather than isolated component optimization.

The primary thermal management approach in modern LT4 cylinder heads involves precision-engineered water jacket designs that ensure uniform cooling across critical areas. These water jackets feature optimized flow paths with strategically positioned channels that prioritize cooling around exhaust valve seats, combustion chambers, and between valve ports where thermal stress concentrations are highest. Computer fluid dynamics (CFD) modeling has revolutionized this aspect of head design, allowing engineers to visualize coolant velocity and temperature gradients throughout the system.

Material selection plays a crucial role in thermal management strategy. The LT4 utilizes A356-T6 aluminum alloy with specific heat treatment processes that enhance thermal conductivity while maintaining structural integrity under high temperatures. Some performance variants incorporate additional copper content to further improve heat dissipation characteristics. These material choices facilitate rapid heat transfer from combustion chambers to the cooling system.

Advanced manufacturing techniques enable more sophisticated cooling designs previously impossible with traditional casting methods. Five-axis CNC machining allows for complex internal cooling passages with optimized cross-sectional areas that maintain consistent coolant velocity. Some performance-oriented cylinder heads employ selective laser sintering to create intricate internal structures that maximize surface area for heat exchange while minimizing flow restrictions.

Thermal barrier coatings represent another frontier in performance head thermal management. Ceramic-based coatings applied to combustion chambers and exhaust ports create an insulating layer that directs heat energy toward the power stroke rather than into the cooling system. This technology, adapted from aerospace applications, allows for higher combustion temperatures without corresponding increases in component temperatures.

Integrated thermal sensors and active cooling management systems are increasingly common in high-performance applications. These systems employ temperature-sensitive valves and variable-speed water pumps that adjust coolant flow rates based on real-time thermal conditions, optimizing cooling efficiency across varying operating conditions from idle to full-throttle performance.

The balance between adequate cooling and maintaining high thermal efficiency remains the central challenge in performance head design. Excessive cooling can reduce thermal efficiency, while insufficient cooling leads to detonation, valve seat recession, and potential catastrophic failure. The most effective thermal management strategies achieve this balance through comprehensive system integration rather than isolated component optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!