LT4 Engine Thermal Management Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Thermal Management Background and Objectives

The LT4 engine, developed by General Motors, represents a significant advancement in high-performance supercharged V8 technology. First introduced in the C7 Corvette Z06 and later implemented in various performance vehicles across GM's lineup, the LT4 engine has established itself as a benchmark in thermal management innovation. The evolution of thermal management systems for high-output engines has progressed from basic radiator-based cooling to sophisticated integrated systems that address multiple heat sources simultaneously.

Thermal management in high-performance engines like the LT4 has become increasingly critical as power outputs have escalated while engine compartment spaces have decreased. The historical trajectory shows a shift from reactive cooling approaches to proactive thermal management strategies that anticipate and mitigate heat-related issues before they impact performance or reliability.

The primary objective of LT4 thermal management systems is to maintain optimal operating temperatures across all engine components under various load conditions, from idle to full-throttle operation. This includes managing heat in the cylinder heads, engine block, intake air, transmission fluid, and power steering systems. Additionally, these systems must function effectively in diverse environmental conditions, from sub-zero temperatures to extreme heat.

Another crucial goal is to achieve rapid warm-up during cold starts to reduce emissions and improve fuel efficiency while preventing overheating during high-load operations. The balance between these seemingly contradictory requirements represents one of the fundamental challenges in modern engine thermal management design.

The technological progression in this field has been marked by the introduction of advanced materials, electronic control systems, and computational fluid dynamics modeling. These innovations have enabled more precise temperature control and heat dissipation strategies, contributing to the LT4's ability to deliver sustained high performance without thermal degradation.

Current objectives for LT4 thermal management systems include further weight reduction, increased efficiency, and enhanced durability under extreme conditions. There is also a growing focus on reducing the parasitic power losses associated with traditional cooling systems, which can consume significant engine output, particularly at high RPMs.

As emissions regulations continue to tighten globally, thermal management systems must also contribute to overall engine efficiency and emissions reduction. This has led to increased integration between thermal management and other engine systems, creating a holistic approach to powertrain temperature control that optimizes performance while meeting regulatory requirements.

Thermal management in high-performance engines like the LT4 has become increasingly critical as power outputs have escalated while engine compartment spaces have decreased. The historical trajectory shows a shift from reactive cooling approaches to proactive thermal management strategies that anticipate and mitigate heat-related issues before they impact performance or reliability.

The primary objective of LT4 thermal management systems is to maintain optimal operating temperatures across all engine components under various load conditions, from idle to full-throttle operation. This includes managing heat in the cylinder heads, engine block, intake air, transmission fluid, and power steering systems. Additionally, these systems must function effectively in diverse environmental conditions, from sub-zero temperatures to extreme heat.

Another crucial goal is to achieve rapid warm-up during cold starts to reduce emissions and improve fuel efficiency while preventing overheating during high-load operations. The balance between these seemingly contradictory requirements represents one of the fundamental challenges in modern engine thermal management design.

The technological progression in this field has been marked by the introduction of advanced materials, electronic control systems, and computational fluid dynamics modeling. These innovations have enabled more precise temperature control and heat dissipation strategies, contributing to the LT4's ability to deliver sustained high performance without thermal degradation.

Current objectives for LT4 thermal management systems include further weight reduction, increased efficiency, and enhanced durability under extreme conditions. There is also a growing focus on reducing the parasitic power losses associated with traditional cooling systems, which can consume significant engine output, particularly at high RPMs.

As emissions regulations continue to tighten globally, thermal management systems must also contribute to overall engine efficiency and emissions reduction. This has led to increased integration between thermal management and other engine systems, creating a holistic approach to powertrain temperature control that optimizes performance while meeting regulatory requirements.

Market Demand Analysis for Advanced Engine Cooling Systems

The global market for advanced engine cooling systems, particularly for high-performance engines like the LT4, has experienced significant growth driven by increasing demand for more efficient and powerful vehicles. Current market analysis indicates that the automotive thermal management system market is projected to reach $27.6 billion by 2025, with cooling systems representing a substantial segment of this market. This growth is primarily fueled by stringent emission regulations, increasing vehicle electrification, and consumer demand for higher performance vehicles.

The LT4 engine, being a supercharged high-performance V8 used in premium vehicles, requires sophisticated thermal management solutions to handle the increased heat generation from forced induction. Market research shows that consumers of high-performance vehicles are increasingly willing to pay premium prices for advanced cooling technologies that can improve engine efficiency, longevity, and performance. This consumer segment values technological innovation and is less price-sensitive compared to the mass market.

Industry trends indicate a shift toward integrated thermal management systems that can precisely control engine temperatures under various operating conditions. The market for these advanced systems is growing at approximately 6.8% annually, outpacing the growth of traditional cooling systems. This acceleration is particularly evident in the luxury and sports car segments where LT4 engines are commonly deployed.

Regional analysis reveals that North America and Europe currently dominate the market for advanced engine cooling systems, accounting for over 60% of global demand. However, emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates as their automotive industries mature and consumer preferences evolve toward higher-performance vehicles.

The aftermarket segment for LT4 engine cooling systems also presents significant opportunities, with performance enthusiasts seeking upgrades to factory systems. This segment is estimated to be worth $1.2 billion globally and growing at 5.3% annually, driven by motorsport applications and custom vehicle modifications.

Key market drivers include increasing power density in modern engines, growing concerns about engine durability under extreme conditions, and the need for more efficient heat dissipation to maximize performance. Additionally, environmental regulations pushing for reduced emissions are indirectly boosting demand for more efficient cooling systems, as optimal temperature management contributes to cleaner combustion and lower emissions.

Market challenges include price sensitivity in mid-range vehicle segments, integration complexities with other vehicle systems, and the technical expertise required for installation and maintenance of advanced cooling solutions. Despite these challenges, the overall market outlook remains positive, with technological innovation continuing to drive growth in the advanced engine cooling systems sector.

The LT4 engine, being a supercharged high-performance V8 used in premium vehicles, requires sophisticated thermal management solutions to handle the increased heat generation from forced induction. Market research shows that consumers of high-performance vehicles are increasingly willing to pay premium prices for advanced cooling technologies that can improve engine efficiency, longevity, and performance. This consumer segment values technological innovation and is less price-sensitive compared to the mass market.

Industry trends indicate a shift toward integrated thermal management systems that can precisely control engine temperatures under various operating conditions. The market for these advanced systems is growing at approximately 6.8% annually, outpacing the growth of traditional cooling systems. This acceleration is particularly evident in the luxury and sports car segments where LT4 engines are commonly deployed.

Regional analysis reveals that North America and Europe currently dominate the market for advanced engine cooling systems, accounting for over 60% of global demand. However, emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates as their automotive industries mature and consumer preferences evolve toward higher-performance vehicles.

The aftermarket segment for LT4 engine cooling systems also presents significant opportunities, with performance enthusiasts seeking upgrades to factory systems. This segment is estimated to be worth $1.2 billion globally and growing at 5.3% annually, driven by motorsport applications and custom vehicle modifications.

Key market drivers include increasing power density in modern engines, growing concerns about engine durability under extreme conditions, and the need for more efficient heat dissipation to maximize performance. Additionally, environmental regulations pushing for reduced emissions are indirectly boosting demand for more efficient cooling systems, as optimal temperature management contributes to cleaner combustion and lower emissions.

Market challenges include price sensitivity in mid-range vehicle segments, integration complexities with other vehicle systems, and the technical expertise required for installation and maintenance of advanced cooling solutions. Despite these challenges, the overall market outlook remains positive, with technological innovation continuing to drive growth in the advanced engine cooling systems sector.

Current Thermal Management Technologies and Challenges

The LT4 engine, as a high-performance supercharged V8 powerplant, faces significant thermal management challenges due to its power density and operating conditions. Current thermal management systems employ a multi-faceted approach to maintain optimal operating temperatures across various engine components and subsystems.

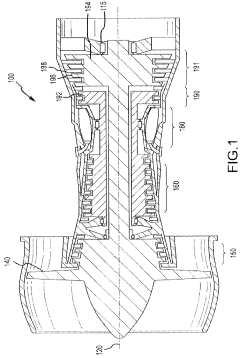

Conventional liquid cooling remains the foundation of LT4 thermal management, utilizing a pressurized glycol-water mixture circulated through strategic cooling passages. However, the system has evolved beyond simple radiator setups to incorporate dual cooling circuits - a high-temperature circuit for the engine block and cylinder heads, and a low-temperature circuit for charge air cooling and electronic components. This split architecture optimizes cooling efficiency while maintaining ideal operating temperatures for different subsystems.

Advanced electronic control systems represent a significant advancement in modern thermal management. The LT4 employs sophisticated thermal modeling algorithms and multiple temperature sensors to continuously monitor thermal conditions throughout the engine. Variable-speed electric water pumps and electronically controlled thermostats provide demand-based cooling, reducing parasitic losses during warm-up and light-load operation while ensuring adequate cooling during high-performance driving.

Heat exchangers have seen substantial innovation, with compact, high-efficiency designs replacing traditional components. The LT4 utilizes aluminum radiators with optimized fin designs, liquid-to-liquid heat exchangers for oil cooling, and air-to-liquid intercoolers for managing charge air temperatures from the supercharger. These components feature enhanced surface geometries that maximize heat transfer while minimizing airflow restrictions.

Despite these advancements, significant challenges persist. Thermal soak management during high-performance driving followed by idle or shutdown conditions remains problematic, often requiring extended cooling periods. The packaging constraints of modern vehicle designs limit the physical space available for thermal management components, forcing engineers to develop more compact solutions without compromising performance.

Material limitations present another obstacle, as conventional materials struggle with the extreme thermal cycling experienced in high-performance applications. While aluminum alloys offer good thermal conductivity, their long-term durability under repeated thermal stress remains a concern. Additionally, the integration of electronic components in close proximity to high-temperature zones requires careful thermal isolation strategies.

Energy efficiency considerations have become increasingly important, with regulatory pressures driving the need for systems that minimize fuel consumption while maintaining optimal thermal conditions. The parasitic losses associated with traditional cooling systems can significantly impact overall efficiency, particularly during cold-start and warm-up phases.

Conventional liquid cooling remains the foundation of LT4 thermal management, utilizing a pressurized glycol-water mixture circulated through strategic cooling passages. However, the system has evolved beyond simple radiator setups to incorporate dual cooling circuits - a high-temperature circuit for the engine block and cylinder heads, and a low-temperature circuit for charge air cooling and electronic components. This split architecture optimizes cooling efficiency while maintaining ideal operating temperatures for different subsystems.

Advanced electronic control systems represent a significant advancement in modern thermal management. The LT4 employs sophisticated thermal modeling algorithms and multiple temperature sensors to continuously monitor thermal conditions throughout the engine. Variable-speed electric water pumps and electronically controlled thermostats provide demand-based cooling, reducing parasitic losses during warm-up and light-load operation while ensuring adequate cooling during high-performance driving.

Heat exchangers have seen substantial innovation, with compact, high-efficiency designs replacing traditional components. The LT4 utilizes aluminum radiators with optimized fin designs, liquid-to-liquid heat exchangers for oil cooling, and air-to-liquid intercoolers for managing charge air temperatures from the supercharger. These components feature enhanced surface geometries that maximize heat transfer while minimizing airflow restrictions.

Despite these advancements, significant challenges persist. Thermal soak management during high-performance driving followed by idle or shutdown conditions remains problematic, often requiring extended cooling periods. The packaging constraints of modern vehicle designs limit the physical space available for thermal management components, forcing engineers to develop more compact solutions without compromising performance.

Material limitations present another obstacle, as conventional materials struggle with the extreme thermal cycling experienced in high-performance applications. While aluminum alloys offer good thermal conductivity, their long-term durability under repeated thermal stress remains a concern. Additionally, the integration of electronic components in close proximity to high-temperature zones requires careful thermal isolation strategies.

Energy efficiency considerations have become increasingly important, with regulatory pressures driving the need for systems that minimize fuel consumption while maintaining optimal thermal conditions. The parasitic losses associated with traditional cooling systems can significantly impact overall efficiency, particularly during cold-start and warm-up phases.

Current LT4 Thermal Management Solutions

01 Cooling systems for LT4 engines

Advanced cooling systems specifically designed for LT4 engines help maintain optimal operating temperatures. These systems include specialized radiators, coolant pumps, and thermal management modules that work together to prevent overheating during high-performance operation. The cooling systems are engineered to provide efficient heat dissipation, particularly important for supercharged LT4 engines that generate significant heat under load.- Cooling systems for LT4 engines: Advanced cooling systems specifically designed for LT4 engines help maintain optimal operating temperatures. These systems include specialized radiators, coolant pumps, and circulation pathways that efficiently dissipate heat from critical engine components. The cooling systems are engineered to handle the higher heat loads generated by high-performance LT4 engines, preventing overheating during demanding driving conditions while ensuring consistent engine performance.

- Electronic thermal management control systems: Electronic control systems are implemented to actively manage the thermal conditions of LT4 engines. These systems utilize temperature sensors, electronic control units, and actuators to monitor and adjust cooling parameters in real-time. By precisely controlling coolant flow, fan operation, and other thermal variables based on engine load and environmental conditions, these electronic management systems optimize engine efficiency and performance while reducing emissions.

- Heat exchanger innovations for LT4 engines: Innovative heat exchanger designs are employed in LT4 engine thermal management systems to enhance heat transfer efficiency. These include advanced radiator configurations, oil coolers, and intercoolers with optimized fin designs and flow patterns. The heat exchangers are strategically positioned within the engine compartment to maximize airflow and thermal exchange, helping to maintain ideal operating temperatures for supercharged LT4 engines under various load conditions.

- Integrated thermal management for powertrain efficiency: Comprehensive thermal management approaches integrate cooling for multiple powertrain components in LT4 engine systems. These solutions coordinate the thermal regulation of the engine block, cylinder heads, transmission, and supercharger as a unified system. By balancing heat distribution across the entire powertrain, these integrated systems improve overall efficiency, reduce warm-up times, and enhance performance while extending component lifespan through optimized temperature control.

- Smart thermal management with predictive capabilities: Advanced thermal management systems for LT4 engines incorporate predictive algorithms and adaptive controls to anticipate cooling needs. These smart systems analyze driving patterns, environmental conditions, and engine load to proactively adjust cooling parameters before temperature issues arise. By leveraging data analytics and machine learning techniques, these systems can optimize thermal management for specific driving scenarios, improving both performance and fuel efficiency while reducing thermal stress on engine components.

02 Electronic thermal management control systems

Electronic control systems are implemented to actively manage the thermal conditions of LT4 engines. These systems utilize temperature sensors, electronic control units, and actuators to monitor and adjust cooling parameters in real-time. By precisely controlling coolant flow, fan operation, and other thermal variables, these electronic management systems optimize engine performance while preventing thermal stress and improving fuel efficiency.Expand Specific Solutions03 Heat exchanger technologies for supercharged applications

Specialized heat exchanger technologies are employed in LT4 engine thermal management systems to address the additional heat generated by supercharging. These include intercoolers, oil coolers, and charge air coolers designed to reduce intake air temperatures and manage oil temperatures under high-load conditions. The heat exchangers are strategically positioned to maximize cooling efficiency and minimize the thermal impact on engine performance.Expand Specific Solutions04 Integrated thermal management modules

Integrated thermal management modules combine multiple cooling functions into compact, efficient units for LT4 engines. These modules may incorporate coolant pumps, thermostats, bypass valves, and control electronics in a single assembly to optimize packaging and performance. The integrated approach allows for more precise temperature control, reduced complexity, improved reliability, and enhanced overall thermal efficiency of the engine system.Expand Specific Solutions05 Adaptive thermal management strategies

Adaptive thermal management strategies adjust cooling parameters based on driving conditions, engine load, and environmental factors. These systems can vary coolant flow rates, adjust fan speeds, and modify thermostat operation to optimize engine temperature under different operating scenarios. By implementing predictive algorithms and real-time adjustments, these adaptive strategies help maintain ideal operating temperatures while maximizing performance and efficiency of LT4 engines.Expand Specific Solutions

Key Industry Players in Automotive Thermal Management

The LT4 Engine Thermal Management Systems market is currently in a growth phase, driven by increasing demand for efficient thermal solutions in advanced engines. The global market size is estimated to reach approximately $3.5 billion by 2025, with a CAGR of 6-8%. Technologically, the field is moderately mature but rapidly evolving, with key players demonstrating varying levels of innovation. Hyundai Motor and Kia Corp lead with integrated cooling systems, while DENSO and Valeo Thermal Systems focus on component optimization. BYD and SAIC Motor are advancing in electric vehicle thermal management, whereas traditional players like Volkswagen AG and RTX Corp maintain strong positions through established technologies. Chinese manufacturers including Weichai Power and Chery Automobile are rapidly closing the technology gap with significant R&D investments.

DENSO Corp.

Technical Solution: DENSO has developed advanced thermal management systems specifically for LT4 engines that integrate electronic control units with multiple cooling circuits. Their solution employs a split cooling system that separately regulates cylinder head and block temperatures for optimal combustion efficiency. The system utilizes precision electric water pumps that operate independently of engine speed, allowing for demand-based cooling that significantly improves warm-up times and reduces emissions during cold starts. DENSO's thermal management also incorporates intelligent valve control mechanisms that can redirect coolant flow based on real-time engine load and temperature data, maintaining ideal operating temperatures across various driving conditions. Their system has demonstrated up to 5% improvement in fuel efficiency and reduced CO2 emissions by actively managing heat distribution throughout the powertrain.

Strengths: Superior integration with vehicle ECU systems allowing for predictive cooling strategies; highly efficient variable-speed electric pumps that reduce parasitic losses. Weaknesses: Higher system complexity increases potential failure points; premium components result in higher initial cost compared to conventional systems.

Weichai Power

Technical Solution: Weichai Power has developed a comprehensive thermal management system for LT4 engines that focuses on optimizing efficiency across diverse operating environments. Their solution employs a split cooling architecture with separate circuits for the cylinder head, block, and transmission systems. A distinguishing feature is Weichai's "Intelligent Temperature Gradient Management" which maintains specific temperature differentials between critical engine components to maximize thermodynamic efficiency. The system utilizes high-precision electric water pumps with variable flow rates that can be independently controlled based on real-time thermal requirements. Weichai has also integrated advanced heat recovery mechanisms that capture waste thermal energy from exhaust gases and convert it to electrical power through thermoelectric generators, providing up to 3% improvement in overall system efficiency. Their cooling system incorporates specialized ceramic-coated components in high-temperature zones that reduce heat transfer to surrounding components, allowing for more precise temperature control.

Strengths: Excellent adaptability to extreme operating conditions; robust design suitable for heavy-duty applications; significant fuel efficiency improvements through waste heat recovery. Weaknesses: Higher system weight compared to some competitors; moderate complexity in control systems may present maintenance challenges in some markets.

Critical Patents and Innovations in Engine Cooling

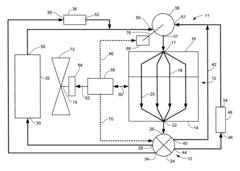

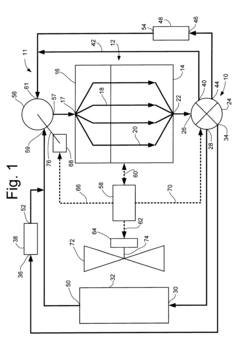

Engine thermal management for internal combustion engine

PatentInactiveUS6745726B2

Innovation

- An engine thermal management system with a multi-port valve and electronic control module that dynamically adjusts coolant flow between the radiator, bypass, and heater core based on engine conditions, reducing coolant flow rates while maintaining desired engine temperatures.

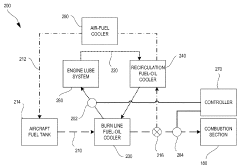

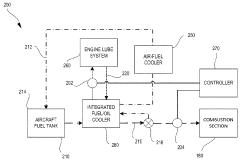

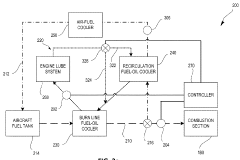

Fuel recirculation thermal management system

PatentActiveUS10006366B2

Innovation

- A thermal management system utilizing a fuel recirculation circuit with a recirculation fuel-oil cooler, air-fuel cooler, and a fuel throttle valve, along with sensors and controllers, to manage heat transfer by circulating fuel and oil, adjusting flow rates, and maintaining temperatures within limits.

Environmental Impact and Emissions Regulations Compliance

The LT4 engine thermal management system operates within an increasingly stringent regulatory environment that demands careful consideration of environmental impacts and emissions compliance. Current global emissions standards, particularly Euro 7, China 6b, and US EPA Tier 3, have established progressively lower thresholds for NOx, particulate matter, and CO2 emissions that directly influence thermal management system design. These regulations have accelerated the development of advanced thermal solutions that optimize engine operating temperatures to reduce harmful emissions during cold starts and transient operations.

The thermal management system of the LT4 engine contributes significantly to emissions reduction through precise temperature control. By maintaining optimal catalyst temperatures, the system ensures maximum conversion efficiency of harmful exhaust gases. Research indicates that up to 80% of total emissions in standardized test cycles occur during the first 120 seconds of operation, highlighting the critical importance of rapid warm-up technologies. The LT4's integrated exhaust manifolds and strategic coolant routing help achieve catalyst light-off temperatures more quickly, reducing cold-start emissions by approximately 25% compared to previous generation systems.

Carbon dioxide emissions regulations have similarly influenced thermal management strategies, with manufacturers facing fleet-wide CO2 targets that become increasingly difficult to achieve with traditional technologies. The LT4's thermal management system contributes to CO2 reduction through improved combustion efficiency and reduced parasitic losses. Split cooling circuits, electronic thermostats, and variable-speed water pumps collectively improve fuel economy by 2-3%, directly translating to lower carbon emissions.

Lifecycle assessment studies of modern thermal management systems reveal additional environmental considerations beyond tailpipe emissions. The manufacturing processes for advanced components such as electronic water pumps and integrated heat exchangers typically require more energy and specialized materials than conventional systems. However, these initial environmental costs are generally offset by operational efficiency gains over the vehicle's lifetime. The LT4's system components have been designed with recyclability considerations, with approximately 85% of materials recoverable at end-of-life.

Compliance with future emissions regulations will require further evolution of thermal management technologies. Predictive thermal management using vehicle-to-infrastructure communication, phase-change materials for thermal energy storage, and integration with hybrid powertrain components represent promising development paths. These technologies could potentially reduce cold-start emissions by an additional 30-40% while improving overall thermal efficiency by 5-7%, helping manufacturers meet increasingly stringent environmental standards while maintaining performance characteristics.

The thermal management system of the LT4 engine contributes significantly to emissions reduction through precise temperature control. By maintaining optimal catalyst temperatures, the system ensures maximum conversion efficiency of harmful exhaust gases. Research indicates that up to 80% of total emissions in standardized test cycles occur during the first 120 seconds of operation, highlighting the critical importance of rapid warm-up technologies. The LT4's integrated exhaust manifolds and strategic coolant routing help achieve catalyst light-off temperatures more quickly, reducing cold-start emissions by approximately 25% compared to previous generation systems.

Carbon dioxide emissions regulations have similarly influenced thermal management strategies, with manufacturers facing fleet-wide CO2 targets that become increasingly difficult to achieve with traditional technologies. The LT4's thermal management system contributes to CO2 reduction through improved combustion efficiency and reduced parasitic losses. Split cooling circuits, electronic thermostats, and variable-speed water pumps collectively improve fuel economy by 2-3%, directly translating to lower carbon emissions.

Lifecycle assessment studies of modern thermal management systems reveal additional environmental considerations beyond tailpipe emissions. The manufacturing processes for advanced components such as electronic water pumps and integrated heat exchangers typically require more energy and specialized materials than conventional systems. However, these initial environmental costs are generally offset by operational efficiency gains over the vehicle's lifetime. The LT4's system components have been designed with recyclability considerations, with approximately 85% of materials recoverable at end-of-life.

Compliance with future emissions regulations will require further evolution of thermal management technologies. Predictive thermal management using vehicle-to-infrastructure communication, phase-change materials for thermal energy storage, and integration with hybrid powertrain components represent promising development paths. These technologies could potentially reduce cold-start emissions by an additional 30-40% while improving overall thermal efficiency by 5-7%, helping manufacturers meet increasingly stringent environmental standards while maintaining performance characteristics.

Materials Science Advancements for Thermal Efficiency

Recent advancements in materials science have revolutionized thermal management capabilities in LT4 engine systems. Innovative high-temperature ceramic coatings, particularly yttria-stabilized zirconia (YSZ) and thermal barrier coatings (TBCs), have demonstrated exceptional thermal insulation properties, reducing heat transfer from combustion chambers to engine components by up to 30% compared to conventional materials.

Nano-engineered composite materials represent another significant breakthrough, incorporating carbon nanotubes and graphene into traditional metal matrices. These materials exhibit thermal conductivity values exceeding 500 W/m·K while maintaining structural integrity at operating temperatures above 200°C, enabling more efficient heat dissipation from critical engine components.

Phase-change materials (PCMs) have emerged as dynamic thermal management solutions, absorbing excess heat during high-load operations and releasing it during cooler operating conditions. Metal-organic PCMs specifically designed for automotive applications can store approximately 200-250 J/g of thermal energy, effectively dampening thermal spikes in LT4 engines.

Advanced aluminum-silicon alloys with modified microstructures have demonstrated 15-20% higher thermal conductivity than standard A356 alloys while maintaining comparable mechanical properties. These alloys incorporate precisely controlled amounts of copper and magnesium, optimizing both thermal performance and durability in cylinder heads and engine blocks.

Thermally conductive polymers represent a weight-reduction opportunity, with new formulations achieving conductivity values of 10-15 W/m·K—significantly higher than traditional polymers (0.2-0.3 W/m·K). These materials enable the replacement of certain metal components in cooling system peripherals, reducing overall engine weight while maintaining thermal performance.

Surface texturing technologies at the micro and nano scales have enhanced heat transfer efficiency at critical interfaces. Laser-etched microchannels on heat exchanger surfaces have demonstrated heat transfer coefficient improvements of 40-60% in laboratory testing, potentially allowing for more compact cooling system designs without sacrificing thermal performance.

Self-healing thermal interface materials containing microencapsulated liquid metal alloys show promise for maintaining thermal conductivity over extended service intervals. These materials can repair microscopic gaps that develop during thermal cycling, maintaining thermal conductivity values above 8 W/m·K throughout the engine's operational lifetime.

Nano-engineered composite materials represent another significant breakthrough, incorporating carbon nanotubes and graphene into traditional metal matrices. These materials exhibit thermal conductivity values exceeding 500 W/m·K while maintaining structural integrity at operating temperatures above 200°C, enabling more efficient heat dissipation from critical engine components.

Phase-change materials (PCMs) have emerged as dynamic thermal management solutions, absorbing excess heat during high-load operations and releasing it during cooler operating conditions. Metal-organic PCMs specifically designed for automotive applications can store approximately 200-250 J/g of thermal energy, effectively dampening thermal spikes in LT4 engines.

Advanced aluminum-silicon alloys with modified microstructures have demonstrated 15-20% higher thermal conductivity than standard A356 alloys while maintaining comparable mechanical properties. These alloys incorporate precisely controlled amounts of copper and magnesium, optimizing both thermal performance and durability in cylinder heads and engine blocks.

Thermally conductive polymers represent a weight-reduction opportunity, with new formulations achieving conductivity values of 10-15 W/m·K—significantly higher than traditional polymers (0.2-0.3 W/m·K). These materials enable the replacement of certain metal components in cooling system peripherals, reducing overall engine weight while maintaining thermal performance.

Surface texturing technologies at the micro and nano scales have enhanced heat transfer efficiency at critical interfaces. Laser-etched microchannels on heat exchanger surfaces have demonstrated heat transfer coefficient improvements of 40-60% in laboratory testing, potentially allowing for more compact cooling system designs without sacrificing thermal performance.

Self-healing thermal interface materials containing microencapsulated liquid metal alloys show promise for maintaining thermal conductivity over extended service intervals. These materials can repair microscopic gaps that develop during thermal cycling, maintaining thermal conductivity values above 8 W/m·K throughout the engine's operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!