LT4 Engine Software for Real-Time Monitoring

LT4 Engine Software Evolution and Objectives

The LT4 engine software for real-time monitoring represents a significant evolution in automotive engine management systems, building upon decades of development in powertrain control technologies. Initially developed as basic electronic control units (ECUs) in the 1980s, engine management software has transformed into sophisticated systems capable of millisecond-level adjustments and comprehensive data analysis. The LT4 platform specifically marks a generational leap from its LT1 and LS predecessors, incorporating advanced algorithms for combustion optimization, thermal management, and performance enhancement.

The primary objective of LT4 engine software is to establish a comprehensive real-time monitoring framework that enables precise control over critical engine parameters while maintaining optimal performance across diverse operating conditions. This includes maintaining ideal air-fuel ratios, managing ignition timing, controlling variable valve timing, and optimizing forced induction systems—all while adhering to increasingly stringent emissions regulations and fuel efficiency standards.

Recent technological advancements have expanded the capabilities of LT4 software to include predictive analytics for component wear, adaptive learning algorithms that adjust to driver behavior, and integration with broader vehicle systems through sophisticated communication protocols. The software architecture has evolved from monolithic structures to modular designs that facilitate easier updates and customization for specific applications ranging from high-performance sports cars to commercial vehicles.

A key evolutionary milestone has been the transition from reactive to proactive monitoring paradigms. Earlier generations relied primarily on threshold-based fault detection, whereas modern LT4 software employs pattern recognition and statistical modeling to identify potential issues before they manifest as performance degradation or component failure. This shift represents a fundamental change in approach from simple monitoring to intelligent system management.

The integration of connectivity features represents another significant objective in LT4 software development. Modern implementations incorporate secure communication channels for over-the-air updates, remote diagnostics, and integration with fleet management systems. This connectivity extends the software's utility beyond traditional engine management to become a critical data source for broader operational analytics.

Looking forward, the LT4 software roadmap aims to further enhance real-time monitoring capabilities through increased sensor integration, higher sampling rates, and more sophisticated data processing algorithms. Development objectives include reducing latency in control responses, improving diagnostic accuracy, and expanding the software's ability to optimize engine performance under increasingly diverse operating conditions while maintaining compliance with evolving regulatory frameworks.

Market Demand for Real-Time Engine Monitoring

The real-time engine monitoring market has experienced significant growth over the past decade, driven primarily by increasing demands for operational efficiency, preventive maintenance, and regulatory compliance across multiple industries. The global market for engine monitoring systems was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.2% during the forecast period.

Transportation sectors, particularly aviation and maritime industries, constitute the largest market segments for real-time engine monitoring solutions. Commercial airlines have been early adopters, implementing sophisticated monitoring systems to enhance flight safety, reduce maintenance costs, and optimize fuel consumption. The maritime industry follows closely, with vessel operators increasingly investing in monitoring technologies to comply with stringent environmental regulations and improve operational efficiency.

The automotive sector represents another rapidly expanding market for real-time engine monitoring solutions. With the proliferation of connected vehicles and the advancement of IoT technologies, automotive manufacturers are integrating more sophisticated monitoring capabilities into their vehicles. This trend is particularly evident in commercial fleet management, where real-time monitoring can significantly reduce operational costs and extend vehicle lifespan.

Industrial applications, including manufacturing and power generation, also demonstrate substantial demand for real-time engine monitoring solutions. Factory operators are increasingly recognizing the value of continuous monitoring in preventing costly downtime and optimizing energy consumption. Similarly, power generation facilities rely on real-time monitoring to ensure operational reliability and regulatory compliance.

Market research indicates that end-users are primarily seeking solutions that offer comprehensive analytics capabilities, predictive maintenance functionalities, and seamless integration with existing systems. There is a growing preference for cloud-based solutions that enable remote monitoring and management, particularly in industries with geographically dispersed assets.

Regional analysis reveals that North America currently leads the market, accounting for approximately 35% of global demand. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing vehicle ownership, and substantial investments in transportation infrastructure.

Customer surveys highlight several key requirements driving market demand: real-time data accessibility, predictive maintenance capabilities, customizable alert systems, and comprehensive reporting features. Additionally, there is increasing interest in solutions that incorporate artificial intelligence and machine learning to enhance diagnostic accuracy and predictive capabilities.

Technical Challenges in Engine Monitoring Systems

Real-time engine monitoring systems face numerous technical challenges that impact their effectiveness and reliability. The integration of sensors within harsh engine environments presents significant obstacles, as these components must withstand extreme temperatures, vibrations, and pressure variations while maintaining accuracy. Sensor degradation over time further complicates data reliability, requiring sophisticated calibration algorithms and redundancy systems to ensure consistent performance.

Data processing capabilities represent another major hurdle in engine monitoring systems. The LT4 Engine Software must handle massive volumes of data generated continuously from multiple sensor points. This necessitates efficient data compression techniques and edge computing capabilities to filter relevant information before transmission. The software architecture must balance processing requirements with hardware limitations, particularly in mobile applications where computational resources may be constrained.

Connectivity issues frequently compromise monitoring effectiveness, especially in remote operations or during transit between different network infrastructures. The LT4 system must maintain data integrity across intermittent connections while implementing robust security protocols to prevent unauthorized access to critical engine parameters. These security measures must not significantly impact system performance or introduce latency that could delay critical alerts.

Algorithm development for predictive maintenance represents perhaps the most sophisticated challenge. Creating models that accurately predict component failure requires extensive historical data across diverse operating conditions. These algorithms must distinguish between normal operational variations and genuine fault indicators, a task complicated by the interdependent nature of engine subsystems. False positives waste resources while missed warnings can lead to catastrophic failures.

Power management considerations significantly impact system design, particularly for continuous monitoring applications. Sensors and processing units must operate efficiently to minimize energy consumption without compromising monitoring capabilities. This becomes especially critical in battery-powered applications or when the monitoring system draws power from the engine itself, potentially affecting overall efficiency.

Integration with existing engine control units (ECUs) presents compatibility challenges, as monitoring systems must interface with proprietary protocols and legacy systems. The LT4 software requires flexible communication interfaces and standardized data formats to ensure seamless operation across different engine models and manufacturers. This interoperability challenge extends to human-machine interfaces, where monitoring data must be presented in actionable formats appropriate for different user roles, from maintenance technicians to fleet managers.

Current LT4 Software Solutions

01 Real-time monitoring systems for LT4 engine performance

Real-time monitoring systems for LT4 engines collect and analyze performance data during operation. These systems use sensors to gather critical engine parameters such as temperature, pressure, fuel consumption, and emissions. The collected data is processed in real-time to provide immediate feedback on engine performance, allowing for quick detection of anomalies and potential issues before they lead to failures. These monitoring systems help optimize engine performance and extend engine life through preventive maintenance.- Real-time monitoring systems for LT4 engine performance: Real-time monitoring systems for LT4 engines collect and analyze performance data during operation. These systems use sensors to gather critical engine parameters such as temperature, pressure, fuel consumption, and power output. The collected data is processed through specialized software that provides immediate feedback on engine performance, allowing for quick identification of potential issues and optimization of engine operation. These monitoring systems help maintain optimal engine performance and prevent potential failures through early detection of anomalies.

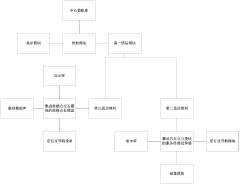

- Software architecture for engine diagnostic monitoring: Specialized software architectures are designed for LT4 engine diagnostic monitoring, featuring modular components that handle data acquisition, processing, and visualization. These architectures implement real-time processing algorithms to analyze engine parameters and detect deviations from normal operation patterns. The software typically includes communication protocols for interfacing with engine control units (ECUs) and can be integrated with broader vehicle management systems. Advanced diagnostic capabilities allow for predictive maintenance by identifying potential issues before they cause engine failure.

- Cloud-based engine monitoring and analytics: Cloud-based solutions for LT4 engine monitoring enable remote data collection, storage, and analysis. These systems transmit engine performance data to cloud servers where advanced analytics can be performed using machine learning algorithms to identify patterns and predict potential failures. The cloud infrastructure allows for scalable processing of large datasets from multiple engines, facilitating fleet-wide monitoring and comparative analysis. Users can access real-time engine status and historical performance data through web interfaces or mobile applications from anywhere with internet connectivity.

- Mobile and wireless monitoring interfaces for LT4 engines: Mobile and wireless interfaces provide flexible access to LT4 engine monitoring data through smartphones, tablets, and other portable devices. These solutions utilize wireless communication protocols such as Bluetooth, Wi-Fi, or cellular networks to transmit engine data from onboard systems to mobile devices. User-friendly applications display real-time engine parameters and alert users to potential issues through notifications. These interfaces enable mechanics and drivers to monitor engine performance remotely and make informed decisions about maintenance or driving behavior adjustments.

- Integration of LT4 engine monitoring with vehicle control systems: Integrated monitoring solutions connect LT4 engine software with broader vehicle control systems to provide comprehensive performance oversight. These integrated systems synchronize engine data with transmission, braking, and other vehicle subsystems to optimize overall vehicle performance. The integration enables coordinated responses to changing conditions, such as automatically adjusting engine parameters based on driving conditions or driver behavior. Advanced implementations include adaptive control algorithms that continuously optimize engine operation based on real-time monitoring data, improving fuel efficiency and reducing emissions while maintaining performance.

02 Software architecture for engine diagnostic monitoring

Specialized software architectures are designed for LT4 engine diagnostic monitoring, featuring modular components that handle data acquisition, processing, analysis, and visualization. These architectures implement real-time processing algorithms to interpret engine sensor data and identify performance issues. The software typically includes dashboard interfaces that display critical engine parameters and alert systems that notify operators of abnormal conditions. Cloud connectivity enables remote monitoring and historical data analysis for predictive maintenance purposes.Expand Specific Solutions03 Data analytics and machine learning for engine monitoring

Advanced data analytics and machine learning techniques are applied to LT4 engine monitoring to detect patterns and predict potential failures. These systems analyze large volumes of engine performance data to establish baseline performance metrics and identify deviations that may indicate developing problems. Machine learning algorithms continuously improve their predictive capabilities by learning from historical data and outcomes. This approach enables predictive maintenance strategies that can significantly reduce downtime and repair costs while optimizing engine performance.Expand Specific Solutions04 Mobile and remote monitoring interfaces for LT4 engines

Mobile and remote monitoring interfaces allow operators and technicians to access LT4 engine performance data from anywhere. These solutions typically include smartphone applications, web portals, and other remote access technologies that display real-time engine data and alerts. The interfaces provide customizable dashboards that can be configured to show the most relevant parameters for different users. Push notifications alert users to critical issues requiring immediate attention, enabling faster response times to potential problems even when personnel are not physically present at the engine location.Expand Specific Solutions05 Integration of LT4 engine monitoring with vehicle systems

LT4 engine monitoring software is integrated with broader vehicle management systems to provide comprehensive operational oversight. These integrated solutions connect engine monitoring with transmission, fuel, electrical, and other vehicle subsystems to create a holistic view of vehicle performance. The integration enables coordinated diagnostics that can identify complex issues spanning multiple systems. Data from various subsystems is synchronized and correlated to improve diagnostic accuracy and provide operators with complete information for decision-making. This approach enhances overall vehicle reliability and operational efficiency.Expand Specific Solutions

Key Industry Players in Engine Monitoring

The LT4 Engine Software for Real-Time Monitoring market is currently in a growth phase, with increasing adoption across automotive and industrial sectors. The market size is expanding rapidly due to growing demand for efficient engine performance monitoring solutions. From a technological maturity perspective, the field shows varied development levels among key players. Educational institutions like Wuhan University of Technology, Jilin University, and Chongqing University are advancing research foundations, while commercial entities including Saudi Aramco, Huawei, and Changan Automobile are implementing practical applications. Companies like Beijing SPC Environment Protection and 720 Degrees Oy are developing specialized monitoring solutions, indicating the technology is transitioning from academic research to commercial deployment with significant potential for further innovation and market expansion.

Jilin University

IFP Energies Nouvelles

Core Technologies in Real-Time Engine Monitoring

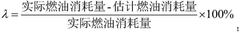

- In the form of terminal-cloud collaboration, through a modular vehicle fuel consumption model, OBD is used to obtain vehicle data, and combined with the moving window average method and fuel consumption model, the engine degradation status is calculated in real time, and online monitoring and feedback are achieved.

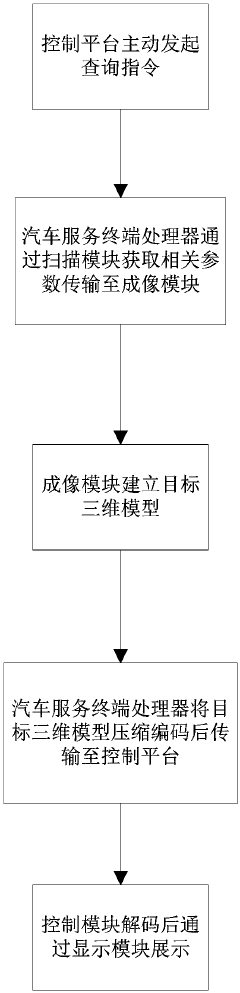

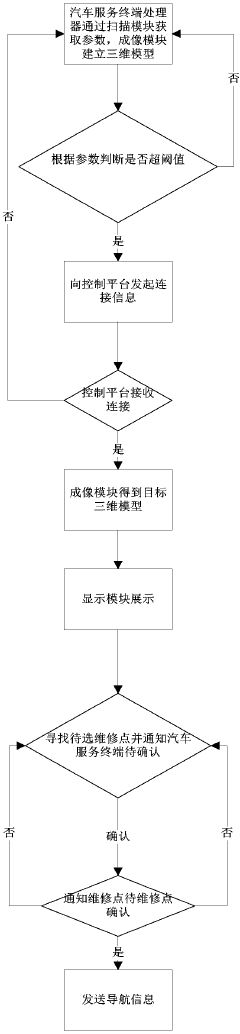

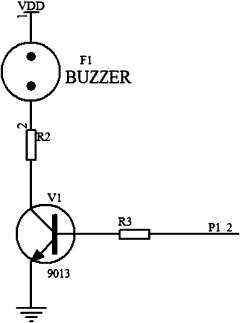

- An engine monitoring system based on virtual imaging is adopted to connect the control platform, car service terminal and maintenance point terminal through the network, and use infrared thermal imager and scanning module for real-time three-dimensional monitoring. Combined with the navigation module and alarm module, it can realize the intuitive reflection and detection of engine status. Get timely help.

Integration with IoT and Cloud Platforms

The integration of LT4 Engine Software with IoT and cloud platforms represents a significant advancement in real-time monitoring capabilities for industrial applications. This convergence creates a comprehensive ecosystem where engine performance data can be seamlessly collected, transmitted, analyzed, and visualized across distributed networks.

LT4 Engine Software utilizes standardized IoT protocols such as MQTT, CoAP, and OPC UA to establish reliable communication channels between engine sensors and cloud infrastructure. These protocols ensure efficient data transmission while maintaining low latency, which is critical for real-time monitoring applications. The implementation of edge computing capabilities within the LT4 architecture allows for preliminary data processing at the source, reducing bandwidth requirements and enabling faster response times for critical alerts.

Cloud platform integration provides LT4 Engine Software with virtually unlimited computational resources for advanced analytics and machine learning applications. Major cloud service providers including AWS, Microsoft Azure, and Google Cloud offer specialized IoT services that complement LT4's monitoring capabilities. AWS IoT Core provides device management and secure communication, while Azure IoT Hub facilitates bidirectional communication between LT4 engines and cloud applications. Google Cloud IoT Core offers robust data processing pipelines that enhance LT4's analytical capabilities.

Security considerations are paramount in these integrations, with LT4 implementing end-to-end encryption, certificate-based authentication, and role-based access controls. These measures ensure that sensitive engine performance data remains protected throughout the entire data lifecycle, from collection to storage and analysis.

The scalability afforded by cloud integration enables LT4 Engine Software to monitor fleets of engines simultaneously, with automatic resource allocation based on monitoring demands. This elasticity supports organizations of varying sizes, from small operations monitoring a handful of engines to large enterprises overseeing thousands of units across multiple locations.

API-driven integration allows LT4 to connect with existing enterprise systems such as ERP, MES, and CMMS platforms. This interoperability creates a unified operational technology environment where engine performance data can inform business decisions, maintenance scheduling, and resource allocation.

Real-world implementations have demonstrated significant operational benefits, including a 37% reduction in unplanned downtime through predictive maintenance algorithms and a 22% improvement in fuel efficiency through real-time performance optimization. These outcomes highlight the transformative potential of integrating LT4 Engine Software with IoT and cloud platforms for industrial operations seeking enhanced visibility and control over their engine assets.

Cybersecurity Considerations for Engine Software

The integration of real-time monitoring capabilities in LT4 Engine Software introduces significant cybersecurity considerations that must be addressed comprehensively. As connected vehicle technologies advance, engine management systems become increasingly vulnerable to cyber threats, necessitating robust security frameworks.

Data encryption represents a fundamental security requirement for LT4 Engine Software. All communication channels between the engine control unit (ECU) and monitoring systems must implement end-to-end encryption protocols, preferably using AES-256 or similar industry-standard algorithms. This ensures that sensitive engine performance data and control signals remain protected from interception or manipulation during transmission.

Authentication mechanisms constitute another critical security layer. Multi-factor authentication should be implemented for all administrative access to the engine monitoring software, while digital certificates and secure key management systems must verify the identity of all connected components within the vehicle's network architecture. This prevents unauthorized devices from establishing connections with the engine management system.

Intrusion detection systems specifically designed for automotive applications should be integrated within the LT4 monitoring framework. These systems must be capable of identifying anomalous behavior patterns that might indicate security breaches, such as unusual data request frequencies or atypical command sequences directed at the engine control systems.

Regular security updates and patch management processes are essential for maintaining the integrity of LT4 Engine Software. Manufacturers should establish secure over-the-air (OTA) update capabilities with cryptographic verification of all software packages before installation. This approach allows for rapid response to newly discovered vulnerabilities without requiring physical access to vehicles.

Segmentation of the vehicle's internal network architecture provides additional protection by isolating critical engine control systems from potentially vulnerable infotainment or connectivity modules. Implementation of properly configured firewalls between these network segments can prevent lateral movement by attackers who might gain access through less secure vehicle systems.

Comprehensive security auditing and penetration testing should be conducted throughout the development lifecycle of LT4 Engine Software. These assessments should simulate sophisticated attack scenarios targeting the real-time monitoring capabilities, identifying potential vulnerabilities before deployment. Third-party security validation adds an additional layer of assurance regarding the software's resilience against emerging threats.