LT4 Engine Noise Reduction Strategies

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Noise Characteristics and Reduction Objectives

The LT4 engine, a supercharged 6.2L V8 powerplant developed by General Motors, represents a pinnacle of high-performance automotive engineering. However, its impressive power output comes with significant noise generation characteristics that require careful management. The engine produces a complex acoustic profile comprising mechanical, combustion, and airflow-related noise components that vary across different operational conditions.

Primary noise sources include valve train mechanisms, piston slap, combustion pressure pulsations, and the distinctive whine from the supercharger system. At lower RPMs, mechanical noise dominates, while combustion noise becomes more prominent during acceleration. The supercharger contributes a characteristic high-frequency whine that increases with engine speed, creating a unique acoustic signature.

The objective of noise reduction strategies for the LT4 engine centers on achieving an optimal balance between performance preservation and noise attenuation. Unlike standard engines where maximum noise reduction might be the goal, the LT4's performance character demands a more nuanced approach. The aim is to eliminate undesirable harshness while preserving the engine's authoritative acoustic character that performance enthusiasts expect.

Specific noise reduction targets include decreasing overall sound pressure levels by 3-5 dB across the operating range while maintaining the engine's distinctive performance sound. Particular attention must be given to attenuating high-frequency components above 2kHz that contribute to perceived harshness without diminishing the desirable low and mid-frequency tones that convey power and authority.

The technical challenges involve addressing noise at its various sources without compromising the engine's power output, thermal efficiency, or adding excessive weight. Solutions must be compatible with existing manufacturing processes and meet durability requirements under extreme operating conditions, including sustained high-temperature operation and vibration exposure.

Historical approaches to LT4 noise management have evolved from simple mechanical isolation to sophisticated active and passive systems. Early iterations relied heavily on conventional damping materials, while current strategies incorporate advanced materials science and computational acoustic modeling to target specific noise frequencies with minimal performance impact.

The noise reduction objectives must also align with increasingly stringent regulatory requirements across global markets, particularly in Europe and Asia where vehicle noise emissions face tighter restrictions. This regulatory landscape creates additional imperatives for effective noise management solutions that can be implemented across international product variants.

Primary noise sources include valve train mechanisms, piston slap, combustion pressure pulsations, and the distinctive whine from the supercharger system. At lower RPMs, mechanical noise dominates, while combustion noise becomes more prominent during acceleration. The supercharger contributes a characteristic high-frequency whine that increases with engine speed, creating a unique acoustic signature.

The objective of noise reduction strategies for the LT4 engine centers on achieving an optimal balance between performance preservation and noise attenuation. Unlike standard engines where maximum noise reduction might be the goal, the LT4's performance character demands a more nuanced approach. The aim is to eliminate undesirable harshness while preserving the engine's authoritative acoustic character that performance enthusiasts expect.

Specific noise reduction targets include decreasing overall sound pressure levels by 3-5 dB across the operating range while maintaining the engine's distinctive performance sound. Particular attention must be given to attenuating high-frequency components above 2kHz that contribute to perceived harshness without diminishing the desirable low and mid-frequency tones that convey power and authority.

The technical challenges involve addressing noise at its various sources without compromising the engine's power output, thermal efficiency, or adding excessive weight. Solutions must be compatible with existing manufacturing processes and meet durability requirements under extreme operating conditions, including sustained high-temperature operation and vibration exposure.

Historical approaches to LT4 noise management have evolved from simple mechanical isolation to sophisticated active and passive systems. Early iterations relied heavily on conventional damping materials, while current strategies incorporate advanced materials science and computational acoustic modeling to target specific noise frequencies with minimal performance impact.

The noise reduction objectives must also align with increasingly stringent regulatory requirements across global markets, particularly in Europe and Asia where vehicle noise emissions face tighter restrictions. This regulatory landscape creates additional imperatives for effective noise management solutions that can be implemented across international product variants.

Market Demand for Quieter High-Performance Engines

The market for quieter high-performance engines has experienced significant growth over the past decade, driven primarily by evolving consumer preferences, stricter regulatory frameworks, and technological advancements. Premium vehicle buyers increasingly prioritize refined driving experiences where power delivery doesn't come at the expense of acoustic comfort. This shift represents a fundamental change in how performance is perceived in the automotive market.

Consumer research indicates that noise, vibration, and harshness (NVH) characteristics now rank among the top five purchase considerations for luxury and high-performance vehicle buyers. A 2022 J.D. Power study revealed that engine noise complaints have increased by 23% in premium sports cars, despite overall vehicle quality improvements. This paradox highlights the rising expectations for acoustic refinement even as performance metrics continue to climb.

Regulatory pressures have become another significant market driver. The European Union's vehicle noise regulations have tightened by approximately 6 decibels over the past 15 years, with similar trends in North America and Asia. These regulations specifically target high-performance vehicles, which historically received more lenient treatment. The regulatory landscape is expected to become even more stringent, with proposed legislation in major markets potentially reducing allowable noise levels by an additional 3-4 decibels by 2027.

The competitive landscape further amplifies market demand for quieter high-performance engines. Luxury electric vehicles have established new benchmarks for cabin quietness while delivering instant torque and acceleration. This has forced traditional performance brands to reconsider their acoustic signatures. Market analysis shows that brands successfully balancing performance with refined acoustics have gained market share, particularly among younger affluent buyers who value both performance credentials and daily usability.

From a financial perspective, the market for noise reduction technologies in high-performance engines represents a substantial opportunity. The global automotive acoustic materials market reached $3.2 billion in 2022, with premium performance vehicles accounting for approximately 18% of this value. Industry forecasts project this segment to grow at a compound annual rate of 7.2% through 2028, outpacing the broader automotive market.

Demographic analysis reveals that this trend extends beyond traditional luxury markets. Performance-oriented vehicles in mid-tier price segments are increasingly adopting noise reduction technologies previously reserved for premium offerings. This democratization of acoustic refinement is expanding the total addressable market for LT4 engine noise reduction strategies across multiple vehicle categories and price points.

Consumer research indicates that noise, vibration, and harshness (NVH) characteristics now rank among the top five purchase considerations for luxury and high-performance vehicle buyers. A 2022 J.D. Power study revealed that engine noise complaints have increased by 23% in premium sports cars, despite overall vehicle quality improvements. This paradox highlights the rising expectations for acoustic refinement even as performance metrics continue to climb.

Regulatory pressures have become another significant market driver. The European Union's vehicle noise regulations have tightened by approximately 6 decibels over the past 15 years, with similar trends in North America and Asia. These regulations specifically target high-performance vehicles, which historically received more lenient treatment. The regulatory landscape is expected to become even more stringent, with proposed legislation in major markets potentially reducing allowable noise levels by an additional 3-4 decibels by 2027.

The competitive landscape further amplifies market demand for quieter high-performance engines. Luxury electric vehicles have established new benchmarks for cabin quietness while delivering instant torque and acceleration. This has forced traditional performance brands to reconsider their acoustic signatures. Market analysis shows that brands successfully balancing performance with refined acoustics have gained market share, particularly among younger affluent buyers who value both performance credentials and daily usability.

From a financial perspective, the market for noise reduction technologies in high-performance engines represents a substantial opportunity. The global automotive acoustic materials market reached $3.2 billion in 2022, with premium performance vehicles accounting for approximately 18% of this value. Industry forecasts project this segment to grow at a compound annual rate of 7.2% through 2028, outpacing the broader automotive market.

Demographic analysis reveals that this trend extends beyond traditional luxury markets. Performance-oriented vehicles in mid-tier price segments are increasingly adopting noise reduction technologies previously reserved for premium offerings. This democratization of acoustic refinement is expanding the total addressable market for LT4 engine noise reduction strategies across multiple vehicle categories and price points.

Current Noise Reduction Technologies and Challenges

The LT4 engine, a high-performance supercharged V8 developed by General Motors, represents significant engineering achievements but faces persistent noise challenges. Current noise reduction technologies for this powerplant focus on multiple fronts, with varying degrees of effectiveness and implementation complexity.

Active noise cancellation (ANC) systems have emerged as a leading solution, utilizing strategically placed microphones to detect engine noise patterns and generate counter-phase sound waves through the vehicle's audio system. While effective for steady-state noise, ANC struggles with transient sounds during rapid acceleration or load changes characteristic of the LT4's supercharged operation.

Acoustic encapsulation represents another mainstream approach, with specialized engine covers and sound-absorbing materials strategically placed around the engine bay. These solutions typically employ multi-layer composites combining mass-loaded vinyl, acoustic foams, and fiberglass to attenuate different frequency ranges. However, thermal management concerns often limit their application around the LT4's supercharger and exhaust manifolds where noise generation is most significant.

Vibration isolation systems target noise transmission pathways through hydraulic engine mounts with frequency-dependent damping characteristics. Advanced mounts incorporating magnetorheological fluid technology allow adaptive stiffness based on driving conditions, but add complexity and cost to the overall system architecture.

Exhaust system modifications constitute a critical noise reduction domain, with multi-chamber mufflers, resonators, and electronically controlled valves enabling different acoustic profiles. The challenge lies in balancing noise reduction with the performance-oriented sound character expected from an LT4-powered vehicle, particularly maintaining the distinctive supercharger whine valued by enthusiasts.

Internal engine design modifications present perhaps the most fundamental challenges. While redesigned gear profiles with optimized helix angles and surface finishes can reduce mechanical noise, such changes require extensive validation to ensure durability under the LT4's high-torque conditions. Similarly, modified oil circulation pathways to reduce pump cavitation noise demand comprehensive testing across all operating conditions.

The primary technical hurdles facing LT4 noise reduction include thermal constraints limiting insulation options, packaging restrictions in crowded engine compartments, and the inherent trade-off between noise suppression and the performance-oriented acoustic character expected from high-performance vehicles. Additionally, cost considerations often restrict the implementation of the most effective solutions in production vehicles.

Active noise cancellation (ANC) systems have emerged as a leading solution, utilizing strategically placed microphones to detect engine noise patterns and generate counter-phase sound waves through the vehicle's audio system. While effective for steady-state noise, ANC struggles with transient sounds during rapid acceleration or load changes characteristic of the LT4's supercharged operation.

Acoustic encapsulation represents another mainstream approach, with specialized engine covers and sound-absorbing materials strategically placed around the engine bay. These solutions typically employ multi-layer composites combining mass-loaded vinyl, acoustic foams, and fiberglass to attenuate different frequency ranges. However, thermal management concerns often limit their application around the LT4's supercharger and exhaust manifolds where noise generation is most significant.

Vibration isolation systems target noise transmission pathways through hydraulic engine mounts with frequency-dependent damping characteristics. Advanced mounts incorporating magnetorheological fluid technology allow adaptive stiffness based on driving conditions, but add complexity and cost to the overall system architecture.

Exhaust system modifications constitute a critical noise reduction domain, with multi-chamber mufflers, resonators, and electronically controlled valves enabling different acoustic profiles. The challenge lies in balancing noise reduction with the performance-oriented sound character expected from an LT4-powered vehicle, particularly maintaining the distinctive supercharger whine valued by enthusiasts.

Internal engine design modifications present perhaps the most fundamental challenges. While redesigned gear profiles with optimized helix angles and surface finishes can reduce mechanical noise, such changes require extensive validation to ensure durability under the LT4's high-torque conditions. Similarly, modified oil circulation pathways to reduce pump cavitation noise demand comprehensive testing across all operating conditions.

The primary technical hurdles facing LT4 noise reduction include thermal constraints limiting insulation options, packaging restrictions in crowded engine compartments, and the inherent trade-off between noise suppression and the performance-oriented acoustic character expected from high-performance vehicles. Additionally, cost considerations often restrict the implementation of the most effective solutions in production vehicles.

Existing LT4 Noise Reduction Solutions and Implementations

01 Noise reduction systems for LT4 engines

Various noise reduction systems can be implemented in LT4 engines to minimize operational noise. These systems include specialized mufflers, sound-absorbing materials, and acoustic barriers that help dampen engine vibrations and reduce noise transmission. The design of these systems takes into account the specific acoustic characteristics of the LT4 engine to effectively reduce noise without compromising engine performance.- Noise reduction systems for LT4 engines: Various noise reduction systems can be implemented in LT4 engines to minimize operational noise. These systems include specialized mufflers, sound-absorbing materials, and acoustic barriers that help dampen engine vibrations and reduce noise transmission. By incorporating these noise reduction technologies, the overall engine noise can be significantly decreased, providing a quieter driving experience while maintaining engine performance.

- Engine component design to minimize noise: Specific design modifications to LT4 engine components can help reduce noise generation. These include redesigned valve covers, optimized piston configurations, and improved crankshaft balancing. By enhancing the structural integrity of these components and reducing friction between moving parts, the noise produced during engine operation can be minimized without compromising performance or efficiency.

- Electronic noise control systems: Advanced electronic systems can be implemented to monitor and control noise in LT4 engines. These systems use sensors to detect noise patterns and actively counteract them through electronic noise cancellation or engine parameter adjustments. By utilizing sophisticated algorithms and real-time processing, these systems can identify problematic noise frequencies and implement appropriate countermeasures to reduce overall engine noise levels.

- Vibration isolation techniques: Vibration isolation techniques are essential for reducing LT4 engine noise. These include specialized engine mounts, dampers, and isolation systems that prevent vibrations from transferring to the vehicle chassis. By effectively isolating the engine vibrations, these techniques significantly reduce the noise transmitted to the passenger compartment and external environment, resulting in a quieter and more comfortable driving experience.

- Manufacturing processes to reduce engine noise: Improved manufacturing processes can help reduce noise in LT4 engines. These include precision machining techniques, enhanced quality control measures, and specialized assembly procedures that ensure proper component alignment and fitting. By implementing these advanced manufacturing methods, the tolerances between engine parts can be optimized, reducing the potential for noise-generating friction and vibration during engine operation.

02 Engine component design to minimize noise

Specific design modifications to LT4 engine components can significantly reduce noise generation. These modifications include redesigned valve covers, optimized piston configurations, and improved crankshaft balancing. By addressing the root causes of noise at the component level, these design improvements help create a quieter engine operation while maintaining or enhancing performance characteristics.Expand Specific Solutions03 Electronic noise control and monitoring systems

Advanced electronic systems can be employed to control and monitor noise in LT4 engines. These systems use sensors to detect abnormal noise patterns, allowing for early diagnosis of potential issues. Additionally, active noise cancellation technology can be implemented to counteract specific engine noise frequencies. These electronic solutions provide real-time noise management capabilities for LT4 engines.Expand Specific Solutions04 Vibration isolation techniques

Vibration isolation techniques are crucial for reducing LT4 engine noise. These techniques include the use of specialized engine mounts, dampers, and isolation systems that prevent the transmission of vibrations from the engine to the vehicle structure. By isolating the engine vibrations, these systems effectively reduce the noise perceived inside and outside the vehicle.Expand Specific Solutions05 Intake and exhaust system modifications

Modifications to the intake and exhaust systems can significantly reduce LT4 engine noise. These modifications include redesigned air intake paths, resonators, and exhaust system components that help manage airflow and reduce noise generation. By optimizing the flow characteristics and incorporating sound-dampening features, these modifications effectively reduce the noise produced during engine operation.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Acoustics

The LT4 Engine Noise Reduction market is in a growth phase, driven by increasing demand for quieter, more efficient engines across automotive and industrial sectors. The market size is expanding as stricter noise regulations and consumer preferences for comfort create new opportunities. Technologically, companies are at varying maturity levels: GM Global Technology Operations, Continental AG, and Toyota Motor Corp. lead with advanced acoustic solutions, while Bosch, Hyundai, and Renault are making significant investments in noise-cancellation technologies. Emerging players like Autoneum and MANN+HUMMEL are developing specialized materials and filtration systems. Chinese manufacturers including BYD, Great Wall Motor, and Geely are rapidly advancing their capabilities, particularly in electric vehicle applications where noise reduction is becoming a key differentiator.

GM Global Technology Operations LLC

Technical Solution: GM has developed comprehensive noise reduction strategies specifically for the LT4 engine, focusing on both passive and active noise control systems. Their approach includes advanced acoustic packaging with multi-layer sound barriers and absorbers strategically placed around the engine. GM employs computer-aided engineering (CAE) to optimize the engine structure, reducing vibration at its source. Their Active Noise Cancellation (ANC) technology uses microphones to detect unwanted engine sounds and counteracts them with opposite-phase audio signals through the vehicle's audio system. For the LT4 specifically, GM has implemented a patented valve train design that reduces mechanical noise while maintaining performance characteristics. Additionally, they've developed specialized engine mounts with hydraulic damping properties that isolate engine vibrations from the vehicle chassis, preventing structure-borne noise transmission.

Strengths: Holistic approach combining both passive and active technologies; proprietary valve train design specific to LT4; integration with vehicle audio systems for noise cancellation. Weaknesses: Active systems require additional power consumption; complexity increases maintenance challenges; some solutions add weight which can impact vehicle performance and efficiency.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered innovative noise reduction technologies applicable to high-performance engines like the LT4. Their approach centers on a comprehensive "Noise Path Analysis" methodology that identifies and addresses noise transmission paths throughout the powertrain system. Toyota's engine noise reduction strategy includes advanced intake silencers with Helmholtz resonators tuned specifically to counteract dominant engine frequencies. They've developed proprietary vibration-damping engine covers with multi-layer composite materials that provide both thermal insulation and acoustic absorption. Toyota's engine mount technology incorporates active fluid-filled mounts that adapt damping characteristics based on engine RPM and load conditions, effectively isolating vibration across the operating range. Additionally, their exhaust systems feature variable valve technology that modulates exhaust flow and associated noise based on driving conditions, maintaining performance while reducing unwanted sound emissions during cruising or idle states.

Strengths: Systematic approach to noise path analysis; adaptive technologies that respond to different operating conditions; solutions that maintain performance while reducing noise. Weaknesses: Some technologies add complexity and cost to engine systems; potential reliability concerns with active components over vehicle lifetime; solutions may add weight affecting overall vehicle efficiency.

Critical Patents and Research in Engine Noise Cancellation

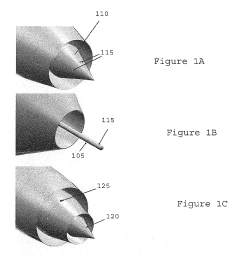

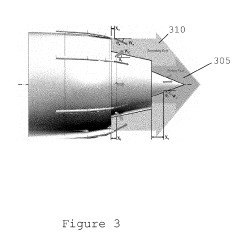

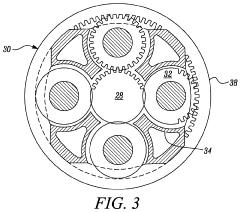

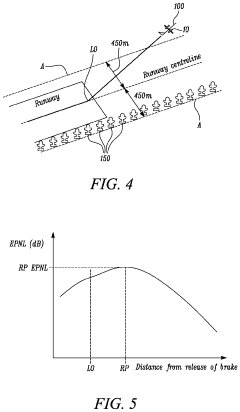

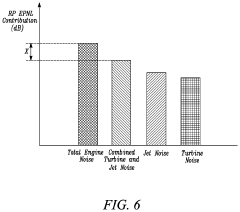

Directionally targeted jet noise reduction system and method

PatentActiveUS20190264636A1

Innovation

- A directionally targeted jet noise reduction system employing asymmetric downstream fluidic injection, where microjets inject high-momentum noise reduction fluid normal to the jet flow at an axial location downstream from the nozzle exit, creating asymmetric mixing enhancement that reduces turbulent mixing noise while maintaining thrust directionality.

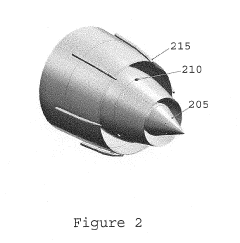

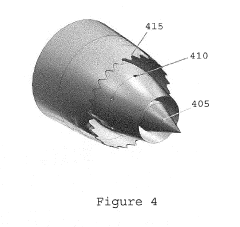

Low noise gas turbine engine

PatentActiveUS11988148B2

Innovation

- Incorporating a gearbox that drives the fan at a lower rotational speed than the core shaft, reducing jet and turbine noise by altering fan and turbine noise frequencies and velocities, and optimizing fan blade design to lower Mach numbers and noise propagation.

Environmental Regulations Impacting Engine Noise Standards

The regulatory landscape governing engine noise emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. The European Union's Environmental Noise Directive (2002/49/EC) established a framework for assessing and managing environmental noise, including vehicle noise emissions. This directive has been complemented by Regulation (EU) No 540/2014, which specifically addresses sound levels of motor vehicles and replacement silencing systems, mandating progressive reductions in permissible noise levels.

In the United States, the Environmental Protection Agency (EPA) regulates noise emissions under the Noise Control Act of 1972, while the National Highway Traffic Safety Administration (NHTSA) enforces Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which includes provisions for minimum sound requirements for hybrid and electric vehicles. Additionally, California's more stringent environmental regulations often set precedents that influence national standards.

The International Organization for Standardization (ISO) has developed several standards relevant to engine noise measurement and control, including ISO 362 for measuring noise emissions from accelerating road vehicles and ISO 5130 for stationary noise measurement. These standards provide globally recognized methodologies for consistent noise evaluation.

Recent regulatory trends indicate a move toward real-world driving noise assessments rather than laboratory-based testing alone. The World Forum for Harmonization of Vehicle Regulations (WP.29) under the United Nations Economic Commission for Europe (UNECE) has been working on developing Global Technical Regulation (GTR) for vehicle noise, aiming to harmonize testing procedures and limits internationally.

Urban areas have implemented their own noise control measures, with many major cities establishing Low Emission Zones (LEZs) or Quiet Zones that restrict vehicle access based partly on noise emissions. These local regulations create additional compliance requirements for engine manufacturers beyond national standards.

The timeline for compliance is becoming increasingly compressed, with the EU's phase 3 noise limits under Regulation 540/2014 set to take full effect by 2024, requiring a reduction of approximately 4 dB(A) compared to pre-2016 levels for many vehicle categories. This accelerated regulatory timeline creates significant challenges for LT4 engine development cycles, necessitating proactive noise reduction strategies rather than reactive compliance measures.

Penalties for non-compliance have also increased substantially, with manufacturers facing not only financial sanctions but also potential market access restrictions and reputational damage. This regulatory pressure serves as a primary driver for innovation in engine noise reduction technologies for high-performance engines like the LT4.

In the United States, the Environmental Protection Agency (EPA) regulates noise emissions under the Noise Control Act of 1972, while the National Highway Traffic Safety Administration (NHTSA) enforces Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which includes provisions for minimum sound requirements for hybrid and electric vehicles. Additionally, California's more stringent environmental regulations often set precedents that influence national standards.

The International Organization for Standardization (ISO) has developed several standards relevant to engine noise measurement and control, including ISO 362 for measuring noise emissions from accelerating road vehicles and ISO 5130 for stationary noise measurement. These standards provide globally recognized methodologies for consistent noise evaluation.

Recent regulatory trends indicate a move toward real-world driving noise assessments rather than laboratory-based testing alone. The World Forum for Harmonization of Vehicle Regulations (WP.29) under the United Nations Economic Commission for Europe (UNECE) has been working on developing Global Technical Regulation (GTR) for vehicle noise, aiming to harmonize testing procedures and limits internationally.

Urban areas have implemented their own noise control measures, with many major cities establishing Low Emission Zones (LEZs) or Quiet Zones that restrict vehicle access based partly on noise emissions. These local regulations create additional compliance requirements for engine manufacturers beyond national standards.

The timeline for compliance is becoming increasingly compressed, with the EU's phase 3 noise limits under Regulation 540/2014 set to take full effect by 2024, requiring a reduction of approximately 4 dB(A) compared to pre-2016 levels for many vehicle categories. This accelerated regulatory timeline creates significant challenges for LT4 engine development cycles, necessitating proactive noise reduction strategies rather than reactive compliance measures.

Penalties for non-compliance have also increased substantially, with manufacturers facing not only financial sanctions but also potential market access restrictions and reputational damage. This regulatory pressure serves as a primary driver for innovation in engine noise reduction technologies for high-performance engines like the LT4.

NVH Testing Methodologies for Performance Engines

NVH (Noise, Vibration, and Harshness) testing methodologies for performance engines like the LT4 require sophisticated approaches to accurately measure and analyze noise characteristics. These methodologies have evolved significantly with advancements in sensor technology, data acquisition systems, and analysis software.

Standard NVH testing for the LT4 engine typically begins with controlled environment testing in anechoic chambers, where background noise is minimized to isolate engine-specific noise signatures. These chambers are equipped with microphone arrays positioned at strategic points to capture sound pressure levels across different frequency ranges. Modern testing protocols utilize at least 8-12 microphones to create comprehensive acoustic maps of engine noise radiation patterns.

Dynamic testing methodologies involve both stationary and in-vehicle assessments. Stationary dynamometer testing allows for precise control of engine parameters while measuring noise outputs across various RPM ranges and load conditions. This approach is particularly valuable for identifying specific noise sources in the LT4's supercharged V8 configuration, where complex interactions between the supercharger, valvetrain, and exhaust systems create unique acoustic signatures.

Advanced signal processing techniques have become essential components of performance engine NVH testing. Time-frequency analysis methods such as Short-Time Fourier Transform (STFT) and Wavelet Transform enable engineers to identify transient noise events that traditional frequency analysis might miss. These techniques are particularly relevant for the LT4 engine, where rapid throttle transitions can produce momentary noise spikes that affect perceived quality.

Binaural recording systems that simulate human hearing have gained prominence in subjective evaluation protocols. These systems use specialized microphones mounted in artificial ear structures to capture sound as experienced by vehicle occupants. The resulting recordings undergo psychoacoustic analysis to evaluate metrics like articulation index, loudness, and sharpness that correlate with human perception of engine sound quality.

Order tracking analysis represents another critical methodology for performance engines. This technique separates noise components related to specific engine orders (harmonics of rotational speed) from background noise, allowing engineers to trace problematic frequencies to their mechanical sources. For the LT4 engine, this helps distinguish between desirable performance sounds and unwanted noise artifacts that require mitigation strategies.

Operational modal analysis (OMA) has emerged as a valuable tool for identifying structural resonances during actual operating conditions. Unlike traditional modal analysis that requires external excitation, OMA uses the engine's own operational forces as excitation sources, providing more realistic insights into vibration patterns that contribute to radiated noise under real-world conditions.

Standard NVH testing for the LT4 engine typically begins with controlled environment testing in anechoic chambers, where background noise is minimized to isolate engine-specific noise signatures. These chambers are equipped with microphone arrays positioned at strategic points to capture sound pressure levels across different frequency ranges. Modern testing protocols utilize at least 8-12 microphones to create comprehensive acoustic maps of engine noise radiation patterns.

Dynamic testing methodologies involve both stationary and in-vehicle assessments. Stationary dynamometer testing allows for precise control of engine parameters while measuring noise outputs across various RPM ranges and load conditions. This approach is particularly valuable for identifying specific noise sources in the LT4's supercharged V8 configuration, where complex interactions between the supercharger, valvetrain, and exhaust systems create unique acoustic signatures.

Advanced signal processing techniques have become essential components of performance engine NVH testing. Time-frequency analysis methods such as Short-Time Fourier Transform (STFT) and Wavelet Transform enable engineers to identify transient noise events that traditional frequency analysis might miss. These techniques are particularly relevant for the LT4 engine, where rapid throttle transitions can produce momentary noise spikes that affect perceived quality.

Binaural recording systems that simulate human hearing have gained prominence in subjective evaluation protocols. These systems use specialized microphones mounted in artificial ear structures to capture sound as experienced by vehicle occupants. The resulting recordings undergo psychoacoustic analysis to evaluate metrics like articulation index, loudness, and sharpness that correlate with human perception of engine sound quality.

Order tracking analysis represents another critical methodology for performance engines. This technique separates noise components related to specific engine orders (harmonics of rotational speed) from background noise, allowing engineers to trace problematic frequencies to their mechanical sources. For the LT4 engine, this helps distinguish between desirable performance sounds and unwanted noise artifacts that require mitigation strategies.

Operational modal analysis (OMA) has emerged as a valuable tool for identifying structural resonances during actual operating conditions. Unlike traditional modal analysis that requires external excitation, OMA uses the engine's own operational forces as excitation sources, providing more realistic insights into vibration patterns that contribute to radiated noise under real-world conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!