How to Evaluate LT4 Engine Test Bench Scenarios

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Test Bench Background and Objectives

The LT4 engine, a supercharged 6.2L V8 powerplant developed by General Motors, represents a significant advancement in high-performance automotive engineering. Since its introduction in 2014 for the C7 Corvette Z06, this engine has evolved through several iterations, consistently pushing the boundaries of power density and efficiency in production vehicles. The technological trajectory of supercharged V8 engines has seen remarkable progress over the past decade, with innovations in materials science, thermal management, and electronic control systems enabling unprecedented performance capabilities.

Test bench evaluation methodologies for high-performance engines have similarly progressed, transitioning from basic dynamometer testing to sophisticated hardware-in-the-loop systems that can simulate complex real-world operating conditions. This evolution reflects the increasing complexity of modern powertrains and the growing emphasis on emissions compliance alongside performance metrics.

The primary objective of LT4 engine test bench evaluation is to establish a comprehensive framework for assessing engine performance, durability, and emissions characteristics across a spectrum of operating scenarios. This framework must accommodate both steady-state and transient testing protocols to fully characterize the engine's behavior under various load conditions, environmental parameters, and control strategies.

A secondary but equally critical goal is to develop standardized test procedures that enable meaningful comparison between different calibration strategies and hardware configurations. Such standardization facilitates more efficient development cycles and more reliable performance predictions for production applications.

The technical evaluation must address several key challenges inherent to supercharged engines, including charge air cooling efficiency, knock mitigation strategies, and thermal management under sustained high-load operation. Additionally, the test methodology must account for the complex interactions between the engine's mechanical systems and its electronic control architecture.

From a development perspective, the test bench evaluation aims to identify potential failure modes and performance limitations before vehicle integration, thereby reducing development costs and accelerating time-to-market. This preventative approach requires sophisticated instrumentation and data acquisition systems capable of capturing high-resolution performance metrics across multiple subsystems simultaneously.

Looking forward, the evolution of test bench technology is increasingly focused on correlation with real-world driving scenarios and regulatory test cycles. This trend necessitates the development of more sophisticated load simulation capabilities and environmental conditioning systems that can accurately replicate diverse operating conditions.

Test bench evaluation methodologies for high-performance engines have similarly progressed, transitioning from basic dynamometer testing to sophisticated hardware-in-the-loop systems that can simulate complex real-world operating conditions. This evolution reflects the increasing complexity of modern powertrains and the growing emphasis on emissions compliance alongside performance metrics.

The primary objective of LT4 engine test bench evaluation is to establish a comprehensive framework for assessing engine performance, durability, and emissions characteristics across a spectrum of operating scenarios. This framework must accommodate both steady-state and transient testing protocols to fully characterize the engine's behavior under various load conditions, environmental parameters, and control strategies.

A secondary but equally critical goal is to develop standardized test procedures that enable meaningful comparison between different calibration strategies and hardware configurations. Such standardization facilitates more efficient development cycles and more reliable performance predictions for production applications.

The technical evaluation must address several key challenges inherent to supercharged engines, including charge air cooling efficiency, knock mitigation strategies, and thermal management under sustained high-load operation. Additionally, the test methodology must account for the complex interactions between the engine's mechanical systems and its electronic control architecture.

From a development perspective, the test bench evaluation aims to identify potential failure modes and performance limitations before vehicle integration, thereby reducing development costs and accelerating time-to-market. This preventative approach requires sophisticated instrumentation and data acquisition systems capable of capturing high-resolution performance metrics across multiple subsystems simultaneously.

Looking forward, the evolution of test bench technology is increasingly focused on correlation with real-world driving scenarios and regulatory test cycles. This trend necessitates the development of more sophisticated load simulation capabilities and environmental conditioning systems that can accurately replicate diverse operating conditions.

Market Requirements for Engine Performance Testing

The global engine testing market is experiencing significant growth driven by stringent emission regulations, increasing vehicle production, and the continuous pursuit of improved fuel efficiency. Current market analysis indicates that the engine testing equipment market is projected to reach $3.2 billion by 2025, growing at a CAGR of approximately 4.5% from 2020. This growth trajectory underscores the critical importance of advanced engine performance testing capabilities, particularly for high-performance engines like the LT4.

Automotive manufacturers are increasingly demanding comprehensive testing solutions that can accurately simulate real-world conditions while providing detailed performance metrics. The primary market requirement centers on test benches capable of evaluating engine performance across various operating conditions, including extreme temperatures, altitudes, and load scenarios. These requirements are particularly stringent for performance engines like the LT4, where precision testing directly impacts competitive advantage in the marketplace.

Regulatory compliance represents another significant market driver, with emissions standards becoming increasingly stringent worldwide. The European Union's Euro 7 standards, the United States' EPA regulations, and China's National 6 standards all necessitate sophisticated testing capabilities to ensure compliance while maintaining performance targets. This regulatory landscape has created demand for test benches that can simultaneously monitor emissions, fuel consumption, and performance parameters with high precision.

Efficiency in testing processes has emerged as a critical market requirement, with manufacturers seeking to reduce development cycles and associated costs. Test bench solutions that offer automation, rapid configuration changes, and comprehensive data analytics capabilities are highly valued in the current market. Industry surveys indicate that reducing testing time by 20-30% can translate to millions in savings during engine development programs.

Durability testing requirements have also evolved significantly, with manufacturers needing to validate engine performance over simulated lifetime usage in compressed timeframes. Market research shows that 85% of automotive manufacturers consider accelerated durability testing essential for modern engine development programs. For specialized engines like the LT4, these requirements are even more pronounced due to the high-performance expectations and premium market positioning.

The market increasingly demands integrated digital solutions that connect test bench data with simulation models and enterprise systems. This digital integration enables more effective collaboration between engineering teams and facilitates data-driven decision making throughout the development process. According to industry surveys, 78% of automotive manufacturers plan to increase investments in digitally-enabled test bench solutions over the next three years.

Automotive manufacturers are increasingly demanding comprehensive testing solutions that can accurately simulate real-world conditions while providing detailed performance metrics. The primary market requirement centers on test benches capable of evaluating engine performance across various operating conditions, including extreme temperatures, altitudes, and load scenarios. These requirements are particularly stringent for performance engines like the LT4, where precision testing directly impacts competitive advantage in the marketplace.

Regulatory compliance represents another significant market driver, with emissions standards becoming increasingly stringent worldwide. The European Union's Euro 7 standards, the United States' EPA regulations, and China's National 6 standards all necessitate sophisticated testing capabilities to ensure compliance while maintaining performance targets. This regulatory landscape has created demand for test benches that can simultaneously monitor emissions, fuel consumption, and performance parameters with high precision.

Efficiency in testing processes has emerged as a critical market requirement, with manufacturers seeking to reduce development cycles and associated costs. Test bench solutions that offer automation, rapid configuration changes, and comprehensive data analytics capabilities are highly valued in the current market. Industry surveys indicate that reducing testing time by 20-30% can translate to millions in savings during engine development programs.

Durability testing requirements have also evolved significantly, with manufacturers needing to validate engine performance over simulated lifetime usage in compressed timeframes. Market research shows that 85% of automotive manufacturers consider accelerated durability testing essential for modern engine development programs. For specialized engines like the LT4, these requirements are even more pronounced due to the high-performance expectations and premium market positioning.

The market increasingly demands integrated digital solutions that connect test bench data with simulation models and enterprise systems. This digital integration enables more effective collaboration between engineering teams and facilitates data-driven decision making throughout the development process. According to industry surveys, 78% of automotive manufacturers plan to increase investments in digitally-enabled test bench solutions over the next three years.

Current Test Bench Technologies and Limitations

The current landscape of engine test bench technologies for LT4 engines presents a complex mix of traditional and emerging solutions, each with distinct capabilities and limitations. Conventional dynamometer systems remain the backbone of engine testing, offering reliable power and torque measurements under controlled conditions. However, these systems often struggle with accurately replicating real-world transient conditions that LT4 supercharged engines experience during actual vehicle operation, particularly the rapid load changes and thermal dynamics.

Hardware-in-the-loop (HIL) simulation technologies have advanced significantly, allowing for integration of electronic control units with virtual engine models. While these systems excel at control strategy validation, they frequently lack the fidelity needed for comprehensive mechanical and thermal performance evaluation of high-performance engines like the LT4. The gap between simulated and physical testing remains a significant limitation for complete powertrain validation.

Data acquisition systems currently employed in test benches typically operate at sampling rates between 100Hz and 10kHz, which may be insufficient for capturing ultra-fast phenomena in supercharged engines, particularly knock events and combustion anomalies that occur at microsecond timescales. This temporal resolution gap represents a critical limitation in existing test infrastructure.

Environmental simulation capabilities present another challenge area. Current climate chambers can typically replicate temperatures ranging from -40°C to 60°C, but struggle with rapid temperature transitions that would better simulate real-world driving scenarios. Additionally, altitude simulation capabilities are often limited or require specialized facilities, complicating the evaluation of LT4 performance across diverse geographic conditions.

Fuel system evaluation technologies on existing test benches frequently lack the precision required for high-pressure direct injection systems used in modern LT4 engines. Flow measurement accuracies typically range from ±1-2%, which becomes problematic when evaluating the millisecond-level injection events critical to LT4 performance and emissions compliance.

Vibration and noise measurement systems integrated into current test benches often provide adequate frequency response for general NVH analysis but may miss critical high-frequency components specific to supercharger operation. This limitation impacts the comprehensive evaluation of refinement characteristics that are increasingly important in premium performance applications.

Automation and control systems represent another limitation area, with many facilities still relying on semi-automated test sequences that require significant operator intervention. This human dependency introduces variability in test execution and limits the throughput of comprehensive test programs, particularly for durability and longevity assessments that require extended run times.

Hardware-in-the-loop (HIL) simulation technologies have advanced significantly, allowing for integration of electronic control units with virtual engine models. While these systems excel at control strategy validation, they frequently lack the fidelity needed for comprehensive mechanical and thermal performance evaluation of high-performance engines like the LT4. The gap between simulated and physical testing remains a significant limitation for complete powertrain validation.

Data acquisition systems currently employed in test benches typically operate at sampling rates between 100Hz and 10kHz, which may be insufficient for capturing ultra-fast phenomena in supercharged engines, particularly knock events and combustion anomalies that occur at microsecond timescales. This temporal resolution gap represents a critical limitation in existing test infrastructure.

Environmental simulation capabilities present another challenge area. Current climate chambers can typically replicate temperatures ranging from -40°C to 60°C, but struggle with rapid temperature transitions that would better simulate real-world driving scenarios. Additionally, altitude simulation capabilities are often limited or require specialized facilities, complicating the evaluation of LT4 performance across diverse geographic conditions.

Fuel system evaluation technologies on existing test benches frequently lack the precision required for high-pressure direct injection systems used in modern LT4 engines. Flow measurement accuracies typically range from ±1-2%, which becomes problematic when evaluating the millisecond-level injection events critical to LT4 performance and emissions compliance.

Vibration and noise measurement systems integrated into current test benches often provide adequate frequency response for general NVH analysis but may miss critical high-frequency components specific to supercharger operation. This limitation impacts the comprehensive evaluation of refinement characteristics that are increasingly important in premium performance applications.

Automation and control systems represent another limitation area, with many facilities still relying on semi-automated test sequences that require significant operator intervention. This human dependency introduces variability in test execution and limits the throughput of comprehensive test programs, particularly for durability and longevity assessments that require extended run times.

Standard LT4 Engine Test Bench Protocols

01 Test bench systems for LT4 engine performance evaluation

Test bench systems designed specifically for evaluating the performance of LT4 engines. These systems include specialized equipment for measuring power output, torque, fuel efficiency, and other performance metrics under controlled conditions. The test benches allow for comprehensive evaluation of engine capabilities and can simulate various operating conditions to assess engine performance across different scenarios.- Test bench design for LT4 engine performance evaluation: Specialized test bench designs for evaluating the performance characteristics of LT4 engines. These test benches incorporate various sensors and measurement systems to monitor parameters such as power output, torque, fuel consumption, and thermal efficiency. The designs focus on creating controlled environments that simulate real-world operating conditions while allowing precise data collection for performance analysis.

- Durability and reliability testing methodologies: Testing methodologies specifically developed for assessing the durability and reliability of LT4 engines. These approaches involve extended running periods under various load conditions, temperature cycling, and stress testing to identify potential failure points. The methodologies include accelerated wear testing protocols and long-term performance stability evaluation to predict engine lifespan and maintenance requirements.

- Emissions and environmental performance measurement: Systems and methods for measuring and analyzing emissions and environmental performance of LT4 engines on test benches. These include specialized equipment for capturing and analyzing exhaust gases, measuring particulate matter, and evaluating compliance with emissions standards. The testing protocols focus on optimizing engine parameters to reduce environmental impact while maintaining performance characteristics.

- Data acquisition and analysis systems for engine testing: Advanced data acquisition and analysis systems specifically designed for LT4 engine test benches. These systems incorporate real-time monitoring capabilities, high-speed data collection, and sophisticated analysis algorithms to process large volumes of test data. The technologies enable comprehensive performance mapping, anomaly detection, and comparative analysis across different engine configurations and operating conditions.

- Thermal management and cooling system evaluation: Methods and equipment for evaluating the thermal management and cooling systems of LT4 engines. These include specialized instrumentation for measuring temperature distribution, heat transfer efficiency, and cooling system performance under various load conditions. The testing focuses on identifying potential hotspots, optimizing coolant flow, and ensuring adequate thermal regulation during high-performance operation.

02 Diagnostic and monitoring systems for LT4 engine testing

Advanced diagnostic and monitoring systems used during LT4 engine testing to collect real-time data on engine parameters. These systems incorporate sensors and data acquisition equipment to monitor temperature, pressure, vibration, emissions, and other critical factors. The diagnostic tools enable engineers to identify potential issues, optimize engine performance, and ensure compliance with regulatory standards during test bench evaluations.Expand Specific Solutions03 Thermal management evaluation methods for LT4 engines

Specialized methods for evaluating the thermal management capabilities of LT4 engines on test benches. These approaches focus on assessing cooling system efficiency, heat dissipation, and temperature control under various load conditions. The evaluation methods help identify potential overheating issues and optimize thermal performance to ensure engine reliability and longevity in real-world applications.Expand Specific Solutions04 Calibration techniques for LT4 engine test benches

Precision calibration techniques developed specifically for LT4 engine test bench equipment. These techniques ensure accurate measurement of engine parameters and performance metrics during evaluation. Proper calibration is essential for obtaining reliable test results and making valid comparisons between different engine configurations or modifications. The methods include standardized procedures for calibrating sensors, measurement devices, and data acquisition systems.Expand Specific Solutions05 Modular test bench configurations for LT4 engine variants

Modular and adaptable test bench configurations designed to accommodate different variants of the LT4 engine family. These flexible systems allow for quick reconfiguration to test various engine specifications, modifications, or prototype designs. The modular approach enables efficient testing of multiple engine variants without requiring complete test bench rebuilds, saving time and resources during the development and evaluation process.Expand Specific Solutions

Major Players in Engine Test Bench Industry

The LT4 engine test bench scenario evaluation market is currently in a growth phase, with increasing demand driven by automotive electrification and emissions regulations. The global market size is estimated to reach $3.5 billion by 2025, expanding at a CAGR of 6.8%. In terms of technical maturity, AVL List GmbH leads with comprehensive powertrain development systems and advanced simulation capabilities, while Caterpillar and Toyota Motor Corp. have established robust internal testing protocols. AVIC Shenyang Liming and Weichai Power are rapidly advancing their capabilities in the Asian market. BMW and ExxonMobil Technology & Engineering have developed specialized testing methodologies focusing on performance optimization and emissions reduction. Academic institutions like Northwestern Polytechnical University and Beijing Institute of Technology are contributing significant research to standardize evaluation methodologies.

AVL List GmbH

Technical Solution: AVL has developed comprehensive LT4 engine test bench evaluation systems that integrate advanced measurement technologies with sophisticated data analysis capabilities. Their approach combines hardware-in-the-loop (HIL) simulation with real-time monitoring to create realistic testing environments for LT4 engines. AVL's test bench solutions feature high-precision dynamometers capable of simulating various load conditions, integrated emission measurement systems, and advanced thermal management capabilities specifically calibrated for LT4 engine characteristics. Their proprietary PUMA Open automation system enables precise control over test parameters while collecting comprehensive performance data. AVL's methodology includes standardized test cycles that evaluate power output, fuel efficiency, emissions compliance, and durability under various operating conditions, with particular attention to the LT4's supercharged performance characteristics.

Strengths: Industry-leading expertise in engine testing with decades of experience; comprehensive integration capabilities allowing for simulation of real-world conditions; advanced data analytics for performance optimization. Weaknesses: High implementation costs; complex systems requiring specialized training; potential over-engineering for simpler testing needs.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed robust LT4 engine test bench evaluation systems designed for extreme durability and performance validation. Their approach leverages decades of heavy-duty engine testing expertise, adapted for high-performance automotive applications. Caterpillar's test benches feature industrial-grade dynamometers capable of handling the LT4's substantial torque output while providing precise load control across the entire RPM range. Their evaluation methodology incorporates specialized thermal shock testing to validate the LT4's supercharger and cooling systems under extreme conditions. Caterpillar's test protocols include extended full-load endurance runs exceeding 500 hours to identify potential failure points, with comprehensive vibration analysis during these tests to detect early warning signs of component fatigue. Their data acquisition systems capture high-resolution performance metrics at sampling rates up to 10kHz, allowing for detailed analysis of transient behaviors that might be missed in less sophisticated test environments.

Strengths: Unmatched durability testing capabilities; industrial-grade equipment providing exceptional reliability; extensive experience with high-torque engine evaluation. Weaknesses: Systems potentially overbuilt for standard automotive applications; focus on durability may come at the expense of refinement testing; higher operating costs compared to purpose-built automotive test systems.

Critical Test Parameters and Measurement Techniques

Engine test bench

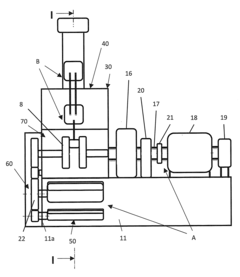

PatentInactiveUS20130283901A1

Innovation

- The mass-balancing device is integrated into a base frame connected to the test stand, allowing for flexible exchange of engine modules such as the cylinder, crankshaft, and crosshead, with adjustable balancing masses and separate lubrication circuits, enabling the same basic setup to accommodate various engine sizes without requiring full component replacement.

Test bench for test-running turbocharger

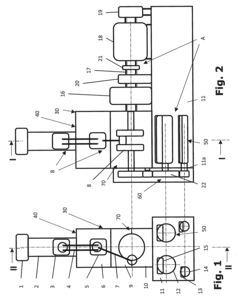

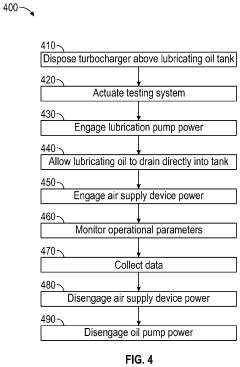

PatentActiveUS20240068378A1

Innovation

- A turbocharger testing system and method that uses a test bench to perform cold tests with unheated air, simulating operational conditions without engine use, to assess the integrity of overhauled turbochargers before reinstallation, ensuring all moving parts and seals function within manufacturer specifications.

Environmental Impact and Emissions Testing Considerations

The evaluation of LT4 engine test bench scenarios must carefully consider environmental impact and emissions testing as a critical component of the assessment process. Modern automotive regulations increasingly emphasize reduced environmental footprints, making emissions testing a fundamental aspect of engine development and validation.

Emissions testing for the LT4 engine requires comprehensive measurement of regulated pollutants including carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM). These measurements must be conducted under various operating conditions to ensure compliance with stringent standards such as EPA Tier 3, EURO 6, and California Air Resources Board (CARB) requirements. The test bench setup should incorporate certified emissions measurement equipment including constant volume sampling (CVS) systems, flame ionization detectors (FID), and chemiluminescence analyzers.

Climate change considerations have expanded emissions testing to include greenhouse gas (GHG) measurements, particularly CO2 and methane. The LT4, as a high-performance supercharged V8 engine, presents unique challenges in balancing power output with environmental responsibility. Test bench scenarios should therefore include specific protocols for measuring GHG emissions across the engine's operating range, with particular attention to high-load conditions where emissions typically increase.

Temperature control during emissions testing represents another critical factor. Ambient conditions significantly impact emissions formation, requiring test chambers with precise climate control capabilities. The evaluation protocol should include cold-start emissions testing at various temperatures (20°C, 0°C, and -7°C) to assess real-world performance in different climatic conditions. This approach aligns with the latest regulatory testing procedures that emphasize real-driving emissions (RDE) profiles.

Regenerative testing for emissions control systems constitutes an essential component of comprehensive evaluation. For the LT4 engine, the catalytic converter efficiency and its degradation over time must be assessed through accelerated aging protocols. Test bench scenarios should include specific cycles that evaluate the performance of the three-way catalyst under various conditions, including rich/lean transitions and high-temperature operation.

Noise pollution, while often overlooked, represents another environmental consideration in engine testing. Sound pressure level measurements should be incorporated into test bench scenarios, evaluating both mechanical noise and exhaust note across the RPM range. These measurements help ensure compliance with community noise regulations while maintaining the characteristic sound profile expected from a performance engine like the LT4.

Emissions testing for the LT4 engine requires comprehensive measurement of regulated pollutants including carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM). These measurements must be conducted under various operating conditions to ensure compliance with stringent standards such as EPA Tier 3, EURO 6, and California Air Resources Board (CARB) requirements. The test bench setup should incorporate certified emissions measurement equipment including constant volume sampling (CVS) systems, flame ionization detectors (FID), and chemiluminescence analyzers.

Climate change considerations have expanded emissions testing to include greenhouse gas (GHG) measurements, particularly CO2 and methane. The LT4, as a high-performance supercharged V8 engine, presents unique challenges in balancing power output with environmental responsibility. Test bench scenarios should therefore include specific protocols for measuring GHG emissions across the engine's operating range, with particular attention to high-load conditions where emissions typically increase.

Temperature control during emissions testing represents another critical factor. Ambient conditions significantly impact emissions formation, requiring test chambers with precise climate control capabilities. The evaluation protocol should include cold-start emissions testing at various temperatures (20°C, 0°C, and -7°C) to assess real-world performance in different climatic conditions. This approach aligns with the latest regulatory testing procedures that emphasize real-driving emissions (RDE) profiles.

Regenerative testing for emissions control systems constitutes an essential component of comprehensive evaluation. For the LT4 engine, the catalytic converter efficiency and its degradation over time must be assessed through accelerated aging protocols. Test bench scenarios should include specific cycles that evaluate the performance of the three-way catalyst under various conditions, including rich/lean transitions and high-temperature operation.

Noise pollution, while often overlooked, represents another environmental consideration in engine testing. Sound pressure level measurements should be incorporated into test bench scenarios, evaluating both mechanical noise and exhaust note across the RPM range. These measurements help ensure compliance with community noise regulations while maintaining the characteristic sound profile expected from a performance engine like the LT4.

Data Analytics and Digital Twin Applications in Engine Testing

Data analytics and digital twin technologies are revolutionizing engine testing methodologies, particularly for advanced powerplants like the LT4 engine. The integration of these technologies enables comprehensive evaluation of test bench scenarios through real-time data collection, processing, and visualization systems that transform traditional testing approaches.

Modern engine test benches now incorporate extensive sensor networks that capture thousands of data points per second, monitoring parameters such as temperature, pressure, vibration, emissions, and performance metrics. This massive data influx requires sophisticated analytics platforms capable of processing information streams with minimal latency while maintaining data integrity and accuracy.

Digital twin technology creates virtual replicas of physical LT4 engines, allowing engineers to simulate various operating conditions and predict performance outcomes before physical testing. These virtual models are continuously refined through machine learning algorithms that compare simulation results with actual test data, progressively improving prediction accuracy and reducing the need for costly physical testing iterations.

Predictive analytics applications in LT4 test environments enable early detection of potential failures or performance anomalies. By analyzing patterns in historical test data, these systems can identify subtle deviations that might indicate developing issues, allowing engineers to address problems before they manifest as catastrophic failures during testing or in production vehicles.

Cloud-based analytics platforms have emerged as essential tools for collaborative engine testing, enabling distributed teams to access and analyze test data simultaneously. These platforms support remote monitoring of test bench operations and facilitate cross-functional collaboration between engineering teams across different geographic locations.

Edge computing implementations at test benches allow for preliminary data processing directly at the source, reducing data transmission requirements and enabling real-time decision making. This approach is particularly valuable for time-critical test scenarios where immediate responses to changing conditions are necessary.

Visualization tools transform complex test data into intuitive dashboards and interactive reports that facilitate faster interpretation and decision-making. Advanced visualization techniques such as augmented reality overlays can project critical performance data directly onto physical engine components during testing, creating an immersive analytical environment for engineers.

The integration of artificial intelligence with digital twin technology is opening new frontiers in test optimization, automatically generating test scenarios that efficiently explore the performance envelope of LT4 engines while minimizing testing time and resource consumption.

Modern engine test benches now incorporate extensive sensor networks that capture thousands of data points per second, monitoring parameters such as temperature, pressure, vibration, emissions, and performance metrics. This massive data influx requires sophisticated analytics platforms capable of processing information streams with minimal latency while maintaining data integrity and accuracy.

Digital twin technology creates virtual replicas of physical LT4 engines, allowing engineers to simulate various operating conditions and predict performance outcomes before physical testing. These virtual models are continuously refined through machine learning algorithms that compare simulation results with actual test data, progressively improving prediction accuracy and reducing the need for costly physical testing iterations.

Predictive analytics applications in LT4 test environments enable early detection of potential failures or performance anomalies. By analyzing patterns in historical test data, these systems can identify subtle deviations that might indicate developing issues, allowing engineers to address problems before they manifest as catastrophic failures during testing or in production vehicles.

Cloud-based analytics platforms have emerged as essential tools for collaborative engine testing, enabling distributed teams to access and analyze test data simultaneously. These platforms support remote monitoring of test bench operations and facilitate cross-functional collaboration between engineering teams across different geographic locations.

Edge computing implementations at test benches allow for preliminary data processing directly at the source, reducing data transmission requirements and enabling real-time decision making. This approach is particularly valuable for time-critical test scenarios where immediate responses to changing conditions are necessary.

Visualization tools transform complex test data into intuitive dashboards and interactive reports that facilitate faster interpretation and decision-making. Advanced visualization techniques such as augmented reality overlays can project critical performance data directly onto physical engine components during testing, creating an immersive analytical environment for engineers.

The integration of artificial intelligence with digital twin technology is opening new frontiers in test optimization, automatically generating test scenarios that efficiently explore the performance envelope of LT4 engines while minimizing testing time and resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!