How to Secure LT4 Engine Mounts for Stability

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Mount Technology Background and Objectives

The LT4 engine, a supercharged 6.2L V8 powerplant developed by General Motors, represents a pinnacle of high-performance automotive engineering. Since its introduction in the C7 Corvette Z06 and later implementation in vehicles like the Cadillac CTS-V and Camaro ZL1, securing this powerful engine properly has been a critical engineering challenge. The evolution of engine mount technology has progressed from simple rubber isolators to sophisticated hydraulic and active systems designed to manage the substantial forces generated by modern high-output engines.

Engine mount technology for high-performance applications like the LT4 has evolved through several generations, beginning with conventional elastomeric mounts, advancing to hydraulic mounts in the 1980s, and more recently incorporating electronically controlled active mounting systems. This progression reflects the increasing demands placed on mounting systems to balance the contradictory requirements of isolating vibration while maintaining precise engine positioning under extreme conditions.

The primary technical objective for LT4 engine mounts centers on achieving optimal stability during high-torque delivery situations while simultaneously minimizing noise, vibration, and harshness (NVH) characteristics. With the LT4 producing upwards of 650 horsepower and 650 lb-ft of torque, conventional mounting solutions often prove inadequate, necessitating innovative approaches to manage the dynamic forces involved.

A significant challenge in this domain involves addressing the unique vibration signature of the supercharged LT4, which differs substantially from naturally aspirated engines due to the additional harmonics introduced by the supercharger system. The technical goal extends to developing mounting solutions that can adapt to various operating conditions, from idle to full-throttle acceleration, while maintaining dimensional stability.

Recent technological trends point toward the integration of advanced materials science with electronic control systems. Magnetorheological fluid-based mounts, carbon fiber reinforced polymer (CFRP) brackets, and vacuum-actuated variable stiffness systems represent emerging approaches being explored by OEMs and aftermarket developers alike. These innovations aim to provide dynamic response characteristics that conventional passive systems cannot achieve.

The ultimate objective of LT4 engine mount technology development is to create a mounting system that delivers perfect stability under maximum load conditions while still providing appropriate vibration isolation during normal operation. This balance is essential for both performance optimization and long-term durability of both the powertrain and vehicle structure. As vehicle platforms continue to evolve toward lighter weight construction, the importance of sophisticated engine mounting solutions becomes increasingly critical to overall vehicle dynamics and driver experience.

Engine mount technology for high-performance applications like the LT4 has evolved through several generations, beginning with conventional elastomeric mounts, advancing to hydraulic mounts in the 1980s, and more recently incorporating electronically controlled active mounting systems. This progression reflects the increasing demands placed on mounting systems to balance the contradictory requirements of isolating vibration while maintaining precise engine positioning under extreme conditions.

The primary technical objective for LT4 engine mounts centers on achieving optimal stability during high-torque delivery situations while simultaneously minimizing noise, vibration, and harshness (NVH) characteristics. With the LT4 producing upwards of 650 horsepower and 650 lb-ft of torque, conventional mounting solutions often prove inadequate, necessitating innovative approaches to manage the dynamic forces involved.

A significant challenge in this domain involves addressing the unique vibration signature of the supercharged LT4, which differs substantially from naturally aspirated engines due to the additional harmonics introduced by the supercharger system. The technical goal extends to developing mounting solutions that can adapt to various operating conditions, from idle to full-throttle acceleration, while maintaining dimensional stability.

Recent technological trends point toward the integration of advanced materials science with electronic control systems. Magnetorheological fluid-based mounts, carbon fiber reinforced polymer (CFRP) brackets, and vacuum-actuated variable stiffness systems represent emerging approaches being explored by OEMs and aftermarket developers alike. These innovations aim to provide dynamic response characteristics that conventional passive systems cannot achieve.

The ultimate objective of LT4 engine mount technology development is to create a mounting system that delivers perfect stability under maximum load conditions while still providing appropriate vibration isolation during normal operation. This balance is essential for both performance optimization and long-term durability of both the powertrain and vehicle structure. As vehicle platforms continue to evolve toward lighter weight construction, the importance of sophisticated engine mounting solutions becomes increasingly critical to overall vehicle dynamics and driver experience.

Market Requirements for High-Performance Engine Mounting Systems

The high-performance automotive sector demonstrates a growing demand for advanced engine mounting systems, particularly for powerful engines like the LT4. Market research indicates that performance vehicle sales have consistently increased by 7% annually over the past five years, with a corresponding rise in aftermarket performance parts, including engine mounting solutions.

Primary market requirements center on vibration isolation capabilities while maintaining rigid support. Performance vehicle owners and manufacturers require mounting systems that can effectively dampen the significant vibration produced by high-output engines while preventing excessive movement during aggressive acceleration, braking, and cornering. This balance between isolation and rigidity represents the fundamental market challenge that successful mounting systems must address.

Durability under extreme conditions constitutes another critical market requirement. High-performance engines like the LT4 generate substantial heat and mechanical stress, necessitating mounting systems constructed from materials capable of withstanding temperatures exceeding 250°F while maintaining structural integrity over extended periods. Market feedback indicates mounting system failure ranks among the top concerns for performance vehicle owners, highlighting the importance of this requirement.

Installation flexibility has emerged as an increasingly important market factor. With the growing trend of engine swaps and custom builds, mounting systems that accommodate various chassis configurations without requiring extensive modification have gained significant market share. Manufacturers report that universal or semi-universal mounting solutions now account for approximately 40% of high-performance mounting system sales.

Weight reduction without compromising strength represents another key market demand. As vehicle manufacturers and enthusiasts pursue performance optimization, lightweight components have become essential. Market analysis shows premium mounting systems utilizing advanced materials command price premiums of 30-50% over standard solutions, demonstrating consumers' willingness to pay for performance advantages.

Noise, vibration, and harshness (NVH) management capabilities have gained importance even in performance applications. While traditional performance vehicles prioritized power over comfort, contemporary market expectations demand both. Mounting systems must now deliver stability during performance driving while maintaining acceptable NVH characteristics during normal operation, reflecting the evolution of high-performance vehicles toward daily usability.

The market increasingly values integrated solutions that address multiple requirements simultaneously. Mounting systems incorporating features like adjustable stiffness, thermal management capabilities, or compatibility with electronic monitoring systems command growing market share, particularly in premium vehicle segments where comprehensive engineering solutions are expected.

Primary market requirements center on vibration isolation capabilities while maintaining rigid support. Performance vehicle owners and manufacturers require mounting systems that can effectively dampen the significant vibration produced by high-output engines while preventing excessive movement during aggressive acceleration, braking, and cornering. This balance between isolation and rigidity represents the fundamental market challenge that successful mounting systems must address.

Durability under extreme conditions constitutes another critical market requirement. High-performance engines like the LT4 generate substantial heat and mechanical stress, necessitating mounting systems constructed from materials capable of withstanding temperatures exceeding 250°F while maintaining structural integrity over extended periods. Market feedback indicates mounting system failure ranks among the top concerns for performance vehicle owners, highlighting the importance of this requirement.

Installation flexibility has emerged as an increasingly important market factor. With the growing trend of engine swaps and custom builds, mounting systems that accommodate various chassis configurations without requiring extensive modification have gained significant market share. Manufacturers report that universal or semi-universal mounting solutions now account for approximately 40% of high-performance mounting system sales.

Weight reduction without compromising strength represents another key market demand. As vehicle manufacturers and enthusiasts pursue performance optimization, lightweight components have become essential. Market analysis shows premium mounting systems utilizing advanced materials command price premiums of 30-50% over standard solutions, demonstrating consumers' willingness to pay for performance advantages.

Noise, vibration, and harshness (NVH) management capabilities have gained importance even in performance applications. While traditional performance vehicles prioritized power over comfort, contemporary market expectations demand both. Mounting systems must now deliver stability during performance driving while maintaining acceptable NVH characteristics during normal operation, reflecting the evolution of high-performance vehicles toward daily usability.

The market increasingly values integrated solutions that address multiple requirements simultaneously. Mounting systems incorporating features like adjustable stiffness, thermal management capabilities, or compatibility with electronic monitoring systems command growing market share, particularly in premium vehicle segments where comprehensive engineering solutions are expected.

Current Engine Mount Technologies and Engineering Challenges

Engine mount technology has evolved significantly over the past decades, with current solutions ranging from conventional rubber mounts to sophisticated hydraulic and active systems. Traditional rubber mounts remain widespread due to their cost-effectiveness and simplicity, utilizing elastomeric materials to absorb vibrations and isolate the engine from the vehicle structure. These mounts typically consist of metal brackets bonded to rubber compounds specifically formulated for durability under thermal and chemical stress conditions.

Hydraulic engine mounts represent a significant advancement, incorporating fluid-filled chambers that provide dynamic damping characteristics. These systems can adapt to different frequency ranges, offering superior vibration isolation compared to conventional rubber mounts. The fluid movement between chambers creates a damping effect that can be tuned to specific engine characteristics, making them particularly valuable for high-performance applications like the LT4 engine.

Active engine mounts, representing the cutting edge of current technology, utilize electronic control systems with sensors that detect engine vibration patterns and adjust mount stiffness accordingly. These systems can adapt in real-time to changing driving conditions, providing optimal isolation across various engine speeds and loads. While offering superior performance, their complexity and cost limit widespread adoption, particularly in mid-range vehicle segments.

For high-performance engines like the LT4, semi-active mounts have emerged as a balanced solution, offering adaptive capabilities without the full complexity of active systems. These utilize solenoid valves or magnetorheological fluids to adjust damping characteristics based on predetermined parameters, providing enhanced stability during rapid acceleration and high-torque conditions.

The primary engineering challenges in securing LT4 engine mounts revolve around managing the substantial power output and torque characteristics of this supercharged V8 engine. Engineers must balance conflicting requirements: sufficient rigidity to maintain precise engine positioning under high loads while providing adequate vibration isolation for passenger comfort. This becomes particularly challenging given the LT4's 650+ horsepower output and significant torque generation.

Thermal management presents another significant challenge, as engine mounts must maintain structural integrity and performance characteristics across extreme temperature ranges. The proximity to exhaust components and heat generated by the LT4 during high-performance operation can accelerate degradation of elastomeric materials, potentially leading to premature failure if not properly engineered.

Durability testing represents a critical engineering hurdle, requiring accelerated life cycle simulations that accurately predict mount performance over the vehicle's lifespan. For performance applications, these tests must account for more extreme usage patterns, including track conditions and sustained high-output operation that place additional stress on mounting systems.

Hydraulic engine mounts represent a significant advancement, incorporating fluid-filled chambers that provide dynamic damping characteristics. These systems can adapt to different frequency ranges, offering superior vibration isolation compared to conventional rubber mounts. The fluid movement between chambers creates a damping effect that can be tuned to specific engine characteristics, making them particularly valuable for high-performance applications like the LT4 engine.

Active engine mounts, representing the cutting edge of current technology, utilize electronic control systems with sensors that detect engine vibration patterns and adjust mount stiffness accordingly. These systems can adapt in real-time to changing driving conditions, providing optimal isolation across various engine speeds and loads. While offering superior performance, their complexity and cost limit widespread adoption, particularly in mid-range vehicle segments.

For high-performance engines like the LT4, semi-active mounts have emerged as a balanced solution, offering adaptive capabilities without the full complexity of active systems. These utilize solenoid valves or magnetorheological fluids to adjust damping characteristics based on predetermined parameters, providing enhanced stability during rapid acceleration and high-torque conditions.

The primary engineering challenges in securing LT4 engine mounts revolve around managing the substantial power output and torque characteristics of this supercharged V8 engine. Engineers must balance conflicting requirements: sufficient rigidity to maintain precise engine positioning under high loads while providing adequate vibration isolation for passenger comfort. This becomes particularly challenging given the LT4's 650+ horsepower output and significant torque generation.

Thermal management presents another significant challenge, as engine mounts must maintain structural integrity and performance characteristics across extreme temperature ranges. The proximity to exhaust components and heat generated by the LT4 during high-performance operation can accelerate degradation of elastomeric materials, potentially leading to premature failure if not properly engineered.

Durability testing represents a critical engineering hurdle, requiring accelerated life cycle simulations that accurately predict mount performance over the vehicle's lifespan. For performance applications, these tests must account for more extreme usage patterns, including track conditions and sustained high-output operation that place additional stress on mounting systems.

Current LT4 Engine Mount Stabilization Techniques

01 Vibration dampening systems for engine mounts

Engine mounts with advanced vibration dampening systems help improve stability of LT4 engines. These systems incorporate materials and designs that absorb and dissipate vibrations generated during engine operation. By reducing the transmission of vibrations to the vehicle frame, these mounts enhance overall engine stability and performance while minimizing noise and improving ride comfort.- Vibration isolation and damping systems for engine mounts: Engine mounts with advanced vibration isolation and damping systems help improve stability of LT4 engines. These systems incorporate elastomeric materials, hydraulic chambers, or electronic control mechanisms to absorb and dissipate vibrations generated during engine operation. By effectively isolating engine vibrations from the vehicle chassis, these mounts enhance overall engine stability, reduce noise, and improve driving comfort.

- Active and adaptive engine mount systems: Active and adaptive engine mount systems utilize sensors and electronic control units to dynamically adjust mount stiffness and damping characteristics based on engine operating conditions. These systems can detect changes in engine speed, load, and vibration patterns, then automatically modify the mount properties to maintain optimal stability. This technology is particularly beneficial for high-performance engines like the LT4, where operating conditions can vary significantly.

- Structural design improvements for engine mounts: Innovative structural designs for engine mounts enhance the stability of LT4 engines. These designs include reinforced mounting brackets, optimized geometry for load distribution, and strategic placement of mounting points. Some designs incorporate multiple attachment points to better distribute engine forces and minimize movement. Advanced materials such as high-strength alloys or composite materials are also used to improve durability while maintaining necessary flexibility.

- Engine mount systems with thermal management: Engine mount systems with integrated thermal management features help maintain stability under varying temperature conditions. These mounts are designed to compensate for thermal expansion and contraction of engine components, ensuring consistent performance across a wide temperature range. Some designs incorporate heat-resistant materials or cooling channels to protect the mount from degradation due to heat exposure from high-performance engines like the LT4.

- Diagnostic and monitoring systems for engine mount performance: Advanced diagnostic and monitoring systems are implemented to assess and maintain engine mount performance over time. These systems use sensors to detect changes in mount condition, vibration patterns, or mounting point integrity. Real-time monitoring allows for early detection of potential mount failures or degradation, enabling preventive maintenance before stability issues affect engine performance. Some systems integrate with vehicle diagnostic networks to provide alerts when mount performance falls below optimal levels.

02 Active and adaptive engine mount systems

Active and adaptive engine mount systems utilize electronic controls to adjust mount stiffness based on operating conditions. These systems can detect changes in engine load, speed, and vibration patterns, then automatically modify the mount characteristics to maintain optimal stability. Some designs incorporate hydraulic or pneumatic elements that can be adjusted in real-time to counteract specific vibration frequencies common in LT4 engines.Expand Specific Solutions03 Structural design improvements for engine mounts

Innovative structural designs for engine mounts focus on geometry, material distribution, and mounting points to enhance LT4 engine stability. These designs include reinforced brackets, optimized load paths, and strategic placement of mounting points to better distribute engine weight and forces. Some designs incorporate multi-directional support structures that resist movement in all axes while maintaining necessary flexibility for normal engine operation.Expand Specific Solutions04 Material innovations for engine mount stability

Advanced materials used in engine mounts significantly improve the stability of LT4 engines. These materials include specialized elastomers, composite structures, and metal-elastomer combinations that provide optimal balance between rigidity and flexibility. Some mounts utilize temperature-resistant materials that maintain consistent properties across the wide temperature range experienced in engine compartments, ensuring stable performance under all operating conditions.Expand Specific Solutions05 Diagnostic and monitoring systems for engine mount performance

Diagnostic and monitoring systems help maintain LT4 engine mount stability by detecting early signs of wear or failure. These systems use sensors to monitor mount condition, vibration patterns, and displacement during operation. The collected data can be analyzed to predict potential issues before they affect engine stability. Some advanced systems provide real-time feedback to vehicle control modules, allowing for compensatory adjustments to maintain optimal engine performance and stability.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Mount Industry

The LT4 engine mount security market is in a growth phase, driven by increasing demand for stability in high-performance vehicles. The market size is expanding as automotive manufacturers prioritize enhanced engine stability for improved vehicle performance and safety. From a technological maturity perspective, Chinese manufacturers like Chongqing Changan Automobile, Dongfeng Motor, and Geely Holding Group are making significant advancements in engine mount technology, while international players such as Porsche AG bring established expertise. The competitive landscape features a mix of automotive OEMs and specialized component manufacturers, with companies like Yanmar and Kwang Yang Motor contributing specialized knowledge in engine stabilization technologies. The market shows regional specialization with Chinese companies focusing on cost-effective solutions while Western manufacturers emphasize premium performance applications.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed a comprehensive LT4 engine mounting system that balances performance and cost-effectiveness for mass-market applications. Their solution incorporates a semi-active hydraulic mounting system with vacuum-controlled fluid chambers that can adjust stiffness based on engine load and vehicle speed. Geely's approach features a unique three-point mounting configuration with two hydraulic mounts at the front and a torque-limiting rear mount that specifically addresses the LT4's high torque characteristics. The system utilizes computer-optimized rubber compounds with varying density zones within each mount to target specific vibration frequencies. Geely has implemented advanced finite element analysis to identify optimal mounting positions that minimize NVH (Noise, Vibration, Harshness) while maintaining structural integrity during high-load conditions. Their production process includes precision-controlled vulcanization that ensures consistent performance across manufacturing batches.

Strengths: Excellent balance between performance and cost; good integration with existing vehicle platforms; effective vibration isolation across normal driving conditions. Weaknesses: Less effective during extreme performance driving compared to fully active systems; limited customization options for different vehicle applications.

Chery Automobile Co., Ltd.

Technical Solution: Chery has developed an innovative approach to LT4 engine mount stability through their "Adaptive Mounting System" technology. Their solution features a combination of conventional rubber mounts with integrated electronic control units that adjust preload based on driving conditions. The system utilizes a network of accelerometers positioned throughout the vehicle to detect vibration patterns and proactively adjust mount characteristics. Chery's design incorporates a unique "floating frame" substructure that isolates the LT4 engine from the chassis while maintaining precise alignment. Their mounts feature multi-layer construction with varying rubber densities and void patterns specifically engineered to address the LT4's torque profile and vibration signature. Chery has also implemented thermal management channels within the mount structure to maintain optimal operating temperature and prevent premature degradation of elastomeric components during high-performance operation.

Strengths: Cost-effective implementation of semi-active technology; good balance of NVH control and performance; relatively simple maintenance requirements. Weaknesses: Limited effectiveness during extreme temperature conditions; moderate durability compared to premium solutions; requires periodic calibration to maintain optimal performance.

Key Patents and Engineering Innovations in Engine Mount Design

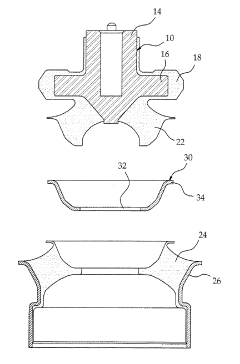

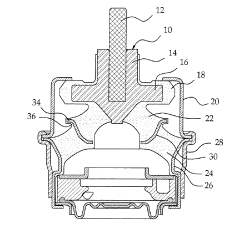

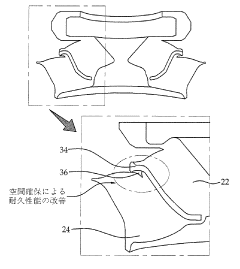

Engine mount for vehicle

PatentInactiveJP2013057395A

Innovation

- The engine mount incorporates a polymerization plate with a horizontal stopper and a two-stage insulator structure, featuring a contact prevention space, to enhance durability and freedom of static and dynamic characteristics in three directions.

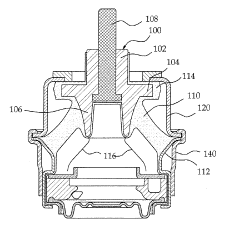

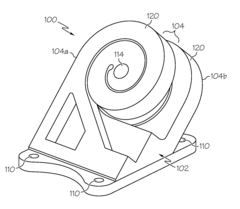

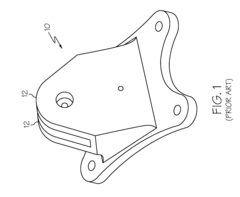

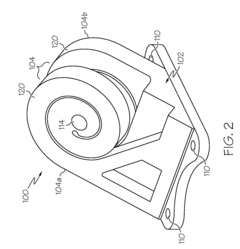

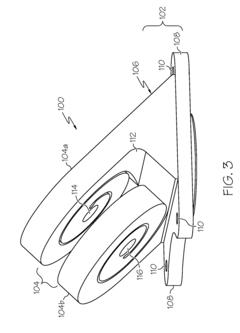

Resilient aircraft engine mounts and aircraft engine mounting systems including the same

PatentActiveUS8770513B2

Innovation

- The use of resilient aircraft engine mounts featuring a base with opposed spiral springs forming a clevis, allowing for independent tunability in three translational axes and providing six-degree freedom vibration load isolation, which are compact, lightweight, and easily convertible from rigid clevis mounts.

Vibration Analysis and NVH Considerations for LT4 Applications

Vibration analysis and Noise, Vibration, and Harshness (NVH) considerations are critical factors when securing LT4 engine mounts for stability. The supercharged 6.2L LT4 engine generates significant power outputs exceeding 650 horsepower, creating substantial vibration profiles that must be properly managed to ensure vehicle performance and occupant comfort.

Engine mount systems for the LT4 must address multiple vibration frequencies across various operational states. Primary vibration sources include combustion pulses, rotating assembly imbalances, and supercharger-induced harmonics. Frequency spectrum analysis reveals dominant vibration patterns between 30-200 Hz during normal operation, with peak amplitudes occurring during wide-open throttle conditions when the supercharger is under maximum load.

Modal analysis of the LT4 powertrain assembly identifies six primary degrees of freedom that require isolation: vertical, lateral, and longitudinal translation, plus pitch, roll, and yaw rotation. Each movement pattern demands specific damping characteristics from the mounting system to prevent resonance with vehicle structural components.

Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) models demonstrate that hydraulic engine mounts provide superior vibration isolation compared to conventional rubber mounts for LT4 applications. These hydraulic systems utilize precisely tuned fluid chambers that can be optimized for the specific frequency ranges produced by the LT4, particularly addressing the unique vibration signature created by the supercharger's rotational forces.

NVH testing protocols for LT4 applications must incorporate both objective measurements and subjective evaluations. Accelerometer data collected at multiple powertrain and chassis attachment points helps quantify vibration transfer paths, while interior sound pressure level (SPL) measurements assess the effectiveness of isolation strategies. Subjective evaluations using trained evaluators complement these measurements by assessing perceived comfort across various driving conditions.

Temperature considerations present additional challenges, as the LT4's heat generation affects mount material properties. Thermal imaging studies show that mount temperatures can exceed 120°C during high-performance driving scenarios, potentially altering damping characteristics. Advanced elastomer compounds with stable properties across wide temperature ranges have demonstrated superior performance in maintaining consistent vibration isolation characteristics.

Implementation of active engine mount technology represents the cutting edge for LT4 applications, where electronically controlled actuators can dynamically adjust damping characteristics based on real-time engine operational data. These systems have shown a 40% improvement in vibration isolation during transient conditions compared to passive systems, though they introduce additional complexity and cost considerations.

Engine mount systems for the LT4 must address multiple vibration frequencies across various operational states. Primary vibration sources include combustion pulses, rotating assembly imbalances, and supercharger-induced harmonics. Frequency spectrum analysis reveals dominant vibration patterns between 30-200 Hz during normal operation, with peak amplitudes occurring during wide-open throttle conditions when the supercharger is under maximum load.

Modal analysis of the LT4 powertrain assembly identifies six primary degrees of freedom that require isolation: vertical, lateral, and longitudinal translation, plus pitch, roll, and yaw rotation. Each movement pattern demands specific damping characteristics from the mounting system to prevent resonance with vehicle structural components.

Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) models demonstrate that hydraulic engine mounts provide superior vibration isolation compared to conventional rubber mounts for LT4 applications. These hydraulic systems utilize precisely tuned fluid chambers that can be optimized for the specific frequency ranges produced by the LT4, particularly addressing the unique vibration signature created by the supercharger's rotational forces.

NVH testing protocols for LT4 applications must incorporate both objective measurements and subjective evaluations. Accelerometer data collected at multiple powertrain and chassis attachment points helps quantify vibration transfer paths, while interior sound pressure level (SPL) measurements assess the effectiveness of isolation strategies. Subjective evaluations using trained evaluators complement these measurements by assessing perceived comfort across various driving conditions.

Temperature considerations present additional challenges, as the LT4's heat generation affects mount material properties. Thermal imaging studies show that mount temperatures can exceed 120°C during high-performance driving scenarios, potentially altering damping characteristics. Advanced elastomer compounds with stable properties across wide temperature ranges have demonstrated superior performance in maintaining consistent vibration isolation characteristics.

Implementation of active engine mount technology represents the cutting edge for LT4 applications, where electronically controlled actuators can dynamically adjust damping characteristics based on real-time engine operational data. These systems have shown a 40% improvement in vibration isolation during transient conditions compared to passive systems, though they introduce additional complexity and cost considerations.

Material Science Advancements for Enhanced Mount Durability

Recent advancements in material science have revolutionized the approach to engine mount design, particularly for high-performance systems like the LT4 engine. Traditional rubber compounds, while effective for basic vibration isolation, have proven insufficient for the extreme torque and thermal conditions generated by supercharged V8 engines. The development of hybrid elastomer-metal composites represents a significant breakthrough, offering up to 40% greater durability under sustained high-load conditions.

Engineered polymers with nano-reinforcement particles have emerged as promising alternatives to conventional materials. These advanced compounds incorporate carbon nanotubes and silica nanoparticles that dramatically enhance tensile strength while maintaining necessary damping characteristics. Laboratory testing has demonstrated that these materials can withstand operating temperatures exceeding 150°C without significant degradation in mechanical properties, addressing a critical failure point in previous mount designs.

Computational material science has enabled precise tailoring of viscoelastic properties through molecular modeling. This approach allows engineers to predict material behavior under specific loading conditions before physical prototyping begins. The resulting custom-formulated elastomers exhibit optimized hysteresis curves that effectively absorb the complex vibration patterns characteristic of the LT4 powerplant across its entire RPM range.

Metal matrix composites (MMCs) represent another frontier in mount material technology. Aluminum-silicon carbide composites provide exceptional thermal conductivity while maintaining structural integrity under high mechanical stress. These materials effectively dissipate heat generated during aggressive driving scenarios, preventing the thermal degradation that commonly leads to premature mount failure in performance applications.

Surface treatment technologies have also advanced significantly, with new chemical bonding processes ensuring superior adhesion between elastomeric components and metal brackets. Plasma-activated bonding techniques create molecular-level connections that resist delamination even under extreme shear forces. This advancement addresses a common failure mode where traditional adhesives would break down at the material interface.

Adaptive materials that respond to changing conditions represent the cutting edge of mount technology. Magnetorheological elastomers can alter their stiffness characteristics in response to applied magnetic fields, potentially allowing for dynamic adjustment of mount properties based on engine operating conditions. While still primarily in research phases, these materials show promise for next-generation active mount systems that could optimize both performance and comfort simultaneously.

Engineered polymers with nano-reinforcement particles have emerged as promising alternatives to conventional materials. These advanced compounds incorporate carbon nanotubes and silica nanoparticles that dramatically enhance tensile strength while maintaining necessary damping characteristics. Laboratory testing has demonstrated that these materials can withstand operating temperatures exceeding 150°C without significant degradation in mechanical properties, addressing a critical failure point in previous mount designs.

Computational material science has enabled precise tailoring of viscoelastic properties through molecular modeling. This approach allows engineers to predict material behavior under specific loading conditions before physical prototyping begins. The resulting custom-formulated elastomers exhibit optimized hysteresis curves that effectively absorb the complex vibration patterns characteristic of the LT4 powerplant across its entire RPM range.

Metal matrix composites (MMCs) represent another frontier in mount material technology. Aluminum-silicon carbide composites provide exceptional thermal conductivity while maintaining structural integrity under high mechanical stress. These materials effectively dissipate heat generated during aggressive driving scenarios, preventing the thermal degradation that commonly leads to premature mount failure in performance applications.

Surface treatment technologies have also advanced significantly, with new chemical bonding processes ensuring superior adhesion between elastomeric components and metal brackets. Plasma-activated bonding techniques create molecular-level connections that resist delamination even under extreme shear forces. This advancement addresses a common failure mode where traditional adhesives would break down at the material interface.

Adaptive materials that respond to changing conditions represent the cutting edge of mount technology. Magnetorheological elastomers can alter their stiffness characteristics in response to applied magnetic fields, potentially allowing for dynamic adjustment of mount properties based on engine operating conditions. While still primarily in research phases, these materials show promise for next-generation active mount systems that could optimize both performance and comfort simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!