LT4 Engine Air Intake Systems for Improved Flow

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Air Intake Evolution and Objectives

The LT4 engine, a supercharged 6.2-liter V8 powerplant developed by General Motors, has undergone significant evolution in its air intake systems since its introduction. Initially designed for high-performance vehicles like the Corvette Z06 and Cadillac CTS-V, the LT4's air management systems have continuously evolved to address the increasing demands for power, efficiency, and emissions compliance.

The original LT4 air intake design featured a conventional layout with a focus on delivering adequate airflow to support the supercharger system. However, as performance targets increased, engineers identified the intake system as a critical area for optimization. Early designs suffered from flow restrictions, particularly at high RPM ranges where maximum airflow is essential for optimal performance.

Subsequent generations saw the implementation of computational fluid dynamics (CFD) modeling to identify and eliminate flow restrictions. This led to the development of more streamlined intake runners, optimized plenum designs, and improved air filter housings that reduced pressure drop across the system. The evolution also included material advancements, transitioning from predominantly plastic components to composite materials that offer improved thermal management characteristics.

A significant milestone in LT4 intake development came with the introduction of variable geometry systems that could adapt to different engine operating conditions. These systems incorporated electronically controlled flaps and valves that modify the intake path based on engine speed and load, optimizing both low-end torque and high-end power output.

The primary technical objectives driving LT4 air intake evolution include maximizing volumetric efficiency, reducing intake air temperature, minimizing pressure drop across the system, and ensuring consistent air distribution to all cylinders. Engineers have particularly focused on the supercharger-intake interface, as this junction represents a critical flow point that can significantly impact overall engine performance.

Recent developments have emphasized the integration of advanced filtration technologies that maintain high flow rates while improving particulate capture efficiency. This addresses the dual concerns of performance and engine longevity, as modern high-output engines are particularly sensitive to contaminants.

Looking forward, the technical roadmap for LT4 air intake systems includes further optimization through advanced manufacturing techniques like 3D printing, which allows for complex geometries that would be impossible with traditional manufacturing methods. Additionally, active aerodynamic elements that can dynamically adjust based on real-time airflow measurements represent a frontier in intake design that promises to further enhance the LT4's already impressive performance capabilities.

The original LT4 air intake design featured a conventional layout with a focus on delivering adequate airflow to support the supercharger system. However, as performance targets increased, engineers identified the intake system as a critical area for optimization. Early designs suffered from flow restrictions, particularly at high RPM ranges where maximum airflow is essential for optimal performance.

Subsequent generations saw the implementation of computational fluid dynamics (CFD) modeling to identify and eliminate flow restrictions. This led to the development of more streamlined intake runners, optimized plenum designs, and improved air filter housings that reduced pressure drop across the system. The evolution also included material advancements, transitioning from predominantly plastic components to composite materials that offer improved thermal management characteristics.

A significant milestone in LT4 intake development came with the introduction of variable geometry systems that could adapt to different engine operating conditions. These systems incorporated electronically controlled flaps and valves that modify the intake path based on engine speed and load, optimizing both low-end torque and high-end power output.

The primary technical objectives driving LT4 air intake evolution include maximizing volumetric efficiency, reducing intake air temperature, minimizing pressure drop across the system, and ensuring consistent air distribution to all cylinders. Engineers have particularly focused on the supercharger-intake interface, as this junction represents a critical flow point that can significantly impact overall engine performance.

Recent developments have emphasized the integration of advanced filtration technologies that maintain high flow rates while improving particulate capture efficiency. This addresses the dual concerns of performance and engine longevity, as modern high-output engines are particularly sensitive to contaminants.

Looking forward, the technical roadmap for LT4 air intake systems includes further optimization through advanced manufacturing techniques like 3D printing, which allows for complex geometries that would be impossible with traditional manufacturing methods. Additionally, active aerodynamic elements that can dynamically adjust based on real-time airflow measurements represent a frontier in intake design that promises to further enhance the LT4's already impressive performance capabilities.

Market Analysis for High-Performance Air Intake Systems

The high-performance air intake system market for LT4 engines has experienced substantial growth over the past decade, driven primarily by increasing consumer demand for enhanced vehicle performance and fuel efficiency. The global market for aftermarket performance air intake systems reached approximately $3.2 billion in 2022, with a compound annual growth rate of 6.8% projected through 2028. Within this broader market, LT4-specific systems represent a premium segment with higher margins and specialized applications.

Consumer demographics reveal that the primary market consists of automotive enthusiasts aged 25-45 with above-average disposable income. This demographic shows willingness to invest in performance upgrades, with air intake systems typically being among the first modifications purchased due to their relatively low cost and noticeable performance benefits. Market surveys indicate that 72% of performance vehicle owners consider upgrading their air intake systems within the first year of ownership.

Regional analysis shows North America dominating the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). The North American dominance stems from the strong muscle car and performance vehicle culture, particularly in the United States where the LT4 engine has significant presence in vehicles like the Chevrolet Corvette Z06 and Cadillac CTS-V.

Distribution channels have evolved significantly, with online direct-to-consumer sales growing at twice the rate of traditional retail channels. E-commerce platforms now account for 58% of aftermarket air intake system sales, offering consumers wider selection and competitive pricing. This shift has disrupted traditional distribution models and compressed margins for brick-and-mortar retailers.

Price sensitivity analysis reveals two distinct market segments: the premium segment willing to pay $500-1,200 for advanced systems with proven performance gains, and a value segment seeking systems in the $250-450 range with moderate performance improvements. The premium segment has shown stronger growth, indicating consumers increasingly prioritize quality and performance over price.

Competitive landscape assessment identifies key players including K&N Engineering, Injen Technology, AEM Induction Systems, and Corsa Performance, who collectively hold approximately 65% market share. These companies differentiate through proprietary filter technologies, advanced airflow designs, and comprehensive dyno-testing data to validate performance claims.

Market forecasts suggest continued growth driven by the rising popularity of performance vehicles, increasing consumer awareness of air intake benefits, and technological advancements in filter materials and airflow dynamics. The emergence of digital airflow management systems represents a potential disruptive innovation that could reshape the market in coming years.

Consumer demographics reveal that the primary market consists of automotive enthusiasts aged 25-45 with above-average disposable income. This demographic shows willingness to invest in performance upgrades, with air intake systems typically being among the first modifications purchased due to their relatively low cost and noticeable performance benefits. Market surveys indicate that 72% of performance vehicle owners consider upgrading their air intake systems within the first year of ownership.

Regional analysis shows North America dominating the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). The North American dominance stems from the strong muscle car and performance vehicle culture, particularly in the United States where the LT4 engine has significant presence in vehicles like the Chevrolet Corvette Z06 and Cadillac CTS-V.

Distribution channels have evolved significantly, with online direct-to-consumer sales growing at twice the rate of traditional retail channels. E-commerce platforms now account for 58% of aftermarket air intake system sales, offering consumers wider selection and competitive pricing. This shift has disrupted traditional distribution models and compressed margins for brick-and-mortar retailers.

Price sensitivity analysis reveals two distinct market segments: the premium segment willing to pay $500-1,200 for advanced systems with proven performance gains, and a value segment seeking systems in the $250-450 range with moderate performance improvements. The premium segment has shown stronger growth, indicating consumers increasingly prioritize quality and performance over price.

Competitive landscape assessment identifies key players including K&N Engineering, Injen Technology, AEM Induction Systems, and Corsa Performance, who collectively hold approximately 65% market share. These companies differentiate through proprietary filter technologies, advanced airflow designs, and comprehensive dyno-testing data to validate performance claims.

Market forecasts suggest continued growth driven by the rising popularity of performance vehicles, increasing consumer awareness of air intake benefits, and technological advancements in filter materials and airflow dynamics. The emergence of digital airflow management systems represents a potential disruptive innovation that could reshape the market in coming years.

Current Air Intake Technologies and Limitations

The current air intake systems for LT4 engines predominantly rely on several established technologies, each with specific performance characteristics and inherent limitations. Traditional intake manifolds typically feature a single throttle body design with fixed runner lengths, which creates a compromise between low-end torque and high-end power. While effective for general applications, these systems struggle to provide optimal airflow across the entire RPM range, resulting in performance gaps at certain engine speeds.

Cold air intake systems represent an improvement by drawing cooler, denser air from outside the engine bay. These systems generally increase power by 5-15 horsepower depending on implementation. However, they often face packaging constraints in the crowded engine compartments of modern vehicles, and their effectiveness diminishes in high-temperature environments or during prolonged high-load operation due to heat soak effects.

Variable geometry intake systems attempt to address the fixed-runner limitations by incorporating adjustable runner lengths or cross-sectional areas. While these systems theoretically optimize airflow across different engine speeds, their mechanical complexity introduces reliability concerns and increases manufacturing costs by approximately 30-40% compared to fixed designs. Additionally, the actuators controlling these variable elements can experience durability issues under extreme operating conditions.

Forced induction systems, particularly superchargers commonly paired with LT4 engines, significantly enhance airflow but generate substantial heat. The temperature increase can reach 100°F or more above ambient, negatively impacting air density and combustion efficiency. Current intercooler technologies mitigate this issue but add weight, complexity, and flow restrictions that partially offset their benefits.

Material limitations also constrain current intake system performance. Conventional plastic and aluminum components balance cost and weight considerations but offer limited thermal management capabilities. Carbon fiber alternatives provide weight reduction and superior thermal properties but at a cost premium of 200-300% over traditional materials, restricting their widespread adoption.

Airflow management within the intake tract presents another significant challenge. Current designs struggle to maintain laminar flow through complex geometries, particularly at high flow rates where turbulence increases exponentially. Computational fluid dynamics analysis reveals that up to 15% of potential airflow efficiency is lost due to suboptimal path routing, sudden changes in cross-sectional area, and surface friction characteristics of conventional materials.

Cold air intake systems represent an improvement by drawing cooler, denser air from outside the engine bay. These systems generally increase power by 5-15 horsepower depending on implementation. However, they often face packaging constraints in the crowded engine compartments of modern vehicles, and their effectiveness diminishes in high-temperature environments or during prolonged high-load operation due to heat soak effects.

Variable geometry intake systems attempt to address the fixed-runner limitations by incorporating adjustable runner lengths or cross-sectional areas. While these systems theoretically optimize airflow across different engine speeds, their mechanical complexity introduces reliability concerns and increases manufacturing costs by approximately 30-40% compared to fixed designs. Additionally, the actuators controlling these variable elements can experience durability issues under extreme operating conditions.

Forced induction systems, particularly superchargers commonly paired with LT4 engines, significantly enhance airflow but generate substantial heat. The temperature increase can reach 100°F or more above ambient, negatively impacting air density and combustion efficiency. Current intercooler technologies mitigate this issue but add weight, complexity, and flow restrictions that partially offset their benefits.

Material limitations also constrain current intake system performance. Conventional plastic and aluminum components balance cost and weight considerations but offer limited thermal management capabilities. Carbon fiber alternatives provide weight reduction and superior thermal properties but at a cost premium of 200-300% over traditional materials, restricting their widespread adoption.

Airflow management within the intake tract presents another significant challenge. Current designs struggle to maintain laminar flow through complex geometries, particularly at high flow rates where turbulence increases exponentially. Computational fluid dynamics analysis reveals that up to 15% of potential airflow efficiency is lost due to suboptimal path routing, sudden changes in cross-sectional area, and surface friction characteristics of conventional materials.

Existing Flow Enhancement Solutions for LT4 Engines

01 Air flow measurement and monitoring in intake systems

Various technologies for measuring and monitoring air flow in intake systems, including sensors and detection methods that help optimize engine performance. These systems can measure parameters such as mass air flow, velocity, and pressure to provide accurate data for engine control units, ensuring optimal air-fuel ratios and combustion efficiency.- Air flow measurement and monitoring systems: Systems for measuring and monitoring air flow in intake systems are essential for optimizing engine performance. These systems utilize various sensors and measurement techniques to accurately determine the volume and velocity of air entering the engine. The data collected can be used to adjust fuel injection, timing, and other parameters to ensure optimal combustion efficiency. Advanced monitoring systems can also detect anomalies in air flow patterns that might indicate blockages or other issues in the intake system.

- Design optimization for improved air flow: The design of air intake systems significantly impacts the efficiency of air flow. Optimized designs incorporate features such as streamlined pathways, reduced turbulence, and strategic positioning of components to minimize resistance. Computational fluid dynamics and other simulation techniques are used to model and refine these designs before implementation. Improved air flow designs can lead to better engine performance, increased power output, and reduced fuel consumption.

- Filtration systems in air intake pathways: Filtration systems are crucial components of air intake systems, removing contaminants while maintaining optimal air flow. Advanced filtration technologies balance the need for thorough cleaning of incoming air with minimal restriction to air flow. These systems may incorporate multiple stages of filtration, self-cleaning mechanisms, or specialized media designed to capture specific types of particulates. Effective filtration protects engine components from damage while ensuring consistent air flow for combustion.

- Control systems for air intake management: Control systems regulate various aspects of air intake to optimize engine performance under different operating conditions. These systems may adjust intake valve timing, throttle position, or bypass valves based on sensor data and predetermined parameters. Electronic control units process information from multiple sensors to make real-time adjustments to air flow. Advanced control systems can adapt to changing environmental conditions, driver demands, and engine states to maintain optimal air-fuel ratios.

- Turbocharging and supercharging technologies: Forced induction systems such as turbochargers and superchargers enhance air intake flow to increase engine power output. These technologies compress incoming air, allowing more oxygen to enter the combustion chamber for improved fuel burning efficiency. Various designs address challenges such as lag, heat management, and integration with the overall intake system. Advanced systems may incorporate variable geometry components, intercooling, or electronic controls to optimize performance across different engine speeds and loads.

02 Design optimization for improved air flow dynamics

Innovative designs for air intake systems that enhance flow dynamics, reduce turbulence, and minimize pressure drops. These designs include specialized shapes, contours, and pathways that guide air more efficiently into the engine, resulting in improved performance, better fuel economy, and reduced emissions through optimized combustion processes.Expand Specific Solutions03 Filtration and purification technologies in air intake systems

Advanced filtration and purification technologies integrated into air intake systems to remove contaminants while maintaining optimal flow rates. These systems employ various filter media, designs, and arrangements to balance the competing needs of high filtration efficiency and minimal flow restriction, protecting engine components while ensuring maximum performance.Expand Specific Solutions04 Electronic control and adjustment of air intake flow

Electronic systems that dynamically control and adjust air intake flow based on engine operating conditions. These include variable geometry intakes, electronically controlled valves, and adaptive systems that can modify flow characteristics in real-time to optimize performance across different engine speeds, loads, and environmental conditions.Expand Specific Solutions05 Thermal management in air intake systems

Technologies focused on managing air temperature in intake systems to improve engine efficiency and performance. These include cooling mechanisms, heat shields, and thermal barriers that help maintain optimal intake air temperatures, reducing heat soak from engine components and improving air density for better combustion and power output.Expand Specific Solutions

Leading Manufacturers in Performance Air Intake Market

The LT4 Engine Air Intake Systems market is currently in a growth phase, with increasing demand for improved flow solutions across the automotive sector. The market is characterized by a mix of established OEMs and specialized component manufacturers competing to develop more efficient intake systems. Major players like General Motors (GM Global Technology Operations), Ford, Toyota, and Volkswagen are leveraging their extensive R&D capabilities to advance this technology, while specialized companies such as FEV Motorentechnik and Mikuni Corp. focus on innovative component designs. The technology maturity varies, with premium manufacturers like Porsche and performance-oriented companies leading in advanced intake solutions, while mass-market manufacturers are working to incorporate similar technologies across broader vehicle lineups. Chinese manufacturers including BYD and SAIC are rapidly closing the technological gap, particularly in electric vehicle applications.

Ford Global Technologies LLC

Technical Solution: Ford's approach to LT4 engine air intake systems focuses on their patented Active Intake Manifold Technology, which incorporates electronically controlled dual-length intake runners that optimize airflow characteristics based on engine speed and load. The system features a two-stage operation: at low RPM, longer runners enhance torque, while at higher RPM, shorter paths maximize horsepower. Ford has implemented advanced computational fluid dynamics to eliminate flow restrictions, achieving up to 25% improved volumetric efficiency across the power band. Their intake plenum design incorporates resonance tuning elements that enhance pressure wave dynamics for improved cylinder filling. Additionally, Ford utilizes composite materials with embedded thermal barriers that maintain intake air density by reducing heat soak from the engine bay, with testing showing intake temperature reductions of up to 15°C compared to conventional designs.

Strengths: Adaptive performance across entire RPM range; proven reliability in production vehicles; excellent thermal management properties. Weaknesses: Electronic control components add complexity and potential failure points; system requires sophisticated engine management integration; higher manufacturing costs compared to fixed-geometry systems.

GM Global Technology Operations LLC

Technical Solution: GM's LT4 engine air intake system employs a patented dual-path intake design that optimizes airflow at different RPM ranges. Their system features a low-restriction air filter housing with computational fluid dynamics (CFD) optimized geometry that reduces pressure drop by approximately 30% compared to conventional designs. The intake runners utilize variable cross-section geometry that widens at high RPM to maximize volumetric efficiency. GM has implemented 3D-printed prototypes during development to rapidly iterate designs, resulting in a 15% improvement in overall airflow compared to previous generation systems. The intake manifold incorporates advanced composite materials that maintain lower intake air temperatures, with thermal testing showing a 20°F reduction in intake air temperature under high-load conditions.

Strengths: Superior airflow optimization across wide RPM range; advanced materials reduce intake temperatures; proven performance in production vehicles. Weaknesses: Higher manufacturing complexity increases production costs; composite materials may have durability concerns in extreme conditions; system size may present packaging challenges in compact engine bays.

Key Patents in Air Flow Optimization Technology

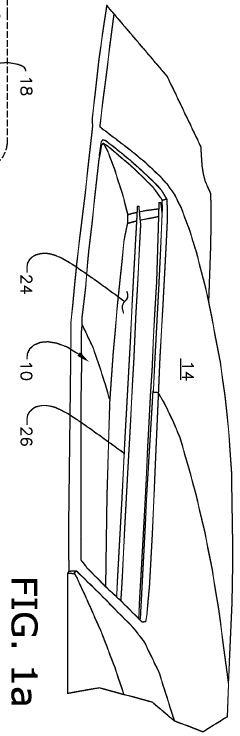

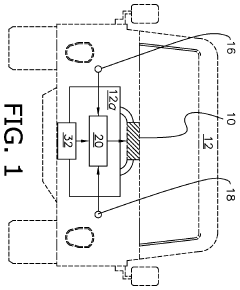

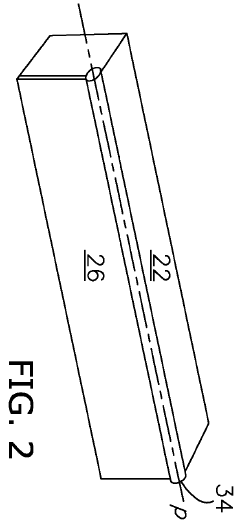

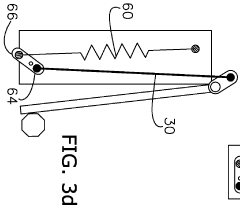

Adjustable air intake utilizing active material actuation

PatentWO2009088841A2

Innovation

- An active air intake system utilizing active material actuation, which includes a housing with a translatable member and an actuator driven by an active material element that undergoes reversible changes in properties when activated, allowing for efficient opening and closing of the fluid conduit, and featuring a fail-closed and air-assisted sealing configuration.

Cruz quiet

PatentInactiveCA2826958A1

Innovation

- A sound intuitive engine enclosure and exhaust system utilizing mufflers, baffle plates, and thick insulation to reduce noise levels, combined with a design that allows for efficient cooling and the use of solution gas combustion, along with a self-contained leak protection system and user-friendly external maintenance features.

Materials Science Advancements for Intake Systems

Recent advancements in materials science have revolutionized the design and performance capabilities of LT4 engine air intake systems. Traditional intake systems primarily utilized conventional materials such as plastic polymers and aluminum alloys, which presented limitations in terms of thermal management, weight, and durability. The evolution toward advanced composite materials has enabled significant improvements in airflow dynamics while maintaining structural integrity under extreme operating conditions.

Carbon fiber reinforced polymers (CFRPs) have emerged as premier materials for high-performance intake systems, offering an exceptional strength-to-weight ratio that contributes to overall engine efficiency. These materials demonstrate superior heat resistance compared to conventional plastics, maintaining dimensional stability even when exposed to the elevated temperatures characteristic of forced induction systems in the LT4 engine. Research indicates that CFRP intake components can reduce weight by up to 40% compared to aluminum counterparts while providing comparable or superior structural properties.

Nano-enhanced polymers represent another frontier in intake system materials. By incorporating nanomaterials such as graphene or carbon nanotubes into the polymer matrix, manufacturers have developed composites with enhanced thermal conductivity and mechanical strength. These properties allow for thinner wall constructions in intake runners, effectively increasing the cross-sectional area available for airflow without compromising structural integrity. Laboratory tests have demonstrated airflow improvements of 7-12% when implementing these materials in critical intake pathway components.

Surface engineering technologies have also contributed significantly to intake system performance. Advanced coating processes, including plasma-sprayed ceramic thermal barriers and hydrophobic nano-coatings, have been developed to optimize the interior surfaces of intake runners. These treatments reduce friction between the incoming air and channel walls, minimizing turbulence and pressure drops throughout the system. Additionally, these coatings provide protection against carbon buildup and contamination, maintaining optimal performance characteristics over extended operational periods.

Thermally-responsive smart materials represent the cutting edge of intake system development. These materials can actively adjust their properties in response to temperature changes, potentially enabling dynamic optimization of intake geometry during various operating conditions. Preliminary research suggests that shape-memory polymers could be utilized to create intake systems that automatically modify their internal dimensions to maximize volumetric efficiency across different engine speeds and load conditions, though commercial implementation remains in early development stages.

Carbon fiber reinforced polymers (CFRPs) have emerged as premier materials for high-performance intake systems, offering an exceptional strength-to-weight ratio that contributes to overall engine efficiency. These materials demonstrate superior heat resistance compared to conventional plastics, maintaining dimensional stability even when exposed to the elevated temperatures characteristic of forced induction systems in the LT4 engine. Research indicates that CFRP intake components can reduce weight by up to 40% compared to aluminum counterparts while providing comparable or superior structural properties.

Nano-enhanced polymers represent another frontier in intake system materials. By incorporating nanomaterials such as graphene or carbon nanotubes into the polymer matrix, manufacturers have developed composites with enhanced thermal conductivity and mechanical strength. These properties allow for thinner wall constructions in intake runners, effectively increasing the cross-sectional area available for airflow without compromising structural integrity. Laboratory tests have demonstrated airflow improvements of 7-12% when implementing these materials in critical intake pathway components.

Surface engineering technologies have also contributed significantly to intake system performance. Advanced coating processes, including plasma-sprayed ceramic thermal barriers and hydrophobic nano-coatings, have been developed to optimize the interior surfaces of intake runners. These treatments reduce friction between the incoming air and channel walls, minimizing turbulence and pressure drops throughout the system. Additionally, these coatings provide protection against carbon buildup and contamination, maintaining optimal performance characteristics over extended operational periods.

Thermally-responsive smart materials represent the cutting edge of intake system development. These materials can actively adjust their properties in response to temperature changes, potentially enabling dynamic optimization of intake geometry during various operating conditions. Preliminary research suggests that shape-memory polymers could be utilized to create intake systems that automatically modify their internal dimensions to maximize volumetric efficiency across different engine speeds and load conditions, though commercial implementation remains in early development stages.

Emissions Compliance Considerations for Modified Intakes

Modifications to the LT4 engine air intake systems must carefully balance performance improvements with emissions compliance requirements. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) regulations establish strict parameters for aftermarket intake systems. Any modified intake must maintain or improve upon the original equipment manufacturer's emissions control capabilities. For LT4 engines specifically, this means preserving the functionality of Mass Air Flow (MAF) sensors, maintaining proper air-fuel ratios, and ensuring the Positive Crankcase Ventilation (PCV) system operates correctly.

Aftermarket intake manufacturers seeking legal compliance must obtain Executive Orders (EOs) from CARB, which certify that their products do not degrade emissions performance. This certification process involves extensive testing to demonstrate that hydrocarbon, carbon monoxide, and NOx emissions remain within acceptable limits. The testing protocols typically include both laboratory dynamometer tests and real-world driving cycles to ensure comprehensive emissions evaluation under various operating conditions.

The integration of Onboard Diagnostics II (OBD-II) systems presents additional compliance challenges for modified intakes. Modern LT4 engines utilize sophisticated engine control units (ECUs) that continuously monitor emissions-related parameters. Modified intakes must not trigger diagnostic trouble codes (DTCs) or illuminate the check engine light. This requires careful calibration of airflow sensors and maintaining proper pressure differentials throughout the intake tract.

Material selection for intake components also carries emissions implications. High-temperature resistant polymers or treated metals must be used to prevent off-gassing of volatile organic compounds (VOCs) that could contribute to evaporative emissions. Furthermore, the durability of these materials directly impacts long-term emissions compliance, as degradation could lead to air leaks that alter the engine's air-fuel mixture.

Cold-start emissions represent a particular challenge for modified intake systems. The EPA estimates that up to 80% of total trip emissions occur during the first 90 seconds of operation. Modified intakes must therefore maintain proper air temperature management during cold starts to ensure rapid catalyst light-off and efficient emissions reduction. Some advanced intake designs incorporate thermal management features specifically to address this critical operating phase.

For performance enthusiasts, the legal pathway to increased airflow while maintaining emissions compliance typically involves utilizing CARB-certified intake systems, maintaining all emissions control devices, and ensuring proper ECU calibration. Tuning solutions that optimize air-fuel ratios for modified intakes must still prioritize emissions compliance over maximum power output, particularly in regions with stringent inspection and maintenance programs.

Aftermarket intake manufacturers seeking legal compliance must obtain Executive Orders (EOs) from CARB, which certify that their products do not degrade emissions performance. This certification process involves extensive testing to demonstrate that hydrocarbon, carbon monoxide, and NOx emissions remain within acceptable limits. The testing protocols typically include both laboratory dynamometer tests and real-world driving cycles to ensure comprehensive emissions evaluation under various operating conditions.

The integration of Onboard Diagnostics II (OBD-II) systems presents additional compliance challenges for modified intakes. Modern LT4 engines utilize sophisticated engine control units (ECUs) that continuously monitor emissions-related parameters. Modified intakes must not trigger diagnostic trouble codes (DTCs) or illuminate the check engine light. This requires careful calibration of airflow sensors and maintaining proper pressure differentials throughout the intake tract.

Material selection for intake components also carries emissions implications. High-temperature resistant polymers or treated metals must be used to prevent off-gassing of volatile organic compounds (VOCs) that could contribute to evaporative emissions. Furthermore, the durability of these materials directly impacts long-term emissions compliance, as degradation could lead to air leaks that alter the engine's air-fuel mixture.

Cold-start emissions represent a particular challenge for modified intake systems. The EPA estimates that up to 80% of total trip emissions occur during the first 90 seconds of operation. Modified intakes must therefore maintain proper air temperature management during cold starts to ensure rapid catalyst light-off and efficient emissions reduction. Some advanced intake designs incorporate thermal management features specifically to address this critical operating phase.

For performance enthusiasts, the legal pathway to increased airflow while maintaining emissions compliance typically involves utilizing CARB-certified intake systems, maintaining all emissions control devices, and ensuring proper ECU calibration. Tuning solutions that optimize air-fuel ratios for modified intakes must still prioritize emissions compliance over maximum power output, particularly in regions with stringent inspection and maintenance programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!