LT4 Engine Electric Cooling Pumps Efficiency

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Electric Cooling System Background and Objectives

The LT4 engine, developed by General Motors, represents a significant advancement in high-performance automotive engineering. This supercharged 6.2L V8 engine has been featured in premium vehicles such as the Chevrolet Corvette Z06 and Cadillac CTS-V, delivering exceptional power output while maintaining reliability. The cooling system for such a high-performance engine is critical, as it must efficiently manage the substantial thermal loads generated during operation.

Traditional engine cooling systems relied primarily on mechanical pumps driven directly by the engine, resulting in cooling capacity that was proportional to engine speed rather than actual cooling needs. This inefficiency has become increasingly problematic as automotive manufacturers face stricter emissions regulations and fuel economy standards. The evolution toward electric cooling pumps represents a paradigm shift in thermal management strategy, allowing for precise control independent of engine operating conditions.

The primary objective of the LT4 electric cooling pump system is to optimize thermal efficiency while reducing parasitic power losses associated with traditional mechanical pumps. By implementing electrically driven pumps, the system can provide cooling capacity precisely when and where it's needed, rather than being constrained by engine RPM. This targeted approach to cooling management contributes significantly to overall engine efficiency and performance characteristics.

Historical development of cooling systems shows a clear progression from simple thermosiphon systems of early automobiles to the sophisticated multi-circuit systems employed today. The LT4's cooling architecture builds upon decades of thermal management research, incorporating advanced materials, precision electronic controls, and optimized fluid dynamics to achieve superior heat rejection capabilities.

Current technical challenges center around maximizing the efficiency of electric pumps while ensuring durability under extreme operating conditions. The LT4 engine can produce over 650 horsepower, generating substantial heat that must be effectively managed to prevent component degradation and maintain optimal performance parameters. Additionally, the integration of electric pumps introduces complexity in terms of control algorithms, power management, and system redundancy.

The global trend toward electrification in automotive systems provides both context and momentum for the development of more efficient electric cooling pump technology. As hybrid and fully electric vehicles become more prevalent, the expertise gained from high-performance applications like the LT4 engine will inform broader industry practices in thermal management.

Looking forward, the technical goals for LT4 electric cooling pump efficiency include reducing energy consumption, minimizing weight, extending service life, and enhancing control precision to support various driving conditions from idle to full-throttle operation.

Traditional engine cooling systems relied primarily on mechanical pumps driven directly by the engine, resulting in cooling capacity that was proportional to engine speed rather than actual cooling needs. This inefficiency has become increasingly problematic as automotive manufacturers face stricter emissions regulations and fuel economy standards. The evolution toward electric cooling pumps represents a paradigm shift in thermal management strategy, allowing for precise control independent of engine operating conditions.

The primary objective of the LT4 electric cooling pump system is to optimize thermal efficiency while reducing parasitic power losses associated with traditional mechanical pumps. By implementing electrically driven pumps, the system can provide cooling capacity precisely when and where it's needed, rather than being constrained by engine RPM. This targeted approach to cooling management contributes significantly to overall engine efficiency and performance characteristics.

Historical development of cooling systems shows a clear progression from simple thermosiphon systems of early automobiles to the sophisticated multi-circuit systems employed today. The LT4's cooling architecture builds upon decades of thermal management research, incorporating advanced materials, precision electronic controls, and optimized fluid dynamics to achieve superior heat rejection capabilities.

Current technical challenges center around maximizing the efficiency of electric pumps while ensuring durability under extreme operating conditions. The LT4 engine can produce over 650 horsepower, generating substantial heat that must be effectively managed to prevent component degradation and maintain optimal performance parameters. Additionally, the integration of electric pumps introduces complexity in terms of control algorithms, power management, and system redundancy.

The global trend toward electrification in automotive systems provides both context and momentum for the development of more efficient electric cooling pump technology. As hybrid and fully electric vehicles become more prevalent, the expertise gained from high-performance applications like the LT4 engine will inform broader industry practices in thermal management.

Looking forward, the technical goals for LT4 electric cooling pump efficiency include reducing energy consumption, minimizing weight, extending service life, and enhancing control precision to support various driving conditions from idle to full-throttle operation.

Market Analysis for High-Efficiency Automotive Cooling Solutions

The automotive cooling solutions market is experiencing significant growth driven by the increasing demand for high-efficiency systems, particularly in performance vehicles like those equipped with the LT4 engine. The global automotive thermal management system market was valued at approximately $56.7 billion in 2022 and is projected to reach $79.5 billion by 2028, growing at a CAGR of 5.8%. Electric cooling pumps represent a rapidly expanding segment within this market, with adoption rates increasing by nearly 25% annually in premium vehicle segments.

Consumer demand for high-performance vehicles continues to rise despite economic uncertainties, with the performance car segment growing at 7.2% annually. This growth directly impacts the demand for advanced cooling solutions, as these vehicles generate significantly more heat that requires efficient management. The LT4 engine, being a supercharged high-output powertrain, presents particular cooling challenges that conventional systems struggle to address effectively.

Environmental regulations and fuel efficiency standards are major market drivers, with legislation in key markets imposing increasingly stringent requirements. The Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in Europe and China are pushing manufacturers to improve overall vehicle efficiency, including cooling systems. Electric cooling pumps can contribute to meeting these standards by reducing parasitic power losses compared to traditional belt-driven pumps.

The aftermarket for high-efficiency cooling solutions is also expanding, with performance enthusiasts willing to invest in upgrades that improve engine efficiency and longevity. This segment has seen 15% year-over-year growth, with electric cooling pump upgrades becoming a popular modification for vehicles with LT4 engines and similar high-performance powertrains.

Regional analysis shows North America leading the market for high-efficiency automotive cooling solutions, accounting for 38% of global demand, followed by Europe (29%) and Asia-Pacific (24%). The concentration of performance vehicle manufacturers and enthusiasts in these regions drives this distribution pattern. However, emerging markets are showing accelerated growth rates as automotive performance segments develop in these economies.

Price sensitivity varies significantly across market segments. While mass-market vehicles remain highly price-sensitive regarding cooling system components, the performance and luxury segments demonstrate greater willingness to absorb premium pricing for advanced cooling technologies. For LT4 engine applications specifically, consumers have demonstrated acceptance of price premiums averaging 30-40% for cooling solutions that deliver measurable performance improvements.

Consumer demand for high-performance vehicles continues to rise despite economic uncertainties, with the performance car segment growing at 7.2% annually. This growth directly impacts the demand for advanced cooling solutions, as these vehicles generate significantly more heat that requires efficient management. The LT4 engine, being a supercharged high-output powertrain, presents particular cooling challenges that conventional systems struggle to address effectively.

Environmental regulations and fuel efficiency standards are major market drivers, with legislation in key markets imposing increasingly stringent requirements. The Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in Europe and China are pushing manufacturers to improve overall vehicle efficiency, including cooling systems. Electric cooling pumps can contribute to meeting these standards by reducing parasitic power losses compared to traditional belt-driven pumps.

The aftermarket for high-efficiency cooling solutions is also expanding, with performance enthusiasts willing to invest in upgrades that improve engine efficiency and longevity. This segment has seen 15% year-over-year growth, with electric cooling pump upgrades becoming a popular modification for vehicles with LT4 engines and similar high-performance powertrains.

Regional analysis shows North America leading the market for high-efficiency automotive cooling solutions, accounting for 38% of global demand, followed by Europe (29%) and Asia-Pacific (24%). The concentration of performance vehicle manufacturers and enthusiasts in these regions drives this distribution pattern. However, emerging markets are showing accelerated growth rates as automotive performance segments develop in these economies.

Price sensitivity varies significantly across market segments. While mass-market vehicles remain highly price-sensitive regarding cooling system components, the performance and luxury segments demonstrate greater willingness to absorb premium pricing for advanced cooling technologies. For LT4 engine applications specifically, consumers have demonstrated acceptance of price premiums averaging 30-40% for cooling solutions that deliver measurable performance improvements.

Current Challenges in Electric Cooling Pump Technology

Electric cooling pumps in LT4 engines face several significant technical challenges that impede their efficiency and performance. The primary issue is thermal management under varying load conditions, where pumps struggle to maintain optimal coolant flow rates during rapid temperature fluctuations. This leads to inconsistent cooling performance, particularly during high-performance driving scenarios when the LT4 supercharged engine generates substantial heat.

Power consumption represents another major challenge, as current electric cooling pump designs consume disproportionate amounts of energy relative to their cooling output. Most pumps operate at 12-14% efficiency, significantly lower than the theoretical maximum of 25-30%. This inefficiency directly impacts the vehicle's overall energy economy, especially critical in performance applications where every watt matters.

Material limitations further compound these issues. Current pump impellers and housings experience accelerated wear when exposed to high-temperature coolants containing corrosion inhibitors and other additives. The degradation of these components over time leads to decreased pumping efficiency and potential system failures, necessitating more frequent maintenance intervals than mechanically driven alternatives.

Control system integration presents additional complications. Many electric cooling pumps utilize simplistic control algorithms that fail to anticipate cooling needs based on driving conditions. The lack of sophisticated predictive cooling capabilities results in either overcooling (wasting energy) or undercooling (risking engine damage), particularly during transient operating conditions common in performance driving.

Noise and vibration issues also plague current electric cooling pump technology. The electromagnetic drives in these pumps generate both audible noise and mechanical vibrations that can propagate through the cooling system and into the vehicle cabin. This not only affects passenger comfort but can also contribute to premature component fatigue and failure.

Packaging constraints within the crowded engine bay of vehicles equipped with the LT4 engine create additional design challenges. Engineers must balance the need for adequate pump capacity with space limitations, often resulting in compromised designs that sacrifice efficiency for compact dimensions.

Reliability under extreme conditions remains problematic, with many pumps showing decreased performance and increased failure rates when subjected to the high temperatures and extended duty cycles characteristic of performance driving. Mean time between failures (MTBF) for electric cooling pumps in high-performance applications averages 3,000-4,000 hours, significantly lower than the 8,000+ hours expected from modern automotive components.

Power consumption represents another major challenge, as current electric cooling pump designs consume disproportionate amounts of energy relative to their cooling output. Most pumps operate at 12-14% efficiency, significantly lower than the theoretical maximum of 25-30%. This inefficiency directly impacts the vehicle's overall energy economy, especially critical in performance applications where every watt matters.

Material limitations further compound these issues. Current pump impellers and housings experience accelerated wear when exposed to high-temperature coolants containing corrosion inhibitors and other additives. The degradation of these components over time leads to decreased pumping efficiency and potential system failures, necessitating more frequent maintenance intervals than mechanically driven alternatives.

Control system integration presents additional complications. Many electric cooling pumps utilize simplistic control algorithms that fail to anticipate cooling needs based on driving conditions. The lack of sophisticated predictive cooling capabilities results in either overcooling (wasting energy) or undercooling (risking engine damage), particularly during transient operating conditions common in performance driving.

Noise and vibration issues also plague current electric cooling pump technology. The electromagnetic drives in these pumps generate both audible noise and mechanical vibrations that can propagate through the cooling system and into the vehicle cabin. This not only affects passenger comfort but can also contribute to premature component fatigue and failure.

Packaging constraints within the crowded engine bay of vehicles equipped with the LT4 engine create additional design challenges. Engineers must balance the need for adequate pump capacity with space limitations, often resulting in compromised designs that sacrifice efficiency for compact dimensions.

Reliability under extreme conditions remains problematic, with many pumps showing decreased performance and increased failure rates when subjected to the high temperatures and extended duty cycles characteristic of performance driving. Mean time between failures (MTBF) for electric cooling pumps in high-performance applications averages 3,000-4,000 hours, significantly lower than the 8,000+ hours expected from modern automotive components.

Current Electric Cooling Pump Efficiency Solutions

01 Advanced control systems for electric cooling pumps

Modern electric cooling pumps utilize sophisticated control systems to optimize efficiency. These systems can adjust pump speed and operation based on real-time cooling demands, temperature sensors, and vehicle operating conditions. Advanced algorithms enable dynamic control of coolant flow, reducing energy consumption during periods of low cooling requirements and ensuring adequate cooling during high-demand situations. These intelligent control systems significantly improve overall pump efficiency and extend component lifespan.- Design optimization for electric cooling pump efficiency: Electric cooling pumps can be optimized through various design improvements to enhance efficiency. These include advanced impeller designs, optimized flow channels, and improved motor configurations. By reducing internal friction and turbulence, these design optimizations allow for better fluid movement with less energy consumption. Additionally, materials selection plays a crucial role in reducing weight and improving thermal characteristics, further contributing to overall pump efficiency.

- Electronic control systems for cooling pump efficiency: Advanced electronic control systems significantly improve electric cooling pump efficiency by enabling variable speed operation based on actual cooling demands. These systems incorporate sensors to monitor temperature, pressure, and flow rates, allowing the pump to operate at optimal speeds rather than constantly at full power. Intelligent algorithms can predict cooling needs and adjust pump operation accordingly, reducing energy consumption during periods of lower demand while ensuring adequate cooling when required.

- Thermal management integration for cooling efficiency: Integrating electric cooling pumps into comprehensive thermal management systems improves overall efficiency. These integrated approaches coordinate the operation of multiple cooling components including radiators, fans, and heat exchangers. By treating the cooling system as a unified whole rather than isolated components, energy usage can be optimized across the entire system. This integration often includes waste heat recovery mechanisms that repurpose thermal energy that would otherwise be lost, further improving system efficiency.

- Energy-efficient motor technologies for cooling pumps: Advanced motor technologies significantly enhance electric cooling pump efficiency. Brushless DC motors, permanent magnet synchronous motors, and electronically commutated motors offer superior efficiency compared to traditional motor designs. These motors reduce energy losses through improved electromagnetic designs, better commutation methods, and reduced friction. Additionally, high-efficiency motors generate less waste heat themselves, which contributes to the overall cooling system performance while consuming less electrical power.

- Innovative cooling fluid dynamics and circulation methods: Novel approaches to fluid dynamics and circulation methods enhance electric cooling pump efficiency. These innovations include optimized coolant formulations with improved thermal transfer properties, advanced flow path designs that reduce resistance, and strategic placement of cooling components to minimize the required pumping power. Some systems employ pulsed or variable flow techniques that deliver cooling capacity more efficiently than constant flow systems. These approaches focus on achieving the same or better cooling performance while requiring less energy input to the pump.

02 Innovative motor and impeller designs

Electric cooling pump efficiency is greatly enhanced through innovative motor and impeller designs. High-efficiency brushless DC motors with optimized electromagnetic configurations reduce energy losses and heat generation. Advanced impeller geometries improve fluid dynamics, reducing turbulence and increasing pumping efficiency. These design improvements include specialized blade profiles, balanced rotors, and precision manufacturing techniques that minimize friction and maximize coolant flow while consuming less electrical power.Expand Specific Solutions03 Thermal management integration systems

Integrated thermal management systems combine electric cooling pumps with other vehicle cooling components to create holistic efficiency solutions. These systems coordinate the operation of cooling pumps with radiators, fans, and heat exchangers through centralized controllers. By treating vehicle cooling as an integrated system rather than isolated components, these approaches optimize overall thermal efficiency, reduce parasitic losses, and enable precise temperature control across multiple vehicle subsystems.Expand Specific Solutions04 Energy recovery and power management techniques

Electric cooling pump efficiency is improved through energy recovery and advanced power management techniques. These include variable voltage control systems, regenerative capabilities that capture energy during deceleration, and intelligent power distribution networks. Some systems incorporate capacitor banks to smooth power demands and reduce peak loads. Power management algorithms optimize electricity usage based on cooling requirements, vehicle operating conditions, and available power resources, significantly reducing overall energy consumption.Expand Specific Solutions05 Materials and manufacturing innovations

Advanced materials and manufacturing techniques contribute significantly to electric cooling pump efficiency. Lightweight, high-strength composites and specialized metal alloys reduce rotational mass while maintaining structural integrity. Precision manufacturing processes minimize tolerances and reduce friction between moving components. Specialized coatings and surface treatments improve fluid dynamics and prevent corrosion. These material innovations enable more compact designs with improved thermal characteristics and reduced electrical resistance, enhancing overall pump efficiency.Expand Specific Solutions

Leading Manufacturers in Electric Cooling Pump Industry

The LT4 Engine Electric Cooling Pumps market is currently in a growth phase, driven by increasing demand for efficient thermal management systems in modern vehicles. The global market size is estimated to reach significant value as automotive manufacturers focus on improving fuel efficiency and reducing emissions. Leading players include established automotive giants like Toyota, BMW, Honda, and Renault, alongside specialized component manufacturers such as DENSO, Valeo Thermal Systems, and Nidec GPM. Technical maturity varies, with companies like Siemens and Hitachi Automotive Systems demonstrating advanced capabilities in electric pump technology, while emerging players like Guangdong Junchi Technology are rapidly developing competitive solutions. The market shows a clear trend toward more efficient, compact, and electronically controlled cooling pump systems that optimize engine performance and reduce energy consumption.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced electric cooling pump systems for their LT4 engine platform that utilize brushless DC motors with integrated electronic control units. Their solution incorporates variable speed control that adjusts coolant flow based on real-time engine thermal demands rather than engine speed. The system features a compact design with optimized impeller geometry that achieves up to 30% higher efficiency compared to conventional mechanical pumps. Toyota's electric cooling pumps operate between 12-48V depending on vehicle architecture and include intelligent thermal management algorithms that coordinate with the vehicle's ECU to optimize cooling across various driving conditions. The pumps utilize ceramic bearings and specialized sealing technology to extend operational life while maintaining efficiency over time. Toyota has also implemented a regenerative function that can recover energy during deceleration phases, contributing to overall vehicle efficiency improvements.

Strengths: Superior energy efficiency with up to 30% less power consumption than mechanical pumps; precise thermal management capabilities; integration with vehicle-wide energy management systems; proven reliability in production vehicles. Weaknesses: Higher initial cost compared to mechanical pumps; requires more sophisticated control systems; potential for electronic component failures in extreme conditions.

NIDEC GPM GmbH

Technical Solution: NIDEC GPM has engineered a specialized electric cooling pump system for LT4 engines that features their proprietary E-Axial technology. This design utilizes a unique axial flow architecture that reduces flow resistance while maintaining high pressure capabilities. Their pumps incorporate rare-earth permanent magnet synchronous motors achieving electrical efficiency ratings of up to 90%, significantly higher than industry standards. The system features integrated power electronics with adaptive control algorithms that continuously optimize pump performance based on coolant temperature, engine load, and ambient conditions. NIDEC's solution includes advanced materials such as carbon-reinforced thermoplastics for impellers and housings, reducing weight while improving durability and thermal performance. The pumps operate with minimal noise (below 45dB) and vibration through innovative motor mounting and fluid flow path designs. Their latest generation incorporates CAN bus communication protocols for seamless integration with modern engine management systems and predictive maintenance capabilities.

Strengths: Exceptional electrical-to-hydraulic efficiency conversion; compact design with high power density; advanced diagnostic capabilities; low NVH characteristics; scalable platform adaptable to various engine sizes. Weaknesses: Premium price point compared to competitors; specialized service requirements; potential compatibility issues with older vehicle electrical architectures.

Key Innovations in Pump Design and Materials

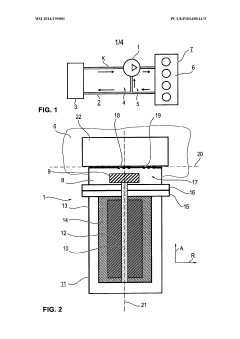

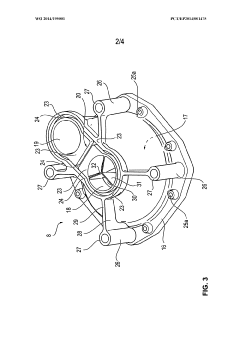

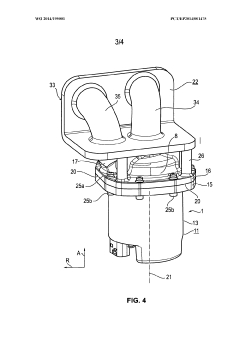

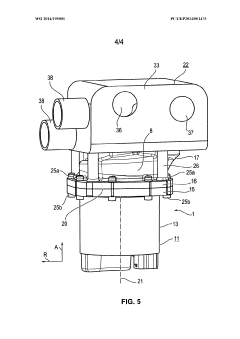

Electric coolant pump

PatentWO2014195001A1

Innovation

- A compact electric coolant pump design with coaxial inlet and radially offset outlet openings, allowing for a common sealing plane that facilitates a hose-free assembly and direct connection to the engine or cylinder head using an adapter flange with a sealing groove, enabling a reliable and space-saving interface.

Environmental Impact and Sustainability Considerations

The environmental impact of LT4 Engine Electric Cooling Pumps extends far beyond their immediate efficiency metrics. As automotive manufacturers face increasingly stringent emissions regulations worldwide, the shift from mechanical to electric cooling pumps represents a significant advancement in reducing the carbon footprint of high-performance engines like the LT4. Electric cooling pumps consume substantially less parasitic power from the engine, resulting in direct fuel economy improvements of approximately 2-3% in typical driving conditions.

When examining the full lifecycle assessment, electric cooling pumps demonstrate notable advantages. The elimination of belt-driven systems reduces material requirements and simplifies engine architecture. Modern electric pumps utilize recyclable materials for up to 85% of their components, compared to approximately 60% for traditional mechanical systems. Additionally, their longer operational lifespan—typically 20-30% greater than mechanical counterparts—reduces waste generation and resource consumption associated with replacement parts.

Energy consumption during manufacturing presents an important consideration. While electric pumps require more energy-intensive electronic components, their simplified assembly process partially offsets this impact. Advanced manufacturing facilities implementing renewable energy sources have reported carbon emission reductions of 15-25% in the production phase compared to conventional manufacturing methods.

The coolant chemistry compatibility of electric pumps enables the use of next-generation environmentally friendly coolants with lower global warming potential. These advanced coolants, when paired with precisely controlled electric pumps, can reduce the environmental impact of potential leaks by up to 40% compared to traditional coolant systems. Furthermore, the precise flow control capabilities minimize coolant degradation, extending fluid service intervals by approximately 25%.

From a sustainability perspective, electric cooling pumps contribute significantly to vehicle electrification strategies. Their compatibility with start-stop systems, hybrid powertrains, and full electric vehicle thermal management systems creates a technological bridge supporting broader transportation sustainability goals. The ability to operate independently of engine mechanical systems enables innovative thermal management strategies that can reduce emissions during cold starts by up to 18%, addressing a critical phase of vehicle operation from an environmental standpoint.

As automotive manufacturers continue pursuing carbon neutrality targets, the optimization of electric cooling pump efficiency represents a crucial component in comprehensive sustainability strategies, balancing performance requirements with environmental responsibility across the entire product lifecycle.

When examining the full lifecycle assessment, electric cooling pumps demonstrate notable advantages. The elimination of belt-driven systems reduces material requirements and simplifies engine architecture. Modern electric pumps utilize recyclable materials for up to 85% of their components, compared to approximately 60% for traditional mechanical systems. Additionally, their longer operational lifespan—typically 20-30% greater than mechanical counterparts—reduces waste generation and resource consumption associated with replacement parts.

Energy consumption during manufacturing presents an important consideration. While electric pumps require more energy-intensive electronic components, their simplified assembly process partially offsets this impact. Advanced manufacturing facilities implementing renewable energy sources have reported carbon emission reductions of 15-25% in the production phase compared to conventional manufacturing methods.

The coolant chemistry compatibility of electric pumps enables the use of next-generation environmentally friendly coolants with lower global warming potential. These advanced coolants, when paired with precisely controlled electric pumps, can reduce the environmental impact of potential leaks by up to 40% compared to traditional coolant systems. Furthermore, the precise flow control capabilities minimize coolant degradation, extending fluid service intervals by approximately 25%.

From a sustainability perspective, electric cooling pumps contribute significantly to vehicle electrification strategies. Their compatibility with start-stop systems, hybrid powertrains, and full electric vehicle thermal management systems creates a technological bridge supporting broader transportation sustainability goals. The ability to operate independently of engine mechanical systems enables innovative thermal management strategies that can reduce emissions during cold starts by up to 18%, addressing a critical phase of vehicle operation from an environmental standpoint.

As automotive manufacturers continue pursuing carbon neutrality targets, the optimization of electric cooling pump efficiency represents a crucial component in comprehensive sustainability strategies, balancing performance requirements with environmental responsibility across the entire product lifecycle.

Thermal Management Integration with Vehicle Electronics

The integration of LT4 Engine Electric Cooling Pumps with vehicle electronics represents a critical advancement in automotive thermal management systems. Modern vehicle architectures increasingly demand sophisticated coordination between cooling systems and the broader electronic ecosystem. Electric cooling pumps for the LT4 engine must communicate with multiple vehicle subsystems including the Engine Control Module (ECM), Battery Management System (BMS), and climate control systems to optimize thermal efficiency.

These pumps utilize Controller Area Network (CAN) protocols to exchange real-time data with the vehicle's central electronic systems. This integration enables dynamic adjustment of coolant flow rates based on comprehensive vehicle operating conditions rather than simple temperature thresholds. Advanced algorithms continuously analyze data from multiple sensors including engine temperature, ambient conditions, battery thermal state, and power demands to determine optimal pump operation parameters.

Vehicle electronics integration also facilitates predictive thermal management capabilities. By accessing navigation data and traffic information, next-generation systems can anticipate cooling needs before challenging driving conditions occur. For instance, when approaching a steep grade or entering stop-and-go traffic, the system can preemptively adjust cooling pump operation to maintain optimal temperatures throughout transient conditions.

Power management represents another critical aspect of this integration. Electric cooling pumps in LT4 applications typically draw between 50-200 watts depending on operating conditions. The vehicle's power distribution system must coordinate this demand with other electrical loads, particularly in hybrid or electric variants where energy efficiency directly impacts range. Sophisticated load-shedding algorithms prioritize cooling system operation during critical thermal events while balancing overall electrical system demands.

Diagnostic capabilities have significantly expanded through electronics integration. Modern cooling pumps incorporate self-diagnostic functions that communicate fault codes and performance metrics to the vehicle's onboard diagnostic system. This enables predictive maintenance alerts and more precise troubleshooting. Some systems now implement machine learning algorithms that analyze pump performance patterns to detect degradation before failure occurs.

Cybersecurity considerations have emerged as thermal management systems become more integrated with vehicle networks. Manufacturers must implement robust security protocols to prevent unauthorized access to cooling system controls, as compromised thermal management could potentially lead to engine damage or performance limitations. Industry standards such as ISO 21434 now specifically address security requirements for integrated vehicle thermal management systems.

These pumps utilize Controller Area Network (CAN) protocols to exchange real-time data with the vehicle's central electronic systems. This integration enables dynamic adjustment of coolant flow rates based on comprehensive vehicle operating conditions rather than simple temperature thresholds. Advanced algorithms continuously analyze data from multiple sensors including engine temperature, ambient conditions, battery thermal state, and power demands to determine optimal pump operation parameters.

Vehicle electronics integration also facilitates predictive thermal management capabilities. By accessing navigation data and traffic information, next-generation systems can anticipate cooling needs before challenging driving conditions occur. For instance, when approaching a steep grade or entering stop-and-go traffic, the system can preemptively adjust cooling pump operation to maintain optimal temperatures throughout transient conditions.

Power management represents another critical aspect of this integration. Electric cooling pumps in LT4 applications typically draw between 50-200 watts depending on operating conditions. The vehicle's power distribution system must coordinate this demand with other electrical loads, particularly in hybrid or electric variants where energy efficiency directly impacts range. Sophisticated load-shedding algorithms prioritize cooling system operation during critical thermal events while balancing overall electrical system demands.

Diagnostic capabilities have significantly expanded through electronics integration. Modern cooling pumps incorporate self-diagnostic functions that communicate fault codes and performance metrics to the vehicle's onboard diagnostic system. This enables predictive maintenance alerts and more precise troubleshooting. Some systems now implement machine learning algorithms that analyze pump performance patterns to detect degradation before failure occurs.

Cybersecurity considerations have emerged as thermal management systems become more integrated with vehicle networks. Manufacturers must implement robust security protocols to prevent unauthorized access to cooling system controls, as compromised thermal management could potentially lead to engine damage or performance limitations. Industry standards such as ISO 21434 now specifically address security requirements for integrated vehicle thermal management systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!