LT4 Engine Valve Timing for Power Optimization

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Valve Timing Background and Objectives

The LT4 engine represents a significant milestone in General Motors' high-performance engine development, evolving from the LS series architecture with substantial enhancements focused on power optimization. Valve timing has emerged as a critical factor in the engine's performance characteristics, directly influencing volumetric efficiency, power output, fuel economy, and emissions control. The historical progression of valve timing technology has moved from fixed timing systems to increasingly sophisticated variable valve timing (VVT) implementations, with the LT4 representing one of the most advanced iterations in production engines.

The LT4 6.2L supercharged V8 engine, introduced in the C7 Corvette Z06 and later implemented in various high-performance GM vehicles, utilizes an advanced valvetrain system designed to maximize power across the entire RPM range. The engine's valve timing strategy must balance multiple competing objectives, including peak power production, low-end torque delivery, fuel efficiency requirements, and increasingly stringent emissions regulations.

The primary technical objective for LT4 valve timing optimization centers on maximizing the supercharged engine's volumetric efficiency while maintaining reliability under high boost conditions. This requires precise control of valve events to ensure optimal cylinder filling and exhaust scavenging, particularly at high RPM where traditional fixed valve timing systems typically compromise performance.

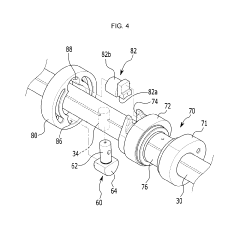

Current valve timing technology in the LT4 employs a dual-equal VVT system that allows for the adjustment of both intake and exhaust valve timing simultaneously. This system provides approximately 62 degrees of camshaft phasing authority, enabling significant flexibility in optimizing engine performance across various operating conditions. The system utilizes hydraulic cam phasers controlled by the engine management system based on inputs from multiple sensors monitoring engine load, RPM, temperature, and other critical parameters.

The evolution of this technology represents a significant advancement from earlier GM performance engines, which either lacked VVT entirely or employed more limited single-phaser systems. The technical progression has been driven by both performance demands and increasingly strict emissions requirements, necessitating more precise control over the combustion process.

Looking forward, the technical goals for further valve timing optimization in LT4-derived engines include expanding the phasing range, implementing independent intake and exhaust phasing (dual-independent VVT), and potentially exploring more radical technologies such as continuously variable valve lift and timing systems. These advancements aim to further enhance power density while simultaneously improving fuel efficiency and emissions performance.

The LT4 6.2L supercharged V8 engine, introduced in the C7 Corvette Z06 and later implemented in various high-performance GM vehicles, utilizes an advanced valvetrain system designed to maximize power across the entire RPM range. The engine's valve timing strategy must balance multiple competing objectives, including peak power production, low-end torque delivery, fuel efficiency requirements, and increasingly stringent emissions regulations.

The primary technical objective for LT4 valve timing optimization centers on maximizing the supercharged engine's volumetric efficiency while maintaining reliability under high boost conditions. This requires precise control of valve events to ensure optimal cylinder filling and exhaust scavenging, particularly at high RPM where traditional fixed valve timing systems typically compromise performance.

Current valve timing technology in the LT4 employs a dual-equal VVT system that allows for the adjustment of both intake and exhaust valve timing simultaneously. This system provides approximately 62 degrees of camshaft phasing authority, enabling significant flexibility in optimizing engine performance across various operating conditions. The system utilizes hydraulic cam phasers controlled by the engine management system based on inputs from multiple sensors monitoring engine load, RPM, temperature, and other critical parameters.

The evolution of this technology represents a significant advancement from earlier GM performance engines, which either lacked VVT entirely or employed more limited single-phaser systems. The technical progression has been driven by both performance demands and increasingly strict emissions requirements, necessitating more precise control over the combustion process.

Looking forward, the technical goals for further valve timing optimization in LT4-derived engines include expanding the phasing range, implementing independent intake and exhaust phasing (dual-independent VVT), and potentially exploring more radical technologies such as continuously variable valve lift and timing systems. These advancements aim to further enhance power density while simultaneously improving fuel efficiency and emissions performance.

Market Demand for High-Performance Engine Technologies

The global market for high-performance engine technologies has experienced substantial growth over the past decade, driven primarily by consumer demand for vehicles that deliver superior power, efficiency, and driving experience. The LT4 engine valve timing optimization represents a critical component within this expanding market segment, addressing the fundamental need for power enhancement without sacrificing fuel economy or emissions compliance.

Recent market research indicates that the performance automotive sector continues to show resilience even amid broader economic fluctuations. Premium and luxury vehicle segments, where advanced valve timing technologies are most prevalent, have maintained steady growth rates despite industry-wide challenges. This resilience underscores the enduring consumer willingness to invest in superior engine performance technologies.

The aftermarket performance parts industry has similarly witnessed significant expansion, with valve timing optimization components representing one of the fastest-growing categories. Performance enthusiasts increasingly seek sophisticated valve timing solutions that can deliver measurable power gains while maintaining daily drivability. This dual requirement has created a specialized market niche that manufacturers are actively competing to fulfill.

From an OEM perspective, advanced valve timing systems have become a key differentiator in marketing high-performance variants. Manufacturers leverage these technologies in their promotional materials, highlighting improvements in horsepower, torque curves, and acceleration metrics. The ability to optimize valve timing specifically for the LT4 engine platform represents a valuable competitive advantage in this crowded marketplace.

Regulatory pressures have paradoxically strengthened market demand for sophisticated valve timing solutions. As emissions standards become increasingly stringent worldwide, manufacturers must develop technologies that can simultaneously enhance performance while reducing environmental impact. Advanced valve timing systems that can optimize combustion efficiency represent one of the most promising approaches to meeting these seemingly contradictory requirements.

Geographic market analysis reveals significant regional variations in demand patterns. North American markets continue to show strong preference for high-displacement performance engines where valve timing optimization delivers substantial power gains. European markets, conversely, emphasize technologies that balance performance with efficiency, while emerging Asian markets display rapidly growing interest in premium performance technologies as disposable incomes rise.

The commercial vehicle and motorsport segments also represent substantial growth opportunities for advanced valve timing technologies. Racing applications in particular drive innovation at the cutting edge, with technologies eventually filtering down to production vehicles after proving their reliability and effectiveness in competitive environments.

Recent market research indicates that the performance automotive sector continues to show resilience even amid broader economic fluctuations. Premium and luxury vehicle segments, where advanced valve timing technologies are most prevalent, have maintained steady growth rates despite industry-wide challenges. This resilience underscores the enduring consumer willingness to invest in superior engine performance technologies.

The aftermarket performance parts industry has similarly witnessed significant expansion, with valve timing optimization components representing one of the fastest-growing categories. Performance enthusiasts increasingly seek sophisticated valve timing solutions that can deliver measurable power gains while maintaining daily drivability. This dual requirement has created a specialized market niche that manufacturers are actively competing to fulfill.

From an OEM perspective, advanced valve timing systems have become a key differentiator in marketing high-performance variants. Manufacturers leverage these technologies in their promotional materials, highlighting improvements in horsepower, torque curves, and acceleration metrics. The ability to optimize valve timing specifically for the LT4 engine platform represents a valuable competitive advantage in this crowded marketplace.

Regulatory pressures have paradoxically strengthened market demand for sophisticated valve timing solutions. As emissions standards become increasingly stringent worldwide, manufacturers must develop technologies that can simultaneously enhance performance while reducing environmental impact. Advanced valve timing systems that can optimize combustion efficiency represent one of the most promising approaches to meeting these seemingly contradictory requirements.

Geographic market analysis reveals significant regional variations in demand patterns. North American markets continue to show strong preference for high-displacement performance engines where valve timing optimization delivers substantial power gains. European markets, conversely, emphasize technologies that balance performance with efficiency, while emerging Asian markets display rapidly growing interest in premium performance technologies as disposable incomes rise.

The commercial vehicle and motorsport segments also represent substantial growth opportunities for advanced valve timing technologies. Racing applications in particular drive innovation at the cutting edge, with technologies eventually filtering down to production vehicles after proving their reliability and effectiveness in competitive environments.

Current State and Challenges in Valve Timing Systems

Valve timing systems in modern engines have evolved significantly over the past decades, with the LT4 engine representing one of the pinnacles of this technological advancement. Currently, the majority of high-performance engines, including the LT4, employ Variable Valve Timing (VVT) systems that allow for adjustments in valve opening and closing times based on engine operating conditions. These systems typically utilize hydraulic actuators controlled by the Engine Control Unit (ECU) to modify camshaft positioning relative to the crankshaft.

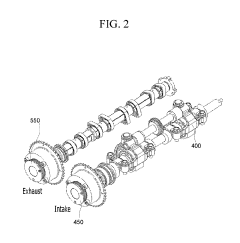

The predominant VVT technologies in the market include Continuous Variable Valve Timing (CVVT), Variable Valve Timing and Lift Electronic Control (VTEC), and Dual Independent Variable Camshaft Timing (DIVCT). The LT4 engine specifically utilizes a sophisticated version of DIVCT that enables independent control of both intake and exhaust camshafts, providing enhanced flexibility for power optimization across various RPM ranges.

Despite these advancements, several significant challenges persist in current valve timing systems. The primary limitation involves response time—the hydraulic mechanisms typically experience a 50-100 millisecond delay between command and execution, which can be problematic during rapid transient conditions such as sudden acceleration or deceleration. This delay reduces the system's ability to optimize power delivery in dynamic driving scenarios.

Another critical challenge is the operational temperature range. Conventional hydraulic VVT systems exhibit suboptimal performance at extreme temperatures, particularly during cold starts when oil viscosity is high. This results in inconsistent valve timing control during the initial warm-up phase, affecting both emissions and power output.

The complexity of current systems also presents reliability concerns. The LT4's valve timing mechanism incorporates numerous components including solenoids, hydraulic passages, and phaser units, all of which represent potential failure points. Industry data indicates that VVT-related issues account for approximately 15% of engine-related warranty claims in high-performance vehicles.

Energy efficiency represents another significant challenge. Current hydraulic VVT systems consume substantial engine power—estimates suggest between 1-3% of total engine output—to maintain hydraulic pressure. This parasitic loss directly impacts overall engine efficiency and, consequently, vehicle fuel economy.

From a manufacturing perspective, the precision requirements for components in advanced valve timing systems like those in the LT4 necessitate tight tolerances, sophisticated machining processes, and extensive quality control measures. These factors contribute to higher production costs and potential supply chain vulnerabilities, particularly for specialized components.

The predominant VVT technologies in the market include Continuous Variable Valve Timing (CVVT), Variable Valve Timing and Lift Electronic Control (VTEC), and Dual Independent Variable Camshaft Timing (DIVCT). The LT4 engine specifically utilizes a sophisticated version of DIVCT that enables independent control of both intake and exhaust camshafts, providing enhanced flexibility for power optimization across various RPM ranges.

Despite these advancements, several significant challenges persist in current valve timing systems. The primary limitation involves response time—the hydraulic mechanisms typically experience a 50-100 millisecond delay between command and execution, which can be problematic during rapid transient conditions such as sudden acceleration or deceleration. This delay reduces the system's ability to optimize power delivery in dynamic driving scenarios.

Another critical challenge is the operational temperature range. Conventional hydraulic VVT systems exhibit suboptimal performance at extreme temperatures, particularly during cold starts when oil viscosity is high. This results in inconsistent valve timing control during the initial warm-up phase, affecting both emissions and power output.

The complexity of current systems also presents reliability concerns. The LT4's valve timing mechanism incorporates numerous components including solenoids, hydraulic passages, and phaser units, all of which represent potential failure points. Industry data indicates that VVT-related issues account for approximately 15% of engine-related warranty claims in high-performance vehicles.

Energy efficiency represents another significant challenge. Current hydraulic VVT systems consume substantial engine power—estimates suggest between 1-3% of total engine output—to maintain hydraulic pressure. This parasitic loss directly impacts overall engine efficiency and, consequently, vehicle fuel economy.

From a manufacturing perspective, the precision requirements for components in advanced valve timing systems like those in the LT4 necessitate tight tolerances, sophisticated machining processes, and extensive quality control measures. These factors contribute to higher production costs and potential supply chain vulnerabilities, particularly for specialized components.

Current Valve Timing Solutions for Power Optimization

01 Variable valve timing systems for LT4 engines

Variable valve timing systems are used in LT4 engines to optimize engine performance across different operating conditions. These systems allow for the adjustment of valve opening and closing times, which can significantly improve power output, fuel efficiency, and emissions. By varying the valve timing based on engine speed and load, these systems can enhance low-end torque while maintaining high-end power, providing a broader power band for the engine.- Variable valve timing systems for LT4 engines: Variable valve timing systems in LT4 engines allow for dynamic adjustment of valve opening and closing times based on engine operating conditions. These systems optimize power output by adjusting the overlap between intake and exhaust valves, improving combustion efficiency across different RPM ranges. Advanced electronic control units manage the timing adjustments to maximize power while maintaining fuel efficiency and emissions compliance.

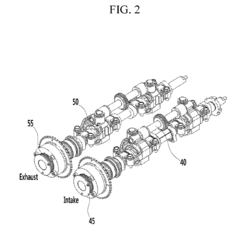

- Camshaft phasing technology for power enhancement: Camshaft phasing technologies enable precise control over the LT4 engine's valve timing to enhance power output. These systems use hydraulic or electric actuators to rotate the camshaft relative to its drive, advancing or retarding valve events. This technology allows for optimized air-fuel mixture at different engine loads and speeds, resulting in improved torque characteristics, better throttle response, and increased overall engine power.

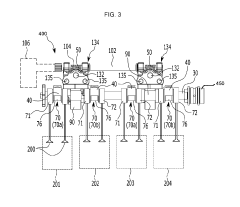

- Dual overhead cam timing coordination for LT4 performance: Dual overhead camshaft systems in LT4 engines require sophisticated timing coordination to maximize power output. These systems independently control intake and exhaust valve operation, allowing for more precise valve events and higher RPM capability. The timing relationship between the two camshafts can be optimized for different performance parameters, enabling better volumetric efficiency and increased power across a broader operating range.

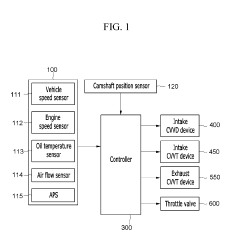

- Electronic valve timing control systems: Electronic control systems for valve timing in LT4 engines utilize sensors and actuators to precisely manage valve events based on real-time engine data. These systems incorporate engine control modules that continuously adjust timing parameters according to inputs such as throttle position, engine load, and RPM. Advanced algorithms optimize valve timing for maximum power output while adapting to changing driving conditions and maintaining reliability under high-performance operation.

- Mechanical valve timing mechanisms for power optimization: Mechanical valve timing mechanisms in LT4 engines establish the fundamental timing relationships that affect power output. These include specialized cam profiles, valve lift characteristics, and timing chain configurations designed specifically for performance applications. The mechanical components work together to create optimal valve opening duration and lift profiles that enhance airflow into and out of the combustion chambers, directly impacting the engine's power generation capabilities.

02 Camshaft phasing mechanisms for power optimization

Camshaft phasing mechanisms are implemented in LT4 engines to adjust the timing relationship between the crankshaft and camshaft. These mechanisms typically use hydraulic or electric actuators to rotate the camshaft relative to its drive, allowing for optimized valve events. Advanced camshaft phasing can provide increased power by improving volumetric efficiency, enhancing combustion stability, and reducing pumping losses across various engine operating conditions.Expand Specific Solutions03 Electronic control systems for valve timing

Electronic control systems are essential for managing valve timing in LT4 engines to maximize power output. These systems use input from various sensors to determine optimal valve timing based on factors such as engine load, speed, temperature, and driver demand. The engine control module (ECM) processes this data and sends commands to the valve timing actuators, enabling real-time adjustments that optimize combustion efficiency and power delivery across the entire operating range.Expand Specific Solutions04 Dual-equal and intake-only valve timing strategies

Different valve timing strategies are employed in LT4 engines to enhance power characteristics. Dual-equal systems adjust both intake and exhaust valve timing simultaneously, while intake-only systems focus on optimizing the intake valve events. These strategies can be tailored to specific performance goals, with intake-focused timing typically providing better low-end torque and throttle response, while dual-equal systems may offer better high-RPM power and emissions control. The selection of timing strategy significantly impacts the engine's power curve and overall performance characteristics.Expand Specific Solutions05 Integration of valve timing with direct injection and forced induction

Modern LT4 engines combine advanced valve timing with direct fuel injection and forced induction (supercharging) to maximize power output. This integration allows for precise control of the combustion process, optimizing air-fuel mixture and ignition timing. The valve timing can be specifically tuned to work with the pressure characteristics of forced induction systems, reducing turbo lag or supercharger inefficiencies. This comprehensive approach to engine management results in significantly higher power density while maintaining reliability and emissions compliance.Expand Specific Solutions

Major Players in Advanced Engine Valve Timing Industry

The LT4 engine valve timing optimization market is in a growth phase, with increasing demand for power-efficient engines driving innovation. The competitive landscape is characterized by established automotive manufacturers like Toyota, Ford, GM, and Volkswagen leading research efforts, while specialized powertrain companies such as Japhl Powertrain Systems, BorgWarner, and Aisin provide critical technological expertise. Asian players, particularly from China and Japan, are rapidly gaining market share through aggressive R&D investments. Universities like Tianjin and Beihang are contributing significant research to advance valve timing technologies. The technology is approaching maturity in traditional applications, but innovations in variable valve timing systems for performance optimization continue to emerge, with companies like Toyota, Ford, and BorgWarner demonstrating the highest technical sophistication in patent activity and commercial implementations.

Toyota Motor Corp.

Technical Solution: Toyota's approach to high-performance engine valve timing optimization incorporates their advanced VVT-iE (Variable Valve Timing-intelligent by Electric motor) system, comparable to technologies used in LT4-class engines. This system utilizes electric motor actuators rather than conventional hydraulic mechanisms to control camshaft timing, enabling more precise and responsive valve timing adjustments independent of engine oil pressure and temperature. Toyota has developed specialized high-flow cylinder heads with optimized port designs that work in conjunction with their Dual VVT-i system, allowing independent control of both intake and exhaust valve timing. Their technology incorporates advanced electronic control units that continuously monitor multiple engine parameters and adjust valve timing up to 70 degrees of crankshaft rotation to optimize volumetric efficiency across the entire RPM range. Toyota's system also features intelligent adaptive control algorithms that learn from driving patterns and adjust timing strategies accordingly, maximizing both power output and fuel efficiency based on actual usage conditions.

Strengths: Electric motor actuation provides faster response times and more precise control than hydraulic systems; system functions optimally even during cold starts and low oil pressure conditions; excellent reliability record with reduced mechanical complexity. Weaknesses: Higher initial cost due to electric motor components; increased electrical system demands; slightly heavier than purely mechanical or hydraulic systems.

Ford Global Technologies LLC

Technical Solution: Ford's approach to LT4-comparable engine valve timing optimization centers on their Ti-VCT (Twin Independent Variable Camshaft Timing) technology, enhanced specifically for high-performance applications. Their system employs independent control of intake and exhaust camshafts with up to 60 degrees of authority, allowing precise optimization across the entire operating range. Ford has developed specialized cam profiles with increased valve lift and duration specifically engineered for power optimization at higher RPMs while maintaining drivability at lower speeds. The technology incorporates advanced electronic solenoids that modulate oil pressure to camshaft phaser mechanisms, enabling rapid adjustments based on driver demand and engine conditions. Ford's proprietary control algorithms continuously calculate optimal valve timing based on inputs from multiple sensors, including mass airflow, crankshaft position, camshaft position, and knock sensors, making up to 30 adjustments per second to maximize power output while balancing fuel efficiency requirements.

Strengths: Independent control of intake and exhaust timing allows for more precise optimization across various operating conditions; rapid response time enables better transient performance; system is relatively compact and lightweight. Weaknesses: Higher manufacturing complexity compared to fixed timing systems; requires precise oil pressure control which can degrade with engine wear; potential for increased NVH (Noise, Vibration, Harshness) at certain operating points.

Key Patents and Innovations in LT4 Valve Timing

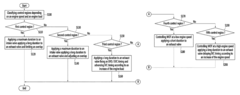

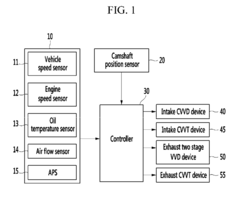

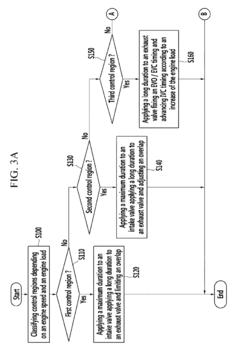

System and method for controlling of valve timing of continuous variable valve duration engine

PatentActiveUS9879619B2

Innovation

- A system and method that independently control the opening and closing timing of intake and exhaust valves using a CVVD device and a two-stage VVD device, with a controller classifying control regions based on engine speed and load to optimize valve duration and timing, applying maximum or long durations and adjusting overlap to improve combustion stability and efficiency.

System and method for controlling valve timing of continuous variable valve duration engine

PatentActiveUS10415488B2

Innovation

- A system and method that integrates continuous variable valve duration (CVVD) and continuous variable valve timing (CVVT) devices for both intake and exhaust valves, allowing for simultaneous control of valve duration and timing based on engine load and speed, with a controller adjusting opening and closing timings to optimize performance across different engine conditions.

Emissions Compliance and Valve Timing Strategies

Emissions regulations have become increasingly stringent worldwide, requiring automotive manufacturers to develop sophisticated valve timing strategies that balance power optimization with emissions compliance. The LT4 supercharged V8 engine, featured in high-performance GM vehicles, employs advanced variable valve timing (VVT) systems specifically calibrated to meet these dual objectives. These systems dynamically adjust intake and exhaust valve timing based on operating conditions to optimize combustion efficiency while minimizing harmful emissions.

The primary emissions challenges addressed through valve timing in the LT4 include NOx (nitrogen oxides), HC (hydrocarbons), CO (carbon monoxide), and particulate matter. At high-load conditions where power optimization is prioritized, the engine must still maintain emissions within regulatory limits. This is achieved through precise control of valve overlap periods, which significantly impacts exhaust gas recirculation (EGR) rates and combustion temperatures.

Advanced valve timing strategies implemented in the LT4 include late intake valve closing during part-load operation to create an Atkinson-like cycle that reduces pumping losses and improves fuel efficiency. During cold starts, when emissions are typically highest, the system employs reduced valve overlap to minimize HC emissions while accelerating catalyst light-off. At high engine speeds where power optimization is critical, the system transitions to increased valve overlap to improve volumetric efficiency while carefully managing NOx formation.

The LT4's emissions compliance strategy also incorporates cylinder deactivation working in concert with valve timing adjustments. When operating in V4 mode, the valve timing profiles for active cylinders are specifically modified to maintain optimal emissions performance despite the altered exhaust pulse dynamics. This integration represents a sophisticated approach to emissions management that preserves the engine's performance characteristics.

Calibration of valve timing maps for emissions compliance involves extensive testing across the engine's operating range, with particular attention to the US EPA's Federal Test Procedure (FTP) and Supplemental Federal Test Procedure (SFTP) drive cycles. The resulting timing strategies are programmed into the engine control module with multiple maps that are selected based on driving conditions, ambient temperature, and catalyst status.

Future developments in LT4 valve timing strategies are likely to include more sophisticated predictive algorithms that anticipate driving conditions and preemptively adjust valve timing to optimize the emissions-performance balance. Integration with hybrid powertrains may also enable more aggressive valve timing strategies during periods when the electric motors can compensate for any temporary reduction in engine output while emissions control is prioritized.

The primary emissions challenges addressed through valve timing in the LT4 include NOx (nitrogen oxides), HC (hydrocarbons), CO (carbon monoxide), and particulate matter. At high-load conditions where power optimization is prioritized, the engine must still maintain emissions within regulatory limits. This is achieved through precise control of valve overlap periods, which significantly impacts exhaust gas recirculation (EGR) rates and combustion temperatures.

Advanced valve timing strategies implemented in the LT4 include late intake valve closing during part-load operation to create an Atkinson-like cycle that reduces pumping losses and improves fuel efficiency. During cold starts, when emissions are typically highest, the system employs reduced valve overlap to minimize HC emissions while accelerating catalyst light-off. At high engine speeds where power optimization is critical, the system transitions to increased valve overlap to improve volumetric efficiency while carefully managing NOx formation.

The LT4's emissions compliance strategy also incorporates cylinder deactivation working in concert with valve timing adjustments. When operating in V4 mode, the valve timing profiles for active cylinders are specifically modified to maintain optimal emissions performance despite the altered exhaust pulse dynamics. This integration represents a sophisticated approach to emissions management that preserves the engine's performance characteristics.

Calibration of valve timing maps for emissions compliance involves extensive testing across the engine's operating range, with particular attention to the US EPA's Federal Test Procedure (FTP) and Supplemental Federal Test Procedure (SFTP) drive cycles. The resulting timing strategies are programmed into the engine control module with multiple maps that are selected based on driving conditions, ambient temperature, and catalyst status.

Future developments in LT4 valve timing strategies are likely to include more sophisticated predictive algorithms that anticipate driving conditions and preemptively adjust valve timing to optimize the emissions-performance balance. Integration with hybrid powertrains may also enable more aggressive valve timing strategies during periods when the electric motors can compensate for any temporary reduction in engine output while emissions control is prioritized.

Thermal Management Considerations for High-Output Engines

Thermal management represents a critical factor in the optimization of valve timing for high-output engines like the LT4. As engine power increases, thermal loads escalate exponentially, creating significant challenges for maintaining optimal valve operation. The LT4 engine, with its supercharged configuration, generates substantially higher combustion temperatures than naturally aspirated counterparts, necessitating advanced thermal management strategies specifically for the valve train system.

Heat dissipation becomes particularly crucial for exhaust valves, which can reach temperatures exceeding 760°C (1400°F) during peak operation. This extreme thermal environment affects valve timing precision through thermal expansion of components and potential degradation of valve seat materials. The LT4's valve timing optimization must therefore incorporate sophisticated heat management solutions to maintain geometric tolerances under varying thermal conditions.

Material selection plays a fundamental role in thermal management for valve train components. The LT4 utilizes titanium intake valves and sodium-filled hollow stem exhaust valves, which provide superior heat transfer characteristics compared to conventional steel valves. This material strategy reduces valve mass while enhancing thermal conductivity, allowing for more aggressive valve timing profiles without compromising durability.

Cooling system integration with valve timing control represents another essential consideration. The LT4's advanced cooling architecture incorporates targeted coolant flow to critical valve train areas, including the cylinder head around valve guides. This precision cooling approach helps maintain more consistent operating temperatures, reducing thermal expansion variability that could otherwise compromise valve timing accuracy.

Oil delivery systems also contribute significantly to thermal management in high-output engines. The LT4 features enhanced oil jet cooling directed at the underside of pistons and valve train components, creating a secondary cooling circuit that complements the primary coolant system. This dual-approach cooling strategy helps stabilize operating temperatures during high-load conditions when valve timing precision becomes most critical for power optimization.

Advanced electronic control systems further enhance thermal management capabilities by incorporating temperature-compensated valve timing adjustments. The LT4's engine control module continuously monitors thermal conditions and applies corrective timing adjustments to maintain optimal valve events despite temperature fluctuations. This adaptive approach ensures consistent performance across varying operating conditions while protecting valve train components from thermal stress.

Heat dissipation becomes particularly crucial for exhaust valves, which can reach temperatures exceeding 760°C (1400°F) during peak operation. This extreme thermal environment affects valve timing precision through thermal expansion of components and potential degradation of valve seat materials. The LT4's valve timing optimization must therefore incorporate sophisticated heat management solutions to maintain geometric tolerances under varying thermal conditions.

Material selection plays a fundamental role in thermal management for valve train components. The LT4 utilizes titanium intake valves and sodium-filled hollow stem exhaust valves, which provide superior heat transfer characteristics compared to conventional steel valves. This material strategy reduces valve mass while enhancing thermal conductivity, allowing for more aggressive valve timing profiles without compromising durability.

Cooling system integration with valve timing control represents another essential consideration. The LT4's advanced cooling architecture incorporates targeted coolant flow to critical valve train areas, including the cylinder head around valve guides. This precision cooling approach helps maintain more consistent operating temperatures, reducing thermal expansion variability that could otherwise compromise valve timing accuracy.

Oil delivery systems also contribute significantly to thermal management in high-output engines. The LT4 features enhanced oil jet cooling directed at the underside of pistons and valve train components, creating a secondary cooling circuit that complements the primary coolant system. This dual-approach cooling strategy helps stabilize operating temperatures during high-load conditions when valve timing precision becomes most critical for power optimization.

Advanced electronic control systems further enhance thermal management capabilities by incorporating temperature-compensated valve timing adjustments. The LT4's engine control module continuously monitors thermal conditions and applies corrective timing adjustments to maintain optimal valve events despite temperature fluctuations. This adaptive approach ensures consistent performance across varying operating conditions while protecting valve train components from thermal stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!