LT4 Engine Calibration for Optimal Output

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Calibration Background and Objectives

The LT4 engine represents a significant milestone in General Motors' high-performance powertrain development, evolving from the rich heritage of small-block V8 engines that have defined American performance for decades. This supercharged 6.2-liter V8 engine, introduced in 2014 for the C7 Corvette Z06 and later implemented in various high-performance GM vehicles, demonstrates the continued evolution of internal combustion technology in an increasingly electrified automotive landscape. The calibration of such sophisticated powertrains has become exponentially more complex as manufacturers balance performance demands with stringent emissions regulations and efficiency requirements.

Engine calibration has transformed from a relatively straightforward mechanical adjustment process to a highly sophisticated digital engineering discipline. Modern engine control units (ECUs) manage thousands of parameters that must be precisely tuned to optimize performance across various operating conditions. For the LT4 specifically, calibration engineers face the challenge of harnessing its supercharged potential while maintaining reliability, drivability, and compliance with global regulatory standards.

The primary objective of LT4 engine calibration is to maximize power output and torque delivery while ensuring consistent performance across varying environmental conditions and driving scenarios. This involves optimizing fuel delivery, ignition timing, boost pressure control, and thermal management systems to extract maximum efficiency from the combustion process. Secondary objectives include minimizing emissions, improving fuel economy, and enhancing overall drivability characteristics that align with the vehicle's intended purpose and brand identity.

Historical approaches to engine calibration relied heavily on dynamometer testing and road evaluations, requiring extensive time and resources. The technological evolution has introduced sophisticated simulation tools, machine learning algorithms, and automated calibration processes that significantly reduce development cycles while improving precision. These advancements have enabled calibration engineers to explore a vastly larger parameter space than was previously possible.

The current technological landscape presents both opportunities and challenges for LT4 calibration. Advanced computational fluid dynamics (CFD) simulations allow for detailed modeling of combustion processes, while real-time data acquisition systems provide unprecedented insight into engine behavior under various conditions. However, the increasing complexity of emissions control systems, particularly in global markets with divergent regulatory requirements, creates additional calibration challenges that must be addressed through innovative approaches.

This technical research aims to explore cutting-edge methodologies for optimizing LT4 engine calibration, identifying best practices from both industry and academic sources, and evaluating emerging technologies that could further enhance the performance envelope of this powertrain platform.

Engine calibration has transformed from a relatively straightforward mechanical adjustment process to a highly sophisticated digital engineering discipline. Modern engine control units (ECUs) manage thousands of parameters that must be precisely tuned to optimize performance across various operating conditions. For the LT4 specifically, calibration engineers face the challenge of harnessing its supercharged potential while maintaining reliability, drivability, and compliance with global regulatory standards.

The primary objective of LT4 engine calibration is to maximize power output and torque delivery while ensuring consistent performance across varying environmental conditions and driving scenarios. This involves optimizing fuel delivery, ignition timing, boost pressure control, and thermal management systems to extract maximum efficiency from the combustion process. Secondary objectives include minimizing emissions, improving fuel economy, and enhancing overall drivability characteristics that align with the vehicle's intended purpose and brand identity.

Historical approaches to engine calibration relied heavily on dynamometer testing and road evaluations, requiring extensive time and resources. The technological evolution has introduced sophisticated simulation tools, machine learning algorithms, and automated calibration processes that significantly reduce development cycles while improving precision. These advancements have enabled calibration engineers to explore a vastly larger parameter space than was previously possible.

The current technological landscape presents both opportunities and challenges for LT4 calibration. Advanced computational fluid dynamics (CFD) simulations allow for detailed modeling of combustion processes, while real-time data acquisition systems provide unprecedented insight into engine behavior under various conditions. However, the increasing complexity of emissions control systems, particularly in global markets with divergent regulatory requirements, creates additional calibration challenges that must be addressed through innovative approaches.

This technical research aims to explore cutting-edge methodologies for optimizing LT4 engine calibration, identifying best practices from both industry and academic sources, and evaluating emerging technologies that could further enhance the performance envelope of this powertrain platform.

Market Demand Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that deliver superior power, torque, and overall performance. The LT4 supercharged V8 engine, as a flagship performance powerplant, sits at the premium end of this expanding market segment. Market research indicates that global demand for high-performance engines is projected to grow at a compound annual growth rate of 6.8% through 2028, with particularly strong demand in North America, Europe, and emerging Asian markets.

Consumer preferences have evolved beyond raw power metrics to encompass efficiency, reliability, and technological sophistication. Modern performance enthusiasts increasingly value engines that deliver optimal output while maintaining reasonable fuel economy and emissions compliance. This shift has created a distinct market opportunity for advanced calibration technologies that can maximize the performance envelope of engines like the LT4 while meeting stringent regulatory requirements.

The aftermarket performance sector represents a substantial portion of this demand, with specialized tuning companies reporting 15-20% annual growth in requests for custom LT4 calibrations. Performance-oriented vehicle segments including sports cars, premium SUVs, and high-end trucks constitute the primary market channels, with the luxury performance segment showing particular resilience even during economic downturns.

Competitive analysis reveals that vehicles equipped with optimally calibrated LT4 engines command price premiums averaging 8-12% over base models, demonstrating strong consumer willingness to pay for enhanced performance characteristics. Dealership surveys indicate that performance specifications rank among the top three purchase considerations for buyers in this segment, alongside brand reputation and design aesthetics.

Regional market analysis shows North America maintaining the largest market share at approximately 42%, followed by Europe at 28% and Asia-Pacific at 22%. Emerging markets are showing accelerated growth rates, albeit from smaller base volumes. The performance engine market demonstrates notable resilience to economic fluctuations, with demand remaining relatively stable even during broader automotive industry contractions.

Industry forecasts suggest that demand for sophisticated engine calibration technologies will continue to grow as manufacturers seek to extract maximum performance from increasingly regulated powertrains. The convergence of digital technologies with traditional mechanical engineering has created new opportunities for advanced calibration methodologies that can optimize multiple performance parameters simultaneously, addressing the complex demands of modern high-performance applications.

Consumer preferences have evolved beyond raw power metrics to encompass efficiency, reliability, and technological sophistication. Modern performance enthusiasts increasingly value engines that deliver optimal output while maintaining reasonable fuel economy and emissions compliance. This shift has created a distinct market opportunity for advanced calibration technologies that can maximize the performance envelope of engines like the LT4 while meeting stringent regulatory requirements.

The aftermarket performance sector represents a substantial portion of this demand, with specialized tuning companies reporting 15-20% annual growth in requests for custom LT4 calibrations. Performance-oriented vehicle segments including sports cars, premium SUVs, and high-end trucks constitute the primary market channels, with the luxury performance segment showing particular resilience even during economic downturns.

Competitive analysis reveals that vehicles equipped with optimally calibrated LT4 engines command price premiums averaging 8-12% over base models, demonstrating strong consumer willingness to pay for enhanced performance characteristics. Dealership surveys indicate that performance specifications rank among the top three purchase considerations for buyers in this segment, alongside brand reputation and design aesthetics.

Regional market analysis shows North America maintaining the largest market share at approximately 42%, followed by Europe at 28% and Asia-Pacific at 22%. Emerging markets are showing accelerated growth rates, albeit from smaller base volumes. The performance engine market demonstrates notable resilience to economic fluctuations, with demand remaining relatively stable even during broader automotive industry contractions.

Industry forecasts suggest that demand for sophisticated engine calibration technologies will continue to grow as manufacturers seek to extract maximum performance from increasingly regulated powertrains. The convergence of digital technologies with traditional mechanical engineering has created new opportunities for advanced calibration methodologies that can optimize multiple performance parameters simultaneously, addressing the complex demands of modern high-performance applications.

Current Calibration Challenges and Limitations

The LT4 engine calibration process currently faces several significant challenges that limit achieving optimal output performance. Traditional calibration methodologies rely heavily on steady-state testing conditions that fail to capture the dynamic operating environments encountered in real-world driving scenarios. This disconnect creates a fundamental limitation in calibration accuracy, particularly during transient operations where engine parameters rapidly change.

One major technical hurdle involves the complex interaction between the LT4's supercharger system and fuel delivery timing. The supercharged architecture creates highly variable pressure conditions that conventional calibration models struggle to predict accurately across the entire operating range. Engineers report deviations of up to 8% between predicted and actual performance metrics when the engine transitions between different load states.

Data acquisition limitations further compound these challenges. Current sensor technologies employed in calibration processes often lack the sampling frequency necessary to capture microsecond-level combustion events critical for optimizing the LT4's high-performance characteristics. This temporal resolution gap results in missed optimization opportunities, particularly in areas of valve timing and ignition advance mapping.

The computational complexity of modern engine management systems presents another significant barrier. The LT4 engine control unit manages over 80,000 calibration parameters, creating a multi-dimensional optimization problem that exceeds the capabilities of traditional calibration approaches. Current methodologies typically optimize parameters in isolation rather than addressing their complex interdependencies, resulting in sub-optimal overall performance.

Environmental variability introduces additional calibration challenges. The LT4 must maintain optimal performance across extreme temperature ranges (-30°C to +50°C) and varying altitudes, yet current calibration procedures typically focus on standard conditions. This results in performance compromises when operating outside nominal environmental parameters, with particularly notable efficiency losses in cold-weather operation.

Manufacturing tolerances introduce further variability that current calibration approaches struggle to address. Component-to-component variations in critical elements like injectors, valves, and the supercharger assembly create performance inconsistencies across production units. Current calibration methodologies lack robust compensation mechanisms for these manufacturing variations, resulting in performance disparities between theoretically identical engines.

Regulatory compliance requirements add another layer of complexity, as calibration must simultaneously optimize for performance, emissions, and fuel economy. These competing objectives create fundamental trade-offs that current optimization algorithms cannot fully resolve, particularly under the increasingly stringent emissions standards in global markets.

One major technical hurdle involves the complex interaction between the LT4's supercharger system and fuel delivery timing. The supercharged architecture creates highly variable pressure conditions that conventional calibration models struggle to predict accurately across the entire operating range. Engineers report deviations of up to 8% between predicted and actual performance metrics when the engine transitions between different load states.

Data acquisition limitations further compound these challenges. Current sensor technologies employed in calibration processes often lack the sampling frequency necessary to capture microsecond-level combustion events critical for optimizing the LT4's high-performance characteristics. This temporal resolution gap results in missed optimization opportunities, particularly in areas of valve timing and ignition advance mapping.

The computational complexity of modern engine management systems presents another significant barrier. The LT4 engine control unit manages over 80,000 calibration parameters, creating a multi-dimensional optimization problem that exceeds the capabilities of traditional calibration approaches. Current methodologies typically optimize parameters in isolation rather than addressing their complex interdependencies, resulting in sub-optimal overall performance.

Environmental variability introduces additional calibration challenges. The LT4 must maintain optimal performance across extreme temperature ranges (-30°C to +50°C) and varying altitudes, yet current calibration procedures typically focus on standard conditions. This results in performance compromises when operating outside nominal environmental parameters, with particularly notable efficiency losses in cold-weather operation.

Manufacturing tolerances introduce further variability that current calibration approaches struggle to address. Component-to-component variations in critical elements like injectors, valves, and the supercharger assembly create performance inconsistencies across production units. Current calibration methodologies lack robust compensation mechanisms for these manufacturing variations, resulting in performance disparities between theoretically identical engines.

Regulatory compliance requirements add another layer of complexity, as calibration must simultaneously optimize for performance, emissions, and fuel economy. These competing objectives create fundamental trade-offs that current optimization algorithms cannot fully resolve, particularly under the increasingly stringent emissions standards in global markets.

Current LT4 Calibration Approaches and Techniques

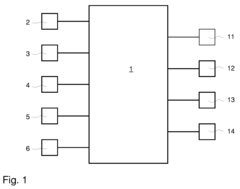

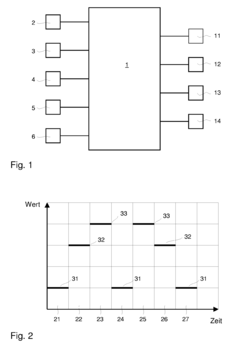

01 Engine control systems for optimal output

Advanced control systems are essential for optimizing LT4 engine output. These systems utilize electronic control units (ECUs) that continuously monitor various engine parameters such as air intake, fuel injection timing, and combustion efficiency. By implementing sophisticated algorithms and feedback mechanisms, these control systems can adjust engine parameters in real-time to maximize power output while maintaining reliability and fuel efficiency. These systems often incorporate adaptive learning capabilities to optimize performance across different operating conditions.- Engine control systems for optimal output: Advanced control systems are essential for optimizing LT4 engine output. These systems utilize electronic control units (ECUs) that continuously monitor various engine parameters such as air intake, fuel injection timing, and combustion efficiency. By implementing sophisticated algorithms and feedback mechanisms, these control systems can adjust engine parameters in real-time to maintain optimal performance under varying operating conditions, resulting in improved power output and efficiency.

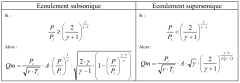

- Supercharger and forced induction optimization: The LT4 engine's performance is significantly enhanced through supercharging and forced induction systems. Optimizing the supercharger design, including impeller geometry and drive ratios, allows for increased air density in the combustion chamber. Advanced intercooling systems reduce intake air temperatures, further improving volumetric efficiency. Proper calibration of boost pressure across the engine's operating range ensures maximum power output while maintaining reliability and thermal efficiency.

- Fuel delivery and combustion optimization: Achieving optimal output in the LT4 engine requires precise fuel delivery and combustion management. Direct injection systems with optimized spray patterns ensure proper fuel atomization and distribution within the combustion chamber. Advanced ignition timing strategies, including multi-spark capabilities, maximize combustion efficiency across various operating conditions. Fuel pressure regulation and variable fuel mapping allow for adaptive performance based on driving conditions, ambient temperature, and fuel quality.

- Thermal management systems: Effective thermal management is crucial for maintaining optimal LT4 engine output. Advanced cooling systems, including precision-controlled electric water pumps and targeted oil cooling, help maintain ideal operating temperatures under high-load conditions. Heat exchangers and integrated cooling circuits for the supercharger system reduce intake air temperatures, improving volumetric efficiency. Temperature-sensitive components are protected through strategic cooling pathways, allowing for sustained high-performance operation without thermal degradation.

- Variable valve timing and lift systems: Variable valve timing and lift systems significantly contribute to the LT4 engine's optimal output across its operating range. These systems dynamically adjust valve opening duration, timing, and lift height based on engine speed and load conditions. By optimizing the intake and exhaust flow characteristics at different RPM ranges, these systems enhance volumetric efficiency, torque production, and fuel economy. Advanced camshaft phasing mechanisms allow for rapid adjustments to valve timing, improving both low-end torque and high-RPM power output.

02 Supercharger and forced induction optimization

Forced induction systems, particularly superchargers, are critical components for enhancing LT4 engine output. Optimizing the supercharger design, boost pressure, and intercooling efficiency can significantly increase power output. Advanced supercharger technologies include variable geometry designs, electronic boost control, and integrated charge cooling systems. These improvements allow for increased air density entering the combustion chamber, resulting in more complete combustion and higher power output while managing heat generation and mechanical stress on engine components.Expand Specific Solutions03 Fuel delivery and combustion optimization

Optimizing fuel delivery systems is crucial for maximizing LT4 engine output. This includes high-precision direct injection systems, advanced fuel mapping, and combustion chamber design improvements. By ensuring optimal fuel atomization, spray pattern, and injection timing, these systems enable more complete combustion and reduced energy losses. Advanced combustion technologies may incorporate multiple injection events per cycle, variable fuel pressure systems, and cylinder-specific fuel delivery adjustments to account for variations in operating conditions and maximize power output across the entire RPM range.Expand Specific Solutions04 Thermal management systems

Effective thermal management is essential for maintaining optimal LT4 engine output, especially under high-load conditions. Advanced cooling systems incorporate precision-controlled coolant flow, targeted cooling for critical components, and integrated oil cooling systems. These systems help maintain ideal operating temperatures throughout the engine, preventing power loss due to heat-related issues such as detonation or reduced volumetric efficiency. Some thermal management systems also include active components that adjust cooling intensity based on real-time operating conditions to optimize performance while protecting engine components.Expand Specific Solutions05 Performance monitoring and diagnostics

Advanced monitoring and diagnostic systems are vital for maintaining optimal LT4 engine output over time. These systems utilize various sensors to continuously track engine performance parameters, detect potential issues before they affect output, and provide data for performance optimization. Real-time monitoring capabilities allow for immediate adjustments to engine parameters when conditions change, while diagnostic functions help identify components that may be limiting maximum output. Some systems also incorporate predictive analytics to recommend maintenance or adjustments that can restore or enhance engine performance.Expand Specific Solutions

Key Industry Players in Engine Management Systems

The LT4 engine calibration market is currently in a growth phase, with increasing demand for optimized engine performance across automotive and industrial sectors. The market size is expanding due to stricter emissions regulations and consumer demand for fuel-efficient yet powerful engines. Technologically, major automotive manufacturers like GM, Toyota, Nissan, and Volkswagen lead the field with advanced calibration capabilities, while specialized component suppliers such as Bosch, DENSO, and Cummins provide critical expertise in engine management systems. Academic institutions including Beijing Institute of Technology and Southeast University contribute valuable research. The competitive landscape shows a mix of established OEMs focusing on proprietary calibration methods and third-party specialists offering cross-platform solutions, with emerging collaboration between traditional manufacturers and technology providers driving innovation.

Toyota Motor Corp.

Technical Solution: Toyota's LT4 Engine Calibration technology centers on their integrated approach combining hardware optimization with sophisticated control strategies. Their methodology employs a holistic calibration process that begins with combustion system design and extends through to ECU programming. Toyota utilizes their proprietary TEMS (Toyota Engine Management System) platform which features adaptive learning algorithms that continuously refine calibration parameters based on driving conditions and engine feedback. Their calibration process incorporates extensive dynamometer testing with specialized equipment capable of simulating various environmental conditions to ensure consistent performance across diverse operating scenarios. Toyota's engineers employ model-predictive control strategies that anticipate required engine responses before conditions change, reducing lag and improving transient performance. Their calibration approach places particular emphasis on emissions compliance without sacrificing performance, utilizing complex exhaust gas recirculation (EGR) strategies and precise fuel injection timing control to optimize the combustion process across the entire operating range.

Strengths: Industry-leading reliability and durability; sophisticated adaptive control strategies; excellent balance between performance and emissions compliance. Weaknesses: Conservative calibration approach may prioritize reliability over maximum performance potential; calibration tools primarily designed for production engines rather than specialized high-performance applications.

Robert Bosch GmbH

Technical Solution: Bosch's approach to LT4 Engine Calibration leverages their Motronic engine management systems with advanced model-based calibration methodologies. Their technology utilizes high-precision sensors and actuators working in conjunction with sophisticated control algorithms to optimize engine performance parameters. Bosch's calibration process employs Design of Experiments (DoE) techniques to efficiently map engine behavior across operating conditions, reducing development time by up to 40% compared to traditional methods. Their ETAS INCA software platform enables real-time calibration adjustments and data acquisition, while their automated calibration tools can simultaneously optimize for multiple objectives including power output, emissions compliance, and fuel economy. Bosch's system incorporates machine learning algorithms that continuously refine calibration parameters based on real-world driving data, allowing for adaptive optimization that accounts for engine aging and environmental variations.

Strengths: Industry-leading engine management hardware and software integration; comprehensive calibration toolchain from development to production; extensive experience across multiple OEMs. Weaknesses: Solutions can be costly to implement; may require significant customization for specific LT4 applications; dependency on Bosch's proprietary ecosystem.

Critical Calibration Parameters and Algorithms

Method for optimising the calibration of an internal combustion engine

PatentInactiveEP1703110A1

Innovation

- A method using a neural network to optimize engine calibration by starting from a defined start condition and systematically varying key parameters like throttle valve position, load, fuel-air ratio, and ignition angle in a predefined order, with online training and consideration of hysteresis effects, to improve model quality and reduce calibration effort.

System for calibrating the operating range of a supercharged internal combustion engine

PatentWO2011001057A2

Innovation

- A calibration system comprising a man-machine interface and an export module, utilizing a mathematical model with adjustable parameters to calculate optimal fuel injection and boost pressure settings for different temperature, pressure, and backpressure conditions, while minimizing the number of physical measurements required.

Emissions Compliance and Regulatory Considerations

Optimizing the LT4 engine for maximum performance must be balanced with increasingly stringent emissions regulations across global markets. The Environmental Protection Agency (EPA) in the United States, European Union's Euro standards, and California Air Resources Board (CARB) requirements establish progressively tighter limits on nitrogen oxides (NOx), carbon monoxide (CO), particulate matter, and hydrocarbon emissions. These regulations directly impact calibration strategies for the LT4 supercharged V8 engine, requiring sophisticated emissions control systems integration.

The LT4 engine calibration must address the trade-off between performance optimization and emissions compliance. Higher combustion temperatures that benefit power output simultaneously increase NOx production, while rich fuel mixtures that maximize supercharged performance tend to elevate hydrocarbon emissions. Modern calibration approaches utilize multi-dimensional mapping to find optimal operating points that satisfy both performance targets and emissions requirements across the engine's operating range.

Catalytic converter efficiency becomes a critical consideration in LT4 calibration. The engine management system must ensure rapid catalyst light-off during cold starts while maintaining appropriate exhaust gas temperatures during high-performance operation. This often necessitates specific calibration strategies for different driving conditions, including temporary enrichment during high-load situations balanced with lean operation when emissions impact is most critical.

On-board diagnostics (OBD) requirements add another layer of complexity to LT4 calibration. The engine control module must continuously monitor emissions system performance, detect malfunctions, and alert drivers when emissions exceed thresholds by 1.5 times the standard. This requires robust sensor integration and diagnostic algorithms that can differentiate between normal performance variations and actual emissions system failures.

Real Driving Emissions (RDE) testing, particularly prevalent in European markets, has shifted calibration approaches from optimizing for standardized laboratory cycles to ensuring compliance across diverse real-world driving conditions. This has led to the implementation of adaptive calibration strategies that can adjust parameters based on driving patterns, ambient conditions, and engine load profiles to maintain emissions compliance without sacrificing the performance characteristics expected from an LT4 engine.

Future-proofing LT4 calibrations requires consideration of upcoming regulatory changes, including potential Euro 7 standards and increasingly stringent CARB requirements. Calibration strategies must incorporate sufficient headroom to accommodate software updates that may be necessary to meet evolving emissions standards throughout the vehicle's service life, while preserving the distinctive performance character that defines LT4-powered vehicles.

The LT4 engine calibration must address the trade-off between performance optimization and emissions compliance. Higher combustion temperatures that benefit power output simultaneously increase NOx production, while rich fuel mixtures that maximize supercharged performance tend to elevate hydrocarbon emissions. Modern calibration approaches utilize multi-dimensional mapping to find optimal operating points that satisfy both performance targets and emissions requirements across the engine's operating range.

Catalytic converter efficiency becomes a critical consideration in LT4 calibration. The engine management system must ensure rapid catalyst light-off during cold starts while maintaining appropriate exhaust gas temperatures during high-performance operation. This often necessitates specific calibration strategies for different driving conditions, including temporary enrichment during high-load situations balanced with lean operation when emissions impact is most critical.

On-board diagnostics (OBD) requirements add another layer of complexity to LT4 calibration. The engine control module must continuously monitor emissions system performance, detect malfunctions, and alert drivers when emissions exceed thresholds by 1.5 times the standard. This requires robust sensor integration and diagnostic algorithms that can differentiate between normal performance variations and actual emissions system failures.

Real Driving Emissions (RDE) testing, particularly prevalent in European markets, has shifted calibration approaches from optimizing for standardized laboratory cycles to ensuring compliance across diverse real-world driving conditions. This has led to the implementation of adaptive calibration strategies that can adjust parameters based on driving patterns, ambient conditions, and engine load profiles to maintain emissions compliance without sacrificing the performance characteristics expected from an LT4 engine.

Future-proofing LT4 calibrations requires consideration of upcoming regulatory changes, including potential Euro 7 standards and increasingly stringent CARB requirements. Calibration strategies must incorporate sufficient headroom to accommodate software updates that may be necessary to meet evolving emissions standards throughout the vehicle's service life, while preserving the distinctive performance character that defines LT4-powered vehicles.

Durability and Reliability Testing Protocols

Durability and reliability testing for the LT4 engine calibration process requires comprehensive protocols to ensure the engine can maintain optimal output under various conditions over its intended lifespan. These protocols typically begin with accelerated life testing, where the engine undergoes simulated usage equivalent to years of operation within a compressed timeframe. This includes thermal cycling between extreme temperatures (-40°F to 240°F) to evaluate component integrity and calibration stability across the operational temperature range.

Load testing represents another critical protocol component, subjecting the LT4 engine to sustained high-load conditions at varying RPM ranges. This process typically involves running the engine at 80-100% throttle for extended periods (4-8 hours) while monitoring performance metrics and ensuring calibration parameters remain within acceptable tolerances. Special attention is paid to supercharger performance and intercooler efficiency during these high-demand scenarios.

Vibration and shock testing protocols evaluate the durability of engine components and calibration stability under mechanical stress. Using specialized test rigs, the engine experiences controlled vibration patterns mimicking real-world conditions, including rough road surfaces and performance driving scenarios. These tests help identify potential failure points in both hardware and calibration maps that might emerge during aggressive driving conditions.

Environmental exposure testing examines how the LT4 calibration performs under varying atmospheric conditions. This includes altitude testing (sea level to 10,000+ feet), humidity variation (20-95% relative humidity), and operation in particulate-heavy environments. Such testing ensures the engine management system can appropriately adjust fuel delivery, boost pressure, and timing across diverse environmental scenarios while maintaining optimal output.

Long-term endurance testing represents perhaps the most comprehensive protocol, involving continuous operation cycles that alternate between idle, normal driving loads, and maximum performance conditions. These tests typically accumulate 500+ hours of operation time, with regular performance benchmarking to detect any degradation in output or efficiency. Oil analysis is performed at predetermined intervals to monitor engine wear patterns and validate the calibration's impact on long-term engine health.

Data acquisition systems record hundreds of parameters throughout all testing phases, creating a comprehensive performance profile that engineers use to refine calibration maps. This data-driven approach ensures that optimizations for maximum power output don't compromise the LT4's legendary reliability and durability standards expected in premium performance applications.

Load testing represents another critical protocol component, subjecting the LT4 engine to sustained high-load conditions at varying RPM ranges. This process typically involves running the engine at 80-100% throttle for extended periods (4-8 hours) while monitoring performance metrics and ensuring calibration parameters remain within acceptable tolerances. Special attention is paid to supercharger performance and intercooler efficiency during these high-demand scenarios.

Vibration and shock testing protocols evaluate the durability of engine components and calibration stability under mechanical stress. Using specialized test rigs, the engine experiences controlled vibration patterns mimicking real-world conditions, including rough road surfaces and performance driving scenarios. These tests help identify potential failure points in both hardware and calibration maps that might emerge during aggressive driving conditions.

Environmental exposure testing examines how the LT4 calibration performs under varying atmospheric conditions. This includes altitude testing (sea level to 10,000+ feet), humidity variation (20-95% relative humidity), and operation in particulate-heavy environments. Such testing ensures the engine management system can appropriately adjust fuel delivery, boost pressure, and timing across diverse environmental scenarios while maintaining optimal output.

Long-term endurance testing represents perhaps the most comprehensive protocol, involving continuous operation cycles that alternate between idle, normal driving loads, and maximum performance conditions. These tests typically accumulate 500+ hours of operation time, with regular performance benchmarking to detect any degradation in output or efficiency. Oil analysis is performed at predetermined intervals to monitor engine wear patterns and validate the calibration's impact on long-term engine health.

Data acquisition systems record hundreds of parameters throughout all testing phases, creating a comprehensive performance profile that engineers use to refine calibration maps. This data-driven approach ensures that optimizations for maximum power output don't compromise the LT4's legendary reliability and durability standards expected in premium performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!