How to Upgrade LT4 Engine for Track Use

LT4 Engine Evolution and Performance Targets

The LT4 engine represents a significant milestone in General Motors' small-block V8 evolution, building upon the foundation established by the LS series. First introduced in the C7 Corvette Z06, the LT4 features a 6.2-liter supercharged architecture that delivers exceptional power and torque characteristics. Throughout its development, GM engineers have continuously refined this powerplant to balance street drivability with performance potential, making it an ideal candidate for track-focused upgrades.

The historical progression of the LT4 demonstrates GM's commitment to advancing forced induction technology in production vehicles. The modern LT4 incorporates direct injection, variable valve timing, and an Eaton R1740 TVS supercharger, enabling it to produce 650 horsepower and 650 lb-ft of torque in factory form. This represents a significant leap from earlier generations, showcasing the platform's robust design and engineering headroom.

For track-specific applications, performance targets must be recalibrated to address the unique demands of circuit driving. Primary objectives include improving thermal management to maintain consistent power delivery throughout extended high-RPM operation, enhancing mechanical durability for sustained high-load scenarios, and optimizing power delivery characteristics to maximize exit speeds and straight-line acceleration.

Current LT4 limitations in track environments primarily stem from heat management challenges, particularly in the supercharger system and cylinder heads. Factory intercooling systems typically become overwhelmed after several laps at racing pace, resulting in power reduction due to heat soak. Additionally, oil system capacity and cooling require enhancement to maintain proper lubrication under sustained high-G cornering and braking.

The evolution path for track-focused LT4 development should target incremental improvements across multiple systems rather than pursuing maximum horsepower figures alone. Specifically, a 10-15% increase in sustainable power output combined with a 25-30% improvement in thermal efficiency represents an optimal balance for track applications. This approach preserves the engine's inherent reliability while significantly enhancing on-track performance.

Achieving these targets requires a comprehensive approach addressing both mechanical and electronic systems. Advanced materials for critical components, revised cooling pathways, and recalibrated engine management systems must work in concert to elevate the LT4's track capabilities while maintaining acceptable service intervals and component longevity.

Track Performance Market Analysis

The track performance market for high-performance engines has experienced significant growth over the past decade, driven by increasing interest in motorsports and track day events among automotive enthusiasts. The market for track-focused vehicle modifications, particularly engine upgrades like those for the LT4 engine, represents a specialized but lucrative segment within the broader automotive aftermarket industry.

Current market analysis indicates that track day participation has grown at approximately 8% annually since 2018, with a corresponding increase in demand for performance upgrades. This growth has been particularly strong in North America and Europe, where established track infrastructures and motorsport cultures support a robust ecosystem of performance enhancement services and products.

The target demographic for LT4 engine track upgrades primarily consists of affluent motorsport enthusiasts aged 35-55, with disposable income dedicated to automotive hobbies. This segment demonstrates high brand loyalty and willingness to invest substantially in performance improvements, with typical track-focused engine modification budgets ranging from $5,000 to $25,000 depending on the level of enhancement desired.

Market research reveals that consumers in this segment prioritize reliability under extreme conditions, consistent power delivery, and measurable performance improvements. The value proposition for LT4 track upgrades must therefore balance maximum performance with durability considerations, as track use subjects engines to significantly higher thermal and mechanical stresses than street applications.

Competition in this space comes from both OEM performance divisions offering factory-backed track packages and specialized aftermarket companies. Key market players include established performance shops with proven track records in GM V8 modifications, specialized engineering firms focusing on forced induction systems, and racing development companies offering comprehensive track preparation services.

The market demonstrates seasonal fluctuations corresponding with regional track seasons, with peak demand occurring during spring and early summer months as enthusiasts prepare vehicles for the primary track season. This seasonality creates opportunities for targeted marketing campaigns and promotional timing.

Consumer behavior analysis shows that purchase decisions for significant engine upgrades are heavily influenced by peer recommendations, professional motorsport applications, and demonstrable performance data. Successful products in this market typically feature comprehensive documentation of testing protocols and performance gains, often validated through third-party testing or competition results.

Future market projections indicate continued growth in the track performance segment, with increasing demand for solutions that incorporate advanced materials, precision manufacturing techniques, and data-driven optimization. The emergence of semi-professional track day series and time attack competitions further expands the potential market for specialized LT4 engine upgrades designed specifically for competitive track applications.

Current LT4 Limitations and Engineering Challenges

The LT4 engine, while impressive in stock form, faces significant limitations when subjected to the extreme demands of track use. The primary challenge lies in thermal management, as the supercharged 6.2L V8 generates substantial heat during high-RPM operation over extended periods. The stock cooling system, designed primarily for street use with intermittent high-performance driving, becomes inadequate under sustained track conditions, leading to power reduction through electronic intervention to prevent damage.

Mechanical stress represents another critical limitation. The connecting rods, while suitable for factory power levels, become potential failure points when the engine is pushed beyond stock specifications. Similarly, the stock pistons have limited headroom for increased boost pressure, creating a ceiling for power enhancement without significant internal modifications.

The fuel delivery system presents additional constraints. The factory injectors and fuel pump assembly were calibrated for production power levels with a reasonable safety margin, but they approach their maximum flow capacity when significant power increases are targeted. This creates a bottleneck that limits potential performance gains without substantial modification to the fuel system architecture.

From an oiling perspective, the LT4's wet sump system experiences oil starvation issues during high-G cornering maneuvers typical in track environments. The oil can migrate away from the pickup, momentarily starving critical engine components of lubrication and potentially causing catastrophic failure under sustained track use.

The factory supercharger, while efficient, has limited headroom for additional boost without generating excessive intake temperatures. The intercooler system becomes overwhelmed during extended high-output operation, reducing charge air density and limiting power potential. The pulley ratio also represents a compromise between street drivability and maximum performance.

Electronic limitations further constrain track potential. The factory ECU contains protective algorithms that reduce power when certain temperature or mechanical stress thresholds are exceeded. While these safeguards protect engine integrity, they significantly limit sustained performance in track environments where these thresholds are regularly approached or exceeded.

Exhaust flow restriction becomes apparent at higher power levels, with the catalytic converters and muffler system creating backpressure that limits top-end power. This restriction becomes more pronounced as engine output increases, creating diminishing returns for other performance modifications without addressing the exhaust flow capacity.

Existing LT4 Track Modification Solutions

01 LT4 Engine Design and Components

The LT4 engine represents a specific design in automotive engineering, characterized by its unique components and architecture. These engines typically feature advanced design elements that contribute to improved performance and efficiency. The design may include specialized cylinder heads, intake manifolds, and other core components that distinguish it from other engine types.- LT4 Engine Design and Components: The LT4 engine is a high-performance engine design with specific components that contribute to its power and efficiency. These components include specialized cylinder heads, valve systems, and internal engine parts that are engineered for optimal performance. The design focuses on maximizing power output while maintaining reliability under demanding conditions.

- Fuel and Air Management Systems: Advanced fuel and air management systems are incorporated in the LT4 engine to optimize combustion efficiency. These systems include direct injection technology, variable valve timing, and sophisticated air intake designs that enhance fuel economy while delivering superior power. The management systems are controlled by electronic modules that adjust parameters based on operating conditions.

- Supercharging and Forced Induction: The LT4 engine utilizes supercharging technology to increase power output. This forced induction system compresses air before it enters the combustion chamber, allowing for more fuel to be burned and generating additional horsepower. The supercharger design includes intercooling capabilities to manage intake air temperatures and improve overall engine efficiency.

- Engine Monitoring and Diagnostic Systems: Sophisticated monitoring and diagnostic systems are integrated into the LT4 engine platform to ensure optimal performance and reliability. These systems include sensors that track various engine parameters such as temperature, pressure, and timing. The diagnostic capabilities allow for early detection of potential issues and facilitate maintenance procedures to extend engine life.

- Cooling and Thermal Management: The LT4 engine incorporates advanced cooling and thermal management systems to handle the high heat output associated with its performance capabilities. These systems include specialized coolant circulation, oil cooling mechanisms, and heat exchangers designed to maintain optimal operating temperatures under various load conditions. Effective thermal management is crucial for maintaining engine durability and consistent performance.

02 Performance Enhancement Systems for LT4 Engines

Various systems and methods have been developed to enhance the performance of LT4 engines. These include advanced fuel injection systems, supercharging or turbocharging technologies, and specialized exhaust systems. These enhancements are designed to increase horsepower, torque, and overall engine efficiency while maintaining reliability under various operating conditions.Expand Specific Solutions03 Diagnostic and Monitoring Systems for LT4 Engines

Specialized diagnostic and monitoring systems have been developed for LT4 engines to ensure optimal performance and early detection of potential issues. These systems may include sensors, electronic control units, and software algorithms that monitor various engine parameters such as temperature, pressure, and combustion efficiency. Advanced diagnostic tools help in troubleshooting and maintaining the engine's performance over its operational life.Expand Specific Solutions04 Cooling and Thermal Management for LT4 Engines

Effective cooling and thermal management systems are crucial for high-performance LT4 engines. These systems may include specialized coolant circulation designs, oil cooling mechanisms, and heat exchangers. Proper thermal management ensures optimal engine operating temperatures, prevents overheating, and contributes to the longevity and reliability of the engine under various load conditions.Expand Specific Solutions05 Integration of LT4 Engines with Vehicle Systems

The integration of LT4 engines with other vehicle systems involves specialized mounting solutions, transmission interfaces, and electronic control integration. These integration approaches ensure optimal power delivery, vibration control, and compatibility with vehicle chassis and drivetrain components. Advanced integration techniques may also address issues related to weight distribution, packaging constraints, and overall vehicle dynamics.Expand Specific Solutions

Major Manufacturers and Aftermarket Specialists

The LT4 engine track upgrade market is in a growth phase, with increasing demand from performance enthusiasts and racing teams. The competitive landscape features traditional automotive manufacturers like Geely, Changan, and Great Wall Motor focusing on performance engineering, while tech companies such as Huawei and Baidu are entering the space with smart technology integration. Chinese automakers including BYD and Dongfeng are developing performance variants to compete with established players. The technology maturity varies significantly - traditional manufacturers have strong mechanical engineering foundations, while tech companies bring advanced data analytics and electronic control systems. This creates a fragmented market where partnerships between traditional automotive expertise and cutting-edge technology providers are becoming increasingly valuable for comprehensive track-focused engine solutions.

Zhejiang Geely Holding Group Co., Ltd.

Jiangling Motors Co., Ltd.

Critical Patents in Forced Induction Technology

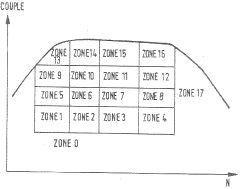

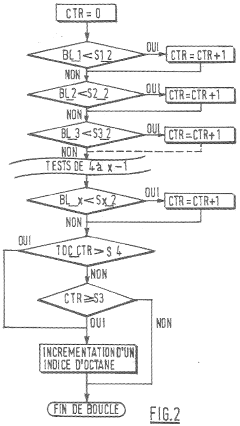

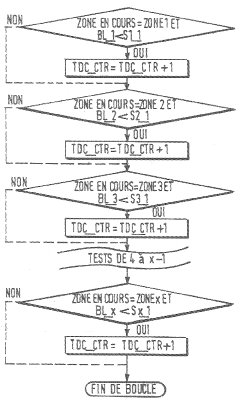

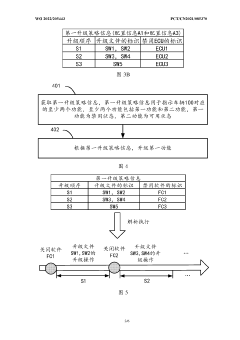

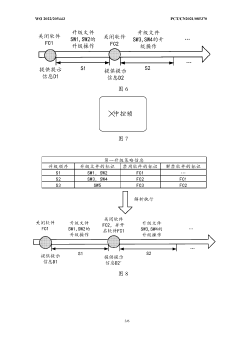

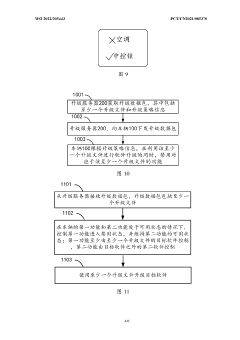

- A method that adjusts the engine's ignition advance by incrementing the learned octane number through a process involving counter increments and zone-based correction loops, allowing the engine to switch to a reference setting corresponding to a higher octane number when knocking is detected, thereby optimizing performance and reducing knocking phenomena.

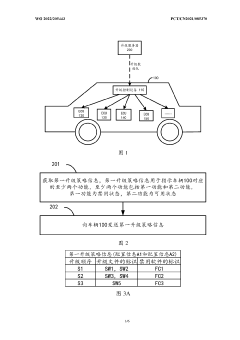

- By obtaining upgrade policy information, the vehicle is instructed to set certain functions to a disabled state during the upgrade process, while other functions remain available, and users can continue to use some functions.

Cooling System Optimization Strategies

The LT4 supercharged engine, while powerful in stock form, requires significant cooling system enhancements to withstand the extreme thermal loads encountered during track use. Track conditions generate substantially higher heat levels than street driving due to sustained high RPMs, increased boost pressure, and minimal airflow during low-speed corners. Effective cooling system optimization must address multiple heat sources simultaneously to maintain optimal engine performance and prevent thermal-induced failures.

Primary cooling system modifications should focus on radiator upgrades, implementing larger units with increased core thickness and fin density. Aluminum racing radiators with dual-pass designs offer superior heat dissipation characteristics compared to stock components. Supplementary oil coolers represent another critical upgrade path, as oil temperatures frequently exceed safe operating thresholds during extended track sessions. Remote-mounted oil coolers with dedicated airflow channels can maintain oil temperatures within the optimal 180-220°F range even under extreme conditions.

Intercooler efficiency becomes particularly crucial for the supercharged LT4 platform. Heat-exchanger upgrades featuring larger surface areas and more efficient core designs can significantly reduce intake air temperatures, preventing power-robbing heat soak during consecutive hot laps. Water-to-air intercooler systems with dedicated cooling circuits have demonstrated superior performance compared to traditional air-to-air designs in track environments, maintaining consistent charge temperatures throughout extended sessions.

Cooling system control strategies must also be optimized through upgraded thermostats, high-flow water pumps, and precision-controlled electric fans. Implementing dual-stage thermostats that open at lower temperatures (160-170°F) helps maintain more consistent engine operating temperatures. High-capacity water pumps increase coolant flow rates by 15-20%, while programmable fan controllers with temperature sensors at multiple engine locations ensure cooling activation occurs precisely when needed.

Heat extraction represents the final critical element in comprehensive cooling optimization. Hood extractors, functional side vents, and underbody airflow management systems create pressure differentials that actively pull hot air away from critical components. Computational fluid dynamics testing indicates that properly designed extraction systems can reduce underhood temperatures by 30-40°F during high-load operation, significantly extending component life and maintaining consistent power output.

Implementation of these cooling system optimizations must be approached holistically, as modifications to one system invariably affect others. Comprehensive testing under simulated track conditions, utilizing thermal imaging and data acquisition systems, remains essential to validate the effectiveness of any cooling system enhancement strategy for track-focused LT4 applications.

Emissions Compliance for Modified Track Engines

Emissions compliance represents a significant challenge when upgrading the LT4 engine for track use. Modern performance engines like the LT4 are designed with sophisticated emissions control systems that maintain environmental standards while delivering power. However, track modifications often conflict with these systems, creating regulatory and technical hurdles.

Track-focused engine modifications typically involve alterations to fuel delivery, exhaust systems, and engine control units (ECUs) that can compromise emissions compliance. The removal of catalytic converters, oxygen sensors, or modifications to exhaust gas recirculation (EGR) systems directly impacts the engine's emissions profile. These modifications, while performance-enhancing, often result in increased nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions that exceed legal thresholds.

The regulatory landscape for modified track engines varies significantly across regions. In the United States, the EPA's stance on competition vehicles has evolved, with the Recognizing the Protection of Motorsports Act (RPM Act) seeking to clarify the legality of converting street vehicles to dedicated competition use. However, vehicles must still comply with emissions standards when operated on public roads, creating a complex compliance scenario for dual-purpose vehicles.

Technical solutions for maintaining emissions compliance while enhancing track performance include adaptive ECU programming that can switch between track and street modes, maintaining different fuel maps and emissions control strategies based on usage context. Advanced catalytic converter technologies designed specifically for high-performance applications offer reduced back pressure while still providing emissions reduction capabilities.

Manufacturers and aftermarket suppliers have developed CARB (California Air Resources Board) compliant performance parts that maintain legal emissions levels while offering modest performance gains. These components represent a compromise solution for enthusiasts seeking both track capability and street legality.

For dedicated track vehicles, emissions compliance requirements may be less stringent, but owners must understand the legal implications of operating modified vehicles. Many track organizations now require emissions compliance documentation or restrict certain modifications to maintain environmental standards and community relations.

Future trends point toward electronically controlled valved exhaust systems that can maintain emissions compliance during street use while opening for maximum flow during track sessions. Additionally, emerging technologies like water-methanol injection systems offer potential for reducing emissions while improving performance through charge cooling and combustion efficiency.