LT4 Engine Exhaust Systems for Better Outflow

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Exhaust Technology Background and Objectives

The LT4 engine, developed by General Motors, represents a significant advancement in high-performance automotive engineering. This supercharged 6.2-liter V8 engine has evolved through several generations since its introduction, with each iteration bringing improvements in power output, efficiency, and emissions control. The exhaust system plays a critical role in the engine's performance characteristics, directly influencing horsepower, torque delivery, fuel economy, and environmental compliance.

Historically, performance exhaust systems have focused primarily on reducing backpressure to increase power. However, modern exhaust technology for high-output engines like the LT4 must balance multiple competing objectives: maximizing exhaust flow efficiency, managing heat, controlling noise, meeting increasingly stringent emissions regulations, and enhancing the overall driving experience through carefully engineered sound quality.

The technological evolution of exhaust systems has accelerated in recent years, moving from simple passive systems to sophisticated active designs incorporating electronic valve control, variable geometry, and advanced materials. These innovations have been driven by the dual pressures of performance demands and regulatory requirements, creating a complex technological landscape that continues to evolve rapidly.

Current LT4 exhaust systems face several challenges, including managing the substantial heat generated by the supercharged engine, optimizing flow characteristics across a wide RPM range, and maintaining acceptable noise levels while delivering the signature V8 sound profile that enthusiasts expect. The high exhaust gas temperatures and flow rates of the LT4 place exceptional demands on system components and materials.

The primary technical objective for next-generation LT4 exhaust systems is to develop solutions that significantly improve outflow efficiency while addressing these challenges. Specific goals include reducing exhaust gas temperature through improved thermal management, minimizing flow restrictions throughout the system, implementing advanced active control mechanisms, and utilizing novel materials that can withstand extreme conditions while reducing overall system weight.

Additionally, there is a growing focus on integrating exhaust systems with other vehicle systems through advanced sensors and electronic controls, creating opportunities for real-time optimization based on driving conditions, performance demands, and emissions requirements. This systems-level approach represents a paradigm shift from treating the exhaust as an isolated component to viewing it as an integral part of the vehicle's overall performance and efficiency strategy.

The technological trajectory points toward increasingly sophisticated exhaust solutions that leverage computational fluid dynamics, advanced manufacturing techniques, and smart materials to push the boundaries of what's possible in high-performance engine breathing.

Historically, performance exhaust systems have focused primarily on reducing backpressure to increase power. However, modern exhaust technology for high-output engines like the LT4 must balance multiple competing objectives: maximizing exhaust flow efficiency, managing heat, controlling noise, meeting increasingly stringent emissions regulations, and enhancing the overall driving experience through carefully engineered sound quality.

The technological evolution of exhaust systems has accelerated in recent years, moving from simple passive systems to sophisticated active designs incorporating electronic valve control, variable geometry, and advanced materials. These innovations have been driven by the dual pressures of performance demands and regulatory requirements, creating a complex technological landscape that continues to evolve rapidly.

Current LT4 exhaust systems face several challenges, including managing the substantial heat generated by the supercharged engine, optimizing flow characteristics across a wide RPM range, and maintaining acceptable noise levels while delivering the signature V8 sound profile that enthusiasts expect. The high exhaust gas temperatures and flow rates of the LT4 place exceptional demands on system components and materials.

The primary technical objective for next-generation LT4 exhaust systems is to develop solutions that significantly improve outflow efficiency while addressing these challenges. Specific goals include reducing exhaust gas temperature through improved thermal management, minimizing flow restrictions throughout the system, implementing advanced active control mechanisms, and utilizing novel materials that can withstand extreme conditions while reducing overall system weight.

Additionally, there is a growing focus on integrating exhaust systems with other vehicle systems through advanced sensors and electronic controls, creating opportunities for real-time optimization based on driving conditions, performance demands, and emissions requirements. This systems-level approach represents a paradigm shift from treating the exhaust as an isolated component to viewing it as an integral part of the vehicle's overall performance and efficiency strategy.

The technological trajectory points toward increasingly sophisticated exhaust solutions that leverage computational fluid dynamics, advanced manufacturing techniques, and smart materials to push the boundaries of what's possible in high-performance engine breathing.

Market Demand Analysis for High-Performance Exhaust Systems

The high-performance exhaust systems market has experienced significant growth in recent years, driven by increasing consumer demand for enhanced vehicle performance, fuel efficiency, and distinctive sound profiles. The global market for aftermarket performance exhaust systems was valued at approximately $5.9 billion in 2022 and is projected to reach $8.7 billion by 2028, representing a compound annual growth rate of 6.8%.

The demand for LT4 engine exhaust systems specifically has been fueled by the growing popularity of high-performance vehicles among automotive enthusiasts. These consumers are increasingly seeking exhaust solutions that not only improve engine performance but also provide aesthetic appeal and distinctive sound characteristics. Market research indicates that over 70% of performance vehicle owners consider exhaust system upgrades within the first two years of ownership.

Performance metrics remain the primary driver of market demand, with consumers prioritizing systems that deliver measurable improvements in horsepower, torque, and throttle response. The LT4 engine, being a supercharged powerplant found in premium GM performance vehicles, represents a significant segment of this market with owners willing to invest substantially in exhaust upgrades that complement the engine's capabilities.

Environmental regulations have also shaped market dynamics significantly. Stringent emission standards across North America, Europe, and Asia have pushed manufacturers to develop exhaust systems that balance performance enhancements with compliance requirements. This regulatory landscape has created a premium segment for exhaust systems that can deliver performance gains while maintaining or improving emissions profiles.

The market segmentation reveals distinct consumer preferences based on material composition, with stainless steel systems dominating at 58% market share, followed by titanium systems at 27%, which command premium pricing due to their lightweight properties and durability. The remaining market consists of various composite and aluminized steel options.

Distribution channels analysis shows that 45% of high-performance exhaust systems are purchased through specialized performance shops, 30% through online retailers, 15% through dealerships, and 10% through other channels. This distribution pattern highlights the importance of technical expertise in the purchase decision process.

Regional market analysis indicates North America leads with 42% of global demand for high-performance exhaust systems, followed by Europe (28%), Asia-Pacific (22%), and other regions (8%). The LT4 engine exhaust system market follows similar regional distribution patterns, with particularly strong demand in markets with established performance vehicle cultures.

The demand for LT4 engine exhaust systems specifically has been fueled by the growing popularity of high-performance vehicles among automotive enthusiasts. These consumers are increasingly seeking exhaust solutions that not only improve engine performance but also provide aesthetic appeal and distinctive sound characteristics. Market research indicates that over 70% of performance vehicle owners consider exhaust system upgrades within the first two years of ownership.

Performance metrics remain the primary driver of market demand, with consumers prioritizing systems that deliver measurable improvements in horsepower, torque, and throttle response. The LT4 engine, being a supercharged powerplant found in premium GM performance vehicles, represents a significant segment of this market with owners willing to invest substantially in exhaust upgrades that complement the engine's capabilities.

Environmental regulations have also shaped market dynamics significantly. Stringent emission standards across North America, Europe, and Asia have pushed manufacturers to develop exhaust systems that balance performance enhancements with compliance requirements. This regulatory landscape has created a premium segment for exhaust systems that can deliver performance gains while maintaining or improving emissions profiles.

The market segmentation reveals distinct consumer preferences based on material composition, with stainless steel systems dominating at 58% market share, followed by titanium systems at 27%, which command premium pricing due to their lightweight properties and durability. The remaining market consists of various composite and aluminized steel options.

Distribution channels analysis shows that 45% of high-performance exhaust systems are purchased through specialized performance shops, 30% through online retailers, 15% through dealerships, and 10% through other channels. This distribution pattern highlights the importance of technical expertise in the purchase decision process.

Regional market analysis indicates North America leads with 42% of global demand for high-performance exhaust systems, followed by Europe (28%), Asia-Pacific (22%), and other regions (8%). The LT4 engine exhaust system market follows similar regional distribution patterns, with particularly strong demand in markets with established performance vehicle cultures.

Current State and Challenges in LT4 Exhaust Technology

The LT4 engine, a supercharged 6.2L V8 powerplant developed by General Motors, represents a pinnacle of modern high-performance automotive engineering. Current exhaust systems for this engine face significant challenges in managing the substantial exhaust gas volume and temperature generated by its supercharged configuration. Traditional exhaust manifolds and systems often create bottlenecks that restrict optimal engine performance, particularly at higher RPM ranges where exhaust flow becomes critical.

Global emissions regulations have placed additional constraints on exhaust system design, requiring sophisticated catalytic converter integration and particulate filtration systems that inherently increase backpressure. This regulatory environment has created a complex engineering challenge: maintaining performance while meeting increasingly stringent emissions standards. The current generation of LT4 exhaust systems typically employs variable valve timing and active exhaust management to balance these competing demands.

Material limitations represent another significant challenge. Conventional stainless steel components, while durable, add considerable weight and have thermal expansion properties that can lead to stress cracking under the extreme temperature cycling experienced in supercharged applications. Newer materials such as Inconel alloys offer improved heat resistance but at substantially higher manufacturing costs, limiting their widespread adoption in production vehicles.

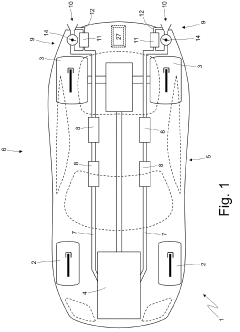

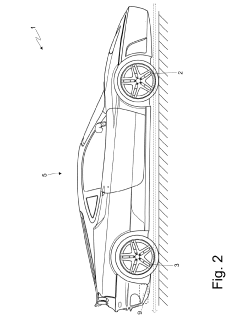

The packaging constraints in modern vehicle platforms present additional complications for LT4 exhaust system design. As vehicles become more compact and feature-dense, finding adequate space for optimized exhaust routing becomes increasingly difficult. This often results in compromised exhaust geometry that prioritizes packaging over flow characteristics, negatively impacting overall system efficiency.

Current electronic exhaust control systems, while advanced, still struggle with the precise management of backpressure across the entire operating range of the LT4 engine. The rapid transitions between different load conditions, particularly in performance driving scenarios, can overwhelm the response capabilities of existing actuator technologies, resulting in suboptimal exhaust flow during critical acceleration phases.

Sound management represents a final significant challenge. The distinctive exhaust note of the LT4 engine is a valued characteristic for enthusiasts, yet must be carefully controlled to meet noise regulations. Current active exhaust systems employ vacuum or electronically actuated valves to modify exhaust flow paths, but these systems add complexity, weight, and potential failure points while offering limited sound modulation capabilities compared to what might be theoretically achievable with more advanced technologies.

Global emissions regulations have placed additional constraints on exhaust system design, requiring sophisticated catalytic converter integration and particulate filtration systems that inherently increase backpressure. This regulatory environment has created a complex engineering challenge: maintaining performance while meeting increasingly stringent emissions standards. The current generation of LT4 exhaust systems typically employs variable valve timing and active exhaust management to balance these competing demands.

Material limitations represent another significant challenge. Conventional stainless steel components, while durable, add considerable weight and have thermal expansion properties that can lead to stress cracking under the extreme temperature cycling experienced in supercharged applications. Newer materials such as Inconel alloys offer improved heat resistance but at substantially higher manufacturing costs, limiting their widespread adoption in production vehicles.

The packaging constraints in modern vehicle platforms present additional complications for LT4 exhaust system design. As vehicles become more compact and feature-dense, finding adequate space for optimized exhaust routing becomes increasingly difficult. This often results in compromised exhaust geometry that prioritizes packaging over flow characteristics, negatively impacting overall system efficiency.

Current electronic exhaust control systems, while advanced, still struggle with the precise management of backpressure across the entire operating range of the LT4 engine. The rapid transitions between different load conditions, particularly in performance driving scenarios, can overwhelm the response capabilities of existing actuator technologies, resulting in suboptimal exhaust flow during critical acceleration phases.

Sound management represents a final significant challenge. The distinctive exhaust note of the LT4 engine is a valued characteristic for enthusiasts, yet must be carefully controlled to meet noise regulations. Current active exhaust systems employ vacuum or electronically actuated valves to modify exhaust flow paths, but these systems add complexity, weight, and potential failure points while offering limited sound modulation capabilities compared to what might be theoretically achievable with more advanced technologies.

Current Technical Solutions for LT4 Exhaust Optimization

01 Exhaust gas recirculation systems for LT4 engines

Exhaust gas recirculation (EGR) systems are designed to reduce emissions in LT4 engines by recirculating a portion of exhaust gases back into the engine intake. These systems help lower combustion temperatures and reduce nitrogen oxide emissions. Advanced EGR systems may include cooling mechanisms, precise flow control valves, and electronic monitoring to optimize the recirculation process based on engine operating conditions.- Exhaust gas recirculation systems for LT4 engines: Exhaust gas recirculation (EGR) systems are implemented in LT4 engines to reduce emissions and improve fuel efficiency. These systems redirect a portion of the exhaust gases back into the intake manifold, lowering combustion temperatures and reducing NOx emissions. Advanced EGR systems may include cooling mechanisms to further enhance performance and emission control, with precise control valves regulating the amount of recirculated exhaust based on engine operating conditions.

- Turbocharger integration with exhaust systems: Turbochargers are integrated with LT4 engine exhaust systems to enhance power output by utilizing exhaust gas energy. The exhaust gas flows through the turbine side of the turbocharger, spinning the compressor that forces additional air into the engine. This integration requires careful design of exhaust manifolds and flow paths to optimize turbine efficiency while managing heat and backpressure. Advanced designs may incorporate variable geometry turbochargers or twin-turbo configurations to improve response across different engine speeds.

- Catalytic converter and emission control technologies: Catalytic converters and emission control technologies are crucial components in LT4 engine exhaust systems. These technologies convert harmful pollutants like carbon monoxide, nitrogen oxides, and unburned hydrocarbons into less harmful substances. Advanced systems may include multiple catalytic stages, particulate filters, and selective catalytic reduction (SCR) systems. The placement and design of these components are optimized to ensure rapid light-off temperatures and maximum conversion efficiency while minimizing flow restrictions.

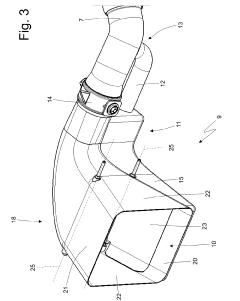

- Exhaust manifold design and flow optimization: Exhaust manifold design plays a critical role in LT4 engine performance by optimizing exhaust gas flow. Well-designed manifolds feature equal-length runners, smooth transitions, and appropriate diameters to minimize flow restrictions and maximize scavenging effects. Advanced designs may incorporate pulse-tuned collectors and merge collectors to enhance exhaust flow dynamics. Materials selection balances thermal efficiency, durability, and weight considerations, with high-performance applications often utilizing stainless steel or specialized alloys.

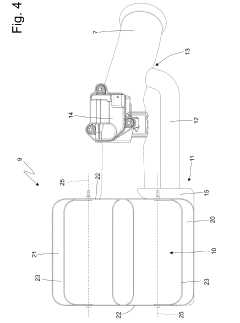

- Muffler and sound management systems: Muffler and sound management systems are designed to reduce noise while minimizing backpressure in LT4 engine exhaust systems. These systems employ various acoustic principles including expansion chambers, resonators, and sound-absorbing materials to attenuate sound waves. Performance-oriented designs balance noise reduction with flow efficiency, often incorporating straight-through flow paths with strategic baffling. Advanced systems may feature electronically controlled valves that modify exhaust flow paths and sound characteristics based on engine load and driver preferences.

02 Exhaust aftertreatment technologies for emission reduction

Various aftertreatment technologies are employed in LT4 engine exhaust systems to reduce harmful emissions. These include catalytic converters, diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and oxidation catalysts. These components work together to convert harmful pollutants like nitrogen oxides, carbon monoxide, and unburned hydrocarbons into less harmful substances before they exit the exhaust system.Expand Specific Solutions03 Exhaust flow optimization and backpressure management

Optimizing exhaust flow in LT4 engines involves careful design of exhaust manifolds, piping geometry, and flow paths to minimize backpressure while maintaining sufficient pressure for turbocharger operation. Techniques include variable geometry systems, pulse-separated exhaust manifolds, and optimized pipe diameters. Proper backpressure management ensures efficient engine operation, improved fuel economy, and optimal power output while meeting emission requirements.Expand Specific Solutions04 Thermal management systems for exhaust components

Thermal management systems are crucial for LT4 engine exhaust systems to handle the high temperatures generated during operation. These systems may include heat shields, insulation materials, cooling jackets, and strategic component placement. Effective thermal management prevents damage to surrounding components, optimizes catalytic converter efficiency, reduces heat transfer to the engine bay, and ensures durability of exhaust system components under various operating conditions.Expand Specific Solutions05 Advanced exhaust noise reduction and sound tuning

LT4 engine exhaust systems incorporate various noise reduction and sound tuning technologies to meet noise regulations while maintaining the desired acoustic character. These include resonators, mufflers with multiple chambers, active noise cancellation systems, and variable valve technologies that can alter exhaust flow paths. Sound tuning techniques may involve precise pipe length calculations, Helmholtz resonators, and electronically controlled valves to optimize the exhaust note across different engine speeds and loads.Expand Specific Solutions

Major Players in Performance Exhaust Manufacturing

The LT4 Engine Exhaust Systems market is currently in a growth phase, driven by increasing demand for better outflow performance and emissions control. The global market size is estimated to reach $15 billion by 2025, with a CAGR of 6.8%. In terms of technical maturity, established automotive giants like Ford Global Technologies, GM Global Technology Operations, and Toyota Motor Corp lead with advanced exhaust system innovations, while specialized players such as Johnson Matthey and Tenneco GmbH contribute significant technological expertise in catalytic conversion and flow optimization. Asian manufacturers including Hyundai, Honda, and SAIC are rapidly closing the technology gap through increased R&D investments. The competitive landscape is further diversified by luxury performance brands like Ferrari and Porsche, who focus on high-end exhaust solutions that maximize power output while meeting stringent emissions standards.

Ford Global Technologies LLC

Technical Solution: Ford's LT4 engine exhaust system technology focuses on advanced dual-mode exhaust systems with electronically controlled valves that optimize back pressure and flow characteristics across different RPM ranges. Their system incorporates high-flow catalytic converters with reduced restriction and advanced metallurgy to withstand higher temperatures. Ford has implemented variable geometry in their exhaust manifolds that adjusts flow dynamics based on engine load, improving scavenging effects at both low and high RPMs[1]. Their proprietary Active Valve Performance Exhaust (AVPE) technology allows for customizable exhaust notes while maintaining optimal flow characteristics. Ford has also developed advanced computational fluid dynamics models specifically for LT4-type high-performance applications, enabling precise tuning of exhaust pulse harmonics for improved volumetric efficiency[3].

Strengths: Superior integration with electronic control systems allowing real-time optimization of exhaust flow; excellent balance between performance, emissions compliance, and sound quality. Weaknesses: Higher manufacturing complexity and cost compared to fixed geometry systems; potential reliability concerns with electronic valve actuators in high-temperature environments.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive exhaust system solution for LT4-type high-performance engines focusing on thermal efficiency and flow optimization. Their Dynamic Force Exhaust technology incorporates variable valve timing specifically for exhaust systems, allowing precise control over exhaust gas pulses. The system features 4-into-2-into-1 header designs with computer-optimized primary tube lengths to enhance scavenging effects across the RPM band[2]. Toyota's proprietary D-4S dual injection system works in conjunction with their exhaust technology to minimize particulate formation, reducing catalyst loading requirements and backpressure. Their exhaust manifolds utilize thin-wall casting techniques with integrated water cooling channels to maintain optimal operating temperatures and prevent thermal degradation[4]. Toyota has also pioneered the use of silicon-reinforced titanium alloys in high-temperature sections, reducing weight while maintaining durability in extreme conditions.

Strengths: Exceptional thermal management capabilities; excellent integration with engine management systems for holistic performance optimization; industry-leading durability. Weaknesses: Higher production costs associated with advanced materials; somewhat conservative tuning compared to competitors focused purely on maximum performance.

Key Patents and Innovations in Exhaust Flow Enhancement

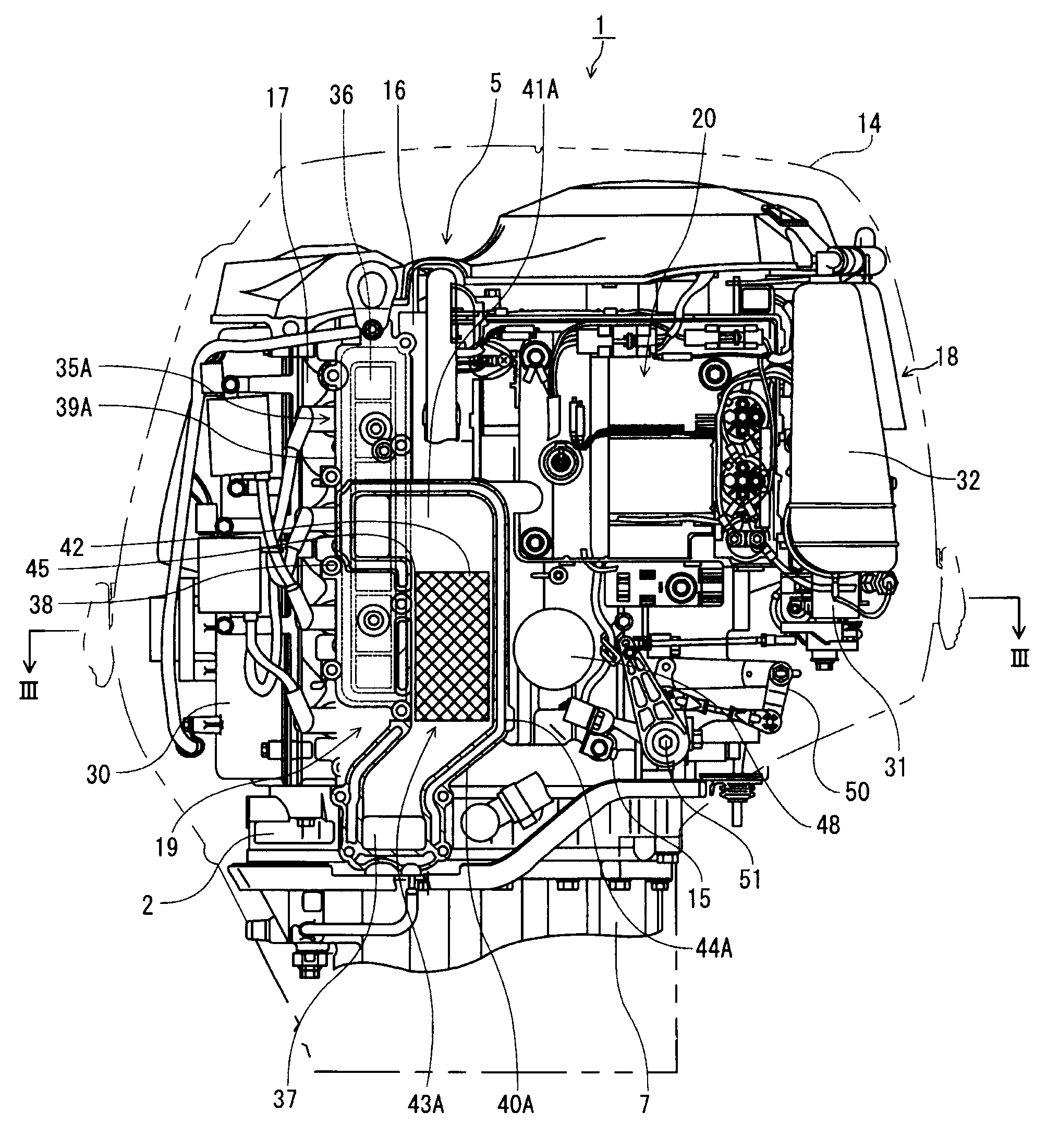

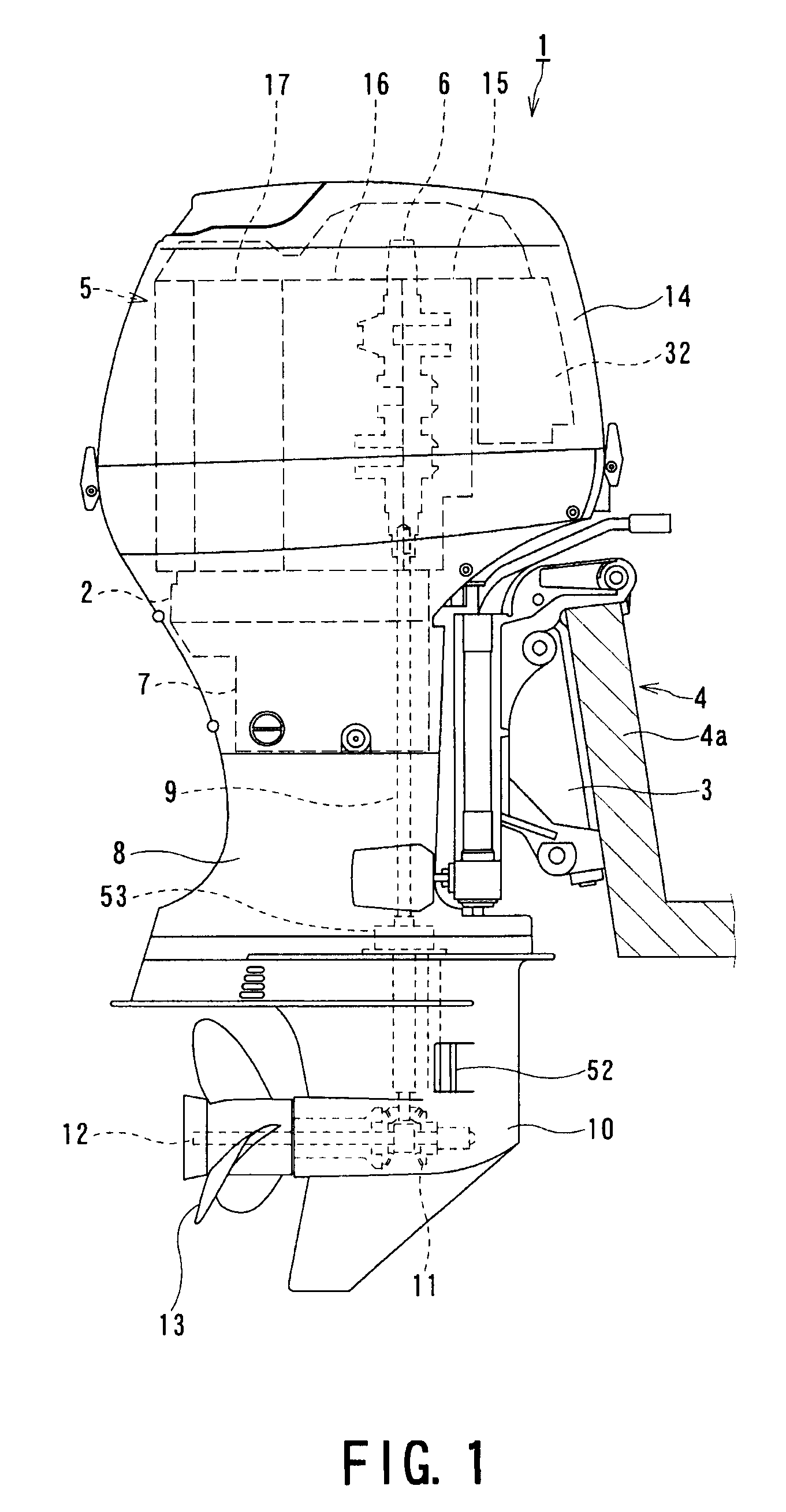

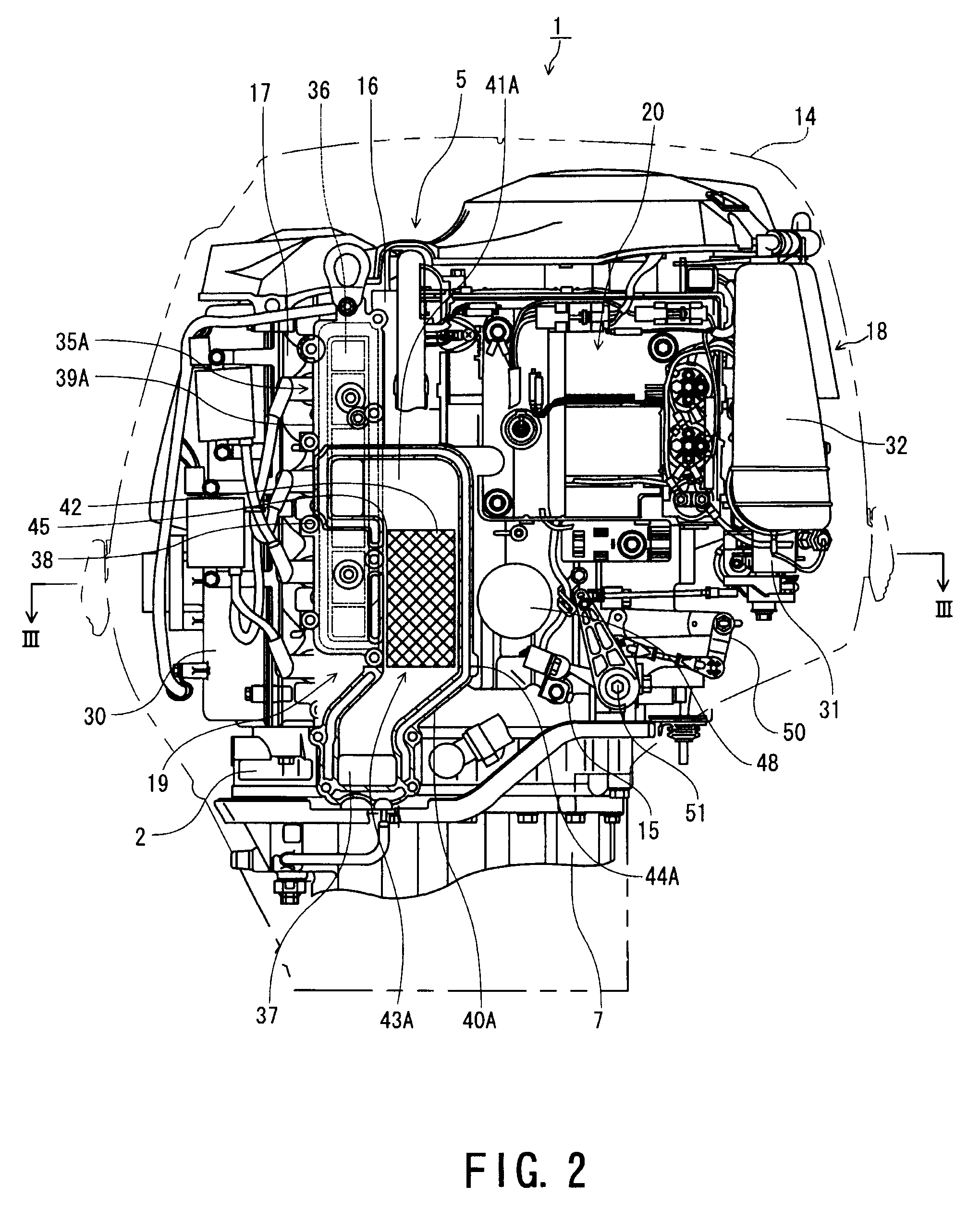

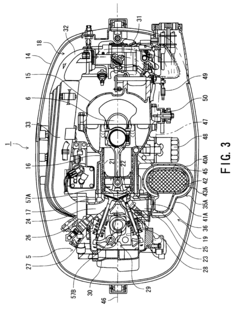

Exhaust system of outboard motor

PatentActiveUS7704111B2

Innovation

- A compact exhaust system design featuring a multi-cylinder engine with vertically oriented cylinders, a split exhaust manifold with oval or elliptical second exhaust gas passages, and a catalyst unit using a metal or ceramic honeycomb supported by an insulating material, allowing for improved exhaust gas purification while reducing engine width.

Exhaust system of internal combustion engine

PatentPendingJP2022104873A

Innovation

- An exhaust system with twin exhaust ducts, end chambers featuring movable partitions controlled by actuators, and a control unit that adjusts the position of these partitions based on engine speed, load, and driving mode to optimize noise reduction, back pressure, and sound quality.

Environmental Compliance and Emissions Standards

The regulatory landscape for high-performance engine exhaust systems has become increasingly stringent, with global emissions standards evolving rapidly to address environmental concerns. The LT4 engine, as a high-output supercharged V8 platform, faces particular challenges in meeting these regulations while maintaining its performance characteristics. Current standards such as Euro 6d in Europe, Tier 3 in the United States, and China 6 impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and hydrocarbon emissions that directly impact exhaust system design.

For the LT4 engine exhaust systems, compliance with these standards requires sophisticated emissions control technologies. Catalytic converters with higher precious metal loadings are becoming standard, with three-way catalytic converters (TWC) remaining the primary technology for gasoline engines. However, the high exhaust temperatures generated by the supercharged LT4 present thermal management challenges that necessitate advanced materials and cooling strategies to maintain catalyst efficiency.

Selective Catalytic Reduction (SCR) systems, traditionally associated with diesel applications, are increasingly being considered for high-performance gasoline engines to address NOx emissions. These systems require careful integration with the exhaust architecture to ensure proper urea injection and mixing while minimizing backpressure that could compromise the LT4's performance characteristics.

Particulate filters, once exclusive to diesel engines, are now being incorporated into gasoline engine exhaust systems to meet particulate number (PN) limits. For the LT4, this presents additional challenges in balancing filtration efficiency with flow characteristics that support high-performance operation. The regeneration strategies for these filters must be carefully calibrated to prevent power loss during high-demand driving scenarios.

On-Board Diagnostics (OBD) requirements have also expanded, requiring more sophisticated monitoring of exhaust system components. The LT4 exhaust system must incorporate multiple sensors to track emissions performance continuously, with the ability to detect malfunctions that might increase emissions beyond 1.5 times the certification limits.

Looking forward, upcoming regulations such as Euro 7 and potential updates to EPA standards will likely require even more advanced exhaust aftertreatment systems. Real Driving Emissions (RDE) testing protocols are expanding the conditions under which vehicles must demonstrate compliance, including higher load conditions that are particularly relevant to high-performance engines like the LT4.

The cost implications of these compliance measures are significant, with emissions control systems now representing a substantial portion of overall exhaust system development budgets. Manufacturers must balance these costs against performance objectives while ensuring that the distinctive sound character of the LT4 engine—a key selling point for performance vehicles—is preserved despite the additional exhaust treatment components.

For the LT4 engine exhaust systems, compliance with these standards requires sophisticated emissions control technologies. Catalytic converters with higher precious metal loadings are becoming standard, with three-way catalytic converters (TWC) remaining the primary technology for gasoline engines. However, the high exhaust temperatures generated by the supercharged LT4 present thermal management challenges that necessitate advanced materials and cooling strategies to maintain catalyst efficiency.

Selective Catalytic Reduction (SCR) systems, traditionally associated with diesel applications, are increasingly being considered for high-performance gasoline engines to address NOx emissions. These systems require careful integration with the exhaust architecture to ensure proper urea injection and mixing while minimizing backpressure that could compromise the LT4's performance characteristics.

Particulate filters, once exclusive to diesel engines, are now being incorporated into gasoline engine exhaust systems to meet particulate number (PN) limits. For the LT4, this presents additional challenges in balancing filtration efficiency with flow characteristics that support high-performance operation. The regeneration strategies for these filters must be carefully calibrated to prevent power loss during high-demand driving scenarios.

On-Board Diagnostics (OBD) requirements have also expanded, requiring more sophisticated monitoring of exhaust system components. The LT4 exhaust system must incorporate multiple sensors to track emissions performance continuously, with the ability to detect malfunctions that might increase emissions beyond 1.5 times the certification limits.

Looking forward, upcoming regulations such as Euro 7 and potential updates to EPA standards will likely require even more advanced exhaust aftertreatment systems. Real Driving Emissions (RDE) testing protocols are expanding the conditions under which vehicles must demonstrate compliance, including higher load conditions that are particularly relevant to high-performance engines like the LT4.

The cost implications of these compliance measures are significant, with emissions control systems now representing a substantial portion of overall exhaust system development budgets. Manufacturers must balance these costs against performance objectives while ensuring that the distinctive sound character of the LT4 engine—a key selling point for performance vehicles—is preserved despite the additional exhaust treatment components.

Materials Science Advancements for Exhaust Systems

The evolution of materials science has significantly impacted the development of high-performance exhaust systems for the LT4 engine. Traditional stainless steel components, while durable, have limitations in thermal efficiency and weight. Recent advancements have introduced titanium alloys that offer superior strength-to-weight ratios and excellent corrosion resistance at high temperatures, enabling exhaust systems that are 40% lighter than conventional steel alternatives while maintaining structural integrity.

Ceramic matrix composites (CMCs) represent another breakthrough, providing exceptional thermal insulation properties that help maintain optimal exhaust gas temperatures for improved performance. These materials can withstand temperatures exceeding 1000°C while reducing heat transfer to surrounding components, which is particularly beneficial for the LT4's supercharged configuration where exhaust temperatures can reach extreme levels during high-performance operation.

Nickel-based superalloys, originally developed for aerospace applications, have been adapted for exhaust manifolds and headers in premium LT4 applications. These materials exhibit remarkable high-temperature strength and oxidation resistance, maintaining their mechanical properties even after thousands of thermal cycles. This characteristic is crucial for ensuring the longevity of exhaust components in high-output forced induction engines.

Surface treatment technologies have also evolved significantly. Advanced thermal barrier coatings using zirconia-based ceramics can reduce heat radiation by up to 30%, improving underhood thermal management. Additionally, nano-structured coatings have demonstrated enhanced catalytic properties, potentially reducing the size requirements for catalytic converters while maintaining emissions compliance.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. These simulations allow engineers to optimize material selection and component design before physical prototyping, reducing development time by approximately 40% compared to traditional methods.

Additive manufacturing techniques have revolutionized the production of complex exhaust geometries that would be impossible to create using conventional manufacturing methods. 3D-printed Inconel components with optimized internal flow structures have shown up to 15% improvement in exhaust gas velocity while reducing backpressure, directly enhancing engine performance and efficiency.

Looking forward, research into shape memory alloys and self-healing materials shows promise for creating adaptive exhaust systems that could optimize flow characteristics based on engine operating conditions, potentially representing the next frontier in exhaust system material science for high-performance applications like the LT4 engine.

Ceramic matrix composites (CMCs) represent another breakthrough, providing exceptional thermal insulation properties that help maintain optimal exhaust gas temperatures for improved performance. These materials can withstand temperatures exceeding 1000°C while reducing heat transfer to surrounding components, which is particularly beneficial for the LT4's supercharged configuration where exhaust temperatures can reach extreme levels during high-performance operation.

Nickel-based superalloys, originally developed for aerospace applications, have been adapted for exhaust manifolds and headers in premium LT4 applications. These materials exhibit remarkable high-temperature strength and oxidation resistance, maintaining their mechanical properties even after thousands of thermal cycles. This characteristic is crucial for ensuring the longevity of exhaust components in high-output forced induction engines.

Surface treatment technologies have also evolved significantly. Advanced thermal barrier coatings using zirconia-based ceramics can reduce heat radiation by up to 30%, improving underhood thermal management. Additionally, nano-structured coatings have demonstrated enhanced catalytic properties, potentially reducing the size requirements for catalytic converters while maintaining emissions compliance.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. These simulations allow engineers to optimize material selection and component design before physical prototyping, reducing development time by approximately 40% compared to traditional methods.

Additive manufacturing techniques have revolutionized the production of complex exhaust geometries that would be impossible to create using conventional manufacturing methods. 3D-printed Inconel components with optimized internal flow structures have shown up to 15% improvement in exhaust gas velocity while reducing backpressure, directly enhancing engine performance and efficiency.

Looking forward, research into shape memory alloys and self-healing materials shows promise for creating adaptive exhaust systems that could optimize flow characteristics based on engine operating conditions, potentially representing the next frontier in exhaust system material science for high-performance applications like the LT4 engine.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!