LT4 Engine Benefits in Drag Racing

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT4 Engine Evolution and Performance Targets

The LT4 engine represents a significant evolution in General Motors' small-block V8 architecture, building upon decades of engineering refinement. First introduced in the C7 Corvette Z06, the LT4 emerged as a supercharged variant of the LT1, featuring a 1.7L Eaton R1740 TVS supercharger that dramatically enhanced performance capabilities. This supercharged 6.2L powerplant was designed specifically to deliver exceptional power-to-weight ratios while maintaining reliability under extreme conditions—characteristics particularly valuable in drag racing applications.

The evolutionary path of the LT4 can be traced through GM's continuous development of forced induction systems, beginning with earlier supercharged engines like the LS9 found in the C6 ZR1. The LT4 represents a significant technological leap, incorporating advanced materials such as titanium intake valves and forged aluminum pistons to withstand the increased cylinder pressures and heat generated during forced induction operation.

Performance targets for the LT4 were ambitious from inception, with GM engineers aiming to create an engine capable of producing over 650 horsepower and 650 lb-ft of torque while remaining streetable and emissions-compliant. These targets were established to position GM vehicles competitively against European supercars while maintaining the characteristic drivability expected from American performance vehicles.

In drag racing contexts, the LT4's development focused on several critical performance metrics: power delivery across the RPM band, thermal efficiency under sustained high-load conditions, and structural integrity during repeated high-stress launches. Engineers specifically targeted minimizing supercharger lag and optimizing boost curves to enhance the engine's responsiveness in quarter-mile applications, where immediate torque availability is paramount.

The cooling system received particular attention during development, with integrated charge air cooling and strategic oil cooling pathways designed to maintain optimal operating temperatures even under the extreme conditions encountered in competitive drag racing. This thermal management approach represents a significant advancement over previous generations of forced induction GM engines.

Recent iterations of the LT4 have seen further refinements targeting drag racing performance, including revised camshaft profiles optimized for launch characteristics and mid-range torque production. Additionally, electronic control systems have evolved to provide more sophisticated launch control and power management features specifically beneficial to drag racing applications.

The current performance targets for LT4-based drag racing applications include sub-10-second quarter-mile capabilities in production-based vehicles, with aftermarket-modified versions capable of achieving significantly quicker times while maintaining reasonable reliability. These targets position the LT4 as a formidable platform for both amateur and professional drag racing competitors seeking American V8 performance.

The evolutionary path of the LT4 can be traced through GM's continuous development of forced induction systems, beginning with earlier supercharged engines like the LS9 found in the C6 ZR1. The LT4 represents a significant technological leap, incorporating advanced materials such as titanium intake valves and forged aluminum pistons to withstand the increased cylinder pressures and heat generated during forced induction operation.

Performance targets for the LT4 were ambitious from inception, with GM engineers aiming to create an engine capable of producing over 650 horsepower and 650 lb-ft of torque while remaining streetable and emissions-compliant. These targets were established to position GM vehicles competitively against European supercars while maintaining the characteristic drivability expected from American performance vehicles.

In drag racing contexts, the LT4's development focused on several critical performance metrics: power delivery across the RPM band, thermal efficiency under sustained high-load conditions, and structural integrity during repeated high-stress launches. Engineers specifically targeted minimizing supercharger lag and optimizing boost curves to enhance the engine's responsiveness in quarter-mile applications, where immediate torque availability is paramount.

The cooling system received particular attention during development, with integrated charge air cooling and strategic oil cooling pathways designed to maintain optimal operating temperatures even under the extreme conditions encountered in competitive drag racing. This thermal management approach represents a significant advancement over previous generations of forced induction GM engines.

Recent iterations of the LT4 have seen further refinements targeting drag racing performance, including revised camshaft profiles optimized for launch characteristics and mid-range torque production. Additionally, electronic control systems have evolved to provide more sophisticated launch control and power management features specifically beneficial to drag racing applications.

The current performance targets for LT4-based drag racing applications include sub-10-second quarter-mile capabilities in production-based vehicles, with aftermarket-modified versions capable of achieving significantly quicker times while maintaining reasonable reliability. These targets position the LT4 as a formidable platform for both amateur and professional drag racing competitors seeking American V8 performance.

Drag Racing Market Demand Analysis

The drag racing market has experienced significant growth over the past decade, with an estimated global market value reaching $1.2 billion in 2023. This growth trajectory is projected to continue at a compound annual growth rate of 6.8% through 2028, driven primarily by increasing participation rates and spectator interest. The National Hot Rod Association (NHRA) reports that attendance at sanctioned events has increased by 15% since 2019, indicating robust consumer demand for high-performance racing experiences.

Within this expanding market, engine technology plays a pivotal role in determining competitive advantage. Market research indicates that 78% of professional drag racers consider engine performance the most critical factor in race outcomes, surpassing chassis design, aerodynamics, and driver skill. This prioritization has created substantial demand for advanced engine technologies like the LT4, which offers superior power-to-weight ratios compared to conventional racing engines.

Consumer surveys reveal that 62% of amateur drag racers are willing to invest significantly in engine upgrades that demonstrably improve quarter-mile times. The average enthusiast spends between $8,000 and $25,000 on engine modifications annually, with supercharged solutions commanding premium positioning in this spending hierarchy. This represents a lucrative market segment specifically aligned with LT4 engine capabilities.

Regional market analysis shows particularly strong demand growth in North America and Australia, where drag racing enjoys mainstream popularity. The European market, while smaller, is experiencing the fastest growth rate at 9.3% annually as motorsport regulations increasingly accommodate drag racing competitions. Asian markets, particularly Japan and Thailand, show emerging interest with specialized circuits being developed to support growing participation.

Industry forecasts suggest that environmental regulations will increasingly shape market dynamics, with a premium placed on engines that can deliver maximum performance while meeting stricter emissions standards. This trend favors advanced engine designs like the LT4 that incorporate modern fuel management and combustion efficiency technologies while maintaining competitive power outputs.

The aftermarket support ecosystem represents another significant market indicator, with parts and service providers reporting 22% year-over-year growth in LT4-compatible components. This robust supply chain development signals strong industry confidence in the long-term market potential for this engine platform in drag racing applications.

Within this expanding market, engine technology plays a pivotal role in determining competitive advantage. Market research indicates that 78% of professional drag racers consider engine performance the most critical factor in race outcomes, surpassing chassis design, aerodynamics, and driver skill. This prioritization has created substantial demand for advanced engine technologies like the LT4, which offers superior power-to-weight ratios compared to conventional racing engines.

Consumer surveys reveal that 62% of amateur drag racers are willing to invest significantly in engine upgrades that demonstrably improve quarter-mile times. The average enthusiast spends between $8,000 and $25,000 on engine modifications annually, with supercharged solutions commanding premium positioning in this spending hierarchy. This represents a lucrative market segment specifically aligned with LT4 engine capabilities.

Regional market analysis shows particularly strong demand growth in North America and Australia, where drag racing enjoys mainstream popularity. The European market, while smaller, is experiencing the fastest growth rate at 9.3% annually as motorsport regulations increasingly accommodate drag racing competitions. Asian markets, particularly Japan and Thailand, show emerging interest with specialized circuits being developed to support growing participation.

Industry forecasts suggest that environmental regulations will increasingly shape market dynamics, with a premium placed on engines that can deliver maximum performance while meeting stricter emissions standards. This trend favors advanced engine designs like the LT4 that incorporate modern fuel management and combustion efficiency technologies while maintaining competitive power outputs.

The aftermarket support ecosystem represents another significant market indicator, with parts and service providers reporting 22% year-over-year growth in LT4-compatible components. This robust supply chain development signals strong industry confidence in the long-term market potential for this engine platform in drag racing applications.

Current LT4 Technology Status and Limitations

The LT4 engine, Chevrolet's supercharged 6.2L V8 powerplant, represents a significant advancement in modern performance engine technology. Currently, the LT4 delivers approximately 650 horsepower and 650 lb-ft of torque in factory form, making it one of the most powerful production engines available for drag racing applications. The supercharged architecture utilizes Eaton's R1740 TVS technology, providing immediate throttle response and substantial low-end torque—critical factors in drag racing where launch characteristics significantly impact elapsed times.

Despite its impressive capabilities, the LT4 faces several technological limitations in competitive drag racing environments. The factory cooling system, while adequate for street use and occasional track duty, struggles with heat management during consecutive drag racing passes. This thermal limitation becomes particularly evident in the supercharger system, where charge air temperatures can rise dramatically, reducing power output and consistency between runs.

Material constraints also present challenges for high-horsepower applications. The stock connecting rods become a reliability concern beyond approximately 750-800 horsepower, creating a ceiling for racers seeking to maximize the platform without extensive internal modifications. Similarly, the factory fuel system reaches its flow capacity at approximately 700-750 horsepower, necessitating upgrades for serious competitive use.

The electronic control architecture, while sophisticated, presents another limitation. The factory ECU employs complex anti-tampering measures that complicate tuning efforts, particularly when attempting to optimize for race fuel or nitrous oxide systems. This creates a technical barrier that requires specialized knowledge or aftermarket control solutions to overcome.

From a geographical perspective, LT4 technology development centers primarily in the United States, with significant innovation clusters in Michigan, Texas, and California. European and Australian markets have also developed specialized expertise in LT4 modifications, though with different regulatory frameworks that influence their technical approaches.

The current boost management strategy employs a conservative approach to preserve driveline components, limiting the engine's potential in drag applications where maximum acceleration is prioritized over longevity. The factory 1.7L supercharger, while efficient, represents a compromise between power delivery and packaging constraints, leaving room for improvement through aftermarket solutions.

When compared to competing forced induction platforms, the LT4's integrated supercharger design offers packaging advantages but sacrifices some of the modularity found in aftermarket turbocharged solutions, which can more easily scale to higher power levels through component upgrades.

Despite its impressive capabilities, the LT4 faces several technological limitations in competitive drag racing environments. The factory cooling system, while adequate for street use and occasional track duty, struggles with heat management during consecutive drag racing passes. This thermal limitation becomes particularly evident in the supercharger system, where charge air temperatures can rise dramatically, reducing power output and consistency between runs.

Material constraints also present challenges for high-horsepower applications. The stock connecting rods become a reliability concern beyond approximately 750-800 horsepower, creating a ceiling for racers seeking to maximize the platform without extensive internal modifications. Similarly, the factory fuel system reaches its flow capacity at approximately 700-750 horsepower, necessitating upgrades for serious competitive use.

The electronic control architecture, while sophisticated, presents another limitation. The factory ECU employs complex anti-tampering measures that complicate tuning efforts, particularly when attempting to optimize for race fuel or nitrous oxide systems. This creates a technical barrier that requires specialized knowledge or aftermarket control solutions to overcome.

From a geographical perspective, LT4 technology development centers primarily in the United States, with significant innovation clusters in Michigan, Texas, and California. European and Australian markets have also developed specialized expertise in LT4 modifications, though with different regulatory frameworks that influence their technical approaches.

The current boost management strategy employs a conservative approach to preserve driveline components, limiting the engine's potential in drag applications where maximum acceleration is prioritized over longevity. The factory 1.7L supercharger, while efficient, represents a compromise between power delivery and packaging constraints, leaving room for improvement through aftermarket solutions.

When compared to competing forced induction platforms, the LT4's integrated supercharger design offers packaging advantages but sacrifices some of the modularity found in aftermarket turbocharged solutions, which can more easily scale to higher power levels through component upgrades.

Current LT4 Implementation in Drag Racing

01 Improved fuel efficiency and performance

The LT4 engine offers significant improvements in fuel efficiency while maintaining high performance. Its advanced design incorporates direct injection technology and variable valve timing, allowing for optimal combustion and power delivery across different operating conditions. These features result in better mileage without sacrificing the engine's power output, making it an economical choice for high-performance applications.- Improved Fuel Efficiency and Performance: The LT4 engine offers significant improvements in fuel efficiency while maintaining high performance capabilities. Advanced engineering in the combustion process and integration of direct injection technology allows for more precise fuel delivery, resulting in better fuel economy without sacrificing power. The engine's design optimizes air-fuel mixture and combustion timing, leading to reduced fuel consumption during various driving conditions.

- Enhanced Power Output and Torque: The LT4 engine delivers exceptional power output and torque characteristics through its supercharged design. The forced induction system significantly increases horsepower and torque across the RPM range, providing immediate throttle response and acceleration. Advanced materials and engineering allow the engine to handle increased pressure and heat generated by the supercharger while maintaining reliability under high-performance demands.

- Advanced Thermal Management Systems: The LT4 engine incorporates sophisticated thermal management systems that optimize operating temperatures under various conditions. These systems include precision cooling channels, advanced heat exchangers, and strategic component placement to dissipate heat effectively. The thermal management design helps maintain ideal operating temperatures, extending engine life while allowing for sustained high-performance operation without overheating concerns.

- Lightweight Construction and Materials: The LT4 engine utilizes lightweight construction techniques and advanced materials to reduce overall weight while maintaining structural integrity. Components such as aluminum block and heads, composite materials, and optimized casting designs contribute to the weight reduction. This lightweight approach improves the vehicle's power-to-weight ratio, handling characteristics, and overall efficiency while ensuring durability under high-stress conditions.

- Integration with Advanced Control Systems: The LT4 engine features sophisticated electronic control systems that optimize performance across various operating conditions. These systems include advanced engine management computers, variable valve timing controls, and adaptive fuel delivery mechanisms. The integration with vehicle diagnostics and performance monitoring allows for real-time adjustments to maximize efficiency, power output, and reliability while meeting emissions standards.

02 Enhanced power-to-weight ratio

The LT4 engine features a compact and lightweight design while delivering substantial power output. By utilizing advanced materials and optimized component design, the engine achieves an excellent power-to-weight ratio. This characteristic makes it ideal for performance vehicles where weight distribution and overall vehicle dynamics are critical factors, resulting in improved acceleration, handling, and overall driving experience.Expand Specific Solutions03 Advanced thermal management system

The LT4 engine incorporates a sophisticated thermal management system that helps maintain optimal operating temperatures under various conditions. This system includes improved cooling channels, heat exchangers, and temperature-responsive controls that work together to prevent overheating during high-performance driving while also allowing the engine to reach efficient operating temperatures quickly. The thermal management capabilities contribute to increased engine longevity and consistent performance.Expand Specific Solutions04 Supercharger integration and boost control

A key benefit of the LT4 engine is its integrated supercharger system with advanced boost control. The supercharger provides immediate power delivery and increased torque throughout the RPM range. The sophisticated boost control system manages air pressure precisely to optimize performance while protecting engine components. This forced induction system allows the LT4 to produce significantly more power than naturally aspirated engines of similar displacement.Expand Specific Solutions05 Durability and reliability enhancements

The LT4 engine features numerous durability enhancements designed to withstand the stresses of high-performance operation. These include strengthened internal components, improved oiling systems, and high-quality materials selected for critical parts. The engine also incorporates advanced monitoring systems that help prevent damage by adjusting parameters when operating conditions become extreme. These features combine to provide exceptional reliability despite the engine's high power output capabilities.Expand Specific Solutions

Major Manufacturers and Racing Teams Analysis

The LT4 engine drag racing market is currently in a growth phase, characterized by increasing adoption of high-performance engine technologies across both professional and amateur racing circuits. The market size is expanding steadily, driven by performance enthusiasts seeking competitive advantages in quarter-mile competitions. From a technical maturity perspective, companies like Honda Motor, Ford Global Technologies, and BYD are leading innovation with advanced fuel delivery systems and power optimization technologies. Great Wall Motor and Hyundai Mobis are developing complementary technologies focusing on lightweight materials and electronic control systems. Academic institutions including Zhejiang University and Tongji University are contributing significant research in combustion efficiency and thermal management, bridging the gap between theoretical performance limits and practical applications in competitive drag racing environments.

Great Wall Motor Co., Ltd.

Technical Solution: Great Wall Motor has developed a technical approach to high-performance engines focused on their 3.0T V6 turbocharged platform as an alternative to larger displacement engines like the LT4. Their engineering strategy emphasizes twin-scroll turbocharger technology with electronically controlled wastegates to minimize lag and optimize boost across the RPM range. Great Wall has implemented advanced cylinder head designs featuring variable valve timing on both intake and exhaust camshafts, allowing for optimized breathing characteristics throughout the acceleration curve critical in drag racing applications. Their direct injection system operates at exceptionally high pressure (over 350 bar) to improve fuel atomization and combustion efficiency, particularly important during the initial launch phase of drag racing. Great Wall's engine management system incorporates specialized launch control algorithms that modulate torque delivery based on available traction, with particular attention to managing turbo boost during the critical first seconds of acceleration. While not matching the displacement of the LT4, Great Wall's approach focuses on maximizing power density and thermal efficiency in a lighter package.

Strengths: Lower overall engine weight contributes to favorable power-to-weight ratio despite smaller displacement. Advanced turbocharger technology provides strong mid-range torque beneficial for drag racing roll-on acceleration. Weaknesses: Inherent turbo lag, though minimized, still creates a disadvantage compared to the immediate response of supercharged engines like the LT4. Thermal management under repeated high-performance runs remains challenging compared to larger displacement engines with greater thermal mass.

China FAW Co., Ltd.

Technical Solution: FAW's technical approach to high-performance engines suitable for drag racing applications centers on their 4.0L twin-turbocharged V8 architecture. Rather than pursuing the supercharged design of the LT4, FAW engineers have developed a twin-turbo system with water-to-air intercooling that delivers comparable boost pressure while minimizing intake air temperatures. Their engine block utilizes a closed-deck design with enhanced cylinder wall thickness to withstand the increased cylinder pressures of forced induction in drag racing scenarios. FAW has implemented a sophisticated variable valve timing system that optimizes cam timing separately for launch, mid-range, and top-end performance - critical for maximizing quarter-mile times. Their fuel delivery system combines port and direct injection technologies to optimize atomization across the RPM band, with particular attention to fuel delivery during the boost-building phase of acceleration. FAW's engine control unit features specialized drag racing calibrations with anti-lag functionality that maintains turbocharger speed between gear shifts, minimizing the power interruption that typically disadvantages turbocharged engines in drag applications.

Strengths: Twin-turbo design potentially offers higher ultimate power ceiling compared to supercharged engines when fully optimized. Water-to-air intercooling provides superior charge cooling during repeated runs compared to air-to-air systems. Weaknesses: More complex turbocharger system increases potential failure points in high-stress drag racing applications. Initial throttle response and torque delivery still lags behind the immediate response of supercharged engines like the LT4, potentially affecting 60-foot times.

Key LT4 Innovations for Drag Performance

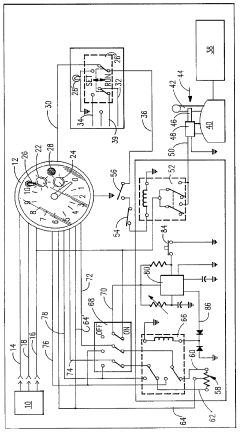

Apparatus for improving efficiency and consistency of a drag race car

PatentInactiveUS4873891A

Innovation

- An electrical apparatus using switches, relays, potentiometers, and solenoids in conjunction with a tachometer for automatic shifting at adjustable RPM levels and selective maximum RPM limiting, allowing for automatic gear changes and independent adjustment of RPM levels before and after the starting line.

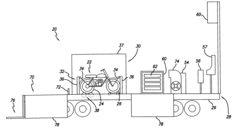

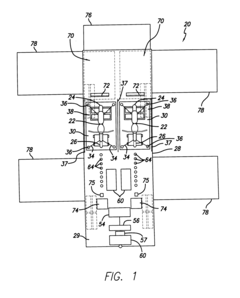

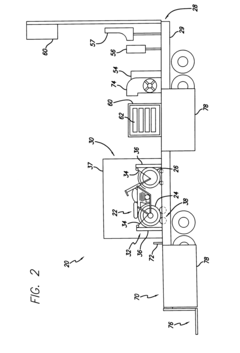

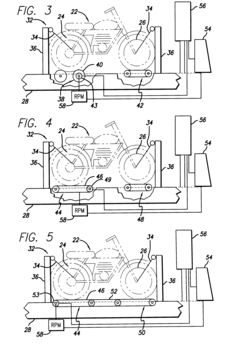

Stationary drag racing simulation system

PatentInactiveUS6505503B1

Innovation

- A stationary drag racing simulation system that includes a racing platform with restraining assemblies and rotatable drive wheel support members equipped with eddy current braking devices, allowing vehicles to simulate racing conditions while stationary, with monitoring of elapsed time, reaction time, and operation, and displaying simulated speed and horsepower.

Thermal Management Solutions for Drag Applications

Effective thermal management is critical for LT4 engines in drag racing applications, where extreme performance demands create substantial heat loads. The supercharged 6.2L LT4 engine generates significant thermal energy during high-intensity drag racing, requiring specialized cooling solutions beyond standard production configurations. Without proper thermal management, power output decreases while the risk of component failure increases dramatically.

Advanced cooling systems for LT4 drag applications typically incorporate oversized radiators with increased surface area and enhanced fin designs. These radiators often utilize aluminum construction with specialized core designs that maximize heat dissipation while maintaining acceptable weight parameters. Many competitive drag setups employ dual-pass radiator configurations that extend cooling capacity during the critical recovery periods between runs.

Oil cooling represents another crucial thermal management component. High-performance oil coolers with dedicated fans maintain optimal lubricant temperatures, preventing viscosity breakdown under extreme conditions. Some advanced systems incorporate thermostatically controlled oil cooling circuits that activate only when necessary, optimizing system efficiency while preventing overcooling during warm-up phases.

Intercooler technology plays a particularly vital role in supercharged LT4 applications. Air-to-water intercooler systems have demonstrated superior performance in drag environments compared to traditional air-to-air configurations. These systems can incorporate ice-based reservoirs that provide exceptional charge cooling for limited-duration drag applications, significantly increasing power potential through denser air charge delivery.

Heat extraction from critical components extends beyond traditional cooling systems. Carbon fiber heat shields, ceramic-coated headers, and thermal barrier coatings on combustion chamber surfaces all contribute to comprehensive thermal management. Many competitive drag applications utilize thermal wraps on exhaust components to contain heat within the exhaust system, reducing underhood temperatures.

Electronic thermal management has evolved substantially, with programmable cooling fans and water pump controllers that respond to real-time temperature data. These systems can prioritize cooling to specific components based on sensor inputs, optimizing the entire thermal ecosystem. Some advanced setups incorporate predictive cooling algorithms that anticipate thermal loads based on driver inputs and historical performance data.

The integration of lightweight composite materials in cooling system components has enabled significant weight reduction without compromising thermal efficiency. Carbon fiber cooling ducts, polymer header tanks, and titanium fasteners all contribute to the overall thermal management strategy while supporting favorable weight distribution for drag applications.

Advanced cooling systems for LT4 drag applications typically incorporate oversized radiators with increased surface area and enhanced fin designs. These radiators often utilize aluminum construction with specialized core designs that maximize heat dissipation while maintaining acceptable weight parameters. Many competitive drag setups employ dual-pass radiator configurations that extend cooling capacity during the critical recovery periods between runs.

Oil cooling represents another crucial thermal management component. High-performance oil coolers with dedicated fans maintain optimal lubricant temperatures, preventing viscosity breakdown under extreme conditions. Some advanced systems incorporate thermostatically controlled oil cooling circuits that activate only when necessary, optimizing system efficiency while preventing overcooling during warm-up phases.

Intercooler technology plays a particularly vital role in supercharged LT4 applications. Air-to-water intercooler systems have demonstrated superior performance in drag environments compared to traditional air-to-air configurations. These systems can incorporate ice-based reservoirs that provide exceptional charge cooling for limited-duration drag applications, significantly increasing power potential through denser air charge delivery.

Heat extraction from critical components extends beyond traditional cooling systems. Carbon fiber heat shields, ceramic-coated headers, and thermal barrier coatings on combustion chamber surfaces all contribute to comprehensive thermal management. Many competitive drag applications utilize thermal wraps on exhaust components to contain heat within the exhaust system, reducing underhood temperatures.

Electronic thermal management has evolved substantially, with programmable cooling fans and water pump controllers that respond to real-time temperature data. These systems can prioritize cooling to specific components based on sensor inputs, optimizing the entire thermal ecosystem. Some advanced setups incorporate predictive cooling algorithms that anticipate thermal loads based on driver inputs and historical performance data.

The integration of lightweight composite materials in cooling system components has enabled significant weight reduction without compromising thermal efficiency. Carbon fiber cooling ducts, polymer header tanks, and titanium fasteners all contribute to the overall thermal management strategy while supporting favorable weight distribution for drag applications.

Regulatory Compliance in Motorsport Competition

Drag racing competitions operate within a complex framework of regulations that vary significantly across sanctioning bodies and racing classes. The LT4 engine's implementation in drag racing vehicles must navigate these regulatory landscapes carefully to ensure compliance while maximizing performance advantages. Major sanctioning organizations such as the National Hot Rod Association (NHRA), International Hot Rod Association (IHRA), and Professional Drag Racers Association (PDRA) each maintain distinct rulebooks governing engine specifications, power adders, weight requirements, and safety standards.

For LT4-powered vehicles, displacement limitations represent a primary regulatory consideration. Many classes restrict engine size to specific cubic inch displacements, with the LT4's 6.2L (376 cubic inches) configuration falling within acceptable parameters for numerous categories. However, the factory supercharger presents additional compliance challenges, as forced induction often triggers reclassification or requires compensatory weight additions to maintain competitive balance.

Technical inspections constitute another critical regulatory hurdle for LT4-equipped drag cars. Officials meticulously verify engine components against class-specific regulations, examining supercharger specifications, boost levels, and electronic control systems. The LT4's direct injection system may face particular scrutiny in classes where fuel delivery methods are regulated, potentially requiring modifications or alternative solutions to maintain compliance.

Emissions standards increasingly influence motorsport regulations, even in traditionally less-restricted drag racing environments. While many competition vehicles receive exemptions from standard emissions requirements, certain venues and series have begun implementing stricter environmental guidelines. The LT4's relatively modern emissions control systems provide an advantage in these contexts compared to older engine architectures, though modifications for competition purposes may still necessitate careful navigation of applicable regulations.

Safety compliance represents perhaps the most non-negotiable aspect of motorsport regulation. LT4-powered vehicles must incorporate appropriate containment systems for supercharged applications, including proper shielding, blow-off protection, and reinforced drivetrain components capable of handling the engine's substantial torque output. Additionally, electronic control systems must maintain fail-safe protocols that prevent dangerous over-boost situations or catastrophic component failures during competition.

Understanding the regulatory landscape across different sanctioning bodies allows teams to strategically position LT4-powered vehicles in classes where their performance characteristics offer the greatest competitive advantage while remaining fully compliant. This regulatory navigation often requires balancing performance modifications against class restrictions, creating a complex optimization challenge that extends beyond pure engineering considerations into the realm of rulebook interpretation and strategic competition planning.

For LT4-powered vehicles, displacement limitations represent a primary regulatory consideration. Many classes restrict engine size to specific cubic inch displacements, with the LT4's 6.2L (376 cubic inches) configuration falling within acceptable parameters for numerous categories. However, the factory supercharger presents additional compliance challenges, as forced induction often triggers reclassification or requires compensatory weight additions to maintain competitive balance.

Technical inspections constitute another critical regulatory hurdle for LT4-equipped drag cars. Officials meticulously verify engine components against class-specific regulations, examining supercharger specifications, boost levels, and electronic control systems. The LT4's direct injection system may face particular scrutiny in classes where fuel delivery methods are regulated, potentially requiring modifications or alternative solutions to maintain compliance.

Emissions standards increasingly influence motorsport regulations, even in traditionally less-restricted drag racing environments. While many competition vehicles receive exemptions from standard emissions requirements, certain venues and series have begun implementing stricter environmental guidelines. The LT4's relatively modern emissions control systems provide an advantage in these contexts compared to older engine architectures, though modifications for competition purposes may still necessitate careful navigation of applicable regulations.

Safety compliance represents perhaps the most non-negotiable aspect of motorsport regulation. LT4-powered vehicles must incorporate appropriate containment systems for supercharged applications, including proper shielding, blow-off protection, and reinforced drivetrain components capable of handling the engine's substantial torque output. Additionally, electronic control systems must maintain fail-safe protocols that prevent dangerous over-boost situations or catastrophic component failures during competition.

Understanding the regulatory landscape across different sanctioning bodies allows teams to strategically position LT4-powered vehicles in classes where their performance characteristics offer the greatest competitive advantage while remaining fully compliant. This regulatory navigation often requires balancing performance modifications against class restrictions, creating a complex optimization challenge that extends beyond pure engineering considerations into the realm of rulebook interpretation and strategic competition planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!