How to Advance Graphene Battery Material Enhancements?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene, a two-dimensional carbon allotrope, has emerged as a revolutionary material in the field of energy storage, particularly in battery technology. Since its discovery in 2004, graphene has captivated researchers and industry experts due to its exceptional properties, including high electrical conductivity, mechanical strength, and large surface area. The evolution of graphene-based battery materials has been marked by significant milestones and breakthroughs, driving the pursuit of more efficient and powerful energy storage solutions.

The primary objective in advancing graphene battery material enhancements is to overcome the limitations of current lithium-ion batteries, such as limited energy density, slow charging rates, and degradation over time. Researchers aim to leverage graphene's unique properties to develop batteries with higher capacity, faster charging capabilities, and improved longevity. This goal aligns with the growing demand for high-performance energy storage systems in various applications, including electric vehicles, portable electronics, and renewable energy integration.

One of the key areas of focus in graphene battery evolution is the development of graphene-based electrodes. By incorporating graphene into both anodes and cathodes, scientists seek to enhance the overall performance of batteries. Graphene's high surface area and excellent conductivity can facilitate faster ion transport and electron transfer, potentially leading to batteries with significantly higher power densities and reduced charging times.

Another important objective is to explore graphene's potential in improving the stability and safety of battery systems. Researchers are investigating how graphene can be used to create more robust battery structures that are less prone to degradation and thermal runaway. This includes the development of graphene-based composite materials that can enhance the mechanical and thermal properties of battery components.

The evolution of graphene battery technology also encompasses the exploration of novel architectures and designs. Scientists are experimenting with various forms of graphene, such as graphene oxide, reduced graphene oxide, and graphene nanoplatelets, to optimize their integration into battery systems. The goal is to create innovative structures that can maximize the benefits of graphene while addressing challenges related to scalability and manufacturing.

As the field progresses, researchers are setting ambitious targets for graphene-enhanced batteries. These include achieving energy densities exceeding 1,000 Wh/kg, reducing charging times to mere minutes, and extending battery lifespans to thousands of cycles. Such advancements could revolutionize various industries, from transportation to consumer electronics, and play a crucial role in the transition towards a more sustainable energy future.

The primary objective in advancing graphene battery material enhancements is to overcome the limitations of current lithium-ion batteries, such as limited energy density, slow charging rates, and degradation over time. Researchers aim to leverage graphene's unique properties to develop batteries with higher capacity, faster charging capabilities, and improved longevity. This goal aligns with the growing demand for high-performance energy storage systems in various applications, including electric vehicles, portable electronics, and renewable energy integration.

One of the key areas of focus in graphene battery evolution is the development of graphene-based electrodes. By incorporating graphene into both anodes and cathodes, scientists seek to enhance the overall performance of batteries. Graphene's high surface area and excellent conductivity can facilitate faster ion transport and electron transfer, potentially leading to batteries with significantly higher power densities and reduced charging times.

Another important objective is to explore graphene's potential in improving the stability and safety of battery systems. Researchers are investigating how graphene can be used to create more robust battery structures that are less prone to degradation and thermal runaway. This includes the development of graphene-based composite materials that can enhance the mechanical and thermal properties of battery components.

The evolution of graphene battery technology also encompasses the exploration of novel architectures and designs. Scientists are experimenting with various forms of graphene, such as graphene oxide, reduced graphene oxide, and graphene nanoplatelets, to optimize their integration into battery systems. The goal is to create innovative structures that can maximize the benefits of graphene while addressing challenges related to scalability and manufacturing.

As the field progresses, researchers are setting ambitious targets for graphene-enhanced batteries. These include achieving energy densities exceeding 1,000 Wh/kg, reducing charging times to mere minutes, and extending battery lifespans to thousands of cycles. Such advancements could revolutionize various industries, from transportation to consumer electronics, and play a crucial role in the transition towards a more sustainable energy future.

Market Demand Analysis for Advanced Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing demand for advanced battery technologies. This surge is primarily fueled by the rapid expansion of electric vehicles (EVs), renewable energy integration, and portable electronics. The graphene battery material sector, in particular, is poised for significant expansion due to its potential to revolutionize energy storage capabilities.

In the EV market, there is a growing need for batteries with higher energy density, faster charging times, and longer lifespans. Graphene-enhanced batteries show promise in addressing these requirements, potentially enabling longer driving ranges and reduced charging times. This aligns with consumer expectations and regulatory pressures for more efficient and environmentally friendly transportation solutions.

The renewable energy sector is another key driver for advanced energy storage. As wind and solar power generation increases, the need for efficient and large-scale energy storage systems becomes critical. Graphene-based batteries could provide the necessary performance improvements to better manage intermittent renewable energy sources, enhancing grid stability and reliability.

In the consumer electronics market, demand for longer-lasting and faster-charging devices continues to grow. Graphene battery materials offer the potential for significant improvements in battery life and charging speed, which could lead to a new generation of high-performance portable devices.

Industrial and aerospace applications are also showing increased interest in graphene-enhanced energy storage solutions. These sectors require batteries with high power density, improved safety, and the ability to operate in extreme conditions – all areas where graphene materials show promise.

The market for graphene battery materials is expected to grow substantially in the coming years. However, challenges remain in scaling up production and reducing costs to make graphene-enhanced batteries commercially viable for mass-market applications. Overcoming these hurdles could unlock significant market potential across multiple industries.

As environmental concerns and energy efficiency regulations become more stringent globally, the demand for advanced energy storage solutions is likely to accelerate further. This creates a favorable market environment for innovations in graphene battery materials, positioning them as a key technology in the transition towards more sustainable energy systems.

In the EV market, there is a growing need for batteries with higher energy density, faster charging times, and longer lifespans. Graphene-enhanced batteries show promise in addressing these requirements, potentially enabling longer driving ranges and reduced charging times. This aligns with consumer expectations and regulatory pressures for more efficient and environmentally friendly transportation solutions.

The renewable energy sector is another key driver for advanced energy storage. As wind and solar power generation increases, the need for efficient and large-scale energy storage systems becomes critical. Graphene-based batteries could provide the necessary performance improvements to better manage intermittent renewable energy sources, enhancing grid stability and reliability.

In the consumer electronics market, demand for longer-lasting and faster-charging devices continues to grow. Graphene battery materials offer the potential for significant improvements in battery life and charging speed, which could lead to a new generation of high-performance portable devices.

Industrial and aerospace applications are also showing increased interest in graphene-enhanced energy storage solutions. These sectors require batteries with high power density, improved safety, and the ability to operate in extreme conditions – all areas where graphene materials show promise.

The market for graphene battery materials is expected to grow substantially in the coming years. However, challenges remain in scaling up production and reducing costs to make graphene-enhanced batteries commercially viable for mass-market applications. Overcoming these hurdles could unlock significant market potential across multiple industries.

As environmental concerns and energy efficiency regulations become more stringent globally, the demand for advanced energy storage solutions is likely to accelerate further. This creates a favorable market environment for innovations in graphene battery materials, positioning them as a key technology in the transition towards more sustainable energy systems.

Current Graphene Battery Technology Challenges

Despite the promising potential of graphene in battery technology, several significant challenges currently hinder its widespread adoption and commercialization. One of the primary obstacles is the high production cost of graphene, which makes it economically unfeasible for large-scale battery manufacturing. The complex synthesis processes and the need for specialized equipment contribute to this cost barrier, limiting its integration into mainstream battery production.

Another critical challenge lies in the scalability of graphene production. While laboratory-scale synthesis has shown remarkable results, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a significant hurdle. The lack of standardized production methods further complicates this issue, leading to variations in graphene quality and performance across different batches.

The integration of graphene into existing battery architectures poses another set of challenges. Graphene's unique properties, while beneficial in many aspects, can also lead to unexpected interactions with other battery components. For instance, the high surface area of graphene can result in unwanted side reactions with the electrolyte, potentially reducing the battery's overall efficiency and lifespan.

Stability and long-term performance of graphene-enhanced batteries are also areas of concern. While initial performance improvements are often observed, maintaining these enhancements over extended charge-discharge cycles remains challenging. The tendency of graphene sheets to restack or agglomerate over time can diminish its effectiveness, reducing the battery's capacity and power output.

Furthermore, the environmental impact and safety considerations of graphene production and disposal need to be thoroughly addressed. The potential health and environmental risks associated with nanoparticles, including graphene, are not yet fully understood, necessitating comprehensive studies before large-scale implementation.

Lastly, the regulatory landscape surrounding graphene-based materials in battery applications is still evolving. The lack of clear guidelines and standards for graphene-enhanced batteries creates uncertainty for manufacturers and may slow down the adoption process. Establishing robust regulatory frameworks and safety protocols is crucial for the widespread acceptance of this technology.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, engineering, and manufacturing processes. Overcoming these hurdles is essential for realizing the full potential of graphene in revolutionizing battery technology and paving the way for next-generation energy storage solutions.

Another critical challenge lies in the scalability of graphene production. While laboratory-scale synthesis has shown remarkable results, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a significant hurdle. The lack of standardized production methods further complicates this issue, leading to variations in graphene quality and performance across different batches.

The integration of graphene into existing battery architectures poses another set of challenges. Graphene's unique properties, while beneficial in many aspects, can also lead to unexpected interactions with other battery components. For instance, the high surface area of graphene can result in unwanted side reactions with the electrolyte, potentially reducing the battery's overall efficiency and lifespan.

Stability and long-term performance of graphene-enhanced batteries are also areas of concern. While initial performance improvements are often observed, maintaining these enhancements over extended charge-discharge cycles remains challenging. The tendency of graphene sheets to restack or agglomerate over time can diminish its effectiveness, reducing the battery's capacity and power output.

Furthermore, the environmental impact and safety considerations of graphene production and disposal need to be thoroughly addressed. The potential health and environmental risks associated with nanoparticles, including graphene, are not yet fully understood, necessitating comprehensive studies before large-scale implementation.

Lastly, the regulatory landscape surrounding graphene-based materials in battery applications is still evolving. The lack of clear guidelines and standards for graphene-enhanced batteries creates uncertainty for manufacturers and may slow down the adoption process. Establishing robust regulatory frameworks and safety protocols is crucial for the widespread acceptance of this technology.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, engineering, and manufacturing processes. Overcoming these hurdles is essential for realizing the full potential of graphene in revolutionizing battery technology and paving the way for next-generation energy storage solutions.

Existing Graphene Battery Enhancement Solutions

01 Graphene-based composite materials for battery electrodes

Composite materials incorporating graphene are developed to enhance battery performance. These composites often combine graphene with other materials like metal oxides or polymers to improve conductivity, capacity, and stability of battery electrodes. The unique properties of graphene, such as high surface area and excellent electrical conductivity, contribute to improved energy storage capabilities.- Graphene-based composite materials for battery electrodes: Composite materials incorporating graphene are developed to enhance battery performance. These composites often combine graphene with other materials like metal oxides or polymers to improve conductivity, capacity, and stability of battery electrodes. The unique properties of graphene, such as high surface area and excellent electrical conductivity, contribute to improved energy storage capabilities.

- Graphene modification techniques for battery applications: Various modification techniques are employed to enhance graphene's properties for battery applications. These may include doping, functionalization, or structural modifications to improve specific characteristics such as ion transport, electron conductivity, or electrochemical stability. Modified graphene materials can lead to better overall battery performance and longevity.

- Graphene-enhanced electrolytes and separators: Graphene is incorporated into battery electrolytes and separators to improve their performance. In electrolytes, graphene can enhance ionic conductivity and stability. When used in separators, graphene can improve mechanical strength, thermal stability, and ion selectivity, leading to safer and more efficient batteries.

- Graphene production and processing methods for battery materials: Advanced methods for producing and processing graphene specifically for battery applications are developed. These techniques focus on creating high-quality graphene with controlled properties, such as specific surface area, defect density, or layer thickness. Optimized production methods can lead to more consistent and higher-performing graphene-based battery materials.

- Graphene-based flexible and wearable battery technologies: Graphene is utilized in the development of flexible and wearable battery technologies. Its unique properties allow for the creation of thin, lightweight, and bendable energy storage devices. These innovations enable new applications in wearable electronics, smart textiles, and flexible devices, where traditional rigid batteries are not suitable.

02 Graphene modification techniques for battery applications

Various modification techniques are employed to enhance graphene's properties for battery applications. These may include doping, functionalization, or structural modifications to improve specific characteristics such as ion transport, electron conductivity, or electrochemical stability. Modified graphene materials can lead to better overall battery performance and longevity.Expand Specific Solutions03 Graphene-enhanced electrolytes and separators

Graphene is incorporated into battery electrolytes and separators to improve their performance. Graphene-based additives or coatings can enhance ionic conductivity, mechanical strength, and thermal stability of these components. This results in batteries with improved safety, faster charging capabilities, and extended cycle life.Expand Specific Solutions04 Graphene synthesis methods for battery materials

Advanced synthesis methods are developed to produce high-quality graphene specifically tailored for battery applications. These methods focus on controlling graphene's structure, thickness, and defects to optimize its performance in energy storage devices. Techniques may include chemical vapor deposition, exfoliation, or reduction of graphene oxide.Expand Specific Solutions05 Graphene-based flexible and wearable battery technologies

Graphene is utilized in the development of flexible and wearable battery technologies. Its mechanical flexibility and high conductivity make it ideal for creating thin, bendable, and stretchable energy storage devices. These innovations enable the integration of batteries into various wearable electronics and flexible devices.Expand Specific Solutions

Key Players in Graphene Battery Research

The graphene battery material enhancement sector is in a dynamic growth phase, with significant market potential driven by the increasing demand for high-performance energy storage solutions. The global market for graphene batteries is expanding rapidly, fueled by applications in electric vehicles, consumer electronics, and renewable energy systems. Technologically, the field is progressing from early-stage research to more advanced development and commercialization efforts. Companies like Honeycomb Battery Co., Samsung Electronics, and Global Graphene Group are at the forefront, leveraging their expertise in materials science and battery technology. Academic institutions such as Northwestern University and Korea Advanced Institute of Science & Technology are contributing crucial research, while established players like Toray Industries and emerging startups like Echion Technologies are pushing the boundaries of graphene battery innovation.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has been actively researching graphene-based battery technologies to enhance the performance of their electronic devices. They have developed a "graphene ball" material that can be used to coat the electrodes in lithium-ion batteries. This coating significantly improves charging speed and capacity retention. Samsung's graphene ball technology has demonstrated the ability to increase battery capacity by up to 45% and charging speed by up to 5 times compared to conventional lithium-ion batteries[5]. The company has also explored the use of graphene in flexible battery designs for wearable devices[6].

Strengths: Significant improvements in charging speed and capacity, potential for flexible battery designs. Weaknesses: Challenges in mass production and integration into existing manufacturing processes.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a graphene-based electrode material for lithium-ion batteries that significantly enhances energy density and cycle life. Their approach involves creating a three-dimensional network structure of graphene sheets, which provides a large surface area for lithium-ion storage and facilitates rapid ion transport. This structure allows for a higher capacity than conventional graphite anodes while maintaining good cycle stability. Toray's graphene electrode material has shown potential to increase the driving range of electric vehicles by up to 200km on a single charge[7]. The company is also exploring the use of graphene in solid-state batteries to further improve safety and energy density[8].

Strengths: High energy density, improved cycle life, and potential application in solid-state batteries. Weaknesses: Complex manufacturing process and potential high costs associated with large-scale production.

Core Innovations in Graphene Material Science

Direct-formation self-assembly graphene from cellulose nanofiber aqueous solution

PatentPendingUS20240088397A1

Innovation

- A self-assembled freestanding graphene membrane or layer is formed using an aqueous dispersion of industrial-grade graphene and cellulose nanofibers with a mass ratio of 12:1 to 20:1, which improves dispersibility and allows for low-temperature direct fabrication, enabling the formation of a stable and conductive graphene scaffold for lithium metal anodes.

Reduced graphene-based material

PatentActiveUS20210230002A1

Innovation

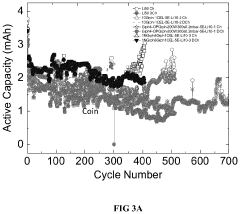

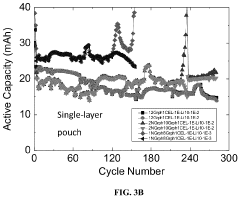

- A reduced graphene-based material with a coating containing lithium, phosphorus, fluorine, and oxygen, derived from lithium difluorophosphate, is used for the negative electrode, improving the charge/discharge efficiency by suppressing side reactions and reducing irreversible capacity.

Environmental Impact of Graphene Battery Production

The production of graphene battery materials presents both opportunities and challenges in terms of environmental impact. While graphene-based batteries offer potential improvements in energy density and charging speed, their manufacturing process requires careful consideration of ecological consequences.

One of the primary environmental concerns is the energy-intensive nature of graphene production. Current methods, such as chemical vapor deposition and exfoliation, often require high temperatures and harsh chemical treatments. This energy consumption contributes to increased carbon emissions if not sourced from renewable energy. Additionally, the use of solvents and strong acids in some production processes can lead to hazardous waste generation, necessitating proper disposal and treatment protocols.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene materials often involve substantial water consumption, potentially straining local water resources in manufacturing regions. Implementing water recycling systems and optimizing production processes can help mitigate this impact.

The extraction and processing of raw materials for graphene production, such as graphite, also have environmental implications. Mining activities can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Sustainable sourcing practices and the development of eco-friendly extraction methods are essential to minimize these effects.

On the positive side, graphene's unique properties may contribute to more environmentally friendly battery solutions in the long term. The potential for longer-lasting and more efficient batteries could reduce overall electronic waste and resource consumption. Furthermore, graphene's excellent conductivity may lead to more energy-efficient devices, indirectly lowering carbon footprints across various industries.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the high value of graphene materials incentivizes recycling efforts, the complex composition of these batteries may require the development of new recycling technologies. Establishing effective recycling infrastructure will be crucial to prevent environmental contamination and recover valuable materials.

As the graphene battery industry evolves, it is imperative to adopt a lifecycle approach to environmental impact assessment. This includes considering the entire production chain, from raw material extraction to manufacturing, use, and disposal. Implementing green chemistry principles, optimizing production processes, and investing in renewable energy sources for manufacturing can significantly reduce the environmental footprint of graphene battery production.

One of the primary environmental concerns is the energy-intensive nature of graphene production. Current methods, such as chemical vapor deposition and exfoliation, often require high temperatures and harsh chemical treatments. This energy consumption contributes to increased carbon emissions if not sourced from renewable energy. Additionally, the use of solvents and strong acids in some production processes can lead to hazardous waste generation, necessitating proper disposal and treatment protocols.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene materials often involve substantial water consumption, potentially straining local water resources in manufacturing regions. Implementing water recycling systems and optimizing production processes can help mitigate this impact.

The extraction and processing of raw materials for graphene production, such as graphite, also have environmental implications. Mining activities can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Sustainable sourcing practices and the development of eco-friendly extraction methods are essential to minimize these effects.

On the positive side, graphene's unique properties may contribute to more environmentally friendly battery solutions in the long term. The potential for longer-lasting and more efficient batteries could reduce overall electronic waste and resource consumption. Furthermore, graphene's excellent conductivity may lead to more energy-efficient devices, indirectly lowering carbon footprints across various industries.

Recycling and end-of-life management of graphene batteries present both challenges and opportunities. While the high value of graphene materials incentivizes recycling efforts, the complex composition of these batteries may require the development of new recycling technologies. Establishing effective recycling infrastructure will be crucial to prevent environmental contamination and recover valuable materials.

As the graphene battery industry evolves, it is imperative to adopt a lifecycle approach to environmental impact assessment. This includes considering the entire production chain, from raw material extraction to manufacturing, use, and disposal. Implementing green chemistry principles, optimizing production processes, and investing in renewable energy sources for manufacturing can significantly reduce the environmental footprint of graphene battery production.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for graphene battery material enhancements are promising, yet face several challenges. The potential for graphene to revolutionize battery technology has attracted significant attention from both industry and academia. However, transitioning from laboratory-scale production to large-scale manufacturing remains a critical hurdle.

One of the primary challenges in scaling up graphene production is maintaining consistent quality and properties across large batches. Current methods, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to produce graphene with uniform characteristics at industrial scales. This inconsistency can lead to variability in battery performance, hindering widespread adoption.

Cost-effective production is another key factor in commercialization. While graphene prices have decreased over the years, they remain relatively high compared to traditional battery materials. Developing more efficient and economical production methods is crucial for making graphene-enhanced batteries commercially viable. Recent advancements in roll-to-roll production techniques show promise in this regard, potentially reducing manufacturing costs.

The integration of graphene into existing battery manufacturing processes presents another challenge. Many current battery production lines are not equipped to handle graphene materials, necessitating significant investments in new equipment and infrastructure. This barrier to entry may slow down the adoption of graphene-enhanced batteries by established manufacturers.

Despite these challenges, the market potential for graphene-enhanced batteries is substantial. The growing demand for high-performance energy storage solutions in electric vehicles, consumer electronics, and renewable energy systems provides a strong incentive for commercialization. Several start-ups and established companies are actively working on overcoming the scalability issues, with some pilot-scale production already underway.

Regulatory considerations also play a role in the commercialization prospects. As a relatively new material, graphene is subject to ongoing safety and environmental assessments. Ensuring compliance with evolving regulations and standards is crucial for market acceptance and long-term viability.

Collaboration between research institutions, material suppliers, and battery manufacturers is accelerating the path to commercialization. These partnerships are addressing key challenges in scalability, such as developing standardized quality control measures and optimizing integration processes. As these efforts progress, the timeline for widespread commercial availability of graphene-enhanced batteries continues to shorten.

One of the primary challenges in scaling up graphene production is maintaining consistent quality and properties across large batches. Current methods, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to produce graphene with uniform characteristics at industrial scales. This inconsistency can lead to variability in battery performance, hindering widespread adoption.

Cost-effective production is another key factor in commercialization. While graphene prices have decreased over the years, they remain relatively high compared to traditional battery materials. Developing more efficient and economical production methods is crucial for making graphene-enhanced batteries commercially viable. Recent advancements in roll-to-roll production techniques show promise in this regard, potentially reducing manufacturing costs.

The integration of graphene into existing battery manufacturing processes presents another challenge. Many current battery production lines are not equipped to handle graphene materials, necessitating significant investments in new equipment and infrastructure. This barrier to entry may slow down the adoption of graphene-enhanced batteries by established manufacturers.

Despite these challenges, the market potential for graphene-enhanced batteries is substantial. The growing demand for high-performance energy storage solutions in electric vehicles, consumer electronics, and renewable energy systems provides a strong incentive for commercialization. Several start-ups and established companies are actively working on overcoming the scalability issues, with some pilot-scale production already underway.

Regulatory considerations also play a role in the commercialization prospects. As a relatively new material, graphene is subject to ongoing safety and environmental assessments. Ensuring compliance with evolving regulations and standards is crucial for market acceptance and long-term viability.

Collaboration between research institutions, material suppliers, and battery manufacturers is accelerating the path to commercialization. These partnerships are addressing key challenges in scalability, such as developing standardized quality control measures and optimizing integration processes. As these efforts progress, the timeline for widespread commercial availability of graphene-enhanced batteries continues to shorten.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!