How to Control Viscosity in Gel Systems with Sodium Alginate?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Gel Viscosity Control Background

Sodium alginate, a naturally occurring polysaccharide derived from brown seaweed, has gained significant attention in various industries due to its unique gelling properties. The ability to control viscosity in gel systems containing sodium alginate is crucial for numerous applications, ranging from food and pharmaceuticals to biomedical engineering and materials science.

The viscosity control of sodium alginate gels has been a subject of research and development for several decades. Initially, the focus was primarily on understanding the fundamental mechanisms of gel formation and the factors influencing viscosity. Early studies in the 1950s and 1960s explored the chemical structure of sodium alginate and its interaction with divalent cations, particularly calcium ions, which play a key role in the gelation process.

As research progressed, scientists began to investigate various methods to manipulate the viscosity of sodium alginate gels. One of the primary approaches involved altering the concentration of sodium alginate and the cross-linking agents. Researchers discovered that higher concentrations of sodium alginate generally led to increased viscosity, while the type and concentration of cross-linking agents could be used to fine-tune the gel's properties.

In the 1980s and 1990s, advancements in polymer science and analytical techniques allowed for more precise control over gel viscosity. Researchers began to explore the effects of molecular weight distribution, guluronic acid to mannuronic acid ratio, and the presence of other additives on the rheological properties of sodium alginate gels. This period saw the development of more sophisticated models to predict and control gel behavior.

The turn of the millennium brought about a surge in interdisciplinary research, combining principles from materials science, chemistry, and biology to develop novel approaches for viscosity control. Techniques such as chemical modification of alginate molecules, incorporation of nanoparticles, and the use of stimuli-responsive additives emerged as promising strategies to achieve dynamic control over gel viscosity.

Recent years have witnessed a growing interest in smart and responsive gel systems. Researchers are now exploring ways to create sodium alginate gels that can change their viscosity in response to external stimuli such as temperature, pH, or light. This has opened up new possibilities for applications in drug delivery, tissue engineering, and adaptive materials.

The overarching goal in the field of sodium alginate gel viscosity control is to develop precise, reproducible, and versatile methods that can be tailored to specific applications. This includes achieving a wide range of viscosities, from low-viscosity solutions to highly structured gels, as well as the ability to dynamically modulate viscosity in situ. Additionally, there is a strong emphasis on developing environmentally friendly and biocompatible approaches, particularly for applications in the food and biomedical industries.

The viscosity control of sodium alginate gels has been a subject of research and development for several decades. Initially, the focus was primarily on understanding the fundamental mechanisms of gel formation and the factors influencing viscosity. Early studies in the 1950s and 1960s explored the chemical structure of sodium alginate and its interaction with divalent cations, particularly calcium ions, which play a key role in the gelation process.

As research progressed, scientists began to investigate various methods to manipulate the viscosity of sodium alginate gels. One of the primary approaches involved altering the concentration of sodium alginate and the cross-linking agents. Researchers discovered that higher concentrations of sodium alginate generally led to increased viscosity, while the type and concentration of cross-linking agents could be used to fine-tune the gel's properties.

In the 1980s and 1990s, advancements in polymer science and analytical techniques allowed for more precise control over gel viscosity. Researchers began to explore the effects of molecular weight distribution, guluronic acid to mannuronic acid ratio, and the presence of other additives on the rheological properties of sodium alginate gels. This period saw the development of more sophisticated models to predict and control gel behavior.

The turn of the millennium brought about a surge in interdisciplinary research, combining principles from materials science, chemistry, and biology to develop novel approaches for viscosity control. Techniques such as chemical modification of alginate molecules, incorporation of nanoparticles, and the use of stimuli-responsive additives emerged as promising strategies to achieve dynamic control over gel viscosity.

Recent years have witnessed a growing interest in smart and responsive gel systems. Researchers are now exploring ways to create sodium alginate gels that can change their viscosity in response to external stimuli such as temperature, pH, or light. This has opened up new possibilities for applications in drug delivery, tissue engineering, and adaptive materials.

The overarching goal in the field of sodium alginate gel viscosity control is to develop precise, reproducible, and versatile methods that can be tailored to specific applications. This includes achieving a wide range of viscosities, from low-viscosity solutions to highly structured gels, as well as the ability to dynamically modulate viscosity in situ. Additionally, there is a strong emphasis on developing environmentally friendly and biocompatible approaches, particularly for applications in the food and biomedical industries.

Market Demand Analysis

The market demand for controlling viscosity in gel systems with sodium alginate has been steadily increasing across various industries. This growth is primarily driven by the versatile applications of sodium alginate-based gels in sectors such as food and beverage, pharmaceuticals, cosmetics, and biomedical engineering.

In the food industry, there is a rising demand for natural thickeners and stabilizers, with sodium alginate being a preferred choice due to its non-toxic and biodegradable properties. The global food hydrocolloids market, which includes sodium alginate, is experiencing significant growth. This trend is fueled by the increasing consumer preference for clean-label and plant-based products, as well as the growing demand for convenience foods and functional beverages.

The pharmaceutical and biomedical sectors are also contributing to the market demand for sodium alginate-based gel systems. The ability to control viscosity in these gels is crucial for drug delivery systems, wound dressings, and tissue engineering applications. The expanding field of regenerative medicine and the development of advanced drug delivery platforms are driving the need for precise viscosity control in alginate-based hydrogels.

In the cosmetics industry, sodium alginate is gaining popularity as a natural ingredient for various skincare and haircare products. The demand for sustainable and eco-friendly cosmetic formulations is propelling the use of alginate-based gels with controlled viscosity properties. This trend aligns with the growing consumer awareness of environmentally friendly beauty products.

The industrial sector, particularly in wastewater treatment and textile printing, is another area where the demand for controlled viscosity in sodium alginate gel systems is increasing. The ability to adjust the viscosity of these gels allows for more efficient water purification processes and improved printing quality in textile manufacturing.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sodium alginate market. This is attributed to the rapid industrialization, increasing population, and growing demand for processed foods in countries like China and India. North America and Europe are also significant markets, driven by advancements in biomedical research and the increasing adoption of natural ingredients in various industries.

The global sodium alginate market is projected to continue its growth trajectory in the coming years. Factors such as the expanding applications in 3D bioprinting, the development of novel drug delivery systems, and the increasing use in functional foods are expected to further drive the demand for viscosity-controlled alginate gel systems.

In the food industry, there is a rising demand for natural thickeners and stabilizers, with sodium alginate being a preferred choice due to its non-toxic and biodegradable properties. The global food hydrocolloids market, which includes sodium alginate, is experiencing significant growth. This trend is fueled by the increasing consumer preference for clean-label and plant-based products, as well as the growing demand for convenience foods and functional beverages.

The pharmaceutical and biomedical sectors are also contributing to the market demand for sodium alginate-based gel systems. The ability to control viscosity in these gels is crucial for drug delivery systems, wound dressings, and tissue engineering applications. The expanding field of regenerative medicine and the development of advanced drug delivery platforms are driving the need for precise viscosity control in alginate-based hydrogels.

In the cosmetics industry, sodium alginate is gaining popularity as a natural ingredient for various skincare and haircare products. The demand for sustainable and eco-friendly cosmetic formulations is propelling the use of alginate-based gels with controlled viscosity properties. This trend aligns with the growing consumer awareness of environmentally friendly beauty products.

The industrial sector, particularly in wastewater treatment and textile printing, is another area where the demand for controlled viscosity in sodium alginate gel systems is increasing. The ability to adjust the viscosity of these gels allows for more efficient water purification processes and improved printing quality in textile manufacturing.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sodium alginate market. This is attributed to the rapid industrialization, increasing population, and growing demand for processed foods in countries like China and India. North America and Europe are also significant markets, driven by advancements in biomedical research and the increasing adoption of natural ingredients in various industries.

The global sodium alginate market is projected to continue its growth trajectory in the coming years. Factors such as the expanding applications in 3D bioprinting, the development of novel drug delivery systems, and the increasing use in functional foods are expected to further drive the demand for viscosity-controlled alginate gel systems.

Current Challenges in Gel Viscosity Control

Controlling viscosity in gel systems with sodium alginate presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the inherent variability of sodium alginate as a natural polymer. The molecular weight and composition of alginate can vary depending on its source and extraction method, leading to inconsistencies in gel formation and viscosity control.

The sensitivity of sodium alginate to environmental factors poses another major challenge. pH levels, temperature, and ionic strength of the surrounding medium can dramatically affect the gelation process and resulting viscosity. This sensitivity makes it difficult to maintain consistent gel properties across different batches or in varying application conditions.

Cross-linking mechanisms, crucial for gel formation, present their own set of challenges. The most common cross-linking agent, calcium ions, can lead to rapid and sometimes uncontrolled gelation. This "egg-box" model of cross-linking can result in inhomogeneous gel structures, affecting the overall viscosity and mechanical properties of the system.

The concentration-dependent behavior of sodium alginate solutions adds another layer of complexity. At low concentrations, the viscosity increase is gradual, but beyond a critical concentration, there's a sharp rise in viscosity. This non-linear relationship makes precise control of viscosity challenging, especially when scaling up production or adjusting formulations.

Shear-thinning behavior, while beneficial in some applications, can complicate viscosity control in others. The viscosity of alginate solutions decreases under shear stress, which can lead to unpredictable flow behaviors during processing or application. Recovering the initial viscosity after shear can also be time-dependent, adding another variable to consider in formulation and processing.

The interaction of sodium alginate with other components in complex formulations presents additional challenges. Proteins, polysaccharides, and other additives can compete for water or interfere with the cross-linking process, altering the gel structure and viscosity in ways that are difficult to predict or control.

Lastly, achieving a specific viscosity while maintaining other desired gel properties (such as strength, elasticity, or biodegradability) often involves trade-offs. Optimizing one property may come at the expense of others, requiring careful balancing and often compromises in formulation.

These challenges underscore the need for advanced research and innovative approaches in controlling the viscosity of sodium alginate gel systems. Addressing these issues is crucial for expanding the application of these versatile biomaterials across various industries, from food and pharmaceuticals to biomedical engineering and beyond.

The sensitivity of sodium alginate to environmental factors poses another major challenge. pH levels, temperature, and ionic strength of the surrounding medium can dramatically affect the gelation process and resulting viscosity. This sensitivity makes it difficult to maintain consistent gel properties across different batches or in varying application conditions.

Cross-linking mechanisms, crucial for gel formation, present their own set of challenges. The most common cross-linking agent, calcium ions, can lead to rapid and sometimes uncontrolled gelation. This "egg-box" model of cross-linking can result in inhomogeneous gel structures, affecting the overall viscosity and mechanical properties of the system.

The concentration-dependent behavior of sodium alginate solutions adds another layer of complexity. At low concentrations, the viscosity increase is gradual, but beyond a critical concentration, there's a sharp rise in viscosity. This non-linear relationship makes precise control of viscosity challenging, especially when scaling up production or adjusting formulations.

Shear-thinning behavior, while beneficial in some applications, can complicate viscosity control in others. The viscosity of alginate solutions decreases under shear stress, which can lead to unpredictable flow behaviors during processing or application. Recovering the initial viscosity after shear can also be time-dependent, adding another variable to consider in formulation and processing.

The interaction of sodium alginate with other components in complex formulations presents additional challenges. Proteins, polysaccharides, and other additives can compete for water or interfere with the cross-linking process, altering the gel structure and viscosity in ways that are difficult to predict or control.

Lastly, achieving a specific viscosity while maintaining other desired gel properties (such as strength, elasticity, or biodegradability) often involves trade-offs. Optimizing one property may come at the expense of others, requiring careful balancing and often compromises in formulation.

These challenges underscore the need for advanced research and innovative approaches in controlling the viscosity of sodium alginate gel systems. Addressing these issues is crucial for expanding the application of these versatile biomaterials across various industries, from food and pharmaceuticals to biomedical engineering and beyond.

Existing Viscosity Control Methods

01 Viscosity control in sodium alginate gel systems

Sodium alginate gel systems can be modified to control viscosity through various methods, including adjusting concentration, adding crosslinking agents, or incorporating other polymers. These modifications allow for tailoring the gel's rheological properties to suit specific applications in fields such as pharmaceuticals, food industry, and biomaterials.- Viscosity control in sodium alginate gel systems: Sodium alginate gel systems can be modified to control viscosity through various methods, including adjusting concentration, adding cross-linking agents, or incorporating other polymers. These modifications allow for tailoring the gel's rheological properties to suit specific applications in fields such as pharmaceuticals, food industry, and cosmetics.

- Temperature-responsive sodium alginate gels: Sodium alginate gels can be formulated to exhibit temperature-responsive behavior, where the viscosity changes with temperature variations. This property is useful in applications such as drug delivery systems, tissue engineering, and smart materials. The temperature sensitivity can be achieved by combining sodium alginate with other temperature-responsive polymers or by modifying the alginate structure.

- Incorporation of nanoparticles in sodium alginate gels: The addition of nanoparticles to sodium alginate gel systems can significantly influence their viscosity and mechanical properties. Various types of nanoparticles, such as metal oxides or carbon-based materials, can be used to enhance the gel's strength, modify its rheological behavior, or impart new functionalities like antimicrobial properties or stimuli-responsiveness.

- Blending sodium alginate with other biopolymers: Combining sodium alginate with other biopolymers, such as chitosan, cellulose derivatives, or pectin, can lead to synergistic effects on gel viscosity and stability. These blended systems often exhibit improved mechanical properties, controlled release characteristics, and enhanced biocompatibility, making them suitable for various biomedical and industrial applications.

- Ionic cross-linking for viscosity modification: The viscosity of sodium alginate gel systems can be significantly altered through ionic cross-linking, typically using divalent cations such as calcium or barium. The degree of cross-linking and the type of cross-linking agent used can be adjusted to fine-tune the gel's viscosity, strength, and swelling behavior, allowing for customization in applications ranging from wound dressings to controlled release formulations.

02 Temperature-responsive sodium alginate gels

Temperature-sensitive sodium alginate gel systems can be developed by incorporating thermoresponsive polymers or modifying the alginate structure. These gels exhibit changes in viscosity and mechanical properties in response to temperature variations, making them suitable for applications in drug delivery and tissue engineering.Expand Specific Solutions03 Composite sodium alginate gels for enhanced viscosity

Composite gel systems combining sodium alginate with other natural or synthetic polymers can be formulated to achieve enhanced viscosity and improved mechanical properties. These composite gels often exhibit synergistic effects, resulting in unique rheological characteristics suitable for various industrial and biomedical applications.Expand Specific Solutions04 Influence of ionic strength on sodium alginate gel viscosity

The viscosity of sodium alginate gel systems can be significantly affected by ionic strength. Manipulating the concentration and type of ions in the gel environment allows for fine-tuning of the gel's viscosity and structural properties, which is crucial in applications such as wound dressings and controlled release systems.Expand Specific Solutions05 Shear-thinning behavior in sodium alginate gels

Sodium alginate gel systems often exhibit shear-thinning behavior, where viscosity decreases under applied shear stress. This property can be exploited or modified through formulation adjustments to develop gels with desired flow characteristics for applications in 3D printing, injectable biomaterials, and topical formulations.Expand Specific Solutions

Key Players in Gel Industry

The market for sodium alginate gel systems is in a growth phase, driven by increasing applications in various industries such as food, pharmaceuticals, and cosmetics. The global market size is expanding, with a projected CAGR of 4-6% over the next five years. Technologically, the field is moderately mature, with ongoing research focused on improving viscosity control and functionality. Key players like CP Kelco, Kimica Corp., and Qingdao Bright Moon Seaweed Group are leading innovation in this space, while companies such as Colgate-Palmolive and L'Oréal are driving demand through product applications. Research institutions like the Industrial Technology Research Institute are contributing to advancements in gel system technologies, indicating a collaborative ecosystem for further development.

CP Kelco US, Inc.

Technical Solution: CP Kelco has developed a range of sodium alginate products specifically designed for viscosity control in gel systems. Their KELCOGEL® gellan gum and GENU® pectin product lines can be used in combination with sodium alginate to create customized gel textures and viscosities. The company employs a proprietary production process that allows for precise control over the molecular weight and chemical structure of the alginate, resulting in consistent performance across batches[1]. They have also introduced a cold-soluble alginate that can form gels without heating, expanding the application range in temperature-sensitive formulations[2].

Strengths: Wide range of alginate products for different applications, proprietary production process for consistent quality. Weaknesses: May be more expensive than generic alternatives, requires expertise to optimize formulations.

Kimica Corp.

Technical Solution: Kimica Corporation specializes in the production of high-quality alginates and has developed a unique "KIMICA Method" for extracting alginates from seaweed. Their process allows for the production of alginates with specific molecular weights and M/G ratios, which directly influence gel viscosity and strength. Kimica's ALGIN series includes products with varying degrees of polymerization, enabling fine-tuning of gel viscosity. They have also introduced a rapid-dissolving alginate that can form gels quickly at room temperature, addressing challenges in cold-processing applications[3]. Kimica's research has shown that their alginates can achieve up to 30% higher viscosity compared to standard alginates at the same concentration[4].

Strengths: Specialized in alginate production with proprietary extraction method, wide range of alginate grades for precise viscosity control. Weaknesses: Limited product range outside of alginates, potentially higher cost due to specialization.

Innovative Approaches in Gel Rheology

Mononuclearly filled microcapsules

PatentInactiveUS20090291168A1

Innovation

- Development of mononuclearly filled seamless microcapsules with a hardened capsule shell based on acid polysaccharides, which are heat stable, resistant to shear forces, and have a low water content, allowing for instantaneous flavor release during ingestion and improved retention of flavor substances.

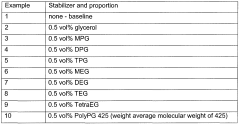

Use of glycols and polyols to stabilize viscoelastic surfactant gelled fluids

PatentWO2007121056A1

Innovation

- Incorporating glycols and polyols as stabilizers in combination with viscoelastic surfactants to maintain the increased viscosity of the fluids, allowing them to sustain viscosity over the necessary time and temperature for effective fracturing operations.

Regulatory Considerations for Gel Products

When developing gel products containing sodium alginate, it is crucial to consider the regulatory landscape to ensure compliance and product safety. The regulatory framework for gel products varies depending on their intended use, application method, and target market. In the United States, the Food and Drug Administration (FDA) oversees the regulation of gel products, categorizing them based on their intended use as cosmetics, medical devices, or drugs.

For cosmetic gel products, manufacturers must comply with the Federal Food, Drug, and Cosmetic Act (FD&C Act) and the Fair Packaging and Labeling Act (FPLA). These regulations require proper labeling, including ingredient lists and safety warnings. Additionally, manufacturers are responsible for ensuring the safety of their products and ingredients before marketing.

Gel products classified as medical devices or drugs face more stringent regulatory requirements. These may include premarket approval processes, good manufacturing practices (GMP) compliance, and post-market surveillance. The FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, while the Center for Drug Evaluation and Research (CDER) oversees drug products.

In the European Union, gel products are regulated under the Cosmetic Products Regulation (EC) No 1223/2009 if intended for cosmetic use. This regulation mandates safety assessments, product information files, and notification to the Cosmetic Products Notification Portal (CPNP) before market entry. For medical applications, gel products may fall under the Medical Devices Regulation (EU) 2017/745 or the Medicinal Products Directive 2001/83/EC, depending on their classification.

Regulatory considerations specific to sodium alginate in gel systems include its status as a generally recognized as safe (GRAS) ingredient by the FDA for certain food applications. However, its use in non-food gel products may require additional safety assessments and documentation. Manufacturers must also consider the sourcing and quality of sodium alginate, ensuring it meets appropriate purity standards and is free from contaminants.

When controlling viscosity in gel systems with sodium alginate, manufacturers must adhere to relevant quality control and testing requirements. This may involve implementing validated analytical methods for viscosity measurement and establishing acceptable ranges for product specifications. Documentation of these processes and results is essential for regulatory compliance and potential inspections.

Lastly, international regulatory harmonization efforts, such as the International Cooperation on Cosmetics Regulation (ICCR), aim to streamline regulatory processes across different regions. Manufacturers developing gel products with sodium alginate should stay informed about these initiatives and consider their impact on global market access and compliance strategies.

For cosmetic gel products, manufacturers must comply with the Federal Food, Drug, and Cosmetic Act (FD&C Act) and the Fair Packaging and Labeling Act (FPLA). These regulations require proper labeling, including ingredient lists and safety warnings. Additionally, manufacturers are responsible for ensuring the safety of their products and ingredients before marketing.

Gel products classified as medical devices or drugs face more stringent regulatory requirements. These may include premarket approval processes, good manufacturing practices (GMP) compliance, and post-market surveillance. The FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, while the Center for Drug Evaluation and Research (CDER) oversees drug products.

In the European Union, gel products are regulated under the Cosmetic Products Regulation (EC) No 1223/2009 if intended for cosmetic use. This regulation mandates safety assessments, product information files, and notification to the Cosmetic Products Notification Portal (CPNP) before market entry. For medical applications, gel products may fall under the Medical Devices Regulation (EU) 2017/745 or the Medicinal Products Directive 2001/83/EC, depending on their classification.

Regulatory considerations specific to sodium alginate in gel systems include its status as a generally recognized as safe (GRAS) ingredient by the FDA for certain food applications. However, its use in non-food gel products may require additional safety assessments and documentation. Manufacturers must also consider the sourcing and quality of sodium alginate, ensuring it meets appropriate purity standards and is free from contaminants.

When controlling viscosity in gel systems with sodium alginate, manufacturers must adhere to relevant quality control and testing requirements. This may involve implementing validated analytical methods for viscosity measurement and establishing acceptable ranges for product specifications. Documentation of these processes and results is essential for regulatory compliance and potential inspections.

Lastly, international regulatory harmonization efforts, such as the International Cooperation on Cosmetics Regulation (ICCR), aim to streamline regulatory processes across different regions. Manufacturers developing gel products with sodium alginate should stay informed about these initiatives and consider their impact on global market access and compliance strategies.

Environmental Impact of Sodium Alginate Gels

The environmental impact of sodium alginate gels is a crucial consideration in their widespread application across various industries. These gels, derived from brown seaweed, have gained popularity due to their biodegradability and renewable nature. However, their production and use still pose certain environmental challenges that warrant careful examination.

One of the primary environmental concerns associated with sodium alginate gels is the potential impact on marine ecosystems. The harvesting of brown seaweed for alginate extraction can lead to disruption of coastal habitats if not managed sustainably. Overharvesting may result in reduced biodiversity and altered ecosystem dynamics in affected areas. To mitigate these effects, responsible sourcing practices and cultivation methods are essential.

The production process of sodium alginate also has environmental implications. The extraction and purification of alginate from seaweed involve chemical treatments that generate waste products. Proper waste management and treatment are necessary to prevent pollution of water bodies and surrounding ecosystems. Additionally, the energy consumption during production contributes to the overall carbon footprint of sodium alginate gels.

On the positive side, sodium alginate gels offer several environmental benefits. Their biodegradability makes them an attractive alternative to synthetic polymers in various applications. When disposed of, these gels break down naturally without leaving persistent pollutants in the environment. This characteristic is particularly valuable in reducing plastic waste and microplastic pollution in aquatic systems.

The use of sodium alginate gels in wastewater treatment and environmental remediation showcases their potential for positive environmental impact. These gels can effectively remove heavy metals and other pollutants from water, contributing to improved water quality and ecosystem health. Their ability to form stable hydrogels also makes them useful in soil stabilization and erosion control applications, helping to preserve land resources.

In the context of controlling viscosity in gel systems, the environmental impact of sodium alginate is generally favorable compared to synthetic alternatives. The ability to fine-tune viscosity using natural, biodegradable materials reduces reliance on potentially harmful synthetic additives. This aligns with the growing demand for environmentally friendly solutions in industries such as food, pharmaceuticals, and cosmetics.

However, it is important to consider the end-of-life management of products containing sodium alginate gels. While biodegradable, improper disposal or excessive use could still lead to temporary alterations in local environments. Educating consumers and implementing appropriate disposal guidelines are crucial steps in maximizing the environmental benefits of these gels.

One of the primary environmental concerns associated with sodium alginate gels is the potential impact on marine ecosystems. The harvesting of brown seaweed for alginate extraction can lead to disruption of coastal habitats if not managed sustainably. Overharvesting may result in reduced biodiversity and altered ecosystem dynamics in affected areas. To mitigate these effects, responsible sourcing practices and cultivation methods are essential.

The production process of sodium alginate also has environmental implications. The extraction and purification of alginate from seaweed involve chemical treatments that generate waste products. Proper waste management and treatment are necessary to prevent pollution of water bodies and surrounding ecosystems. Additionally, the energy consumption during production contributes to the overall carbon footprint of sodium alginate gels.

On the positive side, sodium alginate gels offer several environmental benefits. Their biodegradability makes them an attractive alternative to synthetic polymers in various applications. When disposed of, these gels break down naturally without leaving persistent pollutants in the environment. This characteristic is particularly valuable in reducing plastic waste and microplastic pollution in aquatic systems.

The use of sodium alginate gels in wastewater treatment and environmental remediation showcases their potential for positive environmental impact. These gels can effectively remove heavy metals and other pollutants from water, contributing to improved water quality and ecosystem health. Their ability to form stable hydrogels also makes them useful in soil stabilization and erosion control applications, helping to preserve land resources.

In the context of controlling viscosity in gel systems, the environmental impact of sodium alginate is generally favorable compared to synthetic alternatives. The ability to fine-tune viscosity using natural, biodegradable materials reduces reliance on potentially harmful synthetic additives. This aligns with the growing demand for environmentally friendly solutions in industries such as food, pharmaceuticals, and cosmetics.

However, it is important to consider the end-of-life management of products containing sodium alginate gels. While biodegradable, improper disposal or excessive use could still lead to temporary alterations in local environments. Educating consumers and implementing appropriate disposal guidelines are crucial steps in maximizing the environmental benefits of these gels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!