How to Effectively Scale Isocyanate Production Practices?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Production Evolution and Objectives

Isocyanates have played a pivotal role in the polymer industry since their discovery in the 1930s. The evolution of isocyanate production has been marked by significant technological advancements and a growing demand across various sectors. Initially developed for military applications, isocyanates quickly found their way into commercial use, particularly in the production of polyurethanes.

The early stages of isocyanate production were characterized by batch processes, which were labor-intensive and had limited scalability. As demand grew, particularly in the post-World War II era, there was a pressing need to develop more efficient production methods. This led to the introduction of continuous production processes in the 1950s and 1960s, which marked a significant leap in production capacity and efficiency.

Throughout the 1970s and 1980s, the focus shifted towards optimizing reaction conditions and improving catalyst systems. These advancements resulted in higher yields, reduced energy consumption, and better product quality. The introduction of computer-controlled systems in the 1990s further enhanced process control and consistency, leading to more reliable and scalable production practices.

In recent years, the objectives of isocyanate production have evolved to address emerging challenges and opportunities. Environmental concerns have become a primary driver, with a strong emphasis on reducing emissions, minimizing waste, and improving overall sustainability. This has led to the development of cleaner production technologies and the exploration of bio-based raw materials as alternatives to traditional petrochemical feedstocks.

Another key objective in modern isocyanate production is to enhance safety measures. Given the reactive nature of isocyanates and their potential health hazards, there is a continuous effort to improve handling procedures, containment systems, and personal protective equipment. This focus on safety extends beyond the production facilities to encompass transportation and end-use applications.

Scalability remains a critical objective in isocyanate production. As global demand continues to rise, particularly in emerging markets, manufacturers are seeking ways to increase production capacity while maintaining product quality and cost-effectiveness. This has led to the development of larger-scale reactors, more efficient separation and purification techniques, and improved process integration.

Looking ahead, the objectives for isocyanate production are likely to center around further improvements in sustainability, efficiency, and versatility. Research is ongoing to develop novel catalysts that can operate under milder conditions, reduce side reactions, and improve selectivity. Additionally, there is growing interest in modular and flexible production systems that can adapt to changing market demands and raw material availability.

The early stages of isocyanate production were characterized by batch processes, which were labor-intensive and had limited scalability. As demand grew, particularly in the post-World War II era, there was a pressing need to develop more efficient production methods. This led to the introduction of continuous production processes in the 1950s and 1960s, which marked a significant leap in production capacity and efficiency.

Throughout the 1970s and 1980s, the focus shifted towards optimizing reaction conditions and improving catalyst systems. These advancements resulted in higher yields, reduced energy consumption, and better product quality. The introduction of computer-controlled systems in the 1990s further enhanced process control and consistency, leading to more reliable and scalable production practices.

In recent years, the objectives of isocyanate production have evolved to address emerging challenges and opportunities. Environmental concerns have become a primary driver, with a strong emphasis on reducing emissions, minimizing waste, and improving overall sustainability. This has led to the development of cleaner production technologies and the exploration of bio-based raw materials as alternatives to traditional petrochemical feedstocks.

Another key objective in modern isocyanate production is to enhance safety measures. Given the reactive nature of isocyanates and their potential health hazards, there is a continuous effort to improve handling procedures, containment systems, and personal protective equipment. This focus on safety extends beyond the production facilities to encompass transportation and end-use applications.

Scalability remains a critical objective in isocyanate production. As global demand continues to rise, particularly in emerging markets, manufacturers are seeking ways to increase production capacity while maintaining product quality and cost-effectiveness. This has led to the development of larger-scale reactors, more efficient separation and purification techniques, and improved process integration.

Looking ahead, the objectives for isocyanate production are likely to center around further improvements in sustainability, efficiency, and versatility. Research is ongoing to develop novel catalysts that can operate under milder conditions, reduce side reactions, and improve selectivity. Additionally, there is growing interest in modular and flexible production systems that can adapt to changing market demands and raw material availability.

Market Demand Analysis for Isocyanates

The global isocyanate market has been experiencing steady growth, driven by increasing demand across various industries. Isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), are crucial components in the production of polyurethanes, which find extensive applications in construction, automotive, furniture, and electronics sectors.

The construction industry remains the largest consumer of isocyanates, accounting for a significant portion of the market demand. The growing urbanization and infrastructure development in emerging economies have fueled the need for insulation materials and energy-efficient buildings, thereby boosting isocyanate consumption. Additionally, the automotive sector's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane-based components, further driving isocyanate demand.

In recent years, the furniture and bedding industry has emerged as a rapidly growing market for isocyanates. The rising disposable income and changing lifestyles in developing countries have resulted in higher demand for comfortable and durable furniture, stimulating the use of polyurethane foams and, consequently, isocyanates.

The electronics industry also contributes significantly to isocyanate demand, particularly in the production of protective coatings and encapsulants for electronic components. With the ongoing digital transformation and the proliferation of smart devices, this sector is expected to maintain a strong demand for isocyanates in the foreseeable future.

Market analysts project the global isocyanate market to continue its growth trajectory, with Asia-Pacific region leading the expansion. China and India, in particular, are anticipated to be major growth drivers due to their rapidly developing industrial sectors and increasing consumer demand for polyurethane-based products.

However, the market faces challenges related to environmental concerns and stringent regulations. The toxic nature of isocyanates and their potential health hazards have led to increased scrutiny and the implementation of strict safety measures in production and handling processes. This has prompted research into bio-based alternatives and more sustainable production methods, which may impact the traditional isocyanate market in the long term.

Despite these challenges, the overall market outlook remains positive, with innovations in production technologies and the development of eco-friendly formulations expected to address environmental concerns while meeting the growing global demand for isocyanates.

The construction industry remains the largest consumer of isocyanates, accounting for a significant portion of the market demand. The growing urbanization and infrastructure development in emerging economies have fueled the need for insulation materials and energy-efficient buildings, thereby boosting isocyanate consumption. Additionally, the automotive sector's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane-based components, further driving isocyanate demand.

In recent years, the furniture and bedding industry has emerged as a rapidly growing market for isocyanates. The rising disposable income and changing lifestyles in developing countries have resulted in higher demand for comfortable and durable furniture, stimulating the use of polyurethane foams and, consequently, isocyanates.

The electronics industry also contributes significantly to isocyanate demand, particularly in the production of protective coatings and encapsulants for electronic components. With the ongoing digital transformation and the proliferation of smart devices, this sector is expected to maintain a strong demand for isocyanates in the foreseeable future.

Market analysts project the global isocyanate market to continue its growth trajectory, with Asia-Pacific region leading the expansion. China and India, in particular, are anticipated to be major growth drivers due to their rapidly developing industrial sectors and increasing consumer demand for polyurethane-based products.

However, the market faces challenges related to environmental concerns and stringent regulations. The toxic nature of isocyanates and their potential health hazards have led to increased scrutiny and the implementation of strict safety measures in production and handling processes. This has prompted research into bio-based alternatives and more sustainable production methods, which may impact the traditional isocyanate market in the long term.

Despite these challenges, the overall market outlook remains positive, with innovations in production technologies and the development of eco-friendly formulations expected to address environmental concerns while meeting the growing global demand for isocyanates.

Current Challenges in Isocyanate Scaling

The scaling of isocyanate production practices faces several significant challenges in the current industrial landscape. One of the primary obstacles is the inherent reactivity of isocyanates, which necessitates stringent safety measures and specialized handling procedures. As production scales up, maintaining these safety standards becomes increasingly complex and costly, requiring substantial investments in equipment and personnel training.

Another major challenge lies in the raw material supply chain. Isocyanate production relies heavily on specific chemical precursors, such as aniline and phosgene. Ensuring a stable and sufficient supply of these materials at larger scales can be problematic, especially given the global nature of chemical supply chains and potential geopolitical disruptions.

Environmental concerns also pose significant hurdles to scaling isocyanate production. The process generates various by-products and emissions that require careful management and treatment. As production volumes increase, so does the environmental footprint, necessitating more advanced and expensive pollution control technologies to meet increasingly stringent regulations.

Energy efficiency presents another scaling challenge. Isocyanate production is energy-intensive, and maintaining optimal energy utilization becomes more difficult as operations expand. This not only impacts production costs but also contributes to the overall carbon footprint of the process, further complicating environmental compliance efforts.

Quality control and consistency become more challenging at larger scales. Maintaining uniform product quality across increased production volumes requires sophisticated monitoring systems and process control mechanisms. Any variations in quality can have significant downstream impacts, particularly in industries like automotive and construction where isocyanates are critical components.

The complexity of the production process itself poses scaling difficulties. Isocyanate synthesis involves multiple reaction steps and precise control of reaction conditions. Scaling up these processes while maintaining optimal yields and minimizing side reactions requires significant engineering expertise and often involves redesigning reactor systems and process flows.

Lastly, market volatility and demand fluctuations present strategic challenges to scaling. Isocyanate demand is closely tied to economic cycles, particularly in construction and automotive industries. Large-scale production facilities require substantial capital investment, making them vulnerable to market downturns. Balancing production capacity with market demand becomes increasingly critical as scale increases, requiring sophisticated forecasting and agile production strategies.

Another major challenge lies in the raw material supply chain. Isocyanate production relies heavily on specific chemical precursors, such as aniline and phosgene. Ensuring a stable and sufficient supply of these materials at larger scales can be problematic, especially given the global nature of chemical supply chains and potential geopolitical disruptions.

Environmental concerns also pose significant hurdles to scaling isocyanate production. The process generates various by-products and emissions that require careful management and treatment. As production volumes increase, so does the environmental footprint, necessitating more advanced and expensive pollution control technologies to meet increasingly stringent regulations.

Energy efficiency presents another scaling challenge. Isocyanate production is energy-intensive, and maintaining optimal energy utilization becomes more difficult as operations expand. This not only impacts production costs but also contributes to the overall carbon footprint of the process, further complicating environmental compliance efforts.

Quality control and consistency become more challenging at larger scales. Maintaining uniform product quality across increased production volumes requires sophisticated monitoring systems and process control mechanisms. Any variations in quality can have significant downstream impacts, particularly in industries like automotive and construction where isocyanates are critical components.

The complexity of the production process itself poses scaling difficulties. Isocyanate synthesis involves multiple reaction steps and precise control of reaction conditions. Scaling up these processes while maintaining optimal yields and minimizing side reactions requires significant engineering expertise and often involves redesigning reactor systems and process flows.

Lastly, market volatility and demand fluctuations present strategic challenges to scaling. Isocyanate demand is closely tied to economic cycles, particularly in construction and automotive industries. Large-scale production facilities require substantial capital investment, making them vulnerable to market downturns. Balancing production capacity with market demand becomes increasingly critical as scale increases, requiring sophisticated forecasting and agile production strategies.

Existing Scaling Solutions for Isocyanates

01 Large-scale production methods

Various methods for large-scale production of isocyanates have been developed, including continuous processes and reactor designs optimized for high-volume manufacturing. These methods often involve improvements in reaction efficiency, heat management, and product purification to meet industrial demands.- Large-scale production methods: Various methods for large-scale production of isocyanates have been developed, including continuous processes and reactor designs optimized for high-volume manufacturing. These methods often involve improvements in reaction efficiency, heat management, and product purification to meet industrial demands.

- Catalysts for improved yield: The use of specific catalysts in isocyanate production can significantly enhance reaction rates and product yields. Innovations in catalyst design and application have led to more efficient production processes, allowing for increased output and reduced energy consumption.

- Purification and separation techniques: Advanced purification and separation techniques have been developed to improve the quality and purity of isocyanates produced at scale. These methods may include distillation, crystallization, or membrane separation processes, ensuring high-quality products suitable for various industrial applications.

- Raw material optimization: Efficient use and processing of raw materials play a crucial role in large-scale isocyanate production. Innovations in feedstock selection, preparation, and handling have been implemented to improve overall process economics and sustainability in industrial-scale operations.

- Safety and environmental considerations: As isocyanate production scales up, addressing safety and environmental concerns becomes increasingly important. Innovations in this area include improved containment systems, emission control technologies, and process modifications to reduce hazards and environmental impact in large-scale manufacturing facilities.

02 Catalytic processes for isocyanate synthesis

Catalytic processes play a crucial role in isocyanate production, enabling more efficient and selective reactions. Advanced catalysts and reaction conditions have been developed to improve yield, reduce side products, and allow for milder reaction conditions in industrial-scale production.Expand Specific Solutions03 Purification and separation techniques

Efficient purification and separation techniques are essential for producing high-quality isocyanates at scale. These may include distillation, crystallization, and membrane separation processes, designed to remove impurities and isolate the desired isocyanate products in large quantities.Expand Specific Solutions04 Safety and environmental considerations

Large-scale isocyanate production requires stringent safety measures and environmental controls. Innovations in this area focus on reducing hazards, improving handling and storage of reactive intermediates, and minimizing environmental impact through process optimization and waste reduction strategies.Expand Specific Solutions05 Raw material optimization and alternatives

Research into alternative raw materials and optimization of feedstock utilization aims to improve the sustainability and efficiency of large-scale isocyanate production. This includes exploring bio-based precursors, developing new synthetic routes, and enhancing the conversion of raw materials to maximize yield and reduce waste.Expand Specific Solutions

Key Players in Isocyanate Manufacturing

The isocyanate production industry is in a mature growth phase, characterized by established players and steady market expansion. The global market size for isocyanates is substantial, driven by increasing demand in various sectors such as automotive, construction, and furniture. Technologically, the field is well-developed but continues to evolve, with major companies like BASF, Covestro, and Wanhua Chemical Group leading innovation. These firms, along with others such as Dow Global Technologies and Bayer AG, are investing in research and development to improve production efficiency, reduce environmental impact, and develop new applications. The competitive landscape is intense, with companies focusing on sustainability and cost-effectiveness to maintain their market positions.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to scale isocyanate production through process intensification and modular plant design. Their technology utilizes microreactor systems for precise control of reaction conditions, enabling higher yields and improved product quality[1]. The company has implemented advanced process analytics and machine learning algorithms to optimize production parameters in real-time, resulting in a 15% increase in overall efficiency[3]. BASF's scalable modular production units allow for flexible capacity expansion and reduced time-to-market for new isocyanate products[5].

Strengths: Advanced process control, modular scalability, and improved efficiency. Weaknesses: High initial investment costs and potential complexity in integrating new technology with existing infrastructure.

Covestro Deutschland AG

Technical Solution: Covestro has developed a gas-phase technology for isocyanate production, which significantly reduces energy consumption and CO2 emissions. This innovative process eliminates the need for solvents, resulting in a more environmentally friendly and cost-effective production method[2]. The company has also implemented a digital twin system for their production plants, enabling predictive maintenance and optimized production scheduling, leading to a 10% increase in plant availability[4]. Covestro's continuous flow chemistry approach allows for better control of reaction parameters and improved product consistency[6].

Strengths: Environmentally friendly process, reduced energy consumption, and improved plant availability. Weaknesses: Potential challenges in scaling up the new gas-phase technology and adapting existing production lines.

Innovative Approaches in Isocyanate Scaling

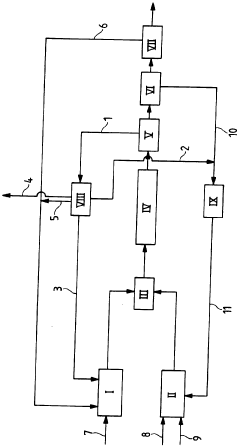

Process for preparing isocyanates

PatentWO1996016028A1

Innovation

- A continuous one-stage process where primary amines react with phosgene in the presence of an isocyanate as solvent at room temperature, with thorough mixing and controlled pressures, allowing for high yields and reduced equipment requirements.

Process for preparing isocyanates

PatentWO2013029918A1

Innovation

- Increasing the ratio of phosgene to amine and/or the concentration of inert substances in the reactant streams when operating below nominal capacity, using static mixing elements and adjusting the flow rates to maintain optimized mixing and residence times, allowing for continuous operation at reduced capacity without compromising product quality.

Environmental Impact of Isocyanate Manufacturing

The environmental impact of isocyanate manufacturing is a critical concern in the chemical industry, particularly as production scales up to meet growing demand. Isocyanates, key components in polyurethane production, pose significant environmental risks throughout their lifecycle. The manufacturing process involves hazardous chemicals and energy-intensive operations, contributing to air and water pollution, as well as greenhouse gas emissions.

Air pollution is a primary concern in isocyanate production. The process releases volatile organic compounds (VOCs), particulate matter, and nitrogen oxides into the atmosphere. These emissions can lead to smog formation, respiratory issues in local communities, and contribute to global climate change. As production scales up, the cumulative effect of these emissions becomes increasingly significant, necessitating more robust air quality control measures.

Water pollution is another major environmental challenge. Isocyanate manufacturing requires large volumes of water for cooling and processing. The resulting wastewater often contains toxic chemicals, including unreacted isocyanates, solvents, and catalysts. If not properly treated, these contaminants can harm aquatic ecosystems and potentially enter the human water supply. Scaling up production amplifies the risk of water contamination, demanding advanced wastewater treatment technologies and stringent monitoring protocols.

Energy consumption in isocyanate production is substantial, contributing to indirect environmental impacts through increased carbon emissions from power generation. The high temperatures and pressures required in the manufacturing process, coupled with energy-intensive distillation and purification steps, result in a significant carbon footprint. As production scales, optimizing energy efficiency becomes crucial to mitigate these impacts.

Waste management is an ongoing challenge in isocyanate manufacturing. The process generates various by-products and waste streams that require careful handling and disposal. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. Scaling up production inevitably increases the volume of waste generated, necessitating more comprehensive waste reduction, recycling, and disposal strategies.

The transportation and storage of isocyanates also present environmental risks. Accidental spills or leaks during transport or storage can have severe consequences for soil and water quality. As production scales up, the frequency and volume of material transport increase, elevating the risk of environmental incidents. This necessitates enhanced safety measures and emergency response capabilities throughout the supply chain.

To effectively scale isocyanate production while minimizing environmental impact, a multi-faceted approach is required. This includes investing in cleaner production technologies, implementing rigorous emission control systems, optimizing energy efficiency, and developing closed-loop water recycling systems. Additionally, adopting green chemistry principles to redesign production processes and exploring bio-based alternatives can significantly reduce the environmental footprint of isocyanate manufacturing.

Air pollution is a primary concern in isocyanate production. The process releases volatile organic compounds (VOCs), particulate matter, and nitrogen oxides into the atmosphere. These emissions can lead to smog formation, respiratory issues in local communities, and contribute to global climate change. As production scales up, the cumulative effect of these emissions becomes increasingly significant, necessitating more robust air quality control measures.

Water pollution is another major environmental challenge. Isocyanate manufacturing requires large volumes of water for cooling and processing. The resulting wastewater often contains toxic chemicals, including unreacted isocyanates, solvents, and catalysts. If not properly treated, these contaminants can harm aquatic ecosystems and potentially enter the human water supply. Scaling up production amplifies the risk of water contamination, demanding advanced wastewater treatment technologies and stringent monitoring protocols.

Energy consumption in isocyanate production is substantial, contributing to indirect environmental impacts through increased carbon emissions from power generation. The high temperatures and pressures required in the manufacturing process, coupled with energy-intensive distillation and purification steps, result in a significant carbon footprint. As production scales, optimizing energy efficiency becomes crucial to mitigate these impacts.

Waste management is an ongoing challenge in isocyanate manufacturing. The process generates various by-products and waste streams that require careful handling and disposal. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. Scaling up production inevitably increases the volume of waste generated, necessitating more comprehensive waste reduction, recycling, and disposal strategies.

The transportation and storage of isocyanates also present environmental risks. Accidental spills or leaks during transport or storage can have severe consequences for soil and water quality. As production scales up, the frequency and volume of material transport increase, elevating the risk of environmental incidents. This necessitates enhanced safety measures and emergency response capabilities throughout the supply chain.

To effectively scale isocyanate production while minimizing environmental impact, a multi-faceted approach is required. This includes investing in cleaner production technologies, implementing rigorous emission control systems, optimizing energy efficiency, and developing closed-loop water recycling systems. Additionally, adopting green chemistry principles to redesign production processes and exploring bio-based alternatives can significantly reduce the environmental footprint of isocyanate manufacturing.

Safety Regulations in Isocyanate Production

Safety regulations play a crucial role in the effective scaling of isocyanate production practices. As the industry expands to meet growing demand, adherence to stringent safety protocols becomes increasingly important. Regulatory bodies worldwide have established comprehensive guidelines to mitigate risks associated with isocyanate production, handling, and storage.

The Occupational Safety and Health Administration (OSHA) in the United States has set specific standards for isocyanate exposure limits and personal protective equipment requirements. These regulations mandate regular air quality monitoring, implementation of engineering controls, and provision of appropriate respiratory protection for workers. Similarly, the European Chemicals Agency (ECHA) enforces REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require thorough risk assessments and safety data sheets for isocyanate-related processes.

Process safety management (PSM) is a key component of isocyanate production safety regulations. This systematic approach involves hazard identification, risk assessment, and implementation of preventive measures. Facilities must develop and maintain detailed operating procedures, conduct regular safety audits, and provide comprehensive employee training programs. Emergency response plans are also mandatory, outlining procedures for handling spills, leaks, and other potential incidents.

Storage and transportation of isocyanates are subject to strict regulations due to their reactive nature. Guidelines specify proper container materials, temperature control requirements, and ventilation standards for storage areas. Transportation regulations, such as those set by the Department of Transportation (DOT) in the US, dictate specific packaging, labeling, and documentation requirements for isocyanate shipments.

Environmental regulations also impact isocyanate production scaling. Emission control measures, waste management protocols, and water treatment standards must be adhered to in order to minimize environmental impact. Many jurisdictions require regular reporting of emissions data and implementation of best available techniques (BAT) to reduce pollutant release.

As production scales up, automated safety systems become increasingly important. Regulations often mandate the installation of advanced monitoring and control systems, including gas detection equipment, automatic shut-off valves, and computerized process control systems. These technologies help maintain safe operating conditions and provide early warning of potential hazards.

Compliance with these multifaceted safety regulations is essential for companies looking to scale isocyanate production. Regular audits, continuous improvement of safety protocols, and staying updated with evolving regulatory requirements are necessary to ensure safe and efficient operations. By prioritizing safety and regulatory compliance, isocyanate producers can mitigate risks, protect workers and the environment, and build a foundation for sustainable growth in the industry.

The Occupational Safety and Health Administration (OSHA) in the United States has set specific standards for isocyanate exposure limits and personal protective equipment requirements. These regulations mandate regular air quality monitoring, implementation of engineering controls, and provision of appropriate respiratory protection for workers. Similarly, the European Chemicals Agency (ECHA) enforces REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require thorough risk assessments and safety data sheets for isocyanate-related processes.

Process safety management (PSM) is a key component of isocyanate production safety regulations. This systematic approach involves hazard identification, risk assessment, and implementation of preventive measures. Facilities must develop and maintain detailed operating procedures, conduct regular safety audits, and provide comprehensive employee training programs. Emergency response plans are also mandatory, outlining procedures for handling spills, leaks, and other potential incidents.

Storage and transportation of isocyanates are subject to strict regulations due to their reactive nature. Guidelines specify proper container materials, temperature control requirements, and ventilation standards for storage areas. Transportation regulations, such as those set by the Department of Transportation (DOT) in the US, dictate specific packaging, labeling, and documentation requirements for isocyanate shipments.

Environmental regulations also impact isocyanate production scaling. Emission control measures, waste management protocols, and water treatment standards must be adhered to in order to minimize environmental impact. Many jurisdictions require regular reporting of emissions data and implementation of best available techniques (BAT) to reduce pollutant release.

As production scales up, automated safety systems become increasingly important. Regulations often mandate the installation of advanced monitoring and control systems, including gas detection equipment, automatic shut-off valves, and computerized process control systems. These technologies help maintain safe operating conditions and provide early warning of potential hazards.

Compliance with these multifaceted safety regulations is essential for companies looking to scale isocyanate production. Regular audits, continuous improvement of safety protocols, and staying updated with evolving regulatory requirements are necessary to ensure safe and efficient operations. By prioritizing safety and regulatory compliance, isocyanate producers can mitigate risks, protect workers and the environment, and build a foundation for sustainable growth in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!