How to Ensure Durability in Displays Using QNED?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Display Evolution

The evolution of QNED (Quantum Nano-Emitting Diode) display technology represents a significant advancement in the field of display durability. This innovative technology combines the benefits of quantum dots and nano-rod LEDs to create a more robust and long-lasting display solution. The journey of QNED displays began with the recognition of limitations in existing display technologies, particularly in terms of longevity and performance under various environmental conditions.

Initially, QNED technology focused on overcoming the inherent weaknesses of OLED displays, such as susceptibility to burn-in and color degradation over time. By utilizing quantum dots and nano-rod LEDs, researchers aimed to develop a display that could maintain consistent brightness and color accuracy throughout its lifespan. This approach led to the creation of self-emissive pixels that are more resistant to degradation, thereby enhancing the overall durability of the display.

As the technology progressed, emphasis shifted towards improving the stability of the quantum dot materials used in QNED displays. Early iterations faced challenges related to the degradation of quantum dots when exposed to high temperatures or intense light. To address this, scientists developed more robust quantum dot compositions and protective encapsulation techniques, significantly extending the lifespan of QNED displays.

Another crucial aspect of QNED display evolution has been the optimization of the nano-rod LED structure. By refining the manufacturing process and materials used in these LEDs, researchers have been able to enhance their efficiency and longevity. This has resulted in displays that not only offer superior color performance but also maintain their quality over extended periods of use.

The integration of advanced thermal management systems has played a vital role in ensuring the durability of QNED displays. As these displays generate less heat compared to traditional LED or OLED technologies, they are inherently more stable. However, the implementation of sophisticated heat dissipation mechanisms has further improved their resilience, allowing for consistent performance even in challenging environmental conditions.

Recent developments in QNED technology have focused on enhancing the scalability and manufacturability of these displays. This has involved refining production processes to ensure consistent quality across large-scale manufacturing, thereby improving the overall reliability and durability of QNED displays in commercial applications. As a result, QNED technology is increasingly being considered for a wide range of applications, from consumer electronics to professional displays where longevity is paramount.

Initially, QNED technology focused on overcoming the inherent weaknesses of OLED displays, such as susceptibility to burn-in and color degradation over time. By utilizing quantum dots and nano-rod LEDs, researchers aimed to develop a display that could maintain consistent brightness and color accuracy throughout its lifespan. This approach led to the creation of self-emissive pixels that are more resistant to degradation, thereby enhancing the overall durability of the display.

As the technology progressed, emphasis shifted towards improving the stability of the quantum dot materials used in QNED displays. Early iterations faced challenges related to the degradation of quantum dots when exposed to high temperatures or intense light. To address this, scientists developed more robust quantum dot compositions and protective encapsulation techniques, significantly extending the lifespan of QNED displays.

Another crucial aspect of QNED display evolution has been the optimization of the nano-rod LED structure. By refining the manufacturing process and materials used in these LEDs, researchers have been able to enhance their efficiency and longevity. This has resulted in displays that not only offer superior color performance but also maintain their quality over extended periods of use.

The integration of advanced thermal management systems has played a vital role in ensuring the durability of QNED displays. As these displays generate less heat compared to traditional LED or OLED technologies, they are inherently more stable. However, the implementation of sophisticated heat dissipation mechanisms has further improved their resilience, allowing for consistent performance even in challenging environmental conditions.

Recent developments in QNED technology have focused on enhancing the scalability and manufacturability of these displays. This has involved refining production processes to ensure consistent quality across large-scale manufacturing, thereby improving the overall reliability and durability of QNED displays in commercial applications. As a result, QNED technology is increasingly being considered for a wide range of applications, from consumer electronics to professional displays where longevity is paramount.

Market Demand Analysis

The market demand for durable displays using QNED (Quantum Nano Emitting Diode) technology is rapidly growing, driven by the increasing need for high-performance, long-lasting display solutions across various industries. As consumers and businesses alike seek more reliable and visually impressive screens, QNED displays have emerged as a promising solution to address these demands.

In the consumer electronics sector, there is a strong appetite for televisions and monitors that offer superior picture quality and extended lifespan. QNED technology, with its potential to deliver enhanced brightness, contrast, and color accuracy while maintaining durability, is well-positioned to capture a significant share of this market. The growing trend of smart homes and the increasing average screen sizes in households further amplify the demand for robust display technologies.

The commercial display market, encompassing digital signage, information kiosks, and large-format displays, also presents substantial opportunities for QNED technology. Businesses are increasingly investing in durable display solutions that can withstand continuous operation in various environmental conditions while maintaining consistent performance. QNED's potential for improved durability addresses these needs, making it an attractive option for sectors such as retail, transportation, and hospitality.

The automotive industry is another key driver of market demand for durable QNED displays. As vehicles become more technologically advanced, the integration of high-quality, long-lasting displays for infotainment systems, instrument clusters, and heads-up displays is becoming crucial. QNED technology's resistance to image retention and potential for enhanced visibility in bright conditions make it particularly suitable for automotive applications.

In the healthcare sector, there is a growing need for reliable, high-resolution displays in medical imaging equipment and patient monitoring systems. QNED's potential for improved durability and image quality aligns well with the stringent requirements of medical devices, where consistent performance and longevity are paramount.

The education and corporate sectors also contribute to the market demand for durable QNED displays. Interactive whiteboards, presentation screens, and collaborative displays in these environments require technologies that can withstand frequent use while maintaining visual clarity. QNED's potential for reduced degradation over time makes it an attractive option for these applications.

As environmental concerns gain prominence, the market is increasingly favoring display technologies that offer improved energy efficiency and reduced environmental impact. QNED's potential for lower power consumption compared to some existing technologies could position it favorably in this context, further driving market demand.

In the consumer electronics sector, there is a strong appetite for televisions and monitors that offer superior picture quality and extended lifespan. QNED technology, with its potential to deliver enhanced brightness, contrast, and color accuracy while maintaining durability, is well-positioned to capture a significant share of this market. The growing trend of smart homes and the increasing average screen sizes in households further amplify the demand for robust display technologies.

The commercial display market, encompassing digital signage, information kiosks, and large-format displays, also presents substantial opportunities for QNED technology. Businesses are increasingly investing in durable display solutions that can withstand continuous operation in various environmental conditions while maintaining consistent performance. QNED's potential for improved durability addresses these needs, making it an attractive option for sectors such as retail, transportation, and hospitality.

The automotive industry is another key driver of market demand for durable QNED displays. As vehicles become more technologically advanced, the integration of high-quality, long-lasting displays for infotainment systems, instrument clusters, and heads-up displays is becoming crucial. QNED technology's resistance to image retention and potential for enhanced visibility in bright conditions make it particularly suitable for automotive applications.

In the healthcare sector, there is a growing need for reliable, high-resolution displays in medical imaging equipment and patient monitoring systems. QNED's potential for improved durability and image quality aligns well with the stringent requirements of medical devices, where consistent performance and longevity are paramount.

The education and corporate sectors also contribute to the market demand for durable QNED displays. Interactive whiteboards, presentation screens, and collaborative displays in these environments require technologies that can withstand frequent use while maintaining visual clarity. QNED's potential for reduced degradation over time makes it an attractive option for these applications.

As environmental concerns gain prominence, the market is increasingly favoring display technologies that offer improved energy efficiency and reduced environmental impact. QNED's potential for lower power consumption compared to some existing technologies could position it favorably in this context, further driving market demand.

QNED Durability Challenges

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display technology, offering the potential for superior image quality and energy efficiency. However, ensuring the durability of QNED displays poses several challenges that must be addressed to make this technology commercially viable and competitive in the long term.

One of the primary durability challenges for QNED displays is the stability of quantum dots under prolonged exposure to light and heat. Quantum dots, which are the core components of QNED technology, can degrade over time when subjected to continuous illumination and elevated temperatures. This degradation can lead to color shift, reduced brightness, and overall deterioration of display performance.

Another critical challenge is the susceptibility of quantum dots to oxidation and moisture. Exposure to oxygen and water vapor can significantly impact the optical properties of quantum dots, leading to decreased efficiency and shortened lifespan of the display. Developing effective encapsulation methods to protect quantum dots from environmental factors is crucial for ensuring long-term durability.

The interface between quantum dots and the surrounding matrix material presents another durability concern. Ensuring strong and stable bonding between these components is essential to prevent delamination or separation over time, which could result in non-uniform light emission and reduced display quality.

Thermal management is a significant challenge in QNED displays. The high current densities required for operation can generate substantial heat, potentially accelerating the degradation of quantum dots and other display components. Implementing efficient heat dissipation mechanisms is crucial for maintaining the longevity of QNED displays.

Electrical stability is another key factor affecting QNED durability. Fluctuations in voltage or current can lead to uneven aging of quantum dots across the display, resulting in non-uniform brightness and color reproduction over time. Developing robust electrical control systems is essential for ensuring consistent performance throughout the display's lifespan.

The mechanical durability of QNED displays is also a concern, particularly for flexible or foldable applications. Ensuring that the quantum dot layer can withstand repeated bending or folding without cracking or delamination is crucial for expanding the potential applications of QNED technology.

Addressing these durability challenges requires a multifaceted approach, combining advancements in materials science, device engineering, and manufacturing processes. Overcoming these obstacles will be critical in realizing the full potential of QNED technology and establishing its position as a leading display solution in the market.

One of the primary durability challenges for QNED displays is the stability of quantum dots under prolonged exposure to light and heat. Quantum dots, which are the core components of QNED technology, can degrade over time when subjected to continuous illumination and elevated temperatures. This degradation can lead to color shift, reduced brightness, and overall deterioration of display performance.

Another critical challenge is the susceptibility of quantum dots to oxidation and moisture. Exposure to oxygen and water vapor can significantly impact the optical properties of quantum dots, leading to decreased efficiency and shortened lifespan of the display. Developing effective encapsulation methods to protect quantum dots from environmental factors is crucial for ensuring long-term durability.

The interface between quantum dots and the surrounding matrix material presents another durability concern. Ensuring strong and stable bonding between these components is essential to prevent delamination or separation over time, which could result in non-uniform light emission and reduced display quality.

Thermal management is a significant challenge in QNED displays. The high current densities required for operation can generate substantial heat, potentially accelerating the degradation of quantum dots and other display components. Implementing efficient heat dissipation mechanisms is crucial for maintaining the longevity of QNED displays.

Electrical stability is another key factor affecting QNED durability. Fluctuations in voltage or current can lead to uneven aging of quantum dots across the display, resulting in non-uniform brightness and color reproduction over time. Developing robust electrical control systems is essential for ensuring consistent performance throughout the display's lifespan.

The mechanical durability of QNED displays is also a concern, particularly for flexible or foldable applications. Ensuring that the quantum dot layer can withstand repeated bending or folding without cracking or delamination is crucial for expanding the potential applications of QNED technology.

Addressing these durability challenges requires a multifaceted approach, combining advancements in materials science, device engineering, and manufacturing processes. Overcoming these obstacles will be critical in realizing the full potential of QNED technology and establishing its position as a leading display solution in the market.

Current QNED Durability Solutions

01 Improved durability through advanced materials

QNED displays utilize advanced materials to enhance durability. These materials may include specialized quantum dot films, nanoparticle-enhanced components, or reinforced panel structures that improve resistance to physical stress, environmental factors, and prolonged use.- Improved durability through advanced materials: QNED displays utilize advanced materials to enhance durability. These materials may include specialized quantum dot and nanorod compositions, as well as protective layers that increase resistance to environmental factors and physical stress. The use of these materials contributes to longer-lasting displays with improved resistance to degradation over time.

- Enhanced structural design for durability: The structural design of QNED displays incorporates features that improve overall durability. This may include reinforced panel structures, optimized component layouts, and shock-absorbing elements. These design enhancements help protect the display from physical damage and extend its operational lifespan.

- Thermal management for increased longevity: QNED displays implement advanced thermal management systems to regulate temperature and prevent heat-related degradation. This may include heat dissipation structures, thermal interface materials, and intelligent temperature control mechanisms. Effective thermal management contributes to the overall durability and longevity of the display.

- Protective coatings and encapsulation techniques: To enhance durability, QNED displays employ protective coatings and encapsulation techniques. These may include anti-scratch coatings, moisture barriers, and hermetic sealing methods. Such protective measures shield the display components from environmental factors and physical damage, thereby extending the display's lifespan.

- Durability testing and quality control measures: Manufacturers implement rigorous durability testing and quality control measures for QNED displays. This includes stress tests, environmental simulations, and long-term performance evaluations. These processes help identify potential weaknesses and ensure that the displays meet high standards of durability before reaching the market.

02 Enhanced thermal management for longevity

QNED displays incorporate innovative thermal management solutions to prevent overheating and extend the lifespan of the display. This may involve advanced heat dissipation techniques, temperature-regulating materials, or optimized component layouts to ensure stable performance over time.Expand Specific Solutions03 Protective coatings and surface treatments

To improve durability, QNED displays may feature specialized protective coatings or surface treatments. These can include scratch-resistant layers, anti-reflective coatings, or moisture-resistant barriers that protect the display from external damage and environmental factors.Expand Specific Solutions04 Structural design for impact resistance

QNED displays may incorporate structural design elements that enhance impact resistance and overall durability. This can include reinforced bezels, shock-absorbing materials, or innovative panel mounting techniques that distribute forces more evenly across the display.Expand Specific Solutions05 Self-healing and maintenance technologies

Some QNED displays may feature self-healing or easy maintenance technologies to prolong their lifespan. This could involve self-repairing pixel structures, modular designs for easy component replacement, or built-in diagnostics to detect and address potential issues before they affect display performance.Expand Specific Solutions

Key QNED Industry Players

The QNED (Quantum Nano Emitting Diode) display technology is in its early development stage, with a growing market potential due to its promise of enhanced durability and performance. The industry is currently transitioning from research to early commercialization, with major players like Samsung Display, BOE Technology, and Sharp Corp. leading the way. These companies are investing heavily in R&D to overcome technical challenges and improve manufacturing processes. The market size is expected to expand rapidly as QNED technology matures and becomes more cost-effective. While still not as mature as OLED or LCD technologies, QNED displays are gaining traction due to their potential for longer lifespan, higher brightness, and better energy efficiency, making durability a key focus for industry players.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) display technology that combines quantum dots with mini-LED backlighting. Their approach focuses on enhancing color gamut and brightness while maintaining long-term durability. BOE's QNED panels utilize a specialized quantum dot film and advanced mini-LED array, which are sealed within a robust encapsulation layer to protect against environmental factors. The company has also implemented an intelligent thermal management system to regulate operating temperatures and prevent degradation of the quantum dot material over time.

Strengths: Wide color gamut, high brightness, and improved energy efficiency. Weaknesses: Higher production costs and potential for color shift over extended use.

Shanghai Tianma Microelectronics Co., Ltd.

Technical Solution: Tianma has been developing QNED technology with a focus on durability for various applications, including automotive displays. Their approach involves a specialized quantum dot-enhanced film that is designed to withstand high temperatures and intense light exposure. Tianma's QNED panels utilize a unique encapsulation method that combines inorganic and organic materials to create a robust barrier against environmental factors. The company has also implemented an advanced thermal management system that efficiently dissipates heat from the display, reducing stress on the quantum dot material. Additionally, Tianma employs a proprietary driving scheme that optimizes power distribution across the mini-LED backlight, further enhancing the longevity of the display.

Strengths: High durability suitable for automotive and outdoor applications, good color performance. Weaknesses: Slightly lower peak brightness compared to some competitors and higher production costs.

QNED Durability Patents

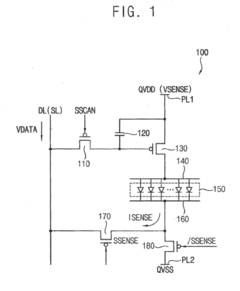

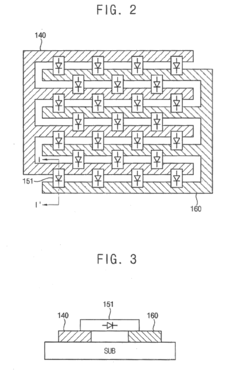

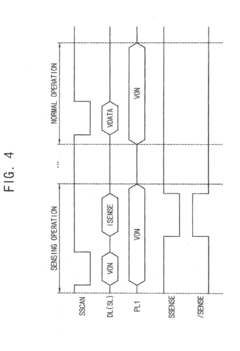

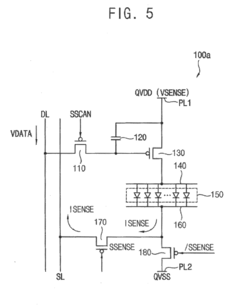

Quantum-nano light emitting diode pixel and quantum-nano light emitting diode display device

PatentActiveUS20190081261A1

Innovation

- A Q-NED pixel and display device design that includes a switching transistor, storage capacitor, driving transistor, and sensing transistors to sense and compensate for ohmic contact resistance deviations, utilizing inorganic materials like gallium nitride for the Q-NEDs, with anode and cathode electrodes having a comb shape to enhance light emission efficiency and maintain luminance over time.

Quantum dot composition and quantum dot light-emitting device

PatentWO2024139483A1

Innovation

- Using a core-shell quantum dot composition, by adjusting the core and shell energy level structures of the quantum dots, ensure that the conduction band and valence band energy level ratio of the core is within the range of 1:0.9-1.1, and the conduction band and valence band of the shell are The energy level is lower than the corresponding energy level of the nucleus, forming an appropriate energy level barrier to control carrier balance and exciton binding, and avoid exciton recombination region deviation.

QNED Material Advancements

Recent advancements in QNED (Quantum Nano Emitting Diode) materials have significantly contributed to improving the durability of displays. These innovations focus on enhancing the stability and longevity of the quantum dot nanoparticles, which are the core components of QNED technology. One key development is the introduction of advanced encapsulation techniques that protect the quantum dots from environmental factors such as moisture, oxygen, and heat.

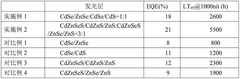

Researchers have made substantial progress in developing more robust quantum dot structures. By incorporating a protective shell around the quantum dot core, scientists have successfully mitigated the effects of oxidation and degradation. This shell, typically composed of inorganic materials like zinc sulfide or cadmium sulfide, acts as a barrier against external stressors while maintaining the optical properties of the quantum dots.

Another significant advancement is the optimization of quantum dot composition. By fine-tuning the elemental ratios and introducing dopants, researchers have created quantum dots with improved thermal stability. These enhanced materials can withstand higher operating temperatures without compromising their emission efficiency, thus extending the overall lifespan of QNED displays.

The development of hybrid organic-inorganic quantum dot materials has also shown promise in improving durability. These hybrid structures combine the benefits of both organic and inorganic materials, resulting in quantum dots with enhanced stability and resistance to environmental factors. This approach has led to the creation of QNED displays that maintain their performance characteristics over extended periods.

Surface modification techniques have been employed to further enhance the durability of QNED materials. By applying specialized coatings or ligands to the quantum dot surface, researchers have improved their resistance to photo-oxidation and thermal degradation. These modifications also enhance the compatibility of quantum dots with the surrounding matrix material, leading to more stable and uniform displays.

Recent research has also focused on developing self-healing quantum dot materials. These innovative materials can repair minor structural defects that occur during operation, effectively prolonging the lifespan of QNED displays. While still in the early stages of development, self-healing quantum dots show great potential for addressing long-term durability concerns in display technologies.

Advancements in manufacturing processes have also contributed to the improved durability of QNED materials. Precision control in synthesis methods has led to more uniform and defect-free quantum dots, reducing the likelihood of premature failure. Additionally, the development of scalable production techniques has enabled the consistent manufacturing of high-quality QNED materials, ensuring reliability across large-scale display production.

Researchers have made substantial progress in developing more robust quantum dot structures. By incorporating a protective shell around the quantum dot core, scientists have successfully mitigated the effects of oxidation and degradation. This shell, typically composed of inorganic materials like zinc sulfide or cadmium sulfide, acts as a barrier against external stressors while maintaining the optical properties of the quantum dots.

Another significant advancement is the optimization of quantum dot composition. By fine-tuning the elemental ratios and introducing dopants, researchers have created quantum dots with improved thermal stability. These enhanced materials can withstand higher operating temperatures without compromising their emission efficiency, thus extending the overall lifespan of QNED displays.

The development of hybrid organic-inorganic quantum dot materials has also shown promise in improving durability. These hybrid structures combine the benefits of both organic and inorganic materials, resulting in quantum dots with enhanced stability and resistance to environmental factors. This approach has led to the creation of QNED displays that maintain their performance characteristics over extended periods.

Surface modification techniques have been employed to further enhance the durability of QNED materials. By applying specialized coatings or ligands to the quantum dot surface, researchers have improved their resistance to photo-oxidation and thermal degradation. These modifications also enhance the compatibility of quantum dots with the surrounding matrix material, leading to more stable and uniform displays.

Recent research has also focused on developing self-healing quantum dot materials. These innovative materials can repair minor structural defects that occur during operation, effectively prolonging the lifespan of QNED displays. While still in the early stages of development, self-healing quantum dots show great potential for addressing long-term durability concerns in display technologies.

Advancements in manufacturing processes have also contributed to the improved durability of QNED materials. Precision control in synthesis methods has led to more uniform and defect-free quantum dots, reducing the likelihood of premature failure. Additionally, the development of scalable production techniques has enabled the consistent manufacturing of high-quality QNED materials, ensuring reliability across large-scale display production.

QNED Environmental Impact

The environmental impact of Quantum Nano-Emitting Diode (QNED) technology in displays is a crucial consideration as this innovative technology gains traction in the market. QNED displays offer several environmental advantages over traditional display technologies, particularly in terms of energy efficiency and longevity.

QNED displays consume significantly less power compared to conventional LCD and OLED displays. This reduced energy consumption translates to lower carbon emissions throughout the product lifecycle, from manufacturing to end-user operation. The improved energy efficiency of QNED technology contributes to the overall reduction of greenhouse gas emissions associated with electronic devices.

The durability of QNED displays also plays a vital role in their environmental impact. These displays have a longer lifespan compared to their counterparts, which means fewer replacements and less electronic waste generation over time. The extended product life cycle reduces the demand for raw materials and energy required for manufacturing new displays, further minimizing the environmental footprint.

In terms of materials used, QNED technology relies on quantum dots, which are typically made from non-toxic semiconductor materials. This composition reduces the potential for harmful environmental contamination during production and disposal processes. Additionally, the manufacturing process for QNED displays generally requires fewer hazardous chemicals compared to traditional display technologies, leading to a decrease in potentially harmful waste products.

The improved color accuracy and brightness of QNED displays also contribute to their environmental benefits. These displays can achieve higher levels of brightness with less power consumption, reducing the need for energy-intensive backlighting systems. This efficiency not only saves energy but also reduces the heat generated by the display, potentially extending the lifespan of other components within the device.

However, it is important to note that the production of quantum dots and other specialized materials used in QNED displays may have some environmental implications. The extraction and processing of rare earth elements often used in these advanced display technologies can have localized environmental impacts. Responsible sourcing and sustainable production practices are crucial to mitigate these concerns.

As QNED technology continues to evolve, ongoing research and development efforts are focused on further improving its environmental performance. This includes exploring more sustainable materials, enhancing recycling processes for QNED components, and optimizing manufacturing techniques to reduce resource consumption and waste generation.

QNED displays consume significantly less power compared to conventional LCD and OLED displays. This reduced energy consumption translates to lower carbon emissions throughout the product lifecycle, from manufacturing to end-user operation. The improved energy efficiency of QNED technology contributes to the overall reduction of greenhouse gas emissions associated with electronic devices.

The durability of QNED displays also plays a vital role in their environmental impact. These displays have a longer lifespan compared to their counterparts, which means fewer replacements and less electronic waste generation over time. The extended product life cycle reduces the demand for raw materials and energy required for manufacturing new displays, further minimizing the environmental footprint.

In terms of materials used, QNED technology relies on quantum dots, which are typically made from non-toxic semiconductor materials. This composition reduces the potential for harmful environmental contamination during production and disposal processes. Additionally, the manufacturing process for QNED displays generally requires fewer hazardous chemicals compared to traditional display technologies, leading to a decrease in potentially harmful waste products.

The improved color accuracy and brightness of QNED displays also contribute to their environmental benefits. These displays can achieve higher levels of brightness with less power consumption, reducing the need for energy-intensive backlighting systems. This efficiency not only saves energy but also reduces the heat generated by the display, potentially extending the lifespan of other components within the device.

However, it is important to note that the production of quantum dots and other specialized materials used in QNED displays may have some environmental implications. The extraction and processing of rare earth elements often used in these advanced display technologies can have localized environmental impacts. Responsible sourcing and sustainable production practices are crucial to mitigate these concerns.

As QNED technology continues to evolve, ongoing research and development efforts are focused on further improving its environmental performance. This includes exploring more sustainable materials, enhancing recycling processes for QNED components, and optimizing manufacturing techniques to reduce resource consumption and waste generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!