How to Explore Isocyanate Usage in Modern Engineering?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the mid-19th century. Initially synthesized as chemical curiosities, these compounds gained significant industrial importance in the 1930s with the development of polyurethanes. The journey of isocyanates in modern engineering began with Otto Bayer's groundbreaking work on polyurethane chemistry in 1937, which laid the foundation for their widespread application.

The 1950s and 1960s saw a rapid expansion in isocyanate usage, particularly in the production of flexible and rigid foams. This period marked the beginning of isocyanates' dominance in the automotive, furniture, and construction industries. The versatility of isocyanates in forming various polymer structures led to their integration into diverse engineering applications, from insulation materials to high-performance coatings.

As environmental and health concerns gained prominence in the 1970s and 1980s, the isocyanate industry faced new challenges. This period witnessed intensive research into safer handling methods and the development of less volatile isocyanate formulations. The introduction of water-based polyurethane systems and blocked isocyanates represented significant advancements in addressing these concerns while maintaining performance characteristics.

The late 20th and early 21st centuries have been characterized by a focus on sustainability and eco-friendly alternatives. This shift has driven innovation in bio-based isocyanates and non-isocyanate polyurethane technologies. Researchers have explored renewable sources for isocyanate precursors, aiming to reduce reliance on petroleum-based raw materials.

Recent years have seen a surge in the development of smart and responsive isocyanate-based materials. These advanced materials can change properties in response to external stimuli, opening up new possibilities in fields such as biomedical engineering and adaptive structures. The integration of nanotechnology with isocyanate chemistry has further expanded the potential applications, enabling the creation of materials with unprecedented properties.

The evolution of isocyanates in modern engineering has been marked by continuous improvements in processing technologies. From traditional batch processes to advanced continuous flow reactors, manufacturing methods have evolved to enhance efficiency and product quality. This progression has been crucial in meeting the growing demand for isocyanate-based products across various industries.

Looking ahead, the future of isocyanates in engineering is likely to be shaped by ongoing efforts to enhance sustainability, improve safety profiles, and develop novel functionalities. As researchers continue to explore new chemistries and applications, isocyanates are poised to remain a critical component in the toolbox of modern engineers, driving innovation across multiple sectors.

The 1950s and 1960s saw a rapid expansion in isocyanate usage, particularly in the production of flexible and rigid foams. This period marked the beginning of isocyanates' dominance in the automotive, furniture, and construction industries. The versatility of isocyanates in forming various polymer structures led to their integration into diverse engineering applications, from insulation materials to high-performance coatings.

As environmental and health concerns gained prominence in the 1970s and 1980s, the isocyanate industry faced new challenges. This period witnessed intensive research into safer handling methods and the development of less volatile isocyanate formulations. The introduction of water-based polyurethane systems and blocked isocyanates represented significant advancements in addressing these concerns while maintaining performance characteristics.

The late 20th and early 21st centuries have been characterized by a focus on sustainability and eco-friendly alternatives. This shift has driven innovation in bio-based isocyanates and non-isocyanate polyurethane technologies. Researchers have explored renewable sources for isocyanate precursors, aiming to reduce reliance on petroleum-based raw materials.

Recent years have seen a surge in the development of smart and responsive isocyanate-based materials. These advanced materials can change properties in response to external stimuli, opening up new possibilities in fields such as biomedical engineering and adaptive structures. The integration of nanotechnology with isocyanate chemistry has further expanded the potential applications, enabling the creation of materials with unprecedented properties.

The evolution of isocyanates in modern engineering has been marked by continuous improvements in processing technologies. From traditional batch processes to advanced continuous flow reactors, manufacturing methods have evolved to enhance efficiency and product quality. This progression has been crucial in meeting the growing demand for isocyanate-based products across various industries.

Looking ahead, the future of isocyanates in engineering is likely to be shaped by ongoing efforts to enhance sustainability, improve safety profiles, and develop novel functionalities. As researchers continue to explore new chemistries and applications, isocyanates are poised to remain a critical component in the toolbox of modern engineers, driving innovation across multiple sectors.

Market Demand Analysis

The market demand for isocyanates in modern engineering has been steadily growing, driven by their versatile applications across various industries. The global isocyanate market size was valued at approximately $40 billion in 2020 and is projected to reach $60 billion by 2027, with a compound annual growth rate (CAGR) of around 6% during the forecast period.

The construction industry remains the largest consumer of isocyanates, particularly in the production of polyurethane foams for insulation and sealants. The increasing focus on energy-efficient buildings and sustainable construction practices has further boosted the demand for isocyanate-based products. Additionally, the automotive sector has emerged as a significant market for isocyanates, with their use in manufacturing lightweight components, coatings, and adhesives to improve fuel efficiency and reduce emissions.

In the electronics industry, isocyanates are gaining traction in the production of flexible and rigid foams for packaging and insulation of electronic components. The growing demand for consumer electronics and the expansion of 5G infrastructure are expected to drive the market growth in this sector.

The healthcare industry has also witnessed an increased adoption of isocyanates in medical devices, prosthetics, and wound care products. The biocompatibility and durability of isocyanate-based materials make them suitable for various medical applications, contributing to market expansion.

However, the market faces challenges due to environmental and health concerns associated with certain isocyanates. Regulatory bodies worldwide are imposing stricter guidelines on the use and handling of these chemicals, which may impact market growth. This has led to a growing demand for eco-friendly alternatives and bio-based isocyanates, presenting new opportunities for innovation and market expansion.

Regionally, Asia-Pacific dominates the isocyanate market, accounting for over 40% of the global share. The rapid industrialization, urbanization, and infrastructure development in countries like China and India are driving the demand for isocyanate-based products. North America and Europe follow, with a focus on advanced applications in automotive, aerospace, and healthcare sectors.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain issues and reduced demand from end-use industries. However, the market has shown resilience, with a surge in demand for isocyanate-based products in healthcare and packaging applications. As economies recover and industrial activities resume, the market is expected to regain its growth trajectory, with a particular emphasis on sustainable and high-performance isocyanate solutions.

The construction industry remains the largest consumer of isocyanates, particularly in the production of polyurethane foams for insulation and sealants. The increasing focus on energy-efficient buildings and sustainable construction practices has further boosted the demand for isocyanate-based products. Additionally, the automotive sector has emerged as a significant market for isocyanates, with their use in manufacturing lightweight components, coatings, and adhesives to improve fuel efficiency and reduce emissions.

In the electronics industry, isocyanates are gaining traction in the production of flexible and rigid foams for packaging and insulation of electronic components. The growing demand for consumer electronics and the expansion of 5G infrastructure are expected to drive the market growth in this sector.

The healthcare industry has also witnessed an increased adoption of isocyanates in medical devices, prosthetics, and wound care products. The biocompatibility and durability of isocyanate-based materials make them suitable for various medical applications, contributing to market expansion.

However, the market faces challenges due to environmental and health concerns associated with certain isocyanates. Regulatory bodies worldwide are imposing stricter guidelines on the use and handling of these chemicals, which may impact market growth. This has led to a growing demand for eco-friendly alternatives and bio-based isocyanates, presenting new opportunities for innovation and market expansion.

Regionally, Asia-Pacific dominates the isocyanate market, accounting for over 40% of the global share. The rapid industrialization, urbanization, and infrastructure development in countries like China and India are driving the demand for isocyanate-based products. North America and Europe follow, with a focus on advanced applications in automotive, aerospace, and healthcare sectors.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain issues and reduced demand from end-use industries. However, the market has shown resilience, with a surge in demand for isocyanate-based products in healthcare and packaging applications. As economies recover and industrial activities resume, the market is expected to regain its growth trajectory, with a particular emphasis on sustainable and high-performance isocyanate solutions.

Technical Challenges

The exploration of isocyanate usage in modern engineering faces several significant technical challenges. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and control during processing. This reactivity, while beneficial for certain applications, can lead to unwanted side reactions and premature curing, affecting the quality and consistency of the final products.

Another major challenge lies in the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This necessitates stringent safety measures and protective equipment in manufacturing environments, which can increase production costs and complexity. The development of safer, less toxic alternatives or improved handling methods remains an ongoing challenge for researchers and engineers.

Environmental concerns also pose significant hurdles in isocyanate usage. Many isocyanates are derived from petroleum-based sources, raising sustainability issues. The industry faces pressure to develop bio-based or renewable isocyanates that maintain the desirable properties of traditional isocyanates while reducing environmental impact. Additionally, the end-of-life disposal and recycling of isocyanate-based products present challenges due to their chemical stability and potential for releasing harmful substances during degradation.

The optimization of isocyanate formulations for specific applications is another technical challenge. Different engineering applications require tailored properties, such as flexibility, durability, or thermal resistance. Achieving the right balance of these properties while maintaining processability and cost-effectiveness demands extensive research and development efforts.

Furthermore, the scaling up of laboratory-developed isocyanate technologies to industrial production levels presents its own set of challenges. Issues such as heat management during large-scale reactions, maintaining product consistency, and ensuring uniform curing in complex geometries need to be addressed for successful commercialization.

Lastly, regulatory compliance poses an ongoing challenge for isocyanate usage in modern engineering. Evolving regulations regarding chemical safety, emissions, and product lifecycle management require continuous adaptation of manufacturing processes and product formulations. This regulatory landscape can vary significantly across different regions, adding complexity to global production and distribution strategies for isocyanate-based products.

Another major challenge lies in the toxicity of isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This necessitates stringent safety measures and protective equipment in manufacturing environments, which can increase production costs and complexity. The development of safer, less toxic alternatives or improved handling methods remains an ongoing challenge for researchers and engineers.

Environmental concerns also pose significant hurdles in isocyanate usage. Many isocyanates are derived from petroleum-based sources, raising sustainability issues. The industry faces pressure to develop bio-based or renewable isocyanates that maintain the desirable properties of traditional isocyanates while reducing environmental impact. Additionally, the end-of-life disposal and recycling of isocyanate-based products present challenges due to their chemical stability and potential for releasing harmful substances during degradation.

The optimization of isocyanate formulations for specific applications is another technical challenge. Different engineering applications require tailored properties, such as flexibility, durability, or thermal resistance. Achieving the right balance of these properties while maintaining processability and cost-effectiveness demands extensive research and development efforts.

Furthermore, the scaling up of laboratory-developed isocyanate technologies to industrial production levels presents its own set of challenges. Issues such as heat management during large-scale reactions, maintaining product consistency, and ensuring uniform curing in complex geometries need to be addressed for successful commercialization.

Lastly, regulatory compliance poses an ongoing challenge for isocyanate usage in modern engineering. Evolving regulations regarding chemical safety, emissions, and product lifecycle management require continuous adaptation of manufacturing processes and product formulations. This regulatory landscape can vary significantly across different regions, adding complexity to global production and distribution strategies for isocyanate-based products.

Current Applications

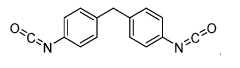

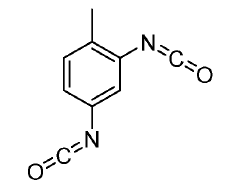

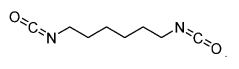

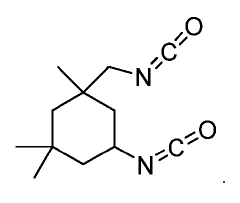

01 Synthesis and properties of isocyanates

Isocyanates are a class of highly reactive compounds characterized by the -NCO functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.- Synthesis and properties of isocyanates: Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.

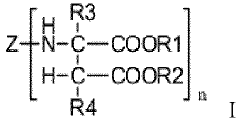

- Applications of isocyanates in polymer chemistry: Isocyanates play a vital role in polymer chemistry, particularly in the production of polyurethanes. They react with polyols to form urethane linkages, which are the basis for a wide range of materials including foams, elastomers, and coatings. The choice of isocyanate and its formulation significantly influences the final properties of the polymer product.

- Isocyanate-based adhesives and sealants: Isocyanates are key components in the formulation of high-performance adhesives and sealants. These products utilize the reactivity of isocyanates to create strong bonds and durable seals. The curing process, which often involves moisture-induced reactions, results in the formation of cross-linked structures that provide excellent adhesion and resistance to environmental factors.

- Safety and handling of isocyanates: Due to their high reactivity, isocyanates require careful handling and safety precautions. Exposure to isocyanates can cause respiratory irritation and sensitization. Proper personal protective equipment, ventilation systems, and handling procedures are essential in industrial settings where isocyanates are used. Regulations and guidelines have been established to ensure safe use and storage of these compounds.

- Environmental and sustainability aspects of isocyanates: The environmental impact and sustainability of isocyanate production and use are important considerations in the chemical industry. Research is ongoing to develop more environmentally friendly isocyanate alternatives and production methods. This includes exploring bio-based sources for isocyanates, improving energy efficiency in manufacturing processes, and developing recycling techniques for isocyanate-containing materials.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a significant role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. These materials find applications in automotive coatings, industrial finishes, and structural adhesives.Expand Specific Solutions03 Isocyanate-based foam production

Isocyanates are key components in the production of polyurethane foams. When combined with polyols and appropriate catalysts and blowing agents, they form flexible or rigid foams used in insulation, cushioning, and packaging applications. The foam properties can be tailored by adjusting the isocyanate and polyol formulations.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity, isocyanates require careful handling and safety precautions. Exposure to isocyanates can cause respiratory irritation and sensitization. Proper personal protective equipment, ventilation systems, and storage conditions are essential when working with these compounds. Regulations and guidelines have been established to ensure safe handling and use of isocyanates in industrial settings.Expand Specific Solutions05 Isocyanate-free alternatives and sustainable approaches

There is growing interest in developing isocyanate-free alternatives and more sustainable approaches in polymer chemistry. This includes the use of bio-based raw materials, non-isocyanate polyurethanes, and alternative crosslinking chemistries. These efforts aim to address environmental and health concerns associated with traditional isocyanate-based systems while maintaining or improving performance characteristics.Expand Specific Solutions

Key Industry Players

The exploration of isocyanate usage in modern engineering is currently in a mature phase, with a well-established market and diverse applications. The global isocyanate market size is substantial, estimated to reach USD 41.5 billion by 2027, driven by growing demand in automotive, construction, and electronics industries. Technologically, isocyanates have reached a high level of maturity, with companies like BASF, Covestro, and Wanhua Chemical leading innovation. These industry giants, along with Mitsui Chemicals and Asahi Kasei, are continuously developing new applications and improving existing formulations, focusing on sustainability and performance enhancement. The competitive landscape is characterized by intense R&D efforts and strategic collaborations to maintain market dominance and address evolving environmental regulations.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant advancements in isocyanate technology for modern engineering applications. They have developed a proprietary process for producing ultra-low monomer content isocyanates, which enhances safety in various applications[7]. Wanhua has also introduced novel isocyanate-based materials for 3D printing, enabling the creation of complex, high-performance parts with improved mechanical properties[8]. Additionally, they have explored the use of bio-based raw materials in isocyanate production, contributing to more sustainable manufacturing processes[9].

Strengths: Advanced safety features, innovative applications in additive manufacturing, focus on sustainability. Weaknesses: Potential challenges in scaling up new technologies.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in isocyanate technology for modern engineering. They have developed a range of low-monomer technology (LMT) isocyanates that reduce exposure risks and improve worker safety[4]. Covestro's innovative BLULOGIQ technology uses isocyanates to create energy-efficient refrigeration systems, reducing carbon footprint in industrial applications[5]. They have also pioneered the use of CO2 as a raw material for polyols in isocyanate-based polyurethanes, contributing to more sustainable production processes[6].

Strengths: Focus on safety and sustainability, innovative applications in energy efficiency. Weaknesses: Potential higher costs associated with advanced technologies.

Innovative Formulations

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

Polyether-modified polyisocyanate composition

PatentInactiveEP3988596A1

Innovation

- A polyether-modified polyisocyanate composition is developed by reacting a polyisocyanate with a polyoxyalkylene monoether alcohol, having a specific molecular weight and oxypropylene content, to achieve a balanced isocyanate functionality and content, which is used as a crosslinking agent in coatings, improving working time and drying efficiency while maintaining high hardness.

Environmental Impact

The environmental impact of isocyanate usage in modern engineering is a critical consideration that demands thorough examination. Isocyanates, widely used in the production of polyurethanes, have both positive and negative effects on the environment throughout their lifecycle. On the positive side, isocyanate-based materials contribute to energy efficiency in buildings and vehicles, reducing overall carbon emissions. Polyurethane insulation, for instance, helps decrease energy consumption in structures, leading to lower greenhouse gas emissions over time.

However, the production and disposal of isocyanate-containing products pose significant environmental challenges. The manufacturing process of isocyanates often involves the use of fossil fuels and releases various pollutants, including volatile organic compounds (VOCs) and greenhouse gases. These emissions contribute to air pollution and climate change, necessitating stringent control measures in production facilities.

Water pollution is another concern associated with isocyanate usage. Improper disposal or accidental release of isocyanates can contaminate water bodies, potentially harming aquatic ecosystems. The persistence of certain isocyanate compounds in the environment further exacerbates this issue, as they may not readily biodegrade and can accumulate in sediments and organisms.

The end-of-life management of isocyanate-based products presents additional environmental challenges. Many polyurethane products are difficult to recycle due to their complex chemical composition, leading to increased waste in landfills. Incineration of these materials can release toxic substances, including hydrogen cyanide and other harmful compounds, necessitating advanced emission control technologies.

To mitigate these environmental impacts, the engineering community is exploring several avenues. Research into bio-based isocyanates derived from renewable resources aims to reduce reliance on petrochemicals and decrease the carbon footprint of production. Additionally, advancements in recycling technologies, such as chemical depolymerization, offer promising solutions for the sustainable management of isocyanate-based waste.

Efforts to improve production processes focus on reducing emissions and enhancing energy efficiency. Closed-loop systems and catalytic oxidation technologies are being implemented to minimize the release of VOCs and other pollutants. Furthermore, the development of water-based and solvent-free polyurethane systems helps reduce the environmental impact of application processes.

As environmental regulations become more stringent, the industry is also investing in safer alternatives and greener chemistries. This includes the exploration of non-isocyanate polyurethanes (NIPUs) that offer similar performance characteristics without the associated environmental and health risks of traditional isocyanates.

However, the production and disposal of isocyanate-containing products pose significant environmental challenges. The manufacturing process of isocyanates often involves the use of fossil fuels and releases various pollutants, including volatile organic compounds (VOCs) and greenhouse gases. These emissions contribute to air pollution and climate change, necessitating stringent control measures in production facilities.

Water pollution is another concern associated with isocyanate usage. Improper disposal or accidental release of isocyanates can contaminate water bodies, potentially harming aquatic ecosystems. The persistence of certain isocyanate compounds in the environment further exacerbates this issue, as they may not readily biodegrade and can accumulate in sediments and organisms.

The end-of-life management of isocyanate-based products presents additional environmental challenges. Many polyurethane products are difficult to recycle due to their complex chemical composition, leading to increased waste in landfills. Incineration of these materials can release toxic substances, including hydrogen cyanide and other harmful compounds, necessitating advanced emission control technologies.

To mitigate these environmental impacts, the engineering community is exploring several avenues. Research into bio-based isocyanates derived from renewable resources aims to reduce reliance on petrochemicals and decrease the carbon footprint of production. Additionally, advancements in recycling technologies, such as chemical depolymerization, offer promising solutions for the sustainable management of isocyanate-based waste.

Efforts to improve production processes focus on reducing emissions and enhancing energy efficiency. Closed-loop systems and catalytic oxidation technologies are being implemented to minimize the release of VOCs and other pollutants. Furthermore, the development of water-based and solvent-free polyurethane systems helps reduce the environmental impact of application processes.

As environmental regulations become more stringent, the industry is also investing in safer alternatives and greener chemistries. This includes the exploration of non-isocyanate polyurethanes (NIPUs) that offer similar performance characteristics without the associated environmental and health risks of traditional isocyanates.

Safety Regulations

The use of isocyanates in modern engineering applications necessitates strict adherence to comprehensive safety regulations due to their potential health and environmental hazards. Regulatory bodies worldwide have established stringent guidelines to govern the handling, storage, and disposal of isocyanates in industrial settings.

Occupational exposure limits for isocyanates are set by various agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the Health and Safety Executive (HSE) in the United Kingdom. These limits typically specify the maximum allowable concentration of isocyanate compounds in the air to which workers can be exposed over a given time period. For instance, OSHA has set a permissible exposure limit (PEL) of 0.02 parts per million (ppm) for most isocyanates over an 8-hour workday.

Personal protective equipment (PPE) requirements are a crucial aspect of isocyanate safety regulations. Workers handling these compounds must wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus (SCBA), depending on the concentration and duration of exposure. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact with isocyanates.

Ventilation and engineering controls play a vital role in minimizing isocyanate exposure. Regulations often mandate the use of local exhaust ventilation systems and enclosed processes to capture and remove isocyanate vapors at their source. Regular monitoring of air quality and the implementation of real-time detection systems are frequently required to ensure compliance with exposure limits.

Storage and handling regulations for isocyanates are designed to prevent accidental releases and minimize the risk of fire or explosion. These include requirements for proper labeling, segregation from incompatible materials, and the use of secondary containment systems. Many jurisdictions also mandate specific training programs for workers involved in isocyanate-related operations, covering topics such as hazard recognition, emergency procedures, and proper use of PPE.

Environmental regulations addressing isocyanate usage focus on preventing releases into air, water, and soil. Facilities using isocyanates must often implement spill prevention and control measures, as well as proper waste disposal procedures. In some regions, permits may be required for the storage or use of large quantities of isocyanates, necessitating regular inspections and compliance audits.

As the understanding of isocyanate hazards evolves, safety regulations continue to be updated and refined. Recent trends include the development of more sensitive analytical methods for detecting isocyanates in various matrices, leading to more stringent exposure limits and monitoring requirements. Additionally, there is an increasing emphasis on substitution and risk reduction strategies, encouraging the use of less hazardous alternatives where feasible in modern engineering applications.

Occupational exposure limits for isocyanates are set by various agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the Health and Safety Executive (HSE) in the United Kingdom. These limits typically specify the maximum allowable concentration of isocyanate compounds in the air to which workers can be exposed over a given time period. For instance, OSHA has set a permissible exposure limit (PEL) of 0.02 parts per million (ppm) for most isocyanates over an 8-hour workday.

Personal protective equipment (PPE) requirements are a crucial aspect of isocyanate safety regulations. Workers handling these compounds must wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus (SCBA), depending on the concentration and duration of exposure. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact with isocyanates.

Ventilation and engineering controls play a vital role in minimizing isocyanate exposure. Regulations often mandate the use of local exhaust ventilation systems and enclosed processes to capture and remove isocyanate vapors at their source. Regular monitoring of air quality and the implementation of real-time detection systems are frequently required to ensure compliance with exposure limits.

Storage and handling regulations for isocyanates are designed to prevent accidental releases and minimize the risk of fire or explosion. These include requirements for proper labeling, segregation from incompatible materials, and the use of secondary containment systems. Many jurisdictions also mandate specific training programs for workers involved in isocyanate-related operations, covering topics such as hazard recognition, emergency procedures, and proper use of PPE.

Environmental regulations addressing isocyanate usage focus on preventing releases into air, water, and soil. Facilities using isocyanates must often implement spill prevention and control measures, as well as proper waste disposal procedures. In some regions, permits may be required for the storage or use of large quantities of isocyanates, necessitating regular inspections and compliance audits.

As the understanding of isocyanate hazards evolves, safety regulations continue to be updated and refined. Recent trends include the development of more sensitive analytical methods for detecting isocyanates in various matrices, leading to more stringent exposure limits and monitoring requirements. Additionally, there is an increasing emphasis on substitution and risk reduction strategies, encouraging the use of less hazardous alternatives where feasible in modern engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!