How to Improve Stearic Acid Blend for Increased Rigidness

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Stearic Acid Blend Technology Background and Objectives

Stearic acid blends have evolved significantly over the past several decades, transitioning from simple fatty acid additives to sophisticated formulations engineered for specific material properties. Originally utilized primarily as lubricants and release agents in the early 1950s, these compounds gained prominence in the 1970s when manufacturers began exploring their potential for enhancing polymer rigidity and structural integrity in various industrial applications.

The technological evolution of stearic acid blends has been driven by the increasing demands of modern manufacturing processes, particularly in plastics, rubber, and composite materials industries. Traditional single-acid formulations have gradually given way to complex multi-component systems that leverage synergistic interactions between different fatty acids, metal salts, and complementary additives to achieve superior performance characteristics.

Recent advancements in analytical techniques, particularly high-resolution spectroscopy and thermal analysis methods, have enabled researchers to develop a more nuanced understanding of the molecular interactions that govern the behavior of stearic acid blends in polymer matrices. This improved understanding has facilitated the development of more effective formulations tailored to specific application requirements.

The current technological trajectory points toward increasingly specialized stearic acid blend formulations designed to address specific performance challenges. Industry data indicates a growing focus on developing blends that can simultaneously enhance rigidity while maintaining or improving other critical material properties such as impact resistance, thermal stability, and processing characteristics.

The primary technical objective in this field is to develop optimized stearic acid blend formulations that significantly increase the rigidity of polymer and composite materials without compromising other essential properties. This includes identifying ideal acid compositions, determining optimal concentration ranges, and establishing effective processing parameters to maximize performance benefits.

Secondary objectives include enhancing the compatibility of stearic acid blends with a broader range of base materials, improving the thermal stability of the resulting compounds, and developing more environmentally sustainable formulations that maintain high performance standards while reducing environmental impact.

The technological landscape is further shaped by emerging trends in materials science, including the growing interest in bio-based alternatives to traditional petroleum-derived stearic acid sources. Research indicates that plant-derived stearic acids, when properly formulated, can potentially offer comparable rigidity enhancement while addressing sustainability concerns that are becoming increasingly important in industrial applications.

The technological evolution of stearic acid blends has been driven by the increasing demands of modern manufacturing processes, particularly in plastics, rubber, and composite materials industries. Traditional single-acid formulations have gradually given way to complex multi-component systems that leverage synergistic interactions between different fatty acids, metal salts, and complementary additives to achieve superior performance characteristics.

Recent advancements in analytical techniques, particularly high-resolution spectroscopy and thermal analysis methods, have enabled researchers to develop a more nuanced understanding of the molecular interactions that govern the behavior of stearic acid blends in polymer matrices. This improved understanding has facilitated the development of more effective formulations tailored to specific application requirements.

The current technological trajectory points toward increasingly specialized stearic acid blend formulations designed to address specific performance challenges. Industry data indicates a growing focus on developing blends that can simultaneously enhance rigidity while maintaining or improving other critical material properties such as impact resistance, thermal stability, and processing characteristics.

The primary technical objective in this field is to develop optimized stearic acid blend formulations that significantly increase the rigidity of polymer and composite materials without compromising other essential properties. This includes identifying ideal acid compositions, determining optimal concentration ranges, and establishing effective processing parameters to maximize performance benefits.

Secondary objectives include enhancing the compatibility of stearic acid blends with a broader range of base materials, improving the thermal stability of the resulting compounds, and developing more environmentally sustainable formulations that maintain high performance standards while reducing environmental impact.

The technological landscape is further shaped by emerging trends in materials science, including the growing interest in bio-based alternatives to traditional petroleum-derived stearic acid sources. Research indicates that plant-derived stearic acids, when properly formulated, can potentially offer comparable rigidity enhancement while addressing sustainability concerns that are becoming increasingly important in industrial applications.

Market Analysis for Rigid Stearic Acid Applications

The global market for rigid stearic acid applications has been experiencing significant growth, driven by increasing demand across multiple industries. The market size for stearic acid was valued at approximately 4.2 billion USD in 2022 and is projected to reach 5.8 billion USD by 2028, with applications requiring enhanced rigidity showing particularly strong growth potential.

The plastic and polymer industry represents the largest market segment for rigid stearic acid applications, accounting for nearly 38% of total consumption. In this sector, stearic acid blends function as crucial additives that improve material hardness, impact resistance, and dimensional stability. The construction materials industry follows closely, utilizing rigid stearic acid formulations in PVC products, sealants, and specialized concrete additives.

Consumer demand trends strongly favor products with improved durability and mechanical strength, particularly in regions experiencing rapid industrialization such as Southeast Asia and parts of Latin America. Market research indicates that manufacturers are willing to pay premium prices for stearic acid blends that demonstrably enhance product rigidity without compromising other performance characteristics.

Regulatory factors are increasingly influencing market dynamics, with stricter environmental regulations in Europe and North America pushing demand toward bio-based stearic acid alternatives. This regulatory pressure has created a distinct market segment for sustainable rigid stearic acid blends, currently growing at twice the rate of conventional products.

Regional analysis reveals that Asia-Pacific dominates consumption, representing 45% of the global market for rigid stearic acid applications. China alone accounts for 22% of global demand, followed by India at 8%. North America and Europe collectively represent approximately 40% of the market, with more specialized, high-performance applications predominating.

Price sensitivity varies significantly by application. Industrial applications demonstrate high price elasticity, while specialized sectors like medical devices and high-performance polymers show willingness to absorb premium pricing for superior rigidity characteristics. The average price premium for enhanced-rigidity stearic acid blends ranges between 15-30% above standard formulations.

Market forecasts indicate that demand for rigid stearic acid applications will grow at a CAGR of 6.2% through 2028, outpacing the broader stearic acid market. This growth trajectory is supported by expanding applications in emerging technologies such as 3D printing materials, where rigidity specifications are particularly stringent.

The plastic and polymer industry represents the largest market segment for rigid stearic acid applications, accounting for nearly 38% of total consumption. In this sector, stearic acid blends function as crucial additives that improve material hardness, impact resistance, and dimensional stability. The construction materials industry follows closely, utilizing rigid stearic acid formulations in PVC products, sealants, and specialized concrete additives.

Consumer demand trends strongly favor products with improved durability and mechanical strength, particularly in regions experiencing rapid industrialization such as Southeast Asia and parts of Latin America. Market research indicates that manufacturers are willing to pay premium prices for stearic acid blends that demonstrably enhance product rigidity without compromising other performance characteristics.

Regulatory factors are increasingly influencing market dynamics, with stricter environmental regulations in Europe and North America pushing demand toward bio-based stearic acid alternatives. This regulatory pressure has created a distinct market segment for sustainable rigid stearic acid blends, currently growing at twice the rate of conventional products.

Regional analysis reveals that Asia-Pacific dominates consumption, representing 45% of the global market for rigid stearic acid applications. China alone accounts for 22% of global demand, followed by India at 8%. North America and Europe collectively represent approximately 40% of the market, with more specialized, high-performance applications predominating.

Price sensitivity varies significantly by application. Industrial applications demonstrate high price elasticity, while specialized sectors like medical devices and high-performance polymers show willingness to absorb premium pricing for superior rigidity characteristics. The average price premium for enhanced-rigidity stearic acid blends ranges between 15-30% above standard formulations.

Market forecasts indicate that demand for rigid stearic acid applications will grow at a CAGR of 6.2% through 2028, outpacing the broader stearic acid market. This growth trajectory is supported by expanding applications in emerging technologies such as 3D printing materials, where rigidity specifications are particularly stringent.

Current Limitations and Challenges in Stearic Acid Blending

Despite the widespread use of stearic acid in various industrial applications, current blending techniques face significant limitations that hinder achieving optimal rigidity in end products. The primary challenge lies in the inconsistent crystallization behavior of stearic acid when blended with other components. This inconsistency results in unpredictable mechanical properties, particularly rigidity, which affects product performance and quality control in manufacturing processes.

Temperature sensitivity presents another major obstacle in stearic acid blending. The narrow processing window between melting and solidification points creates difficulties in maintaining uniform dispersion during production. When processing temperatures fluctuate even slightly, phase separation can occur, leading to structural weaknesses and compromised rigidity in the final product.

Compatibility issues between stearic acid and various polymer matrices represent a persistent technical barrier. The hydrophobic nature of stearic acid often results in poor interfacial adhesion with hydrophilic components, creating internal stress points that reduce overall structural integrity. This incompatibility limits the concentration of stearic acid that can be effectively incorporated before negative effects on mechanical properties become apparent.

Current blending methodologies also struggle with achieving homogeneous distribution of stearic acid throughout the matrix. Conventional mechanical mixing techniques often result in localized concentrations or "islands" of stearic acid, creating weak points in the material structure. These inhomogeneities directly impact the rigidity profile across the product, resulting in inconsistent performance characteristics.

The oxidative stability of stearic acid blends presents additional challenges, particularly in applications requiring long-term durability. Oxidation of stearic acid can lead to chain scission and degradation of the molecular structure, progressively reducing rigidity over time. Current antioxidant systems have shown limited effectiveness in preventing this degradation without introducing other undesirable effects on material properties.

Scale-up issues further complicate industrial implementation of stearic acid blending technologies. Laboratory-scale successes often fail to translate to production environments due to differences in mixing dynamics, heat transfer, and processing times. This scale-dependency creates significant barriers to consistent quality in mass production scenarios.

Environmental and regulatory constraints are increasingly limiting the use of certain processing aids and additives traditionally employed to enhance stearic acid blending. As sustainability requirements become more stringent, manufacturers must develop new approaches that maintain or improve rigidity while eliminating potentially harmful chemical modifiers, creating additional technical hurdles for formulation scientists.

Temperature sensitivity presents another major obstacle in stearic acid blending. The narrow processing window between melting and solidification points creates difficulties in maintaining uniform dispersion during production. When processing temperatures fluctuate even slightly, phase separation can occur, leading to structural weaknesses and compromised rigidity in the final product.

Compatibility issues between stearic acid and various polymer matrices represent a persistent technical barrier. The hydrophobic nature of stearic acid often results in poor interfacial adhesion with hydrophilic components, creating internal stress points that reduce overall structural integrity. This incompatibility limits the concentration of stearic acid that can be effectively incorporated before negative effects on mechanical properties become apparent.

Current blending methodologies also struggle with achieving homogeneous distribution of stearic acid throughout the matrix. Conventional mechanical mixing techniques often result in localized concentrations or "islands" of stearic acid, creating weak points in the material structure. These inhomogeneities directly impact the rigidity profile across the product, resulting in inconsistent performance characteristics.

The oxidative stability of stearic acid blends presents additional challenges, particularly in applications requiring long-term durability. Oxidation of stearic acid can lead to chain scission and degradation of the molecular structure, progressively reducing rigidity over time. Current antioxidant systems have shown limited effectiveness in preventing this degradation without introducing other undesirable effects on material properties.

Scale-up issues further complicate industrial implementation of stearic acid blending technologies. Laboratory-scale successes often fail to translate to production environments due to differences in mixing dynamics, heat transfer, and processing times. This scale-dependency creates significant barriers to consistent quality in mass production scenarios.

Environmental and regulatory constraints are increasingly limiting the use of certain processing aids and additives traditionally employed to enhance stearic acid blending. As sustainability requirements become more stringent, manufacturers must develop new approaches that maintain or improve rigidity while eliminating potentially harmful chemical modifiers, creating additional technical hurdles for formulation scientists.

Current Methodologies for Enhancing Stearic Acid Rigidity

01 Stearic acid in cosmetic and personal care formulations

Stearic acid is commonly used in cosmetic and personal care formulations to provide structure and rigidity. It acts as a thickening agent and emulsion stabilizer in products like creams, lotions, and lipsticks. When blended with other fatty acids or emollients, stearic acid helps to achieve the desired consistency and hardness. The concentration of stearic acid in the formulation directly affects the rigidity of the final product.- Stearic acid in cosmetic and personal care formulations: Stearic acid is commonly used in cosmetic and personal care formulations to provide rigidity and structure. It functions as a thickening agent and stabilizer in products like lipsticks, creams, and lotions. When blended with other ingredients such as waxes and oils, stearic acid helps to achieve the desired consistency and hardness. The concentration of stearic acid in these formulations directly affects the final product's rigidity, with higher concentrations resulting in firmer textures.

- Stearic acid in polymer and plastic compositions: Stearic acid is utilized in polymer and plastic compositions to modify the mechanical properties, including rigidity. It acts as an internal lubricant and processing aid that can influence the crystallization behavior of polymers. By incorporating stearic acid into polymer blends, manufacturers can control the hardness and flexibility of the final product. The interaction between stearic acid and polymer chains affects the molecular arrangement, which in turn impacts the material's rigidity and other physical properties.

- Stearic acid in food applications: In food applications, stearic acid blends are used to control the texture and melting properties of fat-based products. It contributes to the structural rigidity of confectionery products, chocolate, and margarine. The crystallization behavior of stearic acid affects the hardness and snap of these products. By carefully controlling the ratio of stearic acid in fat blends, food manufacturers can achieve specific textural properties and melting profiles that are essential for product quality and consumer acceptance.

- Stearic acid in industrial lubricants and greases: Stearic acid is an important component in industrial lubricants and greases where it contributes to the consistency and rigidity of the formulation. When blended with other fatty acids and base oils, stearic acid helps to form a stable structure that provides the necessary lubrication properties. The concentration and distribution of stearic acid within these blends directly influence the hardness, dropping point, and performance characteristics of the lubricant under various temperature and pressure conditions.

- Stearic acid in pharmaceutical and drug delivery systems: Stearic acid blends are utilized in pharmaceutical formulations and drug delivery systems to control drug release rates and provide structural integrity. The rigidity of stearic acid-based matrices affects the dissolution rate and bioavailability of active pharmaceutical ingredients. By adjusting the composition of stearic acid blends with other excipients, pharmaceutical scientists can design solid dosage forms with specific release profiles. The crystalline structure formed by stearic acid contributes to the mechanical strength and stability of tablets, suppositories, and other solid pharmaceutical forms.

02 Stearic acid in polymer and plastic compositions

Stearic acid is utilized in polymer and plastic compositions to modify the mechanical properties, including rigidity. It can function as an internal lubricant, processing aid, or release agent in plastic formulations. By incorporating stearic acid into polymer blends, manufacturers can control the hardness, flexibility, and overall performance characteristics of the material. The interaction between stearic acid and polymer chains affects the crystallization behavior and resulting physical properties.Expand Specific Solutions03 Stearic acid in food applications

In food applications, stearic acid blends are used to control the texture and rigidity of various products. It contributes to the firmness and melting properties of confectionery items, particularly chocolate and fat-based fillings. The crystallization behavior of stearic acid affects the snap, mouthfeel, and stability of food products. By carefully formulating stearic acid with other fatty acids, food manufacturers can achieve specific textural properties and prevent issues like bloom formation.Expand Specific Solutions04 Stearic acid in industrial lubricants and greases

Stearic acid is an important component in industrial lubricants and greases where it contributes to the consistency and rigidity of the formulation. When blended with other fatty acids and base oils, stearic acid helps form a stable structure that provides lubrication under various conditions. The soap structure formed by stearic acid salts determines the dropping point, mechanical stability, and water resistance of greases. The ratio of stearic acid in these blends significantly impacts the final performance characteristics.Expand Specific Solutions05 Stearic acid in wax and candle formulations

Stearic acid is extensively used in wax and candle formulations to increase rigidity and improve burning characteristics. It raises the melting point of wax blends, resulting in candles that maintain their shape at higher temperatures. The crystalline structure formed by stearic acid contributes to the opacity and hardness of the final product. By adjusting the proportion of stearic acid in the blend, manufacturers can control the rigidity, burn time, and appearance of candles and wax-based products.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Fatty Acid Industry

The stearic acid blend rigidness improvement market is currently in a growth phase, with increasing demand across automotive, construction, and industrial applications. The market size is expanding due to rising needs for high-performance materials with enhanced mechanical properties. Technologically, the field shows moderate maturity with ongoing innovation. Key players include LG Chem and Shanghai PRET Composites leading in polymer modification applications, while China Petroleum & Chemical Corp and Sumitomo Rubber Industries focus on industrial-scale production. NIPPON STEEL and Holcim are advancing construction applications, with specialized players like Rhodia Chimie (Solvay) and Mitsui Chemicals developing proprietary formulations. Research institutions like China University of Mining & Technology are contributing to fundamental advancements, creating a competitive landscape balanced between established corporations and specialized material science innovators.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced stearic acid blend formulations incorporating metal stearates (particularly zinc and calcium stearates) with precisely controlled particle sizes to enhance polymer rigidity. Their proprietary technology involves a dual-modification approach where stearic acid is first chemically modified to improve compatibility with various polymer matrices, then blended with nano-scale reinforcing agents. This creates strong interfacial bonding between the polymer chains and the stearic acid derivatives. LG Chem's process includes a specialized cooling protocol that promotes optimal crystallization of the stearic acid components, resulting in more uniform dispersion throughout the polymer matrix and consequently improved mechanical properties including rigidity, impact resistance, and dimensional stability.

Strengths: Superior dispersion technology allowing for lower loading levels while maintaining performance; excellent compatibility with diverse polymer systems; consistent quality control. Weaknesses: Higher production costs compared to conventional stearic acid blends; requires specialized processing equipment; performance benefits may diminish under extreme temperature conditions.

Shanghai PRET Composites Co. Ltd.

Technical Solution: Shanghai PRET Composites has pioneered a multi-functional stearic acid blend system specifically engineered for high-rigidity composite applications. Their technology combines modified stearic acid with silane coupling agents and specialized nucleating agents to create a synergistic effect that enhances crystallization behavior in semi-crystalline polymers. The company's proprietary processing technique involves a controlled reaction between stearic acid and metal oxides under precise temperature and pressure conditions, resulting in metal stearate complexes with optimized morphology. These complexes act as both processing aids and structural reinforcement in polymer matrices. PRET's formulations typically include 3-5% of their specialized stearic acid blend, which has been documented to increase flexural modulus by up to 25% in polypropylene composites while maintaining good impact properties.

Strengths: Exceptional balance between rigidity enhancement and processability; proven performance in demanding applications like automotive structural components; cost-effective compared to alternative rigidity-enhancing additives. Weaknesses: Requires careful control of processing parameters; potential for reduced elongation properties; limited effectiveness in amorphous polymer systems.

Key Patents and Research on Stearic Acid Crystallization

Method for reinforcing the mechanical properties of a plant fiber

PatentInactiveEP2585627A1

Innovation

- A method involving the application of axial tensile stresses at varying relative humidity levels and temperatures to plant fibers, which can increase their stiffness by up to 3.5 times the initial value, utilizing a DMA device or traditional testing machines to apply sinusoidal stresses and control humidity, without the need for chemical treatments or high energy processes.

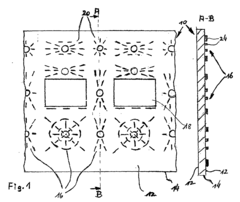

Method for increasing the stiffness of panel-like elements, panel-like element and its use

PatentInactiveEP1092818A3

Innovation

- The method involves additively joining additional coating structures to the large surfaces of flat components using simple joining methods like cold and hot gluing, spraying, or welding, allowing for flexible production and increased rigidity without substantial weight gain, and can be designed using FEM calculations for optimal layout.

Environmental Impact and Sustainability Considerations

The environmental impact of stearic acid blends and their production processes has become increasingly important as industries strive for more sustainable practices. Traditional methods of enhancing rigidity in stearic acid blends often involve additives or processing techniques that may pose environmental concerns. The carbon footprint associated with the extraction, processing, and disposal of stearic acid and its blends requires careful consideration in any improvement strategy.

Manufacturing processes for enhanced stearic acid blends typically consume significant energy, particularly during heating and cooling cycles. Optimizing these thermal processes can substantially reduce energy consumption and associated greenhouse gas emissions. Additionally, the use of renewable energy sources in production facilities represents a viable path toward reducing the environmental impact of manufacturing rigid stearic acid blends.

Raw material sourcing presents another critical sustainability consideration. Stearic acid derived from palm oil has faced scrutiny due to deforestation concerns, while petroleum-based alternatives raise issues regarding non-renewable resource depletion. Exploring alternative feedstocks such as algae-based or waste-derived stearic acid could significantly improve the sustainability profile of rigid blends while maintaining performance characteristics.

Biodegradability and end-of-life considerations must be integrated into blend formulation strategies. Improving rigidness through additives that compromise biodegradability may create downstream waste management challenges. Research indicates that certain bio-based cross-linking agents can enhance rigidity while maintaining or improving biodegradability profiles, offering a promising direction for sustainable formulation development.

Water usage and contamination represent additional environmental concerns in stearic acid processing. Advanced water recycling systems and closed-loop processing can minimize freshwater consumption and prevent the release of potentially harmful compounds into aquatic ecosystems. Implementation of green chemistry principles in blend formulation can further reduce the use of hazardous substances and minimize waste generation.

Regulatory compliance and certification standards are increasingly driving sustainability improvements in chemical formulations. Frameworks such as REACH in Europe and various eco-certification programs worldwide are establishing stricter requirements for environmental performance. Developing stearic acid blends with enhanced rigidity while meeting these evolving standards will be essential for market acceptance and long-term commercial viability.

Life cycle assessment (LCA) methodologies offer valuable tools for quantifying the environmental impacts of different stearic acid blend formulations and identifying optimization opportunities. Comprehensive LCA studies comparing traditional and innovative approaches to rigidity enhancement can guide development efforts toward truly sustainable solutions that balance performance requirements with environmental responsibility.

Manufacturing processes for enhanced stearic acid blends typically consume significant energy, particularly during heating and cooling cycles. Optimizing these thermal processes can substantially reduce energy consumption and associated greenhouse gas emissions. Additionally, the use of renewable energy sources in production facilities represents a viable path toward reducing the environmental impact of manufacturing rigid stearic acid blends.

Raw material sourcing presents another critical sustainability consideration. Stearic acid derived from palm oil has faced scrutiny due to deforestation concerns, while petroleum-based alternatives raise issues regarding non-renewable resource depletion. Exploring alternative feedstocks such as algae-based or waste-derived stearic acid could significantly improve the sustainability profile of rigid blends while maintaining performance characteristics.

Biodegradability and end-of-life considerations must be integrated into blend formulation strategies. Improving rigidness through additives that compromise biodegradability may create downstream waste management challenges. Research indicates that certain bio-based cross-linking agents can enhance rigidity while maintaining or improving biodegradability profiles, offering a promising direction for sustainable formulation development.

Water usage and contamination represent additional environmental concerns in stearic acid processing. Advanced water recycling systems and closed-loop processing can minimize freshwater consumption and prevent the release of potentially harmful compounds into aquatic ecosystems. Implementation of green chemistry principles in blend formulation can further reduce the use of hazardous substances and minimize waste generation.

Regulatory compliance and certification standards are increasingly driving sustainability improvements in chemical formulations. Frameworks such as REACH in Europe and various eco-certification programs worldwide are establishing stricter requirements for environmental performance. Developing stearic acid blends with enhanced rigidity while meeting these evolving standards will be essential for market acceptance and long-term commercial viability.

Life cycle assessment (LCA) methodologies offer valuable tools for quantifying the environmental impacts of different stearic acid blend formulations and identifying optimization opportunities. Comprehensive LCA studies comparing traditional and innovative approaches to rigidity enhancement can guide development efforts toward truly sustainable solutions that balance performance requirements with environmental responsibility.

Performance Testing Standards and Quality Control Protocols

Establishing robust performance testing standards and quality control protocols is essential for ensuring consistent rigidness in stearic acid blends. The industry currently employs several standardized testing methodologies to evaluate the mechanical properties of stearic acid-enhanced materials, particularly focusing on rigidity measurements.

The primary testing standard for rigidness assessment involves the use of durometer hardness testing (ASTM D2240), which quantifies material resistance to indentation. For stearic acid blends specifically, Shore D hardness measurements provide reliable data on rigidity improvements. Complementary to this, flexural modulus testing (ASTM D790) evaluates the material's resistance to bending under load, offering critical insights into structural rigidity performance.

Thermal analysis protocols, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), have become standard requirements for quality control of stearic acid blends. These methods verify crystallization behavior and thermal stability, both directly correlated with the final rigidity properties. The crystallization onset temperature and enthalpy values serve as key quality indicators during production.

Rheological testing standards have evolved to include both dynamic and steady shear measurements. The complex viscosity and storage modulus parameters, measured according to ASTM D4440, provide valuable information about the material's structural integrity and rigidity potential. These measurements must be conducted at processing temperatures to ensure relevance to manufacturing conditions.

Quality control protocols for stearic acid blends should implement statistical process control (SPC) methodologies with defined acceptance criteria. Establishing upper and lower specification limits for critical parameters such as melt flow index (ASTM D1238), crystallinity percentage, and dispersion uniformity ensures batch-to-batch consistency. Modern protocols increasingly incorporate in-line monitoring systems that utilize near-infrared spectroscopy for real-time blend composition verification.

Accelerated aging tests (ASTM D573) have become standard practice to predict long-term rigidity retention. These protocols subject stearic acid blends to elevated temperatures and controlled environmental conditions, measuring rigidity changes over time. The industry benchmark requires less than 10% reduction in rigidity properties after 1000 hours of accelerated aging to meet quality standards.

Implementation of these standardized testing protocols requires calibrated equipment and trained personnel. Documentation systems must maintain detailed records of test results, statistical analyses, and corrective actions when deviations occur. This comprehensive approach to performance testing and quality control ensures that stearic acid blends consistently deliver the enhanced rigidness properties required for high-performance applications.

The primary testing standard for rigidness assessment involves the use of durometer hardness testing (ASTM D2240), which quantifies material resistance to indentation. For stearic acid blends specifically, Shore D hardness measurements provide reliable data on rigidity improvements. Complementary to this, flexural modulus testing (ASTM D790) evaluates the material's resistance to bending under load, offering critical insights into structural rigidity performance.

Thermal analysis protocols, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), have become standard requirements for quality control of stearic acid blends. These methods verify crystallization behavior and thermal stability, both directly correlated with the final rigidity properties. The crystallization onset temperature and enthalpy values serve as key quality indicators during production.

Rheological testing standards have evolved to include both dynamic and steady shear measurements. The complex viscosity and storage modulus parameters, measured according to ASTM D4440, provide valuable information about the material's structural integrity and rigidity potential. These measurements must be conducted at processing temperatures to ensure relevance to manufacturing conditions.

Quality control protocols for stearic acid blends should implement statistical process control (SPC) methodologies with defined acceptance criteria. Establishing upper and lower specification limits for critical parameters such as melt flow index (ASTM D1238), crystallinity percentage, and dispersion uniformity ensures batch-to-batch consistency. Modern protocols increasingly incorporate in-line monitoring systems that utilize near-infrared spectroscopy for real-time blend composition verification.

Accelerated aging tests (ASTM D573) have become standard practice to predict long-term rigidity retention. These protocols subject stearic acid blends to elevated temperatures and controlled environmental conditions, measuring rigidity changes over time. The industry benchmark requires less than 10% reduction in rigidity properties after 1000 hours of accelerated aging to meet quality standards.

Implementation of these standardized testing protocols requires calibrated equipment and trained personnel. Documentation systems must maintain detailed records of test results, statistical analyses, and corrective actions when deviations occur. This comprehensive approach to performance testing and quality control ensures that stearic acid blends consistently deliver the enhanced rigidness properties required for high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!