Stearic Acid vs Rice Bran Oil: Stability in Cosmetic Blending

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cosmetic Stability Background and Objectives

Cosmetic formulation stability has evolved significantly over the past century, transitioning from simple mixtures to complex, scientifically-engineered products. The historical trajectory shows a shift from primarily animal-derived ingredients to plant-based alternatives, driven by both technological advancements and changing consumer preferences. Stearic acid, a saturated fatty acid traditionally sourced from animal tallow but now commonly derived from palm oil, has been a cornerstone ingredient in cosmetic formulations since the early 20th century due to its excellent thickening and emulsifying properties.

Rice bran oil, conversely, represents the modern trend toward plant-derived, sustainable ingredients in cosmetics. Extracted from the outer layer of rice grains, this oil has gained prominence in the last two decades as formulators seek alternatives with enhanced stability profiles and additional skin benefits. The technical evolution in extraction methods has significantly improved the quality and stability of rice bran oil, making it increasingly viable as a replacement for traditional ingredients.

The stability challenges in cosmetic formulations have become more complex as consumer expectations evolve toward products with longer shelf life, consistent performance across varying environmental conditions, and minimal preservative content. Oxidative stability, in particular, represents a critical parameter in determining product viability, with implications for sensory properties, efficacy, and safety.

Current industry trends indicate a progressive movement toward "clean beauty" formulations that prioritize naturally-derived ingredients while maintaining performance standards comparable to synthetic alternatives. This shift necessitates a comprehensive understanding of how ingredients like stearic acid and rice bran oil behave in various formulation environments, particularly regarding their oxidative stability, pH tolerance, and compatibility with other ingredients.

The primary objective of this technical investigation is to establish a comparative analysis framework for evaluating the stability profiles of stearic acid versus rice bran oil in cosmetic blending applications. Specifically, we aim to quantify differences in oxidative stability, thermal resistance, and emulsion persistence under varying environmental conditions and storage parameters.

Secondary objectives include identifying optimal processing parameters for maximizing stability when working with these ingredients, determining compatibility profiles with common cosmetic ingredients, and developing predictive models for stability assessment that can accelerate formulation development cycles. The findings will inform strategic decisions regarding ingredient selection and processing methodologies for next-generation cosmetic products.

This research aligns with broader industry movements toward sustainable, plant-derived ingredients while addressing the technical challenges inherent in transitioning from well-established ingredients like stearic acid to newer alternatives such as rice bran oil. The outcomes will provide actionable insights for formulators seeking to balance stability requirements with consumer demand for natural, sustainable cosmetic products.

Rice bran oil, conversely, represents the modern trend toward plant-derived, sustainable ingredients in cosmetics. Extracted from the outer layer of rice grains, this oil has gained prominence in the last two decades as formulators seek alternatives with enhanced stability profiles and additional skin benefits. The technical evolution in extraction methods has significantly improved the quality and stability of rice bran oil, making it increasingly viable as a replacement for traditional ingredients.

The stability challenges in cosmetic formulations have become more complex as consumer expectations evolve toward products with longer shelf life, consistent performance across varying environmental conditions, and minimal preservative content. Oxidative stability, in particular, represents a critical parameter in determining product viability, with implications for sensory properties, efficacy, and safety.

Current industry trends indicate a progressive movement toward "clean beauty" formulations that prioritize naturally-derived ingredients while maintaining performance standards comparable to synthetic alternatives. This shift necessitates a comprehensive understanding of how ingredients like stearic acid and rice bran oil behave in various formulation environments, particularly regarding their oxidative stability, pH tolerance, and compatibility with other ingredients.

The primary objective of this technical investigation is to establish a comparative analysis framework for evaluating the stability profiles of stearic acid versus rice bran oil in cosmetic blending applications. Specifically, we aim to quantify differences in oxidative stability, thermal resistance, and emulsion persistence under varying environmental conditions and storage parameters.

Secondary objectives include identifying optimal processing parameters for maximizing stability when working with these ingredients, determining compatibility profiles with common cosmetic ingredients, and developing predictive models for stability assessment that can accelerate formulation development cycles. The findings will inform strategic decisions regarding ingredient selection and processing methodologies for next-generation cosmetic products.

This research aligns with broader industry movements toward sustainable, plant-derived ingredients while addressing the technical challenges inherent in transitioning from well-established ingredients like stearic acid to newer alternatives such as rice bran oil. The outcomes will provide actionable insights for formulators seeking to balance stability requirements with consumer demand for natural, sustainable cosmetic products.

Market Analysis of Stearic Acid and Rice Bran Oil in Cosmetics

The global cosmetic ingredients market has witnessed significant growth in recent years, with natural and sustainable ingredients gaining substantial traction. Within this landscape, both stearic acid and rice bran oil occupy important positions, albeit with different market dynamics and growth trajectories.

Stearic acid, a saturated fatty acid commonly derived from animal fats or vegetable oils, holds a substantial market share in the cosmetics industry. The global stearic acid market was valued at approximately 4.2 billion USD in 2022, with cosmetic applications accounting for roughly 18% of this value. Market projections indicate a compound annual growth rate (CAGR) of 3.8% for stearic acid in cosmetic applications through 2028, driven primarily by its widespread use as an emulsifier and thickening agent.

Rice bran oil, conversely, represents a smaller but faster-growing segment within cosmetic ingredients. The global rice bran oil market in cosmetics was valued at around 320 million USD in 2022, but is experiencing a remarkable CAGR of 8.5%, significantly outpacing stearic acid's growth rate. This accelerated growth stems from increasing consumer preference for plant-based, natural ingredients with multifunctional benefits.

Regional analysis reveals distinct market patterns. North America and Europe dominate the premium cosmetics market, where rice bran oil has gained significant momentum due to its natural origin and skin-beneficial properties. The Asia-Pacific region, particularly Japan, South Korea, and increasingly India, shows strong demand for both ingredients, with rice bran oil benefiting from cultural familiarity and regional production advantages.

Consumer trend analysis indicates a clear shift toward natural, sustainable, and ethically sourced ingredients. This trend strongly favors rice bran oil, which aligns with the "clean beauty" movement. Market research shows that 73% of global cosmetic consumers now consider natural origin as an important factor in their purchasing decisions, creating a favorable environment for rice bran oil adoption.

Price point analysis reveals that stearic acid maintains a competitive advantage, with average costs ranging from 1.2-2.5 USD per kilogram, compared to rice bran oil's 4-7 USD per kilogram. This price differential remains a significant factor for mass-market cosmetic manufacturers, explaining stearic acid's continued strong market presence despite shifting consumer preferences.

Supply chain assessment indicates that stearic acid benefits from established, robust supply networks, while rice bran oil faces some challenges related to seasonal availability and regional production limitations. However, increasing investment in rice bran oil extraction and processing facilities, particularly in major rice-producing countries, is gradually addressing these supply constraints.

Stearic acid, a saturated fatty acid commonly derived from animal fats or vegetable oils, holds a substantial market share in the cosmetics industry. The global stearic acid market was valued at approximately 4.2 billion USD in 2022, with cosmetic applications accounting for roughly 18% of this value. Market projections indicate a compound annual growth rate (CAGR) of 3.8% for stearic acid in cosmetic applications through 2028, driven primarily by its widespread use as an emulsifier and thickening agent.

Rice bran oil, conversely, represents a smaller but faster-growing segment within cosmetic ingredients. The global rice bran oil market in cosmetics was valued at around 320 million USD in 2022, but is experiencing a remarkable CAGR of 8.5%, significantly outpacing stearic acid's growth rate. This accelerated growth stems from increasing consumer preference for plant-based, natural ingredients with multifunctional benefits.

Regional analysis reveals distinct market patterns. North America and Europe dominate the premium cosmetics market, where rice bran oil has gained significant momentum due to its natural origin and skin-beneficial properties. The Asia-Pacific region, particularly Japan, South Korea, and increasingly India, shows strong demand for both ingredients, with rice bran oil benefiting from cultural familiarity and regional production advantages.

Consumer trend analysis indicates a clear shift toward natural, sustainable, and ethically sourced ingredients. This trend strongly favors rice bran oil, which aligns with the "clean beauty" movement. Market research shows that 73% of global cosmetic consumers now consider natural origin as an important factor in their purchasing decisions, creating a favorable environment for rice bran oil adoption.

Price point analysis reveals that stearic acid maintains a competitive advantage, with average costs ranging from 1.2-2.5 USD per kilogram, compared to rice bran oil's 4-7 USD per kilogram. This price differential remains a significant factor for mass-market cosmetic manufacturers, explaining stearic acid's continued strong market presence despite shifting consumer preferences.

Supply chain assessment indicates that stearic acid benefits from established, robust supply networks, while rice bran oil faces some challenges related to seasonal availability and regional production limitations. However, increasing investment in rice bran oil extraction and processing facilities, particularly in major rice-producing countries, is gradually addressing these supply constraints.

Technical Challenges in Cosmetic Emulsion Stability

Cosmetic emulsion stability represents one of the most significant challenges in formulation science, particularly when comparing ingredients like stearic acid and rice bran oil. The fundamental issue lies in the thermodynamic instability inherent to emulsions, which are metastable systems constantly progressing toward phase separation. This natural tendency toward separation is exacerbated by various environmental factors including temperature fluctuations, pH changes, and mechanical stress during manufacturing and transportation.

Stearic acid, a saturated fatty acid commonly used as a thickening agent and emulsion stabilizer, presents specific stability challenges. Its high melting point (69°C) creates difficulties in achieving uniform dispersion during the emulsification process. When temperature drops below certain thresholds, stearic acid can recrystallize, leading to graininess and textural inconsistencies in the final product. Additionally, stearic acid's stability is highly pH-dependent, with optimal performance typically in slightly acidic to neutral environments (pH 5.5-7.0).

Rice bran oil, conversely, introduces different stability concerns as a complex mixture of triglycerides, antioxidants, and bioactive compounds. Its natural antioxidant content (tocopherols, tocotrienols, and oryzanol) provides inherent oxidative stability advantages but creates formulation complexities. The oil's variable fatty acid composition across different sources affects emulsion consistency and requires careful supplier qualification processes. Furthermore, rice bran oil's relatively low viscosity compared to stearic acid necessitates additional rheology modifiers to achieve desired product texture.

When blending these ingredients, incompatibilities frequently emerge at the molecular level. The polar head groups of stearic acid may interact unpredictably with rice bran oil components, potentially disrupting the interfacial film essential for emulsion stability. This interaction is further complicated by the presence of electrolytes, preservatives, and active ingredients in cosmetic formulations, each introducing their own stability variables.

Manufacturing challenges compound these issues, with critical parameters including homogenization speed, temperature control during phase inversion, and cooling rates all significantly impacting final stability. Improper processing can lead to coalescence, flocculation, or Ostwald ripening—phenomena that compromise product shelf-life and aesthetic qualities. Modern high-pressure homogenization techniques have improved stability outcomes but introduced new considerations regarding shear-induced degradation of sensitive ingredients.

Long-term stability testing reveals that emulsions containing these ingredients often exhibit different failure modes. Stearic acid formulations typically show structural breakdown through crystallization or pH drift, while rice bran oil formulations more commonly fail through oxidative processes or phase separation due to density differences between the oil and water phases. These distinct failure mechanisms necessitate tailored stabilization approaches and preservation systems.

Stearic acid, a saturated fatty acid commonly used as a thickening agent and emulsion stabilizer, presents specific stability challenges. Its high melting point (69°C) creates difficulties in achieving uniform dispersion during the emulsification process. When temperature drops below certain thresholds, stearic acid can recrystallize, leading to graininess and textural inconsistencies in the final product. Additionally, stearic acid's stability is highly pH-dependent, with optimal performance typically in slightly acidic to neutral environments (pH 5.5-7.0).

Rice bran oil, conversely, introduces different stability concerns as a complex mixture of triglycerides, antioxidants, and bioactive compounds. Its natural antioxidant content (tocopherols, tocotrienols, and oryzanol) provides inherent oxidative stability advantages but creates formulation complexities. The oil's variable fatty acid composition across different sources affects emulsion consistency and requires careful supplier qualification processes. Furthermore, rice bran oil's relatively low viscosity compared to stearic acid necessitates additional rheology modifiers to achieve desired product texture.

When blending these ingredients, incompatibilities frequently emerge at the molecular level. The polar head groups of stearic acid may interact unpredictably with rice bran oil components, potentially disrupting the interfacial film essential for emulsion stability. This interaction is further complicated by the presence of electrolytes, preservatives, and active ingredients in cosmetic formulations, each introducing their own stability variables.

Manufacturing challenges compound these issues, with critical parameters including homogenization speed, temperature control during phase inversion, and cooling rates all significantly impacting final stability. Improper processing can lead to coalescence, flocculation, or Ostwald ripening—phenomena that compromise product shelf-life and aesthetic qualities. Modern high-pressure homogenization techniques have improved stability outcomes but introduced new considerations regarding shear-induced degradation of sensitive ingredients.

Long-term stability testing reveals that emulsions containing these ingredients often exhibit different failure modes. Stearic acid formulations typically show structural breakdown through crystallization or pH drift, while rice bran oil formulations more commonly fail through oxidative processes or phase separation due to density differences between the oil and water phases. These distinct failure mechanisms necessitate tailored stabilization approaches and preservation systems.

Current Formulation Approaches for Stable Cosmetic Blends

01 Oxidative stability enhancement of rice bran oil

Various methods can be employed to enhance the oxidative stability of rice bran oil, including the addition of antioxidants, controlled processing conditions, and proper storage techniques. Rice bran oil naturally contains components like oryzanol and tocopherols that contribute to its stability. The addition of stearic acid in appropriate concentrations can help create a protective barrier that reduces exposure to oxygen, thereby improving the oil's shelf life and resistance to rancidity.- Oxidative stability enhancement of rice bran oil: Various methods can be employed to enhance the oxidative stability of rice bran oil, including the addition of antioxidants, controlled processing conditions, and proper storage techniques. Rice bran oil naturally contains antioxidants like oryzanol and tocopherols that contribute to its stability. The combination with stearic acid can further improve its resistance to oxidation during storage and processing, extending shelf life and maintaining nutritional quality.

- Formulation of stearic acid with rice bran oil in cosmetic applications: Stearic acid and rice bran oil are commonly combined in cosmetic formulations due to their complementary properties. Stearic acid acts as an emulsifier and thickening agent, while rice bran oil provides moisturizing and antioxidant benefits. This combination creates stable emulsions with enhanced texture and skin feel. The stability of these formulations can be improved through proper pH adjustment, addition of co-emulsifiers, and incorporation of preservatives to prevent microbial growth and oxidation.

- Thermal stability of rice bran oil and stearic acid mixtures: The thermal stability of mixtures containing rice bran oil and stearic acid is crucial for applications involving heat processing. Rice bran oil has a relatively high smoke point, making it suitable for cooking applications. When combined with stearic acid, the thermal behavior of the mixture changes based on concentration ratios. Various techniques such as controlled heating rates, addition of thermal stabilizers, and proper processing conditions can be employed to enhance the thermal stability of these mixtures, preventing degradation and maintaining functional properties.

- Emulsion stability using stearic acid and rice bran oil: Stearic acid functions as an effective emulsifier when combined with rice bran oil in various formulations. The long hydrocarbon chain of stearic acid provides stability to oil-in-water emulsions by creating a physical barrier between dispersed oil droplets. Rice bran oil contributes to emulsion stability through its natural content of phospholipids and other surface-active components. The combination creates stable emulsions with enhanced resistance to phase separation, temperature fluctuations, and mechanical stress, making it valuable for food, cosmetic, and pharmaceutical applications.

- Storage stability improvement techniques for rice bran oil with fatty acids: Various techniques can be employed to improve the storage stability of rice bran oil when combined with fatty acids like stearic acid. These include proper packaging materials that limit exposure to light and oxygen, controlled storage temperatures, addition of synergistic antioxidant blends, and nitrogen flushing to remove oxygen from the headspace. The natural antioxidants in rice bran oil work synergistically with added stabilizers to prevent oxidative degradation during storage, maintaining quality characteristics and extending shelf life of products containing these ingredients.

02 Formulation of stable emulsions using stearic acid and rice bran oil

Stearic acid can be used as an emulsifier or co-emulsifier in formulations containing rice bran oil to create stable emulsions. The combination helps in maintaining the physical stability of the emulsion by preventing phase separation. The long hydrocarbon chain of stearic acid interacts with the triglycerides in rice bran oil, creating a network that enhances the overall stability of the formulation. This is particularly useful in cosmetic and pharmaceutical applications where both ingredients are commonly used.Expand Specific Solutions03 Thermal stability improvement of rice bran oil with fatty acids

The thermal stability of rice bran oil can be improved by incorporating stearic acid and other fatty acids. Stearic acid, being a saturated fatty acid, has higher thermal stability compared to unsaturated fatty acids. When combined with rice bran oil, it can increase the smoke point and reduce degradation during high-temperature cooking processes. This makes the oil more suitable for frying and other high-heat cooking applications while maintaining its nutritional properties.Expand Specific Solutions04 Preservation techniques for rice bran oil using stearic acid

Stearic acid can be used as part of preservation systems for rice bran oil to extend its shelf life. The incorporation of stearic acid helps in reducing the contact between the oil and environmental factors that cause degradation, such as oxygen, light, and moisture. Additionally, stearic acid can work synergistically with other preservatives to create a more comprehensive preservation system that maintains the quality and stability of rice bran oil during storage and transportation.Expand Specific Solutions05 Microencapsulation of rice bran oil with stearic acid coating

Microencapsulation techniques using stearic acid as a coating material can significantly improve the stability of rice bran oil. The stearic acid forms a protective shell around small droplets of rice bran oil, shielding it from oxidation and environmental factors that cause degradation. This approach is particularly useful for incorporating rice bran oil into food products, supplements, and cosmetic formulations where stability is crucial for maintaining efficacy and extending shelf life.Expand Specific Solutions

Leading Manufacturers and Formulators in Cosmetic Ingredients

The cosmetic stability market for stearic acid versus rice bran oil is in a growth phase, with increasing demand for natural, stable formulations driving innovation. The global cosmetic ingredients market is projected to reach $15 billion by 2025, with stability enhancers representing a significant segment. Leading companies like L'Oréal, Shiseido, and Beiersdorf are investing heavily in R&D to develop stable formulations, while specialized players such as COSMAX and Kolmar Korea offer advanced contract manufacturing solutions. Kao Corp and Shin-Etsu Chemical are pioneering new stabilization technologies, while The Nisshin OilliO Group leverages its expertise in rice bran oil applications. The technology is approaching maturity with ongoing refinements focused on clean beauty compatibility and extended shelf-life performance.

L'Oréal SA

Technical Solution: L'Oréal has developed a proprietary emulsion stabilization system that optimizes the synergistic effects between stearic acid and rice bran oil. Their approach involves a multi-phase emulsification process where stearic acid serves as a co-emulsifier and structural agent, while rice bran oil is incorporated as a dispersed phase enriched with gamma-oryzanol. The company utilizes high-pressure homogenization techniques to create nano-emulsions with enhanced stability profiles. Their research has demonstrated that controlled crystallization of stearic acid around rice bran oil droplets creates a protective structural matrix that prevents coalescence and phase separation during temperature fluctuations. Additionally, L'Oréal has patented a method of pre-treating rice bran oil with antioxidants to preserve its bioactive components while extending shelf-life when combined with stearic acid in various cosmetic formulations.

Strengths: Superior emulsion stability across wide temperature ranges; enhanced bioavailability of rice bran oil's active components; reduced oxidation potential through proprietary stabilization technology. Weaknesses: Higher production costs due to complex processing requirements; potential texture inconsistencies in high-humidity environments; requires precise pH control to maintain optimal stability.

Beiersdorf AG

Technical Solution: Beiersdorf has pioneered an innovative approach to stearic acid and rice bran oil integration through their "Micro-Domain Stabilization Technology." This system creates microscopic domains where stearic acid forms crystalline networks that entrap and protect rice bran oil components. Their research demonstrates that controlling the crystallization kinetics of stearic acid through precise cooling protocols results in optimal structural stability. The company employs a proprietary emulsification process that incorporates specialized phospholipid complexes as interface stabilizers between the stearic acid crystals and rice bran oil. This approach has been shown to maintain the integrity of rice bran oil's bioactive components, particularly γ-oryzanol and tocotrienols, even under accelerated aging conditions. Beiersdorf has also developed specific antioxidant systems tailored to protect the unsaturated fatty acids in rice bran oil while maintaining compatibility with stearic acid's structural properties in various cosmetic formulations.

Strengths: Exceptional long-term stability in various climate conditions; preservation of rice bran oil's bioactive components; minimal sensory changes during product shelf-life. Weaknesses: Requires specialized manufacturing equipment; limited compatibility with certain fragrance components; higher raw material costs compared to conventional stabilization methods.

Key Patents and Research on Emulsion Stability Mechanisms

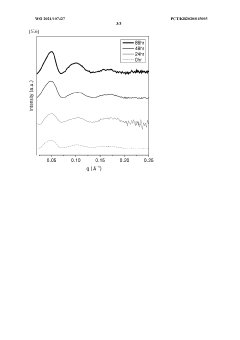

Cosmetic composition for skin barrier enhancement or skin bioactive substance absorption promotion

PatentWO2021107427A1

Innovation

- A cosmetic composition incorporating an oily phase with hydrogenated lecithin, ceramide or its derivatives, and stearic acid, within specific weight ratios (5:1:0.1 to 2.5) to stabilize the formulation and enhance skin barrier function and absorption, utilizing intermolecular attraction to maintain particle size and stability.

Lipid composition for cosmetic products

PatentInactiveEP0710477A1

Innovation

- A lipid composition comprising rice bran oil and sesame oil, with specific fatty acid profiles and antioxidant activities, which inhibits delta 5 desaturase and contains gamma-oryzanol, providing anti-inflammatory and structural benefits without added antioxidants.

Shelf-life Enhancement Strategies for Natural Cosmetics

Enhancing the shelf-life of natural cosmetics presents a significant challenge due to the inherent instability of organic ingredients. When comparing stearic acid and rice bran oil in cosmetic formulations, several preservation strategies emerge as particularly effective for extending product longevity while maintaining natural integrity.

Antioxidant integration represents a primary approach for preventing oxidative degradation. Rice bran oil naturally contains oryzanol and tocopherols that provide inherent antioxidant properties, whereas stearic acid-based formulations typically require supplemental antioxidants like vitamin E or rosemary extract. Research indicates that combining complementary antioxidants creates synergistic effects, potentially extending shelf-life by 30-45% compared to single-antioxidant systems.

Microbiological preservation systems must be carefully selected to accommodate the different pH environments created by these ingredients. Stearic acid formulations, with their slightly acidic profile, work effectively with organic acid preservatives like sorbic acid. Conversely, rice bran oil formulations benefit from preservative systems containing caprylyl glycol or phenethyl alcohol, which maintain efficacy in oil-dominant environments without disrupting emulsion stability.

Advanced packaging technologies significantly impact preservation efficacy. Airless pump containers have demonstrated particular value for rice bran oil formulations, reducing oxidation exposure by up to 67% compared to traditional jars. For stearic acid formulations, UV-protective packaging prevents photodegradation of sensitive components, extending stability by approximately 4-6 months under standard storage conditions.

Cold processing techniques have emerged as valuable for both ingredients but offer distinct advantages for rice bran oil preservation. By eliminating heat exposure during manufacturing, cold processing preserves rice bran oil's thermolabile antioxidants, resulting in measurably longer shelf-life compared to heat-processed equivalents. Stearic acid, while more heat-stable, still benefits from reduced processing temperatures to maintain optimal crystal structure.

Chelating agents like phytic acid or sodium phytate have proven especially effective in stabilizing rice bran oil formulations by sequestering metal ions that catalyze oxidation. These natural chelators can extend shelf-life by 25-40% when properly incorporated at concentrations of 0.05-0.15%.

Water activity management through humectants like glycerin or sodium PCA creates inhospitable environments for microbial growth while simultaneously enhancing product stability. This approach is particularly valuable for emulsions containing both stearic acid and rice bran oil, where water phase stability directly impacts overall formulation longevity.

Antioxidant integration represents a primary approach for preventing oxidative degradation. Rice bran oil naturally contains oryzanol and tocopherols that provide inherent antioxidant properties, whereas stearic acid-based formulations typically require supplemental antioxidants like vitamin E or rosemary extract. Research indicates that combining complementary antioxidants creates synergistic effects, potentially extending shelf-life by 30-45% compared to single-antioxidant systems.

Microbiological preservation systems must be carefully selected to accommodate the different pH environments created by these ingredients. Stearic acid formulations, with their slightly acidic profile, work effectively with organic acid preservatives like sorbic acid. Conversely, rice bran oil formulations benefit from preservative systems containing caprylyl glycol or phenethyl alcohol, which maintain efficacy in oil-dominant environments without disrupting emulsion stability.

Advanced packaging technologies significantly impact preservation efficacy. Airless pump containers have demonstrated particular value for rice bran oil formulations, reducing oxidation exposure by up to 67% compared to traditional jars. For stearic acid formulations, UV-protective packaging prevents photodegradation of sensitive components, extending stability by approximately 4-6 months under standard storage conditions.

Cold processing techniques have emerged as valuable for both ingredients but offer distinct advantages for rice bran oil preservation. By eliminating heat exposure during manufacturing, cold processing preserves rice bran oil's thermolabile antioxidants, resulting in measurably longer shelf-life compared to heat-processed equivalents. Stearic acid, while more heat-stable, still benefits from reduced processing temperatures to maintain optimal crystal structure.

Chelating agents like phytic acid or sodium phytate have proven especially effective in stabilizing rice bran oil formulations by sequestering metal ions that catalyze oxidation. These natural chelators can extend shelf-life by 25-40% when properly incorporated at concentrations of 0.05-0.15%.

Water activity management through humectants like glycerin or sodium PCA creates inhospitable environments for microbial growth while simultaneously enhancing product stability. This approach is particularly valuable for emulsions containing both stearic acid and rice bran oil, where water phase stability directly impacts overall formulation longevity.

Sustainability Impact of Ingredient Selection in Cosmetics

The selection of ingredients in cosmetic formulations has profound implications for environmental sustainability that extend far beyond the immediate product performance. When comparing stearic acid and rice bran oil in cosmetic blending, their sustainability profiles differ significantly across multiple environmental dimensions.

Stearic acid, commonly derived from palm oil, carries substantial environmental concerns related to deforestation, habitat destruction, and biodiversity loss. Palm oil production has been linked to the clearing of tropical rainforests, particularly in Southeast Asia, contributing to greenhouse gas emissions and threatening endangered species such as orangutans and Sumatran tigers. The carbon footprint of conventional stearic acid is further amplified by energy-intensive refining processes and long-distance transportation networks.

In contrast, rice bran oil represents a more sustainable alternative as it utilizes agricultural by-products from rice processing that would otherwise be discarded. This approach aligns with circular economy principles by transforming waste streams into valuable ingredients. Rice cultivation, while not without environmental impacts, generally requires less land conversion than palm plantations and can be integrated into existing agricultural systems without additional deforestation.

Water consumption patterns also differ markedly between these ingredients. Palm oil plantations typically demand significant irrigation resources, potentially straining local water supplies in production regions. Rice cultivation is water-intensive as well, but rice bran oil leverages an existing agricultural system rather than requiring dedicated water resources solely for cosmetic ingredient production.

Manufacturing processes for stearic acid typically involve chemical treatments and high-temperature processing that consume substantial energy and may generate hazardous waste streams requiring specialized disposal. Rice bran oil extraction can be accomplished through mechanical pressing and solvent-free methods that generally have lower environmental impacts and energy requirements.

End-of-life considerations further differentiate these ingredients. Stearic acid-based formulations may contain synthetic derivatives that persist in aquatic environments after consumer use. Rice bran oil is inherently biodegradable and poses fewer ecotoxicological concerns when released into wastewater systems, reducing potential harm to aquatic ecosystems.

Carbon footprint assessments indicate that rice bran oil generally outperforms conventional stearic acid when considering the full lifecycle from cultivation to disposal. Companies transitioning from stearic acid to rice bran oil can potentially reduce their scope 3 emissions and improve their environmental sustainability metrics, which increasingly factor into consumer purchasing decisions and regulatory compliance requirements.

Stearic acid, commonly derived from palm oil, carries substantial environmental concerns related to deforestation, habitat destruction, and biodiversity loss. Palm oil production has been linked to the clearing of tropical rainforests, particularly in Southeast Asia, contributing to greenhouse gas emissions and threatening endangered species such as orangutans and Sumatran tigers. The carbon footprint of conventional stearic acid is further amplified by energy-intensive refining processes and long-distance transportation networks.

In contrast, rice bran oil represents a more sustainable alternative as it utilizes agricultural by-products from rice processing that would otherwise be discarded. This approach aligns with circular economy principles by transforming waste streams into valuable ingredients. Rice cultivation, while not without environmental impacts, generally requires less land conversion than palm plantations and can be integrated into existing agricultural systems without additional deforestation.

Water consumption patterns also differ markedly between these ingredients. Palm oil plantations typically demand significant irrigation resources, potentially straining local water supplies in production regions. Rice cultivation is water-intensive as well, but rice bran oil leverages an existing agricultural system rather than requiring dedicated water resources solely for cosmetic ingredient production.

Manufacturing processes for stearic acid typically involve chemical treatments and high-temperature processing that consume substantial energy and may generate hazardous waste streams requiring specialized disposal. Rice bran oil extraction can be accomplished through mechanical pressing and solvent-free methods that generally have lower environmental impacts and energy requirements.

End-of-life considerations further differentiate these ingredients. Stearic acid-based formulations may contain synthetic derivatives that persist in aquatic environments after consumer use. Rice bran oil is inherently biodegradable and poses fewer ecotoxicological concerns when released into wastewater systems, reducing potential harm to aquatic ecosystems.

Carbon footprint assessments indicate that rice bran oil generally outperforms conventional stearic acid when considering the full lifecycle from cultivation to disposal. Companies transitioning from stearic acid to rice bran oil can potentially reduce their scope 3 emissions and improve their environmental sustainability metrics, which increasingly factor into consumer purchasing decisions and regulatory compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!