How to Increase Neopentane Yield in Industrial Processes?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Production Background and Objectives

Neopentane, also known as 2,2-dimethylpropane, is a highly valuable hydrocarbon compound with numerous industrial applications. The production of neopentane has been a subject of interest in the petrochemical industry for decades, owing to its unique properties and versatile uses. This report aims to provide a comprehensive overview of the background and objectives related to increasing neopentane yield in industrial processes.

The history of neopentane production can be traced back to the early 20th century when it was first synthesized in laboratories. However, its industrial-scale production only gained momentum in the latter half of the century as demand for specialized hydrocarbons grew. Initially, neopentane was primarily obtained as a byproduct of petroleum refining processes, but dedicated production methods were developed as its importance in various applications became apparent.

In recent years, the demand for neopentane has seen a steady increase, driven by its use in the production of high-performance polymers, refrigerants, and aerosol propellants. This growing demand has led to a renewed focus on optimizing neopentane production processes to improve yield and efficiency. The primary objective of current research and development efforts is to identify and implement innovative techniques that can significantly enhance neopentane yield while maintaining cost-effectiveness and environmental sustainability.

The technological evolution in neopentane production has been marked by several key milestones. Early production methods relied heavily on thermal cracking of petroleum fractions, which resulted in relatively low yields. Subsequent advancements in catalytic processes and separation technologies have gradually improved production efficiency. However, there is still considerable room for improvement, particularly in terms of selectivity and conversion rates.

Current research trends in neopentane production focus on several key areas. These include the development of novel catalysts with higher selectivity towards neopentane formation, the optimization of reaction conditions to favor neopentane production, and the exploration of alternative feedstocks that could potentially yield higher amounts of neopentane. Additionally, there is growing interest in integrating advanced process control systems and machine learning algorithms to fine-tune production parameters in real-time, thereby maximizing yield.

The overarching goal of increasing neopentane yield in industrial processes is multifaceted. It aims not only to meet the rising global demand for this valuable compound but also to improve the overall economics of production. By enhancing yield, manufacturers can reduce raw material consumption, lower energy requirements, and minimize waste generation. This, in turn, contributes to more sustainable and cost-effective production practices, aligning with broader industry trends towards greener and more efficient chemical manufacturing processes.

The history of neopentane production can be traced back to the early 20th century when it was first synthesized in laboratories. However, its industrial-scale production only gained momentum in the latter half of the century as demand for specialized hydrocarbons grew. Initially, neopentane was primarily obtained as a byproduct of petroleum refining processes, but dedicated production methods were developed as its importance in various applications became apparent.

In recent years, the demand for neopentane has seen a steady increase, driven by its use in the production of high-performance polymers, refrigerants, and aerosol propellants. This growing demand has led to a renewed focus on optimizing neopentane production processes to improve yield and efficiency. The primary objective of current research and development efforts is to identify and implement innovative techniques that can significantly enhance neopentane yield while maintaining cost-effectiveness and environmental sustainability.

The technological evolution in neopentane production has been marked by several key milestones. Early production methods relied heavily on thermal cracking of petroleum fractions, which resulted in relatively low yields. Subsequent advancements in catalytic processes and separation technologies have gradually improved production efficiency. However, there is still considerable room for improvement, particularly in terms of selectivity and conversion rates.

Current research trends in neopentane production focus on several key areas. These include the development of novel catalysts with higher selectivity towards neopentane formation, the optimization of reaction conditions to favor neopentane production, and the exploration of alternative feedstocks that could potentially yield higher amounts of neopentane. Additionally, there is growing interest in integrating advanced process control systems and machine learning algorithms to fine-tune production parameters in real-time, thereby maximizing yield.

The overarching goal of increasing neopentane yield in industrial processes is multifaceted. It aims not only to meet the rising global demand for this valuable compound but also to improve the overall economics of production. By enhancing yield, manufacturers can reduce raw material consumption, lower energy requirements, and minimize waste generation. This, in turn, contributes to more sustainable and cost-effective production practices, aligning with broader industry trends towards greener and more efficient chemical manufacturing processes.

Market Analysis for Neopentane and Derivatives

The neopentane market has experienced significant growth in recent years, driven by increasing demand across various industries. The global neopentane market size was valued at approximately $700 million in 2020 and is projected to reach $1.2 billion by 2027, growing at a CAGR of 6.5% during the forecast period. This growth is primarily attributed to the expanding applications of neopentane in sectors such as refrigerants, blowing agents, and specialty fuels.

The refrigeration industry remains the largest consumer of neopentane, accounting for over 40% of the total market share. The shift towards more environmentally friendly refrigerants has bolstered the demand for neopentane-based products, as they offer low global warming potential (GWP) and zero ozone depletion potential (ODP). This trend is expected to continue, driven by stringent regulations on traditional refrigerants in major economies.

The construction sector represents another significant market for neopentane, particularly in its use as a blowing agent for insulation materials. The growing emphasis on energy-efficient buildings and sustainable construction practices has led to increased adoption of neopentane-based insulation products. This segment is anticipated to witness the fastest growth rate, with a CAGR of 7.8% from 2021 to 2027.

Geographically, Asia-Pacific dominates the neopentane market, accounting for over 35% of the global consumption. China and India are the key growth drivers in this region, fueled by rapid industrialization and urbanization. North America and Europe follow closely, with steady demand from established end-use industries and ongoing research and development activities.

The neopentane derivatives market, including neopentyl glycol and neopentyl isobutyrate, is also showing promising growth prospects. Neopentyl glycol, used in the production of polyester resins and lubricants, is expected to reach a market value of $350 million by 2025, growing at a CAGR of 5.2%. The increasing demand for high-performance coatings and lubricants in automotive and industrial applications is driving this growth.

Despite the positive outlook, the neopentane market faces challenges such as price volatility of raw materials and stringent environmental regulations. However, ongoing technological advancements in production processes and the development of new applications are expected to create lucrative opportunities for market expansion. The focus on increasing neopentane yield in industrial processes is crucial to meeting the growing demand and ensuring sustainable market growth.

The refrigeration industry remains the largest consumer of neopentane, accounting for over 40% of the total market share. The shift towards more environmentally friendly refrigerants has bolstered the demand for neopentane-based products, as they offer low global warming potential (GWP) and zero ozone depletion potential (ODP). This trend is expected to continue, driven by stringent regulations on traditional refrigerants in major economies.

The construction sector represents another significant market for neopentane, particularly in its use as a blowing agent for insulation materials. The growing emphasis on energy-efficient buildings and sustainable construction practices has led to increased adoption of neopentane-based insulation products. This segment is anticipated to witness the fastest growth rate, with a CAGR of 7.8% from 2021 to 2027.

Geographically, Asia-Pacific dominates the neopentane market, accounting for over 35% of the global consumption. China and India are the key growth drivers in this region, fueled by rapid industrialization and urbanization. North America and Europe follow closely, with steady demand from established end-use industries and ongoing research and development activities.

The neopentane derivatives market, including neopentyl glycol and neopentyl isobutyrate, is also showing promising growth prospects. Neopentyl glycol, used in the production of polyester resins and lubricants, is expected to reach a market value of $350 million by 2025, growing at a CAGR of 5.2%. The increasing demand for high-performance coatings and lubricants in automotive and industrial applications is driving this growth.

Despite the positive outlook, the neopentane market faces challenges such as price volatility of raw materials and stringent environmental regulations. However, ongoing technological advancements in production processes and the development of new applications are expected to create lucrative opportunities for market expansion. The focus on increasing neopentane yield in industrial processes is crucial to meeting the growing demand and ensuring sustainable market growth.

Current Challenges in Neopentane Synthesis

The synthesis of neopentane in industrial processes faces several significant challenges that hinder its efficient production and yield optimization. One of the primary obstacles is the high energy requirement for the reaction to occur. Neopentane synthesis typically involves the hydrogenation of 2,2-dimethylpropanol or the alkylation of isobutane, both of which require substantial energy input to overcome activation barriers.

Another major challenge is the selectivity of the reaction. Competing side reactions often lead to the formation of unwanted byproducts, reducing the overall yield of neopentane. These side reactions can include the formation of isomers, such as isopentane, or the production of higher molecular weight hydrocarbons. Achieving high selectivity towards neopentane formation while minimizing these undesired pathways remains a significant hurdle in industrial processes.

Catalyst performance and stability present additional challenges in neopentane synthesis. The catalysts used in these processes, often based on noble metals or metal oxides, can suffer from deactivation due to coking, sintering, or poisoning. This leads to reduced catalytic activity over time, necessitating frequent catalyst regeneration or replacement, which impacts process efficiency and economics.

The reaction conditions required for neopentane synthesis also pose challenges. High pressures and temperatures are often necessary to drive the reaction forward, which can lead to increased equipment costs, safety concerns, and energy consumption. Balancing these conditions to maximize yield while maintaining process safety and economic viability is a complex optimization problem.

Feedstock purity and availability represent another set of challenges. The production of high-purity neopentane often requires ultra-pure starting materials, which can be costly and difficult to source consistently. Impurities in the feedstock can lead to catalyst poisoning or the formation of additional unwanted byproducts, further complicating the purification process.

Separation and purification of neopentane from the reaction mixture present their own set of difficulties. Due to its low boiling point and similar physical properties to other light hydrocarbons, conventional distillation techniques may not be sufficient for achieving high-purity neopentane. Advanced separation technologies, such as extractive distillation or membrane separation, may be required, adding complexity and cost to the overall process.

Scaling up laboratory processes to industrial production levels introduces additional challenges. Heat and mass transfer limitations, which may not be significant at smaller scales, can become critical factors in large-scale reactors. Ensuring uniform reaction conditions throughout the reactor volume and managing the increased heat generation are essential for maintaining high yields and product quality in industrial-scale operations.

Another major challenge is the selectivity of the reaction. Competing side reactions often lead to the formation of unwanted byproducts, reducing the overall yield of neopentane. These side reactions can include the formation of isomers, such as isopentane, or the production of higher molecular weight hydrocarbons. Achieving high selectivity towards neopentane formation while minimizing these undesired pathways remains a significant hurdle in industrial processes.

Catalyst performance and stability present additional challenges in neopentane synthesis. The catalysts used in these processes, often based on noble metals or metal oxides, can suffer from deactivation due to coking, sintering, or poisoning. This leads to reduced catalytic activity over time, necessitating frequent catalyst regeneration or replacement, which impacts process efficiency and economics.

The reaction conditions required for neopentane synthesis also pose challenges. High pressures and temperatures are often necessary to drive the reaction forward, which can lead to increased equipment costs, safety concerns, and energy consumption. Balancing these conditions to maximize yield while maintaining process safety and economic viability is a complex optimization problem.

Feedstock purity and availability represent another set of challenges. The production of high-purity neopentane often requires ultra-pure starting materials, which can be costly and difficult to source consistently. Impurities in the feedstock can lead to catalyst poisoning or the formation of additional unwanted byproducts, further complicating the purification process.

Separation and purification of neopentane from the reaction mixture present their own set of difficulties. Due to its low boiling point and similar physical properties to other light hydrocarbons, conventional distillation techniques may not be sufficient for achieving high-purity neopentane. Advanced separation technologies, such as extractive distillation or membrane separation, may be required, adding complexity and cost to the overall process.

Scaling up laboratory processes to industrial production levels introduces additional challenges. Heat and mass transfer limitations, which may not be significant at smaller scales, can become critical factors in large-scale reactors. Ensuring uniform reaction conditions throughout the reactor volume and managing the increased heat generation are essential for maintaining high yields and product quality in industrial-scale operations.

Existing Industrial Processes for Neopentane Synthesis

01 Neopentane production methods

Various methods for producing neopentane are described, including catalytic processes and reaction conditions that optimize neopentane yield. These methods may involve specific catalysts, temperature ranges, and pressure conditions to enhance the conversion of precursor materials to neopentane.- Neopentane production methods: Various methods for producing neopentane are described, including catalytic processes and reaction conditions that optimize neopentane yield. These methods may involve specific catalysts, temperature ranges, and pressure conditions to enhance the conversion of precursor materials to neopentane.

- Separation and purification of neopentane: Techniques for separating and purifying neopentane from reaction mixtures are outlined. These may include distillation processes, membrane separation, or adsorption methods to isolate neopentane from other hydrocarbons and increase its yield and purity.

- Catalysts for neopentane synthesis: Development and use of specific catalysts to improve neopentane yield are discussed. These catalysts may include metal-based compounds, zeolites, or other materials designed to selectively promote neopentane formation while minimizing unwanted side reactions.

- Process optimization for neopentane production: Strategies for optimizing neopentane production processes are presented. These may involve adjusting reaction parameters, implementing feedback control systems, or utilizing advanced modeling techniques to maximize neopentane yield while minimizing energy consumption and waste production.

- Feedstock selection for neopentane synthesis: The impact of feedstock selection on neopentane yield is explored. Different starting materials and their preparation methods are discussed, focusing on how the choice of precursors can affect the overall efficiency of neopentane production and the purity of the final product.

02 Separation and purification of neopentane

Techniques for separating and purifying neopentane from reaction mixtures are outlined. These may include distillation processes, membrane separation, or adsorption methods to isolate neopentane from other hydrocarbons and increase its yield and purity.Expand Specific Solutions03 Catalysts for neopentane synthesis

Development and use of specific catalysts to improve neopentane yield are discussed. These catalysts may include metal-based compounds, zeolites, or other materials designed to selectively promote neopentane formation while minimizing unwanted side reactions.Expand Specific Solutions04 Process optimization for neopentane production

Strategies for optimizing neopentane production processes are presented. These may involve adjusting reaction parameters, implementing feedback control systems, or utilizing advanced modeling techniques to maximize neopentane yield while minimizing energy consumption and waste production.Expand Specific Solutions05 Feedstock selection for neopentane synthesis

The impact of feedstock selection on neopentane yield is explored. Different starting materials and their preparation methods are discussed, focusing on how the choice of precursors can affect the overall efficiency of neopentane production and the purity of the final product.Expand Specific Solutions

Key Industrial Players in Neopentane Manufacturing

The competition landscape for increasing neopentane yield in industrial processes is characterized by a mature market with established players and ongoing technological advancements. Major petrochemical companies like ExxonMobil, Sinopec, and Air Liquide are at the forefront of research and development in this area. The market size is significant, driven by the growing demand for neopentane in various industries. Technological maturity varies, with companies like UOP LLC and BASF Corp. leading in process optimization and catalyst development. Emerging players such as Wanhua Chemical Group and Zhejiang Charioteer Pharmaceutical are also contributing to innovation in this field, indicating a dynamic and competitive environment.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced catalytic processes to increase neopentane yield in industrial processes. Their approach involves using zeolite-based catalysts with specific pore structures and acidity levels optimized for neopentane production[1]. The company has also implemented a two-stage reaction system where the first stage focuses on isomerization of normal pentane to isopentane, followed by a second stage that selectively converts isopentane to neopentane[2]. This process is integrated with advanced separation techniques, including pressure swing adsorption and membrane technology, to achieve high neopentane purity and recovery rates[3].

Strengths: Proprietary catalyst technology, integrated process design, and extensive R&D capabilities. Weaknesses: High capital investment required for implementation and potential sensitivity to feedstock quality variations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to increase neopentane yield through a combination of catalytic reforming and isomerization processes. Their method utilizes a dual-function catalyst system that promotes both dehydrocyclization and isomerization reactions[4]. The process incorporates a recycle stream that returns unconverted pentanes to the reactor, maximizing overall neopentane yield[5]. Sinopec has also implemented advanced process control systems that optimize reaction conditions in real-time, adjusting parameters such as temperature, pressure, and feed composition to maintain peak neopentane production[6].

Strengths: Large-scale production capabilities, integrated refining and petrochemical operations. Weaknesses: Potential challenges in adapting the technology to different feedstock sources and varying market demands.

Innovative Catalysts and Reaction Mechanisms

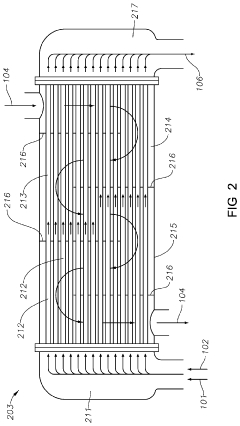

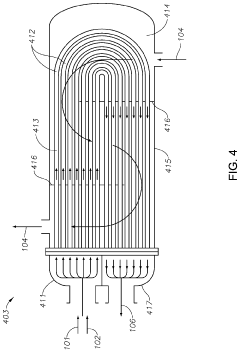

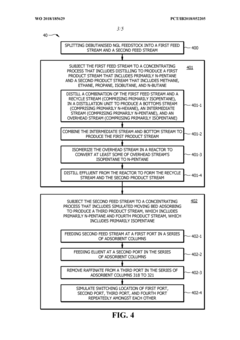

Processes to make neopentane using shell and tube reactors

PatentActiveUS10626064B2

Innovation

- The process involves demethylating C6-C8 alkanes within a shell and tube reactor to produce neopentane, utilizing a catalyst and controlling temperature to achieve high conversion rates and purity, with a shell and tube reactor design that includes tubes with specific diameters and heat transfer coefficients to manage heat effectively.

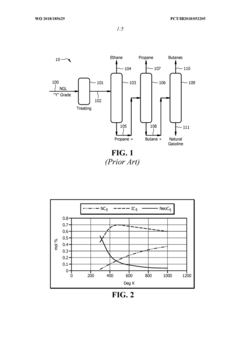

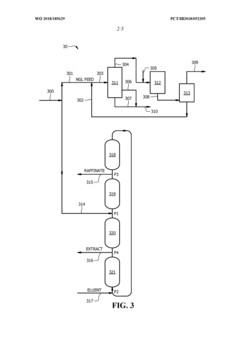

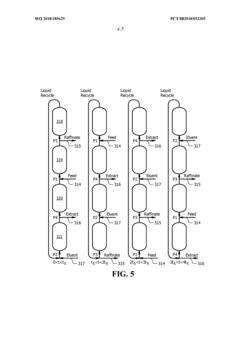

Process for npentanizing debutanized natural gasoline feedstock to thermal crackers

PatentWO2018185629A1

Innovation

- A method involving the splitting of n-pentane and isopentane streams into separate feed streams, followed by distillation and simulated moving bed adsorption processes to increase the concentration of n-pentane, utilizing catalysts like sulfated zirconia and platinum on alumina to isomerize isopentane to n-pentane, thereby enhancing the linear pentane to branched pentane ratio.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of increasing neopentane yield in industrial processes are crucial aspects that require thorough examination. Neopentane, a volatile organic compound (VOC), poses potential risks to the environment and human health if not properly managed. Its production and use can contribute to air pollution, particularly through the formation of ground-level ozone and smog. Therefore, any efforts to increase neopentane yield must be balanced with stringent emission control measures and adherence to environmental regulations.

Industrial processes aimed at enhancing neopentane yield often involve energy-intensive operations, which can lead to increased greenhouse gas emissions. To mitigate this, companies must focus on improving energy efficiency and exploring cleaner energy sources. Implementing heat recovery systems, optimizing process conditions, and utilizing renewable energy can significantly reduce the carbon footprint associated with neopentane production.

Water usage and wastewater management are also critical environmental concerns in neopentane production. Industrial processes may generate contaminated wastewater containing organic compounds and other pollutants. Implementing advanced wastewater treatment technologies and water recycling systems can minimize the environmental impact and conserve water resources.

From a sustainability perspective, increasing neopentane yield should be approached holistically, considering the entire lifecycle of the product. This includes evaluating the sourcing of raw materials, optimizing production processes, and exploring potential recycling or reuse options for neopentane-containing products at the end of their life cycle. Adopting circular economy principles can help reduce waste and maximize resource efficiency.

The development of green chemistry alternatives is another important consideration. Research into bio-based feedstocks and environmentally friendly catalysts could lead to more sustainable production methods for neopentane or its substitutes. Such innovations could potentially reduce reliance on fossil fuel-derived raw materials and minimize the environmental footprint of the production process.

Regulatory compliance and proactive environmental management are essential for sustainable neopentane production. Companies should implement robust environmental management systems, conduct regular environmental impact assessments, and engage in transparent reporting of their sustainability efforts. This approach not only ensures compliance with current regulations but also prepares organizations for future environmental challenges and opportunities.

In conclusion, while increasing neopentane yield is important for industrial efficiency, it must be pursued in a manner that prioritizes environmental protection and sustainability. By addressing emissions, energy use, water management, and exploring greener alternatives, industries can work towards more sustainable neopentane production practices that align with global environmental goals and contribute to long-term business resilience.

Industrial processes aimed at enhancing neopentane yield often involve energy-intensive operations, which can lead to increased greenhouse gas emissions. To mitigate this, companies must focus on improving energy efficiency and exploring cleaner energy sources. Implementing heat recovery systems, optimizing process conditions, and utilizing renewable energy can significantly reduce the carbon footprint associated with neopentane production.

Water usage and wastewater management are also critical environmental concerns in neopentane production. Industrial processes may generate contaminated wastewater containing organic compounds and other pollutants. Implementing advanced wastewater treatment technologies and water recycling systems can minimize the environmental impact and conserve water resources.

From a sustainability perspective, increasing neopentane yield should be approached holistically, considering the entire lifecycle of the product. This includes evaluating the sourcing of raw materials, optimizing production processes, and exploring potential recycling or reuse options for neopentane-containing products at the end of their life cycle. Adopting circular economy principles can help reduce waste and maximize resource efficiency.

The development of green chemistry alternatives is another important consideration. Research into bio-based feedstocks and environmentally friendly catalysts could lead to more sustainable production methods for neopentane or its substitutes. Such innovations could potentially reduce reliance on fossil fuel-derived raw materials and minimize the environmental footprint of the production process.

Regulatory compliance and proactive environmental management are essential for sustainable neopentane production. Companies should implement robust environmental management systems, conduct regular environmental impact assessments, and engage in transparent reporting of their sustainability efforts. This approach not only ensures compliance with current regulations but also prepares organizations for future environmental challenges and opportunities.

In conclusion, while increasing neopentane yield is important for industrial efficiency, it must be pursued in a manner that prioritizes environmental protection and sustainability. By addressing emissions, energy use, water management, and exploring greener alternatives, industries can work towards more sustainable neopentane production practices that align with global environmental goals and contribute to long-term business resilience.

Economic Feasibility of Improved Neopentane Production

The economic feasibility of improved neopentane production is a critical consideration for industrial processes seeking to increase neopentane yield. This analysis examines the potential financial benefits and challenges associated with implementing enhanced production methods.

Neopentane, a valuable hydrocarbon used in various industries, commands a premium price in the market due to its unique properties and limited availability. Improving neopentane yield can significantly impact the profitability of production facilities. The primary economic drivers for enhancing neopentane production include increased revenue from higher product output, reduced waste, and improved resource utilization.

One of the key factors affecting economic feasibility is the capital investment required for upgrading existing production facilities or implementing new technologies. This may involve the installation of advanced separation equipment, catalysts, or process control systems. The return on investment (ROI) for such upgrades must be carefully evaluated against projected increases in neopentane yield and market demand.

Operating costs also play a crucial role in determining economic viability. While improved production methods may lead to higher neopentane yields, they could potentially increase energy consumption, raw material costs, or maintenance requirements. A comprehensive cost-benefit analysis is essential to ensure that the additional revenue generated outweighs any increase in operational expenses.

Market dynamics and demand forecasts are vital considerations in assessing economic feasibility. The global demand for neopentane is influenced by various factors, including growth in the petrochemical industry, expansion of foam insulation markets, and developments in aerosol propellant applications. A stable or growing market demand is crucial for justifying investments in yield improvement technologies.

Regulatory factors and environmental considerations can also impact the economic feasibility of improved neopentane production. Stricter emissions regulations or carbon pricing mechanisms may necessitate additional investments in pollution control technologies, potentially affecting the overall economic viability of yield improvement projects.

The scalability of improved production methods is another important aspect of economic feasibility. Technologies that can be easily scaled up to meet increasing demand without significant additional investment are more likely to provide long-term economic benefits. This scalability factor is particularly relevant for larger production facilities seeking to capitalize on economies of scale.

In conclusion, the economic feasibility of improved neopentane production depends on a complex interplay of factors including capital costs, operational expenses, market demand, regulatory environment, and scalability. A thorough economic analysis, considering both short-term and long-term implications, is essential for industrial decision-makers to determine the viability of investing in neopentane yield improvement technologies.

Neopentane, a valuable hydrocarbon used in various industries, commands a premium price in the market due to its unique properties and limited availability. Improving neopentane yield can significantly impact the profitability of production facilities. The primary economic drivers for enhancing neopentane production include increased revenue from higher product output, reduced waste, and improved resource utilization.

One of the key factors affecting economic feasibility is the capital investment required for upgrading existing production facilities or implementing new technologies. This may involve the installation of advanced separation equipment, catalysts, or process control systems. The return on investment (ROI) for such upgrades must be carefully evaluated against projected increases in neopentane yield and market demand.

Operating costs also play a crucial role in determining economic viability. While improved production methods may lead to higher neopentane yields, they could potentially increase energy consumption, raw material costs, or maintenance requirements. A comprehensive cost-benefit analysis is essential to ensure that the additional revenue generated outweighs any increase in operational expenses.

Market dynamics and demand forecasts are vital considerations in assessing economic feasibility. The global demand for neopentane is influenced by various factors, including growth in the petrochemical industry, expansion of foam insulation markets, and developments in aerosol propellant applications. A stable or growing market demand is crucial for justifying investments in yield improvement technologies.

Regulatory factors and environmental considerations can also impact the economic feasibility of improved neopentane production. Stricter emissions regulations or carbon pricing mechanisms may necessitate additional investments in pollution control technologies, potentially affecting the overall economic viability of yield improvement projects.

The scalability of improved production methods is another important aspect of economic feasibility. Technologies that can be easily scaled up to meet increasing demand without significant additional investment are more likely to provide long-term economic benefits. This scalability factor is particularly relevant for larger production facilities seeking to capitalize on economies of scale.

In conclusion, the economic feasibility of improved neopentane production depends on a complex interplay of factors including capital costs, operational expenses, market demand, regulatory environment, and scalability. A thorough economic analysis, considering both short-term and long-term implications, is essential for industrial decision-makers to determine the viability of investing in neopentane yield improvement technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!