How to Manage Samples for Optimal Dynamic Light Scattering Performance

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Objectives

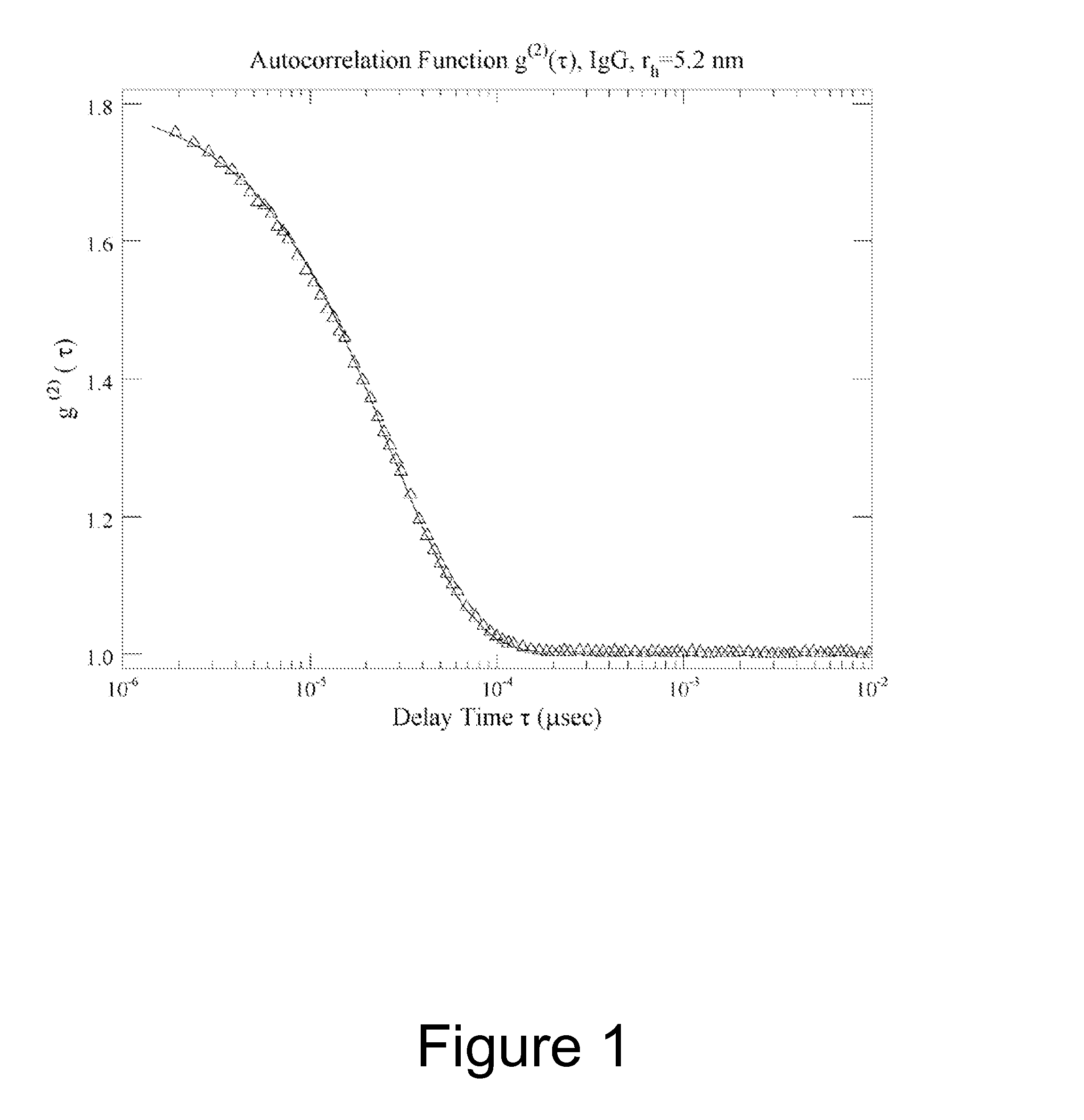

Dynamic Light Scattering (DLS) emerged in the 1960s as a powerful technique for measuring particle size distributions in colloidal suspensions. The technology leverages the Brownian motion of particles in solution, where scattered light intensity fluctuations correlate with particle movement, enabling size determination through mathematical analysis. Over decades, DLS has evolved from basic correlation spectroscopy to sophisticated multi-angle systems with advanced algorithms for polydisperse sample analysis.

The fundamental principle of DLS relies on the fact that smaller particles move more rapidly than larger ones in solution, creating characteristic light scattering patterns that can be analyzed to determine hydrodynamic diameter distributions. Modern DLS instruments typically employ laser light sources, photon detectors, and digital correlators to achieve high precision measurements in the nanometer to micrometer range.

Recent technological trends show integration of DLS with complementary techniques such as static light scattering (SLS), multi-angle light scattering (MALS), and zeta potential measurements, creating more comprehensive particle characterization platforms. Miniaturization and automation have also advanced significantly, with bench-top and even portable DLS systems now available for routine analysis.

The primary objective of sample management for optimal DLS performance is to obtain reproducible, accurate measurements that truly represent the sample's characteristics while minimizing artifacts. This includes developing standardized protocols for sample preparation, handling, and measurement that account for concentration effects, dust contamination, temperature stability, and aggregation phenomena.

Technical goals in this domain include establishing robust methodologies for different sample types, from simple protein solutions to complex biological fluids, nanoparticle suspensions, and industrial formulations. Particular emphasis is placed on minimizing non-specific aggregation, preventing dust contamination, and optimizing concentration ranges for specific applications.

Another critical objective is the development of validated approaches for challenging samples, such as highly polydisperse systems, samples with extreme size distributions, or those with complex optical properties. This includes advanced data interpretation methods that can distinguish between genuine sample characteristics and measurement artifacts.

The evolution of DLS technology continues toward greater sensitivity, improved resolution for polydisperse samples, and enhanced automation of sample preparation and measurement workflows. Machine learning algorithms are increasingly being applied to data interpretation, potentially enabling more accurate analysis of complex mixtures and previously challenging sample types.

The fundamental principle of DLS relies on the fact that smaller particles move more rapidly than larger ones in solution, creating characteristic light scattering patterns that can be analyzed to determine hydrodynamic diameter distributions. Modern DLS instruments typically employ laser light sources, photon detectors, and digital correlators to achieve high precision measurements in the nanometer to micrometer range.

Recent technological trends show integration of DLS with complementary techniques such as static light scattering (SLS), multi-angle light scattering (MALS), and zeta potential measurements, creating more comprehensive particle characterization platforms. Miniaturization and automation have also advanced significantly, with bench-top and even portable DLS systems now available for routine analysis.

The primary objective of sample management for optimal DLS performance is to obtain reproducible, accurate measurements that truly represent the sample's characteristics while minimizing artifacts. This includes developing standardized protocols for sample preparation, handling, and measurement that account for concentration effects, dust contamination, temperature stability, and aggregation phenomena.

Technical goals in this domain include establishing robust methodologies for different sample types, from simple protein solutions to complex biological fluids, nanoparticle suspensions, and industrial formulations. Particular emphasis is placed on minimizing non-specific aggregation, preventing dust contamination, and optimizing concentration ranges for specific applications.

Another critical objective is the development of validated approaches for challenging samples, such as highly polydisperse systems, samples with extreme size distributions, or those with complex optical properties. This includes advanced data interpretation methods that can distinguish between genuine sample characteristics and measurement artifacts.

The evolution of DLS technology continues toward greater sensitivity, improved resolution for polydisperse samples, and enhanced automation of sample preparation and measurement workflows. Machine learning algorithms are increasingly being applied to data interpretation, potentially enabling more accurate analysis of complex mixtures and previously challenging sample types.

Market Applications and Demand Analysis

Dynamic Light Scattering (DLS) technology has witnessed significant market growth across multiple industries due to its ability to accurately characterize nanoparticles and macromolecules in solution. The global market for DLS instrumentation and services is currently valued at several billion dollars, with a compound annual growth rate exceeding 5% projected through 2028.

The pharmaceutical and biotechnology sectors represent the largest market segment for DLS applications, accounting for approximately 40% of the total market share. This demand is primarily driven by the rapid expansion of biopharmaceuticals, where proper sample management for DLS is critical for characterizing protein formulations, assessing stability, and detecting aggregation. The increasing development of complex biologics, including monoclonal antibodies and vaccines, has further intensified the need for precise DLS sample preparation protocols.

Nanotechnology research and development constitutes another significant market segment, where DLS serves as an essential tool for characterizing nanoparticles in various applications including drug delivery systems, nanomaterials, and nanocomposites. The growing emphasis on nanomedicine has created substantial demand for standardized sample management techniques that ensure reproducible DLS measurements.

Academic and research institutions form a stable market base, utilizing DLS for fundamental research across disciplines including polymer science, colloid chemistry, and molecular biology. This segment particularly values cost-effective sample preparation methods that maximize instrument performance while minimizing sample consumption.

The food and beverage industry has emerged as a rapidly growing application area, employing DLS for quality control of emulsions, suspensions, and ingredient characterization. Here, the demand focuses on robust sample preparation techniques suitable for complex food matrices.

Geographically, North America and Europe currently dominate the market for DLS technology and related sample management solutions, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and India. This growth correlates with increasing investments in pharmaceutical research and nanotechnology development in these regions.

Market analysis indicates a clear trend toward automated sample preparation systems that minimize human error and enhance reproducibility. End-users increasingly demand integrated solutions that combine sample management protocols with data analysis software, reflecting the growing complexity of samples being analyzed and the need for standardized approaches.

The COVID-19 pandemic has further accelerated market growth, as DLS became an important tool for characterizing vaccine formulations and understanding virus particle behavior. This has highlighted the critical importance of proper sample management techniques for accurate DLS measurements in time-sensitive applications.

The pharmaceutical and biotechnology sectors represent the largest market segment for DLS applications, accounting for approximately 40% of the total market share. This demand is primarily driven by the rapid expansion of biopharmaceuticals, where proper sample management for DLS is critical for characterizing protein formulations, assessing stability, and detecting aggregation. The increasing development of complex biologics, including monoclonal antibodies and vaccines, has further intensified the need for precise DLS sample preparation protocols.

Nanotechnology research and development constitutes another significant market segment, where DLS serves as an essential tool for characterizing nanoparticles in various applications including drug delivery systems, nanomaterials, and nanocomposites. The growing emphasis on nanomedicine has created substantial demand for standardized sample management techniques that ensure reproducible DLS measurements.

Academic and research institutions form a stable market base, utilizing DLS for fundamental research across disciplines including polymer science, colloid chemistry, and molecular biology. This segment particularly values cost-effective sample preparation methods that maximize instrument performance while minimizing sample consumption.

The food and beverage industry has emerged as a rapidly growing application area, employing DLS for quality control of emulsions, suspensions, and ingredient characterization. Here, the demand focuses on robust sample preparation techniques suitable for complex food matrices.

Geographically, North America and Europe currently dominate the market for DLS technology and related sample management solutions, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and India. This growth correlates with increasing investments in pharmaceutical research and nanotechnology development in these regions.

Market analysis indicates a clear trend toward automated sample preparation systems that minimize human error and enhance reproducibility. End-users increasingly demand integrated solutions that combine sample management protocols with data analysis software, reflecting the growing complexity of samples being analyzed and the need for standardized approaches.

The COVID-19 pandemic has further accelerated market growth, as DLS became an important tool for characterizing vaccine formulations and understanding virus particle behavior. This has highlighted the critical importance of proper sample management techniques for accurate DLS measurements in time-sensitive applications.

Current Challenges in DLS Sample Management

Dynamic Light Scattering (DLS) technology faces several significant challenges in sample management that impact measurement accuracy and reliability. The primary issue is sample contamination, which can severely distort results. Even microscopic dust particles, fibers, or other contaminants can cause significant interference in DLS measurements, as the technique is extremely sensitive to the presence of large particles. These contaminants often contribute disproportionately to the scattered light intensity, masking the signal from the target particles.

Temperature control represents another critical challenge. DLS measurements are highly temperature-dependent, as temperature directly affects the Brownian motion of particles and solvent viscosity. Fluctuations as small as 0.1°C can lead to measurable differences in results. Many laboratories struggle with maintaining consistent temperature conditions throughout the measurement process, particularly when analyzing temperature-sensitive samples or when ambient conditions vary.

Sample concentration optimization continues to be problematic for researchers. Too dilute samples may not scatter sufficient light for reliable detection, while overly concentrated samples can lead to multiple scattering effects and particle interactions that complicate data interpretation. Finding the optimal concentration window for specific sample types often requires extensive trial and error, consuming valuable time and materials.

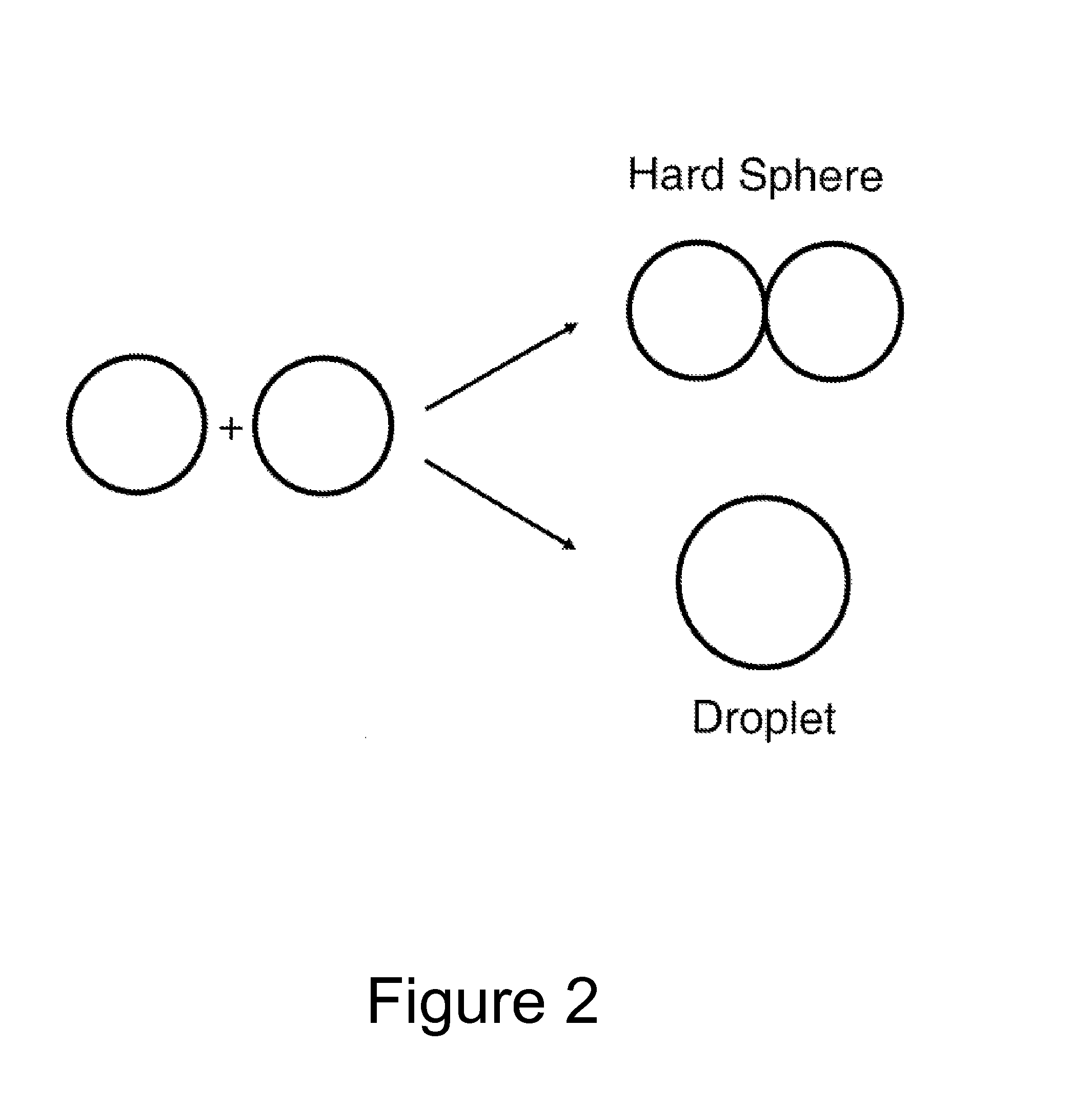

Aggregation and stability issues present ongoing difficulties in DLS sample management. Many biological and polymer samples tend to aggregate over time or under certain conditions, changing their size distribution during measurement. This dynamic behavior can lead to poor reproducibility and misleading results if not properly monitored and controlled throughout the analysis process.

Sample preparation protocols lack standardization across different laboratories and applications. The diversity of sample types analyzed by DLS—from nanoparticles and proteins to polymers and emulsions—means that preparation techniques vary widely. This inconsistency makes it difficult to compare results between different research groups or establish universal best practices.

Filtration techniques, while necessary to remove large contaminants, can inadvertently alter sample composition. Researchers often face the dilemma of choosing between potential contamination effects or potential sample alteration through filtration. The selection of appropriate filter materials and pore sizes requires careful consideration based on sample characteristics.

Finally, the challenge of sample handling during measurement is often overlooked. Sample transfer between preparation vessels and measurement cells can introduce bubbles or contaminants, while improper cleaning of measurement cells between samples can lead to cross-contamination. These seemingly minor handling issues can significantly impact measurement quality and reproducibility in DLS analysis.

Temperature control represents another critical challenge. DLS measurements are highly temperature-dependent, as temperature directly affects the Brownian motion of particles and solvent viscosity. Fluctuations as small as 0.1°C can lead to measurable differences in results. Many laboratories struggle with maintaining consistent temperature conditions throughout the measurement process, particularly when analyzing temperature-sensitive samples or when ambient conditions vary.

Sample concentration optimization continues to be problematic for researchers. Too dilute samples may not scatter sufficient light for reliable detection, while overly concentrated samples can lead to multiple scattering effects and particle interactions that complicate data interpretation. Finding the optimal concentration window for specific sample types often requires extensive trial and error, consuming valuable time and materials.

Aggregation and stability issues present ongoing difficulties in DLS sample management. Many biological and polymer samples tend to aggregate over time or under certain conditions, changing their size distribution during measurement. This dynamic behavior can lead to poor reproducibility and misleading results if not properly monitored and controlled throughout the analysis process.

Sample preparation protocols lack standardization across different laboratories and applications. The diversity of sample types analyzed by DLS—from nanoparticles and proteins to polymers and emulsions—means that preparation techniques vary widely. This inconsistency makes it difficult to compare results between different research groups or establish universal best practices.

Filtration techniques, while necessary to remove large contaminants, can inadvertently alter sample composition. Researchers often face the dilemma of choosing between potential contamination effects or potential sample alteration through filtration. The selection of appropriate filter materials and pore sizes requires careful consideration based on sample characteristics.

Finally, the challenge of sample handling during measurement is often overlooked. Sample transfer between preparation vessels and measurement cells can introduce bubbles or contaminants, while improper cleaning of measurement cells between samples can lead to cross-contamination. These seemingly minor handling issues can significantly impact measurement quality and reproducibility in DLS analysis.

Current Sample Management Protocols

01 Instrumentation and apparatus design for DLS

Various designs and improvements in dynamic light scattering instruments focus on enhancing measurement accuracy and reliability. These include specialized optical configurations, laser systems, and detection mechanisms that optimize the collection of scattered light. Advanced apparatus designs incorporate features like temperature control, automated sample handling, and integrated analysis software to improve performance and ease of use.- Improved DLS measurement techniques: Advanced techniques for enhancing the accuracy and reliability of dynamic light scattering measurements. These improvements include novel algorithms for data processing, noise reduction methods, and calibration procedures that optimize the performance of DLS systems. These techniques allow for more precise particle size determination and better resolution across different sample types.

- DLS instrumentation design innovations: Innovations in the design of dynamic light scattering instruments that enhance performance metrics. These include improved optical configurations, detector systems with higher sensitivity, and specialized components that minimize interference. Such design improvements result in instruments capable of measuring a wider range of particle sizes with greater accuracy and reproducibility.

- Sample preparation methods for DLS: Specialized sample preparation techniques that optimize dynamic light scattering performance. These methods include filtration protocols, dispersion techniques, and concentration adjustments that ensure samples are in optimal condition for measurement. Proper sample preparation significantly improves the quality of DLS data by reducing artifacts and ensuring representative measurements.

- Application-specific DLS adaptations: Customized dynamic light scattering approaches tailored for specific applications such as pharmaceutical formulations, nanoparticle characterization, and biological samples. These adaptations include specialized measurement parameters, data interpretation methods, and hardware modifications that address the unique challenges presented by different sample types and measurement objectives.

- Integration of DLS with complementary technologies: Systems that combine dynamic light scattering with other analytical techniques to provide comprehensive characterization capabilities. These integrated approaches may include coupling DLS with spectroscopic methods, microscopy, or other particle characterization technologies. Such combinations enhance the overall performance by providing correlated data that offers deeper insights into sample properties.

02 Signal processing and data analysis methods

Advanced algorithms and computational methods are essential for processing raw DLS data and extracting meaningful particle size information. These include correlation function analysis, distribution calculation techniques, and noise reduction methods that improve measurement sensitivity and resolution. Modern approaches incorporate machine learning and artificial intelligence to enhance data interpretation and address challenging sample types.Expand Specific Solutions03 Sample preparation and measurement protocols

Specific sample preparation techniques and measurement protocols significantly impact DLS performance. These include methods for controlling sample concentration, reducing dust contamination, and stabilizing dispersions. Standardized procedures for calibration, validation, and quality control ensure reliable and reproducible measurements across different instruments and laboratories.Expand Specific Solutions04 Application-specific DLS enhancements

Specialized adaptations of DLS technology address specific application requirements in fields such as pharmaceuticals, nanomaterials, and biological samples. These include modifications for high-concentration samples, non-spherical particles, and complex mixtures. Custom configurations enable measurements under extreme conditions or with challenging sample types that traditional DLS systems cannot handle effectively.Expand Specific Solutions05 Integration with complementary techniques

Combining DLS with other analytical methods creates powerful hybrid systems that overcome the limitations of standalone DLS. These integrated approaches may incorporate static light scattering, microscopy, spectroscopy, or separation techniques to provide more comprehensive characterization of complex samples. Multi-angle and multi-wavelength measurements enhance the information content and resolution of particle size distributions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Dynamic Light Scattering (DLS) technology is currently in a mature growth phase, with a global market size estimated at $300-400 million annually and growing steadily at 5-7%. The competitive landscape features established analytical instrument manufacturers like Malvern Panalytical, Wyatt Technology, and Shimadzu Corporation dominating with comprehensive DLS solutions, while academic institutions such as South China Normal University and Duke University contribute significant research advancements. Recent technological developments focus on improving sample preparation protocols, automation, and data analysis algorithms. Companies like Agilent Technologies and Hitachi High-Tech are expanding their presence through enhanced software integration and multi-detector systems, while specialized players like Corning and Renishaw are developing application-specific DLS solutions for pharmaceutical and biomedical markets.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has developed advanced sample management protocols for dynamic light scattering (DLS) that focus on automated filtration systems and temperature control. Their DYNAMICS software platform integrates with hardware to monitor sample quality in real-time, automatically flagging contamination issues. Their approach includes multi-angle DLS measurements that provide more comprehensive particle characterization than traditional single-angle systems. Wyatt's technology incorporates adaptive correlation functions that adjust measurement parameters based on sample characteristics, optimizing data collection for different particle sizes and concentrations. Their systems feature automated dilution capabilities that can adjust sample concentration on-the-fly when measurements indicate concentration-dependent effects that might compromise data quality[1][3]. Additionally, they've pioneered non-invasive sample preparation techniques that minimize shear forces that could disrupt delicate biological samples or cause aggregation in sensitive materials.

Strengths: Superior automation capabilities reduce human error in sample preparation; multi-angle measurement provides more robust data for polydisperse samples; specialized algorithms effectively handle complex biological samples. Weaknesses: Higher cost compared to simpler DLS systems; requires more extensive training for operators to fully utilize advanced features; some automated features may not be suitable for unusual or highly specialized sample types.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed a comprehensive sample management approach for DLS centered around their Zetasizer series instruments. Their technology incorporates adaptive correlation techniques that optimize measurement parameters based on real-time feedback from the sample. A key innovation is their non-perturbing sample preparation protocol that minimizes mechanical stress during handling to preserve native particle states. Their systems feature automated temperature ramping capabilities that can identify temperature-dependent aggregation behavior critical for biopharmaceutical applications. Malvern's NanoSampler technology provides automated multi-sample measurement with built-in dilution capabilities, ensuring optimal concentration for each measurement[2]. Their approach includes specialized disposable cuvettes with optical quality verification to eliminate contamination between samples. The company has also developed machine learning algorithms that can identify sample quality issues and recommend specific preparation steps to improve measurement reliability. Their adaptive measurement duration technology automatically extends acquisition time for challenging samples to improve statistical significance[4][5].

Strengths: Extensive validation across pharmaceutical applications provides robust protocols for regulated environments; integrated software offers comprehensive data interpretation tools; wide range of specialized accessories for different sample types. Weaknesses: Some automated features prioritize ease-of-use over flexibility for unusual sample types; premium pricing model; proprietary data formats can complicate integration with third-party analysis tools.

Key Innovations in DLS Sample Handling

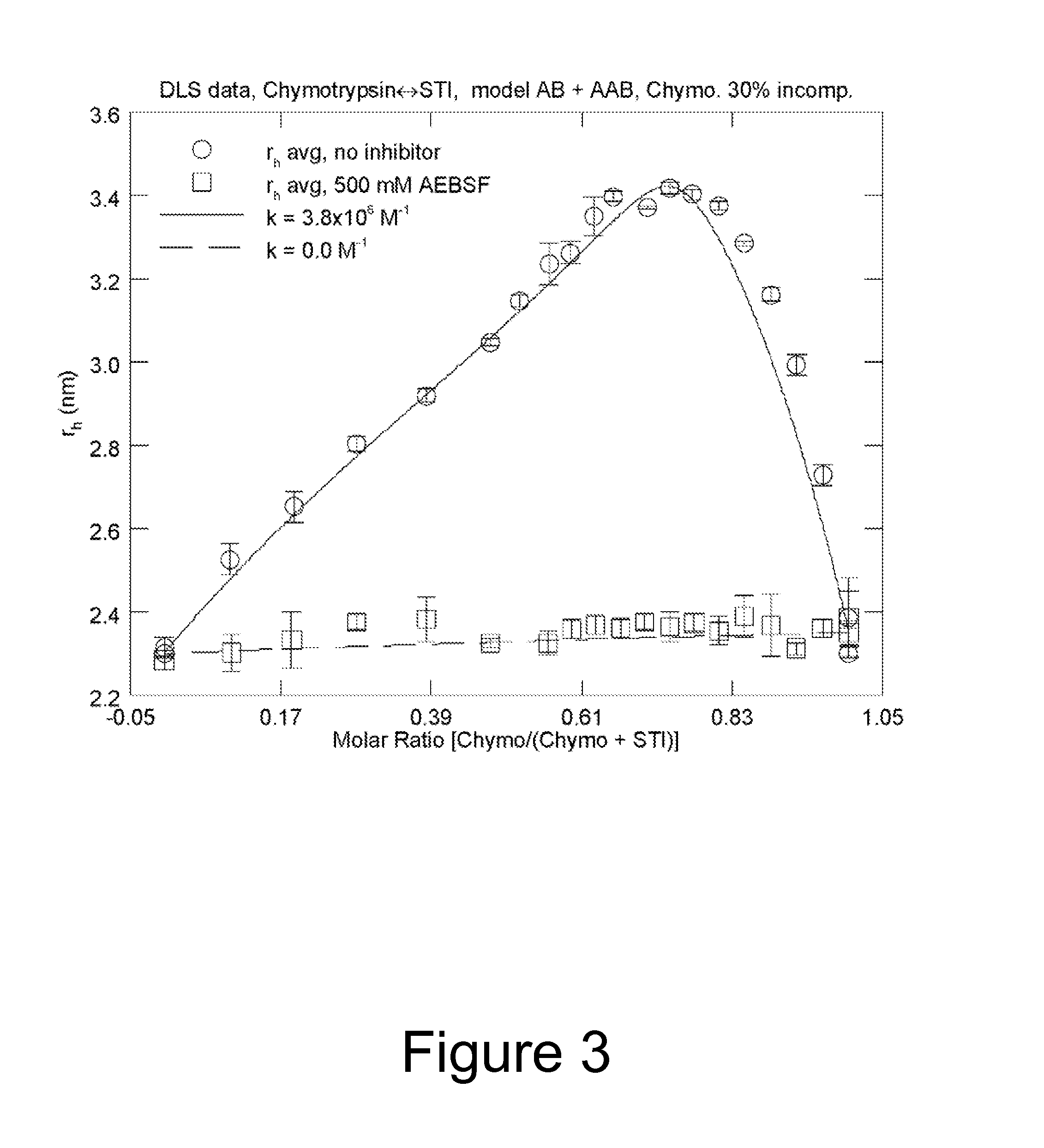

Method of characterizing interactions and screening for effectors

PatentActiveUS20150369732A1

Innovation

- The use of dynamic light scattering (DLS) for high-throughput detection of small molecule effectors, which involves measuring changes in hydrodynamic radius and viscosity to determine stoichiometry and equilibrium association constants, allowing for low sample requirements and the ability to screen multiple systems simultaneously.

Dynamic light scattering for particle size distribution measurement

PatentWO2019108731A1

Innovation

- The implementation of multispectral DLS techniques, which involve directing light of different wavelengths into the mixture and detecting corresponding signals to determine particle size distribution by processing differences in scattered light intensities, allowing for more accurate separation of particle species and reduction of interference from air bubbles.

Quality Control Standards for DLS Measurements

Establishing robust quality control standards for Dynamic Light Scattering (DLS) measurements is essential for ensuring reproducible and reliable results across different laboratories and experimental conditions. The International Organization for Standardization (ISO) has developed specific guidelines (ISO 22412) that outline the minimum requirements for DLS instrumentation calibration, sample preparation protocols, and data reporting formats. These standards emphasize the importance of regular system performance verification using certified reference materials with known size distributions, such as polystyrene latex spheres or gold nanoparticles.

Quality control procedures should include routine checks of instrument sensitivity, alignment, and detector response. The signal-to-noise ratio must be monitored consistently, with established thresholds below which measurements are considered unreliable. Temperature control accuracy should be verified to within ±0.1°C, as even minor temperature fluctuations can significantly impact diffusion coefficients and calculated particle sizes.

Statistical validation protocols represent another critical component of DLS quality standards. Multiple measurements (typically 3-5) should be performed on each sample to establish measurement uncertainty. The polydispersity index (PDI) serves as a key quality indicator, with values below 0.1 generally indicating monodisperse samples suitable for accurate size determination. For more complex samples, additional statistical parameters such as distribution width and peak resolution should be evaluated against predetermined acceptance criteria.

Data processing algorithms must also adhere to standardized approaches. The cumulants method is widely accepted for analyzing monomodal distributions, while CONTIN or non-negative least squares (NNLS) algorithms are preferred for multimodal samples. Regardless of the chosen algorithm, transparency in data processing parameters is essential for result reproducibility. Software settings should be documented, including correlation function fitting ranges, regularization parameters, and any applied filters.

Interlaboratory comparison studies provide an additional layer of quality assurance. Participation in round-robin testing programs allows laboratories to benchmark their DLS performance against peers and identify systematic errors in their measurement protocols. These collaborative efforts have led to the establishment of uncertainty budgets that quantify contributions from various error sources, including sample preparation variability, instrument limitations, and environmental factors.

Documentation requirements constitute the final pillar of DLS quality control standards. Complete records must be maintained for each measurement, including sample history, preparation methods, measurement conditions, raw correlation data, and processed results. This comprehensive documentation enables troubleshooting of anomalous results and facilitates method transfer between different laboratories or instruments.

Quality control procedures should include routine checks of instrument sensitivity, alignment, and detector response. The signal-to-noise ratio must be monitored consistently, with established thresholds below which measurements are considered unreliable. Temperature control accuracy should be verified to within ±0.1°C, as even minor temperature fluctuations can significantly impact diffusion coefficients and calculated particle sizes.

Statistical validation protocols represent another critical component of DLS quality standards. Multiple measurements (typically 3-5) should be performed on each sample to establish measurement uncertainty. The polydispersity index (PDI) serves as a key quality indicator, with values below 0.1 generally indicating monodisperse samples suitable for accurate size determination. For more complex samples, additional statistical parameters such as distribution width and peak resolution should be evaluated against predetermined acceptance criteria.

Data processing algorithms must also adhere to standardized approaches. The cumulants method is widely accepted for analyzing monomodal distributions, while CONTIN or non-negative least squares (NNLS) algorithms are preferred for multimodal samples. Regardless of the chosen algorithm, transparency in data processing parameters is essential for result reproducibility. Software settings should be documented, including correlation function fitting ranges, regularization parameters, and any applied filters.

Interlaboratory comparison studies provide an additional layer of quality assurance. Participation in round-robin testing programs allows laboratories to benchmark their DLS performance against peers and identify systematic errors in their measurement protocols. These collaborative efforts have led to the establishment of uncertainty budgets that quantify contributions from various error sources, including sample preparation variability, instrument limitations, and environmental factors.

Documentation requirements constitute the final pillar of DLS quality control standards. Complete records must be maintained for each measurement, including sample history, preparation methods, measurement conditions, raw correlation data, and processed results. This comprehensive documentation enables troubleshooting of anomalous results and facilitates method transfer between different laboratories or instruments.

Environmental Factors Affecting DLS Performance

Dynamic Light Scattering (DLS) performance is significantly influenced by various environmental factors that can alter measurement accuracy and reproducibility. Temperature stands as one of the most critical parameters affecting DLS measurements, as it directly impacts Brownian motion of particles and solvent viscosity. Even minor temperature fluctuations of 0.5°C can lead to viscosity changes of approximately 1-2%, resulting in corresponding variations in measured particle size. Therefore, precise temperature control systems with stability better than ±0.1°C are essential for reliable DLS analysis.

Vibration represents another substantial environmental challenge for DLS measurements. External vibrations from laboratory equipment, HVAC systems, or even foot traffic can introduce noise into the correlation function, degrading data quality. High-precision DLS instruments typically incorporate vibration isolation platforms, but additional measures such as placement on anti-vibration tables or in dedicated rooms away from mechanical equipment may be necessary for optimal performance.

Ambient light interference poses a particular concern for DLS systems. Stray light entering the detection optics can overwhelm the scattered light signal from samples, especially for weakly scattering materials. Modern DLS instruments incorporate light-tight sample chambers, but additional precautions such as operating in darkened rooms or using specialized light-blocking enclosures may be required for highly sensitive measurements.

Electromagnetic interference (EMI) from nearby electronic devices can disrupt the sensitive photon detection systems in DLS instruments. Sources such as fluorescent lighting, unshielded power supplies, or wireless communication devices may introduce noise into measurements. Proper electrical grounding of instruments and strategic placement away from EMI sources help maintain signal integrity.

Air quality factors, including dust particles and aerosols, can contaminate samples during preparation and measurement. Airborne contaminants as small as submicron size can introduce artifacts in DLS data, particularly when measuring nanoparticles. Implementation of clean room practices, laminar flow hoods, or filtered air environments significantly reduces these contamination risks.

Humidity variations can affect both sample stability and optical components in DLS systems. High humidity environments may accelerate sample degradation through hydrolysis or aggregation processes, while also potentially causing condensation on optical surfaces. Controlled humidity environments (typically 30-50% relative humidity) and proper instrument warm-up procedures help mitigate these effects, ensuring consistent performance across measurement sessions.

Vibration represents another substantial environmental challenge for DLS measurements. External vibrations from laboratory equipment, HVAC systems, or even foot traffic can introduce noise into the correlation function, degrading data quality. High-precision DLS instruments typically incorporate vibration isolation platforms, but additional measures such as placement on anti-vibration tables or in dedicated rooms away from mechanical equipment may be necessary for optimal performance.

Ambient light interference poses a particular concern for DLS systems. Stray light entering the detection optics can overwhelm the scattered light signal from samples, especially for weakly scattering materials. Modern DLS instruments incorporate light-tight sample chambers, but additional precautions such as operating in darkened rooms or using specialized light-blocking enclosures may be required for highly sensitive measurements.

Electromagnetic interference (EMI) from nearby electronic devices can disrupt the sensitive photon detection systems in DLS instruments. Sources such as fluorescent lighting, unshielded power supplies, or wireless communication devices may introduce noise into measurements. Proper electrical grounding of instruments and strategic placement away from EMI sources help maintain signal integrity.

Air quality factors, including dust particles and aerosols, can contaminate samples during preparation and measurement. Airborne contaminants as small as submicron size can introduce artifacts in DLS data, particularly when measuring nanoparticles. Implementation of clean room practices, laminar flow hoods, or filtered air environments significantly reduces these contamination risks.

Humidity variations can affect both sample stability and optical components in DLS systems. High humidity environments may accelerate sample degradation through hydrolysis or aggregation processes, while also potentially causing condensation on optical surfaces. Controlled humidity environments (typically 30-50% relative humidity) and proper instrument warm-up procedures help mitigate these effects, ensuring consistent performance across measurement sessions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!