How UV Stabilizers Enhance Polypropylene Durability Outdoors

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Stabilization Background and Objectives

Ultraviolet (UV) stabilization has become a critical aspect of polymer science, particularly in the context of polypropylene (PP) applications exposed to outdoor environments. The evolution of UV stabilization technology for PP has been driven by the increasing demand for durable, long-lasting plastic products in various sectors, including automotive, construction, and agriculture.

The primary objective of UV stabilization in PP is to mitigate the detrimental effects of solar radiation, which can lead to photo-oxidation, chain scission, and ultimately, the degradation of the polymer's mechanical and aesthetic properties. This degradation process, if left unchecked, results in discoloration, embrittlement, and loss of tensile strength, significantly reducing the service life of PP products.

The development of UV stabilizers for PP has progressed through several generations, each addressing specific challenges and improving upon previous formulations. Early stabilizers focused on simple light absorption, while more advanced systems incorporate mechanisms for free radical scavenging and hydroperoxide decomposition. The current state-of-the-art UV stabilizers for PP often employ synergistic combinations of different additives to provide comprehensive protection against various degradation pathways.

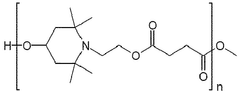

Recent technological advancements in UV stabilization aim to enhance the durability of PP in increasingly demanding outdoor applications. These developments include the creation of more efficient hindered amine light stabilizers (HALS), novel UV absorbers with broader spectral coverage, and the integration of nanoparticles for improved dispersion and effectiveness. The goal is to extend the service life of PP products, reduce maintenance costs, and expand the range of outdoor applications for this versatile polymer.

The objectives of current UV stabilization research for PP encompass several key areas. Firstly, there is a push towards developing more environmentally friendly stabilizers that maintain high performance while reducing potential ecological impacts. Secondly, researchers are working on improving the compatibility between UV stabilizers and other additives in PP formulations to optimize overall performance. Thirdly, there is a focus on creating stabilization systems that can withstand more extreme weather conditions, addressing the challenges posed by climate change and expanding geographical markets.

Furthermore, the industry is exploring ways to enhance the cost-effectiveness of UV stabilization technologies, making them more accessible for a wider range of PP applications. This includes the development of more efficient manufacturing processes for stabilizers and the optimization of additive concentrations to achieve maximum protection with minimal material usage.

As the demand for durable outdoor PP products continues to grow, the field of UV stabilization remains dynamic and innovative. The ongoing research and development in this area are crucial for meeting the evolving needs of various industries and ensuring the long-term viability of PP in outdoor applications.

The primary objective of UV stabilization in PP is to mitigate the detrimental effects of solar radiation, which can lead to photo-oxidation, chain scission, and ultimately, the degradation of the polymer's mechanical and aesthetic properties. This degradation process, if left unchecked, results in discoloration, embrittlement, and loss of tensile strength, significantly reducing the service life of PP products.

The development of UV stabilizers for PP has progressed through several generations, each addressing specific challenges and improving upon previous formulations. Early stabilizers focused on simple light absorption, while more advanced systems incorporate mechanisms for free radical scavenging and hydroperoxide decomposition. The current state-of-the-art UV stabilizers for PP often employ synergistic combinations of different additives to provide comprehensive protection against various degradation pathways.

Recent technological advancements in UV stabilization aim to enhance the durability of PP in increasingly demanding outdoor applications. These developments include the creation of more efficient hindered amine light stabilizers (HALS), novel UV absorbers with broader spectral coverage, and the integration of nanoparticles for improved dispersion and effectiveness. The goal is to extend the service life of PP products, reduce maintenance costs, and expand the range of outdoor applications for this versatile polymer.

The objectives of current UV stabilization research for PP encompass several key areas. Firstly, there is a push towards developing more environmentally friendly stabilizers that maintain high performance while reducing potential ecological impacts. Secondly, researchers are working on improving the compatibility between UV stabilizers and other additives in PP formulations to optimize overall performance. Thirdly, there is a focus on creating stabilization systems that can withstand more extreme weather conditions, addressing the challenges posed by climate change and expanding geographical markets.

Furthermore, the industry is exploring ways to enhance the cost-effectiveness of UV stabilization technologies, making them more accessible for a wider range of PP applications. This includes the development of more efficient manufacturing processes for stabilizers and the optimization of additive concentrations to achieve maximum protection with minimal material usage.

As the demand for durable outdoor PP products continues to grow, the field of UV stabilization remains dynamic and innovative. The ongoing research and development in this area are crucial for meeting the evolving needs of various industries and ensuring the long-term viability of PP in outdoor applications.

Market Analysis for UV-Resistant Polypropylene

The market for UV-resistant polypropylene has experienced significant growth in recent years, driven by increasing demand across various industries. This growth is primarily attributed to the material's excellent durability, cost-effectiveness, and versatility in outdoor applications. The global UV-resistant polypropylene market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

Key industries driving the demand for UV-resistant polypropylene include automotive, construction, packaging, and agriculture. In the automotive sector, the material is widely used for exterior components such as bumpers, trims, and body panels, where long-term UV resistance is crucial for maintaining aesthetic appeal and structural integrity. The construction industry utilizes UV-resistant polypropylene in roofing membranes, outdoor furniture, and decking materials, capitalizing on its ability to withstand prolonged exposure to sunlight and harsh weather conditions.

The packaging industry has also embraced UV-resistant polypropylene for applications such as outdoor storage containers, agricultural films, and protective covers. Its ability to maintain clarity and mechanical properties under UV exposure makes it an ideal choice for these applications. In agriculture, UV-resistant polypropylene finds extensive use in greenhouse films, crop covers, and irrigation systems, where protection against UV degradation is essential for prolonged product life and optimal crop yield.

Geographically, Asia-Pacific leads the market for UV-resistant polypropylene, followed by North America and Europe. The rapid industrialization and urbanization in emerging economies, particularly in China and India, have significantly contributed to the region's market dominance. However, stringent environmental regulations in developed regions are driving innovation in bio-based and recyclable UV-resistant polypropylene formulations, creating new market opportunities.

Consumer trends towards sustainable and long-lasting products have further bolstered the demand for UV-resistant polypropylene. Manufacturers are increasingly focusing on developing advanced UV stabilizer technologies to enhance the material's performance and lifespan, thereby expanding its application scope. This trend is expected to continue, with ongoing research and development efforts aimed at improving UV resistance while maintaining or enhancing other desirable properties of polypropylene.

Key industries driving the demand for UV-resistant polypropylene include automotive, construction, packaging, and agriculture. In the automotive sector, the material is widely used for exterior components such as bumpers, trims, and body panels, where long-term UV resistance is crucial for maintaining aesthetic appeal and structural integrity. The construction industry utilizes UV-resistant polypropylene in roofing membranes, outdoor furniture, and decking materials, capitalizing on its ability to withstand prolonged exposure to sunlight and harsh weather conditions.

The packaging industry has also embraced UV-resistant polypropylene for applications such as outdoor storage containers, agricultural films, and protective covers. Its ability to maintain clarity and mechanical properties under UV exposure makes it an ideal choice for these applications. In agriculture, UV-resistant polypropylene finds extensive use in greenhouse films, crop covers, and irrigation systems, where protection against UV degradation is essential for prolonged product life and optimal crop yield.

Geographically, Asia-Pacific leads the market for UV-resistant polypropylene, followed by North America and Europe. The rapid industrialization and urbanization in emerging economies, particularly in China and India, have significantly contributed to the region's market dominance. However, stringent environmental regulations in developed regions are driving innovation in bio-based and recyclable UV-resistant polypropylene formulations, creating new market opportunities.

Consumer trends towards sustainable and long-lasting products have further bolstered the demand for UV-resistant polypropylene. Manufacturers are increasingly focusing on developing advanced UV stabilizer technologies to enhance the material's performance and lifespan, thereby expanding its application scope. This trend is expected to continue, with ongoing research and development efforts aimed at improving UV resistance while maintaining or enhancing other desirable properties of polypropylene.

Current Challenges in Outdoor PP Applications

Polypropylene (PP) has become a popular material for outdoor applications due to its excellent mechanical properties and cost-effectiveness. However, its susceptibility to UV degradation poses significant challenges for long-term outdoor use. When exposed to sunlight, PP undergoes photo-oxidation, leading to chain scission and deterioration of its physical and mechanical properties.

One of the primary challenges in outdoor PP applications is the rapid loss of tensile strength and elongation at break. UV radiation initiates the formation of free radicals within the polymer structure, causing molecular weight reduction and embrittlement. This results in surface cracking, chalking, and eventual material failure, significantly reducing the service life of PP products.

Color fading and aesthetic degradation present another major challenge. UV exposure causes the breakdown of chromophores in pigments and dyes, leading to discoloration and loss of visual appeal. This is particularly problematic in applications where appearance is crucial, such as outdoor furniture, automotive components, and architectural elements.

Thermal degradation is exacerbated by UV exposure, creating a synergistic effect that accelerates PP deterioration. The combination of heat and UV radiation increases the rate of oxidation reactions, leading to faster degradation of mechanical properties and dimensional stability. This poses challenges in maintaining product integrity, especially in regions with high temperatures and intense sunlight.

The formation of microplastics due to UV-induced degradation is an emerging environmental concern. As PP products break down under prolonged UV exposure, they release small plastic particles into the environment, contributing to plastic pollution in ecosystems. This challenge extends beyond product performance to encompass broader environmental and sustainability issues.

Inconsistent weathering patterns across different geographic locations complicate the development of universally effective UV stabilization strategies. Variations in UV intensity, temperature, humidity, and pollutants across regions necessitate tailored approaches to PP protection, making it challenging to develop a one-size-fits-all solution for global markets.

The need for increased additive loadings to achieve adequate UV protection often compromises other desirable properties of PP, such as transparency, processability, and recyclability. Balancing UV stability with these properties presents a significant challenge in formulation and material design, often requiring trade-offs that can limit the application range of PP in outdoor settings.

One of the primary challenges in outdoor PP applications is the rapid loss of tensile strength and elongation at break. UV radiation initiates the formation of free radicals within the polymer structure, causing molecular weight reduction and embrittlement. This results in surface cracking, chalking, and eventual material failure, significantly reducing the service life of PP products.

Color fading and aesthetic degradation present another major challenge. UV exposure causes the breakdown of chromophores in pigments and dyes, leading to discoloration and loss of visual appeal. This is particularly problematic in applications where appearance is crucial, such as outdoor furniture, automotive components, and architectural elements.

Thermal degradation is exacerbated by UV exposure, creating a synergistic effect that accelerates PP deterioration. The combination of heat and UV radiation increases the rate of oxidation reactions, leading to faster degradation of mechanical properties and dimensional stability. This poses challenges in maintaining product integrity, especially in regions with high temperatures and intense sunlight.

The formation of microplastics due to UV-induced degradation is an emerging environmental concern. As PP products break down under prolonged UV exposure, they release small plastic particles into the environment, contributing to plastic pollution in ecosystems. This challenge extends beyond product performance to encompass broader environmental and sustainability issues.

Inconsistent weathering patterns across different geographic locations complicate the development of universally effective UV stabilization strategies. Variations in UV intensity, temperature, humidity, and pollutants across regions necessitate tailored approaches to PP protection, making it challenging to develop a one-size-fits-all solution for global markets.

The need for increased additive loadings to achieve adequate UV protection often compromises other desirable properties of PP, such as transparency, processability, and recyclability. Balancing UV stability with these properties presents a significant challenge in formulation and material design, often requiring trade-offs that can limit the application range of PP in outdoor settings.

Existing UV Stabilization Methods for PP

01 Chemical structure modifications for improved UV stability

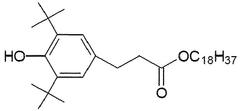

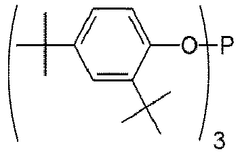

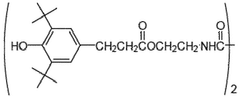

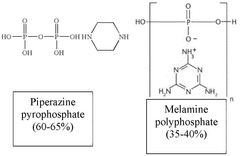

Enhancing UV stabilizer durability through modifications to their chemical structure. This includes incorporating specific functional groups or altering molecular configurations to increase resistance to degradation under UV exposure. Such modifications can lead to longer-lasting protection and improved performance in various applications.- Chemical composition of UV stabilizers: UV stabilizers are compounds designed to protect materials from degradation caused by ultraviolet radiation. They typically include hindered amine light stabilizers (HALS), benzophenones, and benzotriazoles. These compounds work by absorbing UV radiation or neutralizing free radicals formed during photodegradation, thus enhancing the durability of the material they protect.

- Incorporation methods for UV stabilizers: UV stabilizers can be incorporated into materials through various methods to enhance their durability. These methods include blending the stabilizers directly into polymers during processing, surface coating, and grafting onto the material surface. The choice of incorporation method depends on the material type and the desired level of protection.

- Synergistic effects of UV stabilizer combinations: Combining different types of UV stabilizers can lead to synergistic effects, enhancing overall durability. For example, using a mixture of HALS and UV absorbers can provide both radical scavenging and direct UV absorption, resulting in improved long-term stability of the protected material.

- Environmental factors affecting UV stabilizer performance: The durability of UV stabilizers is influenced by various environmental factors such as temperature, humidity, and exposure to pollutants. High temperatures can accelerate the degradation of some stabilizers, while humidity can affect their distribution within the material. Understanding these factors is crucial for optimizing the long-term performance of UV-stabilized materials.

- Novel approaches to enhance UV stabilizer durability: Recent research has focused on developing novel approaches to enhance the durability of UV stabilizers. These include nanoencapsulation of stabilizers to improve their dispersion and longevity, development of regenerative stabilizer systems, and the use of inorganic-organic hybrid materials as UV protectants. These innovations aim to extend the effective lifespan of UV stabilizers in various applications.

02 Synergistic combinations of UV stabilizers

Utilizing combinations of different UV stabilizers to achieve synergistic effects, enhancing overall durability and effectiveness. This approach can involve mixing various classes of stabilizers or combining stabilizers with complementary mechanisms of action to provide broader spectrum protection and increased longevity.Expand Specific Solutions03 Encapsulation and controlled release technologies

Implementing encapsulation techniques to protect UV stabilizers from premature degradation and enable controlled release over time. This can involve using micro or nanoencapsulation methods, or incorporating stabilizers into polymer matrices, resulting in prolonged effectiveness and improved durability in various environmental conditions.Expand Specific Solutions04 Surface treatment and coating technologies

Developing advanced surface treatments and coating technologies to enhance the durability of UV stabilizers. This includes creating protective layers or modifying surface properties to improve adhesion, distribution, and retention of stabilizers, leading to increased longevity and effectiveness in outdoor applications.Expand Specific Solutions05 Novel UV stabilizer compounds with enhanced durability

Designing and synthesizing new UV stabilizer compounds with inherently higher durability. This involves creating molecules with improved photostability, thermal resistance, and compatibility with various substrates, resulting in longer-lasting protection against UV degradation in diverse applications.Expand Specific Solutions

Key Players in UV Stabilizer Industry

The UV stabilizer market for polypropylene outdoor durability is in a mature growth stage, with a significant global market size driven by increasing demand for weather-resistant plastics across various industries. The technology has reached a high level of maturity, with major players like BASF, DuPont, and Borealis leading innovation. These companies, along with others such as Clariant and Covestro, have developed advanced UV stabilizer solutions tailored for polypropylene applications. The competitive landscape is characterized by ongoing research and development efforts to enhance product performance and sustainability, with a focus on meeting stringent environmental regulations and improving long-term outdoor durability of polypropylene materials.

BASF Corp.

Technical Solution: BASF has developed advanced UV stabilizers for polypropylene, such as their Tinuvin® range. These stabilizers work by absorbing harmful UV radiation and dissipating it as heat, preventing polymer degradation. BASF's technology incorporates hindered amine light stabilizers (HALS) that act as free radical scavengers, neutralizing the destructive radicals formed by UV exposure[1]. Their latest formulations, like Tinuvin® XT 55, offer enhanced compatibility with polypropylene, ensuring uniform distribution throughout the polymer matrix for long-lasting protection[3]. BASF has also introduced synergistic blends of UV absorbers and HALS, providing a multi-pronged approach to UV stabilization that significantly extends the service life of outdoor polypropylene products[5].

Strengths: Comprehensive UV protection, long-lasting effectiveness, and compatibility with various PP grades. Weaknesses: Potential for higher costs compared to basic stabilizers and possible color effects in some formulations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered UV stabilization technology for polypropylene with their DuPont™ Elvaloy® resins and modifiers. These products are designed to enhance the weatherability of polypropylene by incorporating UV-resistant polymers directly into the PP matrix. DuPont's approach involves the use of specially engineered ethylene copolymers that act as both impact modifiers and UV stabilizers[2]. The Elvaloy® technology creates a molecular shield around PP chains, preventing UV-induced oxidation and chain scission. Additionally, DuPont has developed nano-scale UV absorbers that can be more efficiently dispersed throughout the polymer, providing superior protection even at lower concentrations[4]. Their latest innovations include smart UV stabilizers that adapt to varying light intensities, offering dynamic protection in different outdoor environments[6].

Strengths: Dual functionality as impact modifier and UV stabilizer, excellent dispersion in PP, and adaptive protection. Weaknesses: May require adjustments to processing conditions and potential impact on recycling.

Innovative UV Stabilizer Mechanisms

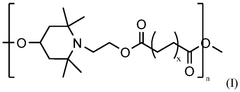

Polypropylene composition having intumescent flame retardant and improved UV stabilization

PatentPendingEP4474417A1

Innovation

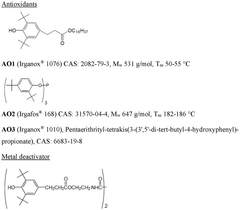

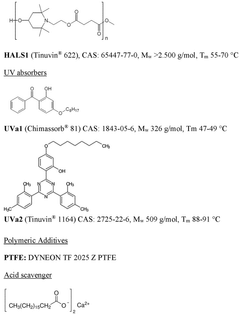

- Incorporating a combination of NOR-HALS and acid scavengers into the polypropylene composition, along with a halogen-free flame retardant containing nitrogen and phosphorus, to enhance UV stability, which can also include additional additives like UV absorbers and antioxidants.

Polypropylene composition having intumescent flame retardant and improved UV stabilization

PatentWO2024251977A1

Innovation

- Incorporating a combination of hindered amine light stabilizers (HALS) with ester groups and acid scavengers into the polypropylene composition, specifically with a halogen-free flame retardant containing nitrogen and phosphorus, to enhance UV stability and protect against hydrolysis caused by the flame retardant's acidity.

Environmental Impact of UV Stabilizers

The use of UV stabilizers in polypropylene products has raised concerns about their potential environmental impact. These additives, while effective in enhancing the durability of plastics exposed to sunlight, may have unintended consequences on ecosystems and human health.

One primary environmental concern is the leaching of UV stabilizers from plastic products into soil and water systems. As polypropylene items degrade over time, these chemical compounds can be released into the environment. Studies have shown that certain UV stabilizers, particularly those containing benzotriazoles and benzophenones, can accumulate in aquatic environments and potentially affect marine life.

The persistence of UV stabilizers in the environment is another significant issue. Many of these compounds are designed to be resistant to degradation, which means they can remain in ecosystems for extended periods. This long-term presence may lead to bioaccumulation in various organisms, potentially disrupting food chains and ecological balance.

Furthermore, the production and disposal of UV stabilizers contribute to the overall environmental footprint of plastic products. The manufacturing process of these additives often involves energy-intensive procedures and the use of potentially hazardous chemicals. When plastic products reach the end of their life cycle, the presence of UV stabilizers can complicate recycling efforts and may lead to the release of harmful substances during incineration or landfill disposal.

There are also concerns about the potential toxicity of some UV stabilizers to various organisms. While the concentrations found in the environment are typically low, long-term exposure effects are not yet fully understood. Some studies have suggested possible endocrine-disrupting properties in certain UV stabilizers, which could have far-reaching consequences for wildlife and potentially human health.

On the other hand, the use of UV stabilizers in polypropylene can be viewed as having some positive environmental impacts. By extending the lifespan of plastic products, these additives reduce the need for frequent replacement, potentially decreasing overall plastic consumption and waste generation. This durability can be particularly beneficial in applications such as agricultural films, where longer-lasting materials can reduce plastic pollution in farmlands.

As awareness of these environmental concerns grows, there is an increasing focus on developing more eco-friendly UV stabilization solutions. Research is being conducted on bio-based and biodegradable UV stabilizers that could offer similar performance benefits with reduced environmental impact. Additionally, improved product design and end-of-life management strategies are being explored to mitigate the release of these compounds into the environment.

One primary environmental concern is the leaching of UV stabilizers from plastic products into soil and water systems. As polypropylene items degrade over time, these chemical compounds can be released into the environment. Studies have shown that certain UV stabilizers, particularly those containing benzotriazoles and benzophenones, can accumulate in aquatic environments and potentially affect marine life.

The persistence of UV stabilizers in the environment is another significant issue. Many of these compounds are designed to be resistant to degradation, which means they can remain in ecosystems for extended periods. This long-term presence may lead to bioaccumulation in various organisms, potentially disrupting food chains and ecological balance.

Furthermore, the production and disposal of UV stabilizers contribute to the overall environmental footprint of plastic products. The manufacturing process of these additives often involves energy-intensive procedures and the use of potentially hazardous chemicals. When plastic products reach the end of their life cycle, the presence of UV stabilizers can complicate recycling efforts and may lead to the release of harmful substances during incineration or landfill disposal.

There are also concerns about the potential toxicity of some UV stabilizers to various organisms. While the concentrations found in the environment are typically low, long-term exposure effects are not yet fully understood. Some studies have suggested possible endocrine-disrupting properties in certain UV stabilizers, which could have far-reaching consequences for wildlife and potentially human health.

On the other hand, the use of UV stabilizers in polypropylene can be viewed as having some positive environmental impacts. By extending the lifespan of plastic products, these additives reduce the need for frequent replacement, potentially decreasing overall plastic consumption and waste generation. This durability can be particularly beneficial in applications such as agricultural films, where longer-lasting materials can reduce plastic pollution in farmlands.

As awareness of these environmental concerns grows, there is an increasing focus on developing more eco-friendly UV stabilization solutions. Research is being conducted on bio-based and biodegradable UV stabilizers that could offer similar performance benefits with reduced environmental impact. Additionally, improved product design and end-of-life management strategies are being explored to mitigate the release of these compounds into the environment.

Regulatory Framework for Additives in Plastics

The regulatory framework for additives in plastics, particularly concerning UV stabilizers in polypropylene for outdoor applications, is a complex and evolving landscape. Globally, various regulatory bodies have established guidelines and standards to ensure the safety and efficacy of these additives. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is one of the most comprehensive frameworks, requiring manufacturers and importers to register chemical substances, including UV stabilizers, and provide safety data.

In the United States, the Food and Drug Administration (FDA) regulates additives used in food-contact plastics, while the Environmental Protection Agency (EPA) oversees chemicals used in non-food applications. The FDA's Code of Federal Regulations Title 21 (21 CFR) specifically addresses the use of UV stabilizers in polymers intended for food contact. For outdoor applications, the EPA's Toxic Substances Control Act (TSCA) plays a crucial role in regulating the introduction of new chemical substances.

Japan's regulatory framework includes the Chemical Substances Control Law (CSCL) and the Food Sanitation Law, which govern the use of chemical additives in plastics. China has implemented the Measures for Environmental Management of New Chemical Substances, requiring manufacturers to register new chemical substances, including UV stabilizers, before production or import.

International standards organizations also contribute to the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards related to plastics and additives, such as ISO 4892 for methods of exposure to laboratory light sources. These standards often inform national regulations and industry practices.

Specific to UV stabilizers in polypropylene, regulations often focus on migration limits and overall safety assessments. For instance, the European Food Safety Authority (EFSA) evaluates the safety of substances used in food contact materials, including UV stabilizers in polypropylene packaging. Their assessments consider factors such as migration potential, toxicological data, and exposure estimates.

Regulatory compliance for UV stabilizers also extends to environmental considerations. Many jurisdictions have implemented restrictions on persistent organic pollutants (POPs) and substances of very high concern (SVHCs), which can impact the selection and use of certain UV stabilizers in outdoor polypropylene applications.

As sustainability becomes increasingly important, regulations are evolving to address the entire lifecycle of plastic products. This includes considerations for recyclability and end-of-life management, which can influence the choice of UV stabilizers used in polypropylene products designed for outdoor use.

In the United States, the Food and Drug Administration (FDA) regulates additives used in food-contact plastics, while the Environmental Protection Agency (EPA) oversees chemicals used in non-food applications. The FDA's Code of Federal Regulations Title 21 (21 CFR) specifically addresses the use of UV stabilizers in polymers intended for food contact. For outdoor applications, the EPA's Toxic Substances Control Act (TSCA) plays a crucial role in regulating the introduction of new chemical substances.

Japan's regulatory framework includes the Chemical Substances Control Law (CSCL) and the Food Sanitation Law, which govern the use of chemical additives in plastics. China has implemented the Measures for Environmental Management of New Chemical Substances, requiring manufacturers to register new chemical substances, including UV stabilizers, before production or import.

International standards organizations also contribute to the regulatory landscape. The International Organization for Standardization (ISO) has developed several standards related to plastics and additives, such as ISO 4892 for methods of exposure to laboratory light sources. These standards often inform national regulations and industry practices.

Specific to UV stabilizers in polypropylene, regulations often focus on migration limits and overall safety assessments. For instance, the European Food Safety Authority (EFSA) evaluates the safety of substances used in food contact materials, including UV stabilizers in polypropylene packaging. Their assessments consider factors such as migration potential, toxicological data, and exposure estimates.

Regulatory compliance for UV stabilizers also extends to environmental considerations. Many jurisdictions have implemented restrictions on persistent organic pollutants (POPs) and substances of very high concern (SVHCs), which can impact the selection and use of certain UV stabilizers in outdoor polypropylene applications.

As sustainability becomes increasingly important, regulations are evolving to address the entire lifecycle of plastic products. This includes considerations for recyclability and end-of-life management, which can influence the choice of UV stabilizers used in polypropylene products designed for outdoor use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!