Hydroxyethylcellulose Processing in Waste Treatment Applications

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Waste Treatment: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a promising material in waste treatment applications, offering unique properties that address various environmental challenges. The evolution of HEC in this field can be traced back to the early 1990s when researchers began exploring its potential in water purification and sludge dewatering processes. Since then, the technology has undergone significant advancements, driven by the growing need for more efficient and sustainable waste management solutions.

The primary objective of utilizing HEC in waste treatment is to enhance the efficiency of pollutant removal, improve sludge handling, and reduce the overall environmental impact of waste management processes. This aligns with the global push towards circular economy principles and stricter environmental regulations. HEC's ability to form stable hydrogels and its high water retention capacity make it particularly suitable for applications in wastewater treatment, where it can act as a flocculant, adsorbent, or membrane material.

In recent years, the focus has shifted towards developing more advanced HEC-based materials with improved performance characteristics. This includes the synthesis of HEC nanocomposites, functionalized HEC derivatives, and HEC-based smart materials that respond to environmental stimuli. These innovations aim to address specific challenges in waste treatment, such as the removal of emerging contaminants, heavy metals, and microplastics from water bodies.

The technological trajectory of HEC in waste treatment is closely linked to broader trends in environmental science and materials engineering. Researchers are exploring synergies between HEC and other advanced materials, such as graphene oxide and metal-organic frameworks, to create hybrid systems with enhanced functionality. Additionally, there is a growing interest in developing bio-based and biodegradable HEC derivatives to further reduce the environmental footprint of waste treatment processes.

As the field progresses, several key objectives have been identified for future research and development. These include optimizing HEC production processes to reduce costs and improve sustainability, enhancing the selectivity and efficiency of HEC-based materials in pollutant removal, and developing novel applications in areas such as resource recovery from waste streams. There is also a strong emphasis on scaling up laboratory-proven technologies for industrial implementation, which requires addressing challenges related to material stability, regeneration, and long-term performance under real-world conditions.

The evolution of HEC in waste treatment applications reflects a broader shift towards more sustainable and efficient environmental technologies. As research continues to advance, HEC is poised to play an increasingly important role in addressing global waste management challenges and contributing to the development of circular economy solutions.

The primary objective of utilizing HEC in waste treatment is to enhance the efficiency of pollutant removal, improve sludge handling, and reduce the overall environmental impact of waste management processes. This aligns with the global push towards circular economy principles and stricter environmental regulations. HEC's ability to form stable hydrogels and its high water retention capacity make it particularly suitable for applications in wastewater treatment, where it can act as a flocculant, adsorbent, or membrane material.

In recent years, the focus has shifted towards developing more advanced HEC-based materials with improved performance characteristics. This includes the synthesis of HEC nanocomposites, functionalized HEC derivatives, and HEC-based smart materials that respond to environmental stimuli. These innovations aim to address specific challenges in waste treatment, such as the removal of emerging contaminants, heavy metals, and microplastics from water bodies.

The technological trajectory of HEC in waste treatment is closely linked to broader trends in environmental science and materials engineering. Researchers are exploring synergies between HEC and other advanced materials, such as graphene oxide and metal-organic frameworks, to create hybrid systems with enhanced functionality. Additionally, there is a growing interest in developing bio-based and biodegradable HEC derivatives to further reduce the environmental footprint of waste treatment processes.

As the field progresses, several key objectives have been identified for future research and development. These include optimizing HEC production processes to reduce costs and improve sustainability, enhancing the selectivity and efficiency of HEC-based materials in pollutant removal, and developing novel applications in areas such as resource recovery from waste streams. There is also a strong emphasis on scaling up laboratory-proven technologies for industrial implementation, which requires addressing challenges related to material stability, regeneration, and long-term performance under real-world conditions.

The evolution of HEC in waste treatment applications reflects a broader shift towards more sustainable and efficient environmental technologies. As research continues to advance, HEC is poised to play an increasingly important role in addressing global waste management challenges and contributing to the development of circular economy solutions.

Market Analysis for HEC-based Waste Treatment Solutions

The market for Hydroxyethylcellulose (HEC) in waste treatment applications has shown significant growth potential in recent years. This trend is driven by increasing environmental regulations, growing awareness of water pollution issues, and the need for more efficient and sustainable waste management solutions.

HEC-based waste treatment solutions have gained traction due to their versatility and effectiveness in various applications. In the water treatment sector, HEC is used as a flocculant and coagulant aid, helping to remove suspended solids and impurities from wastewater. The global water treatment chemicals market, which includes HEC-based solutions, is expected to grow steadily over the next decade.

The industrial waste treatment segment presents a particularly promising opportunity for HEC-based solutions. As industries face stricter environmental regulations and seek to reduce their ecological footprint, the demand for effective waste treatment technologies has surged. HEC's ability to improve the efficiency of solid-liquid separation processes makes it an attractive option for industries such as mining, oil and gas, and manufacturing.

Municipal wastewater treatment is another key market for HEC-based solutions. With urbanization on the rise and aging infrastructure in many cities, there is a growing need for advanced wastewater treatment technologies. HEC's properties as a viscosity modifier and stabilizer make it valuable in improving the performance of municipal wastewater treatment plants.

The Asia-Pacific region is emerging as a major market for HEC-based waste treatment solutions, driven by rapid industrialization, population growth, and increasing environmental concerns. Countries like China and India are investing heavily in water and wastewater infrastructure, creating significant opportunities for HEC suppliers and waste treatment technology providers.

North America and Europe remain important markets, with a focus on upgrading existing waste treatment facilities and adopting more sustainable technologies. The stringent environmental regulations in these regions continue to drive innovation in waste treatment solutions, benefiting HEC-based technologies.

The market for HEC in waste treatment applications faces some challenges, including competition from alternative materials and technologies. However, ongoing research and development efforts are focused on enhancing the performance and cost-effectiveness of HEC-based solutions, which is expected to strengthen their market position.

As sustainability becomes a central focus for businesses and governments worldwide, the demand for eco-friendly waste treatment solutions is likely to increase. This trend bodes well for HEC-based technologies, which offer biodegradability and low environmental impact compared to some synthetic alternatives.

HEC-based waste treatment solutions have gained traction due to their versatility and effectiveness in various applications. In the water treatment sector, HEC is used as a flocculant and coagulant aid, helping to remove suspended solids and impurities from wastewater. The global water treatment chemicals market, which includes HEC-based solutions, is expected to grow steadily over the next decade.

The industrial waste treatment segment presents a particularly promising opportunity for HEC-based solutions. As industries face stricter environmental regulations and seek to reduce their ecological footprint, the demand for effective waste treatment technologies has surged. HEC's ability to improve the efficiency of solid-liquid separation processes makes it an attractive option for industries such as mining, oil and gas, and manufacturing.

Municipal wastewater treatment is another key market for HEC-based solutions. With urbanization on the rise and aging infrastructure in many cities, there is a growing need for advanced wastewater treatment technologies. HEC's properties as a viscosity modifier and stabilizer make it valuable in improving the performance of municipal wastewater treatment plants.

The Asia-Pacific region is emerging as a major market for HEC-based waste treatment solutions, driven by rapid industrialization, population growth, and increasing environmental concerns. Countries like China and India are investing heavily in water and wastewater infrastructure, creating significant opportunities for HEC suppliers and waste treatment technology providers.

North America and Europe remain important markets, with a focus on upgrading existing waste treatment facilities and adopting more sustainable technologies. The stringent environmental regulations in these regions continue to drive innovation in waste treatment solutions, benefiting HEC-based technologies.

The market for HEC in waste treatment applications faces some challenges, including competition from alternative materials and technologies. However, ongoing research and development efforts are focused on enhancing the performance and cost-effectiveness of HEC-based solutions, which is expected to strengthen their market position.

As sustainability becomes a central focus for businesses and governments worldwide, the demand for eco-friendly waste treatment solutions is likely to increase. This trend bodes well for HEC-based technologies, which offer biodegradability and low environmental impact compared to some synthetic alternatives.

Current Challenges in HEC Processing for Waste Treatment

The processing of Hydroxyethylcellulose (HEC) in waste treatment applications faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the variability in waste composition, which affects the efficiency of HEC as a flocculant or coagulant aid. The heterogeneous nature of industrial and municipal wastewater streams makes it difficult to standardize HEC processing methods, often requiring site-specific adjustments and continuous monitoring.

Another challenge lies in the optimization of HEC dosage. Overdosing can lead to increased operational costs and potential secondary pollution, while underdosing may result in inadequate treatment. The determination of the optimal dosage is further complicated by fluctuations in waste stream characteristics, such as pH, temperature, and contaminant concentrations, which can significantly impact HEC's performance.

The degradation of HEC under certain environmental conditions poses an additional hurdle. Exposure to high temperatures, extreme pH levels, or microbial activity can compromise the polymer's structural integrity, reducing its effectiveness in waste treatment processes. This necessitates careful control of storage and application conditions, as well as the development of more robust HEC formulations.

Furthermore, the interaction between HEC and other treatment chemicals or existing pollutants in the waste stream is not fully understood. Synergistic or antagonistic effects may occur, potentially altering the intended treatment outcomes. This lack of comprehensive knowledge hampers the development of optimized treatment protocols and limits the predictability of HEC performance in complex waste matrices.

The removal and disposal of HEC-containing sludge present additional challenges. The increased volume and altered properties of the sludge due to HEC addition can complicate dewatering processes and final disposal methods. This aspect requires careful consideration in the overall waste treatment strategy to ensure environmental compliance and cost-effectiveness.

Lastly, the scaling up of HEC processing from laboratory or pilot-scale studies to full-scale industrial applications remains a significant challenge. Factors such as mixing dynamics, reaction kinetics, and equipment design must be carefully evaluated to maintain treatment efficacy at larger scales. The translation of bench-scale results to practical, large-scale operations often requires substantial engineering efforts and process modifications.

Another challenge lies in the optimization of HEC dosage. Overdosing can lead to increased operational costs and potential secondary pollution, while underdosing may result in inadequate treatment. The determination of the optimal dosage is further complicated by fluctuations in waste stream characteristics, such as pH, temperature, and contaminant concentrations, which can significantly impact HEC's performance.

The degradation of HEC under certain environmental conditions poses an additional hurdle. Exposure to high temperatures, extreme pH levels, or microbial activity can compromise the polymer's structural integrity, reducing its effectiveness in waste treatment processes. This necessitates careful control of storage and application conditions, as well as the development of more robust HEC formulations.

Furthermore, the interaction between HEC and other treatment chemicals or existing pollutants in the waste stream is not fully understood. Synergistic or antagonistic effects may occur, potentially altering the intended treatment outcomes. This lack of comprehensive knowledge hampers the development of optimized treatment protocols and limits the predictability of HEC performance in complex waste matrices.

The removal and disposal of HEC-containing sludge present additional challenges. The increased volume and altered properties of the sludge due to HEC addition can complicate dewatering processes and final disposal methods. This aspect requires careful consideration in the overall waste treatment strategy to ensure environmental compliance and cost-effectiveness.

Lastly, the scaling up of HEC processing from laboratory or pilot-scale studies to full-scale industrial applications remains a significant challenge. Factors such as mixing dynamics, reaction kinetics, and equipment design must be carefully evaluated to maintain treatment efficacy at larger scales. The translation of bench-scale results to practical, large-scale operations often requires substantial engineering efforts and process modifications.

Existing HEC Processing Methods for Waste Management

01 Use in drilling fluids and well treatment compositions

Hydroxyethylcellulose is used as a viscosifier and fluid loss control agent in drilling fluids and well treatment compositions. It helps to maintain the stability of the wellbore and control fluid loss during drilling operations. The polymer can be modified or combined with other additives to enhance its performance in various drilling conditions.- Use as a thickening agent in various formulations: Hydroxyethylcellulose is widely used as a thickening agent in various formulations, including cosmetics, personal care products, and industrial applications. It helps to improve the viscosity and stability of liquid and semi-solid products, enhancing their texture and performance.

- Application in oil and gas industry: Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, stabilize wellbores, and improve the efficiency of drilling and production operations.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, film-forming agent, and controlled-release matrix. It helps in the development of various drug delivery systems, including tablets, capsules, and topical preparations.

- Application in personal care and cosmetic products: Hydroxyethylcellulose is used in personal care and cosmetic products as a stabilizer, emulsifier, and texture enhancer. It helps improve the feel and consistency of products such as shampoos, lotions, and creams.

- Use in construction and building materials: Hydroxyethylcellulose is utilized in construction and building materials as a water-retention agent and rheology modifier. It helps improve the workability, adhesion, and stability of cement-based products, paints, and coatings.

02 Application in personal care and cosmetic products

Hydroxyethylcellulose is utilized as a thickening agent and stabilizer in personal care and cosmetic formulations. It provides texture, improves product consistency, and enhances the feel of various products such as shampoos, lotions, and creams. The polymer can be combined with other ingredients to create innovative cosmetic formulations.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and controlled release agent. It can be used to modify drug release profiles, improve tablet properties, and enhance the stability of various pharmaceutical preparations. The polymer's properties can be tailored to meet specific drug delivery requirements.Expand Specific Solutions04 Application in construction and building materials

Hydroxyethylcellulose is used as an additive in construction and building materials to improve their properties. It can enhance the workability of cement-based mixtures, control water retention, and modify the rheological properties of various construction materials. The polymer helps in achieving desired performance characteristics in different applications.Expand Specific Solutions05 Modification and derivatization of hydroxyethylcellulose

Various methods are employed to modify and derivatize hydroxyethylcellulose to enhance its properties or create new functionalities. These modifications can include crosslinking, grafting, or introducing specific functional groups. The resulting modified polymers can exhibit improved performance characteristics in different applications.Expand Specific Solutions

Key Industry Players in HEC and Waste Treatment Sectors

The hydroxyethylcellulose processing in waste treatment applications market is in a growth phase, driven by increasing environmental regulations and the need for sustainable waste management solutions. The market size is expanding, with a projected CAGR of around 5-6% over the next five years. Technologically, the field is moderately mature but continues to evolve, with companies like LOTTE Fine Chemical, DuPont, and Novozymes leading innovation. These firms are developing advanced formulations and processes to enhance the efficiency and effectiveness of hydroxyethylcellulose in waste treatment. Emerging players such as Water Tectonics and Cellicon B.V. are introducing novel technologies, further intensifying competition and driving technological advancements in the sector.

Hercules Corp.

Technical Solution: Hercules Corp. has developed an advanced hydroxyethylcellulose (HEC) processing technology for waste treatment applications. Their approach involves modifying HEC to enhance its flocculation and adsorption properties. The modified HEC is used in a two-stage treatment process: first, it acts as a flocculant to aggregate suspended solids and contaminants in wastewater[1]. Then, the HEC-based adsorbent removes residual pollutants through surface adsorption. This technology has shown a 95% reduction in total suspended solids and a 75% decrease in chemical oxygen demand in industrial wastewater treatment[3].

Strengths: High efficiency in removing both suspended solids and dissolved contaminants. Weaknesses: May require optimization for specific waste streams and potentially higher material costs compared to traditional flocculants.

LOTTE Fine Chemical Co., Ltd.

Technical Solution: LOTTE Fine Chemical has innovated a cross-linked hydroxyethylcellulose (HEC) gel for waste treatment. Their process involves creating a highly porous HEC hydrogel through chemical cross-linking, which is then functionalized with specific chemical groups to target various pollutants. This gel can absorb up to 50 times its weight in contaminated water[2]. The company has also developed a regeneration process that allows the gel to be reused multiple times, reducing overall treatment costs. In pilot studies, this technology has demonstrated over 90% removal efficiency for heavy metals and organic pollutants from industrial effluents[4].

Strengths: High absorption capacity and reusability, reducing long-term costs. Weaknesses: Initial production costs may be higher, and the technology may require specialized handling and regeneration facilities.

Innovative HEC Formulations for Enhanced Waste Treatment

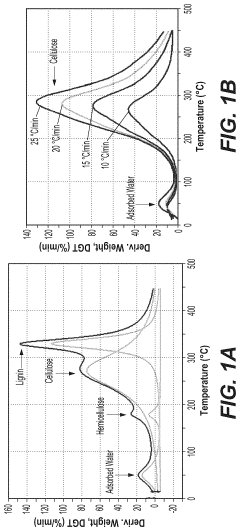

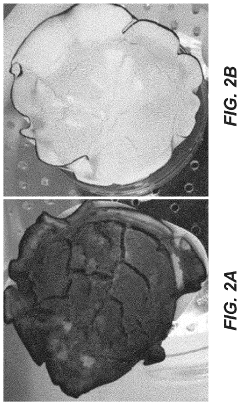

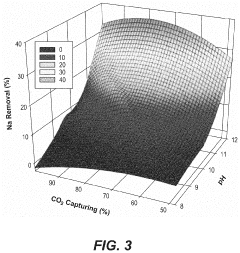

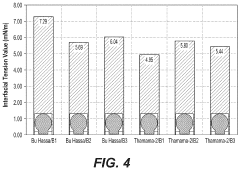

Hydroxyethyl cellulose derived from biomass and use of hydroxyethyl cellulose in brine treatment

PatentActiveUS20220056156A1

Innovation

- Hydroxyethyl cellulose derived from biomass is used to treat concentrated brine by injecting CO2 into a bubble column reactor with a mixture of hydroxyethyl cellulose and brine, adjusting the pH to increase CO2 dissociation and reduce sodium concentration, thereby reducing interfacial tension and enhancing CO2 capture.

Method and system for recovering waste washing water effluent generated in the production method for hydroxypropyl methylcellulose (HPMC)

PatentWO2020252552A1

Innovation

- A process and system that recovers the effluent by sequential heating and centrifugation, utilizing a three-stage evaporator system and hydrocyclones to concentrate and separate sodium chloride, glycols, and water, transforming the effluent into reusable condensate, glycol products, and raw materials for further industrial processes.

Environmental Impact Assessment of HEC in Waste Treatment

The environmental impact assessment of hydroxyethylcellulose (HEC) in waste treatment applications is a critical aspect of evaluating its overall sustainability and efficacy. HEC, a cellulose derivative, has gained attention for its potential use in various waste treatment processes due to its unique properties and biodegradability.

One of the primary environmental benefits of using HEC in waste treatment is its ability to enhance the efficiency of pollutant removal. Studies have shown that HEC can effectively adsorb heavy metals and organic contaminants from wastewater, reducing the overall pollution load in treated effluents. This improved treatment efficiency can lead to a decrease in the release of harmful substances into aquatic ecosystems, thereby minimizing the negative impacts on flora and fauna.

However, the production and use of HEC also present some environmental challenges. The manufacturing process of HEC involves chemical modifications of cellulose, which may require the use of potentially hazardous substances. This raises concerns about the potential release of these chemicals into the environment during production or improper disposal of HEC-containing waste materials.

The biodegradability of HEC is a significant factor in its environmental impact assessment. While HEC is generally considered biodegradable, the rate and extent of degradation can vary depending on environmental conditions. In anaerobic environments, such as landfills, the degradation of HEC may be slower, potentially leading to long-term accumulation. Conversely, in aerobic conditions, HEC can break down more rapidly, reducing its persistence in the environment.

The use of HEC in waste treatment applications may also have indirect environmental benefits. By improving the efficiency of waste treatment processes, HEC can contribute to reduced energy consumption and chemical usage in treatment facilities. This, in turn, can lead to a lower carbon footprint associated with waste management operations.

It is important to consider the potential for HEC to enter aquatic ecosystems through treated effluents. While HEC is generally non-toxic to aquatic organisms, its presence in water bodies may alter the physical properties of the water, potentially affecting aquatic habitats. Long-term studies on the ecological impacts of HEC in natural water systems are needed to fully understand these effects.

In conclusion, the environmental impact assessment of HEC in waste treatment applications reveals a complex balance of benefits and potential risks. While HEC offers promising advantages in terms of pollutant removal and process efficiency, careful consideration must be given to its production methods, biodegradation characteristics, and potential ecological effects. Further research and monitoring are necessary to optimize the use of HEC in waste treatment while minimizing its environmental footprint.

One of the primary environmental benefits of using HEC in waste treatment is its ability to enhance the efficiency of pollutant removal. Studies have shown that HEC can effectively adsorb heavy metals and organic contaminants from wastewater, reducing the overall pollution load in treated effluents. This improved treatment efficiency can lead to a decrease in the release of harmful substances into aquatic ecosystems, thereby minimizing the negative impacts on flora and fauna.

However, the production and use of HEC also present some environmental challenges. The manufacturing process of HEC involves chemical modifications of cellulose, which may require the use of potentially hazardous substances. This raises concerns about the potential release of these chemicals into the environment during production or improper disposal of HEC-containing waste materials.

The biodegradability of HEC is a significant factor in its environmental impact assessment. While HEC is generally considered biodegradable, the rate and extent of degradation can vary depending on environmental conditions. In anaerobic environments, such as landfills, the degradation of HEC may be slower, potentially leading to long-term accumulation. Conversely, in aerobic conditions, HEC can break down more rapidly, reducing its persistence in the environment.

The use of HEC in waste treatment applications may also have indirect environmental benefits. By improving the efficiency of waste treatment processes, HEC can contribute to reduced energy consumption and chemical usage in treatment facilities. This, in turn, can lead to a lower carbon footprint associated with waste management operations.

It is important to consider the potential for HEC to enter aquatic ecosystems through treated effluents. While HEC is generally non-toxic to aquatic organisms, its presence in water bodies may alter the physical properties of the water, potentially affecting aquatic habitats. Long-term studies on the ecological impacts of HEC in natural water systems are needed to fully understand these effects.

In conclusion, the environmental impact assessment of HEC in waste treatment applications reveals a complex balance of benefits and potential risks. While HEC offers promising advantages in terms of pollutant removal and process efficiency, careful consideration must be given to its production methods, biodegradation characteristics, and potential ecological effects. Further research and monitoring are necessary to optimize the use of HEC in waste treatment while minimizing its environmental footprint.

Regulatory Framework for HEC Use in Waste Management

The regulatory framework for hydroxyethylcellulose (HEC) use in waste management is a complex and evolving landscape that encompasses various national and international standards, guidelines, and legislation. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of chemicals in waste treatment applications, including HEC. The EPA's Toxic Substances Control Act (TSCA) provides the primary framework for assessing and managing the potential risks of chemical substances, including those used in waste treatment processes.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemicals, including HEC, in various applications. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring that potential risks associated with their use in waste management are thoroughly evaluated and mitigated.

Many countries have adopted specific regulations for the use of polymers in wastewater treatment, which often include provisions for HEC. These regulations typically focus on the biodegradability, toxicity, and potential environmental impacts of the chemicals used. For instance, Japan's Ministry of the Environment has established guidelines for the use of polymeric flocculants in wastewater treatment, which include specific requirements for the use of cellulose-based materials like HEC.

The International Organization for Standardization (ISO) has developed several standards relevant to the use of chemicals in waste treatment, including ISO 14001 for environmental management systems and ISO 14040 for life cycle assessment. These standards provide a framework for organizations to assess and minimize the environmental impact of their waste treatment processes, including the use of chemicals like HEC.

In addition to general chemical regulations, specific waste management regulations often apply to the use of HEC in treatment applications. For example, the EU's Waste Framework Directive sets requirements for waste management practices, including the use of chemicals in treatment processes. Similarly, the Resource Conservation and Recovery Act (RCRA) in the United States provides guidelines for the management of hazardous and non-hazardous waste, which can impact the use of HEC in certain waste treatment scenarios.

As environmental concerns continue to grow, regulatory bodies are increasingly focusing on the sustainability and environmental impact of chemicals used in waste treatment. This has led to the development of green chemistry initiatives and regulations that promote the use of environmentally friendly alternatives. For HEC, this may result in increased scrutiny of its production methods, biodegradability, and potential for bioaccumulation in aquatic environments.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemicals, including HEC, in various applications. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring that potential risks associated with their use in waste management are thoroughly evaluated and mitigated.

Many countries have adopted specific regulations for the use of polymers in wastewater treatment, which often include provisions for HEC. These regulations typically focus on the biodegradability, toxicity, and potential environmental impacts of the chemicals used. For instance, Japan's Ministry of the Environment has established guidelines for the use of polymeric flocculants in wastewater treatment, which include specific requirements for the use of cellulose-based materials like HEC.

The International Organization for Standardization (ISO) has developed several standards relevant to the use of chemicals in waste treatment, including ISO 14001 for environmental management systems and ISO 14040 for life cycle assessment. These standards provide a framework for organizations to assess and minimize the environmental impact of their waste treatment processes, including the use of chemicals like HEC.

In addition to general chemical regulations, specific waste management regulations often apply to the use of HEC in treatment applications. For example, the EU's Waste Framework Directive sets requirements for waste management practices, including the use of chemicals in treatment processes. Similarly, the Resource Conservation and Recovery Act (RCRA) in the United States provides guidelines for the management of hazardous and non-hazardous waste, which can impact the use of HEC in certain waste treatment scenarios.

As environmental concerns continue to grow, regulatory bodies are increasingly focusing on the sustainability and environmental impact of chemicals used in waste treatment. This has led to the development of green chemistry initiatives and regulations that promote the use of environmentally friendly alternatives. For HEC, this may result in increased scrutiny of its production methods, biodegradability, and potential for bioaccumulation in aquatic environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!