Investigating Non-Toxic Fire-Retardant Polypropylene Formulations

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fire-Retardant PP Evolution and Objectives

Fire-retardant polypropylene (PP) has undergone significant evolution since its inception in the 1960s. Initially, the focus was on improving the inherent flame resistance of PP through the incorporation of halogenated compounds. However, concerns over the toxicity and environmental impact of these additives led to a shift towards more sustainable solutions.

The development of fire-retardant PP has been driven by increasingly stringent safety regulations across various industries, particularly in construction, automotive, and electronics. This has necessitated continuous innovation to meet performance requirements while addressing health and environmental concerns.

In the 1980s and 1990s, research efforts concentrated on developing halogen-free flame retardants, such as metal hydroxides and phosphorus-based compounds. These alternatives offered improved environmental profiles but often required high loading levels, which negatively impacted the mechanical properties of PP.

The turn of the millennium saw a surge in nanotechnology applications, with the introduction of nanocomposites as potential flame retardants for PP. This approach promised enhanced fire performance with lower additive loadings, preserving the polymer's mechanical properties.

Recent years have witnessed a growing emphasis on synergistic systems, combining multiple flame retardant mechanisms to achieve optimal performance. This approach allows for reduced overall additive content while maintaining or improving fire resistance.

The current objective in fire-retardant PP research is to develop non-toxic formulations that offer superior flame retardancy without compromising the polymer's inherent properties or processability. This goal aligns with the broader trend towards sustainable and environmentally friendly materials.

Key targets include achieving V-0 rating in UL 94 vertical burning tests, reducing peak heat release rate, and minimizing smoke production during combustion. Additionally, there is a focus on maintaining or enhancing the mechanical strength, impact resistance, and thermal stability of PP.

Another important objective is to develop cost-effective solutions that can be easily integrated into existing manufacturing processes. This is crucial for widespread adoption across various industries and applications.

Furthermore, researchers aim to create versatile fire-retardant systems that can be tailored to specific end-use requirements, such as different levels of flame resistance or specialized properties for particular applications.

As environmental concerns continue to grow, there is also a push towards developing bio-based and recyclable fire-retardant PP formulations. This aligns with circular economy principles and the increasing demand for sustainable materials across industries.

The development of fire-retardant PP has been driven by increasingly stringent safety regulations across various industries, particularly in construction, automotive, and electronics. This has necessitated continuous innovation to meet performance requirements while addressing health and environmental concerns.

In the 1980s and 1990s, research efforts concentrated on developing halogen-free flame retardants, such as metal hydroxides and phosphorus-based compounds. These alternatives offered improved environmental profiles but often required high loading levels, which negatively impacted the mechanical properties of PP.

The turn of the millennium saw a surge in nanotechnology applications, with the introduction of nanocomposites as potential flame retardants for PP. This approach promised enhanced fire performance with lower additive loadings, preserving the polymer's mechanical properties.

Recent years have witnessed a growing emphasis on synergistic systems, combining multiple flame retardant mechanisms to achieve optimal performance. This approach allows for reduced overall additive content while maintaining or improving fire resistance.

The current objective in fire-retardant PP research is to develop non-toxic formulations that offer superior flame retardancy without compromising the polymer's inherent properties or processability. This goal aligns with the broader trend towards sustainable and environmentally friendly materials.

Key targets include achieving V-0 rating in UL 94 vertical burning tests, reducing peak heat release rate, and minimizing smoke production during combustion. Additionally, there is a focus on maintaining or enhancing the mechanical strength, impact resistance, and thermal stability of PP.

Another important objective is to develop cost-effective solutions that can be easily integrated into existing manufacturing processes. This is crucial for widespread adoption across various industries and applications.

Furthermore, researchers aim to create versatile fire-retardant systems that can be tailored to specific end-use requirements, such as different levels of flame resistance or specialized properties for particular applications.

As environmental concerns continue to grow, there is also a push towards developing bio-based and recyclable fire-retardant PP formulations. This aligns with circular economy principles and the increasing demand for sustainable materials across industries.

Market Analysis for Non-Toxic FR PP

The market for non-toxic fire-retardant polypropylene (FR PP) formulations has been experiencing significant growth in recent years, driven by increasing safety regulations and growing consumer awareness of environmental and health concerns. This segment of the plastics industry is poised for continued expansion as manufacturers seek safer alternatives to traditional flame retardants.

The global market for flame retardant plastics, including FR PP, was valued at approximately $7 billion in 2020 and is projected to reach $10 billion by 2025, with a compound annual growth rate (CAGR) of around 6%. Within this market, non-toxic FR PP formulations are gaining traction due to their improved safety profile and reduced environmental impact.

Key industries driving the demand for non-toxic FR PP include automotive, electronics, construction, and consumer goods. The automotive sector, in particular, has shown strong interest in these materials for interior components, as stringent fire safety standards and the push for lighter vehicles converge. The electronics industry also represents a significant market, with manufacturers seeking flame-retardant materials that do not compromise the performance of sensitive electronic components.

Geographically, North America and Europe lead in the adoption of non-toxic FR PP, primarily due to strict regulations such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing safety standards in countries like China and India.

Consumer preferences are shifting towards eco-friendly and health-conscious products, creating a favorable market environment for non-toxic FR PP. This trend is particularly evident in the consumer goods sector, where manufacturers are actively promoting the use of safer materials in household items and children's products.

Despite the positive outlook, challenges remain in the widespread adoption of non-toxic FR PP formulations. These include higher production costs compared to traditional flame retardants and the need for extensive testing to meet various industry-specific standards. However, ongoing research and development efforts are focused on improving the cost-effectiveness and performance of these materials, which is expected to further drive market growth.

In conclusion, the market for non-toxic FR PP formulations shows strong potential for growth, supported by regulatory pressures, environmental concerns, and increasing consumer demand for safer products. As technology advances and production scales up, this segment is likely to capture a larger share of the overall flame retardant plastics market in the coming years.

The global market for flame retardant plastics, including FR PP, was valued at approximately $7 billion in 2020 and is projected to reach $10 billion by 2025, with a compound annual growth rate (CAGR) of around 6%. Within this market, non-toxic FR PP formulations are gaining traction due to their improved safety profile and reduced environmental impact.

Key industries driving the demand for non-toxic FR PP include automotive, electronics, construction, and consumer goods. The automotive sector, in particular, has shown strong interest in these materials for interior components, as stringent fire safety standards and the push for lighter vehicles converge. The electronics industry also represents a significant market, with manufacturers seeking flame-retardant materials that do not compromise the performance of sensitive electronic components.

Geographically, North America and Europe lead in the adoption of non-toxic FR PP, primarily due to strict regulations such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing safety standards in countries like China and India.

Consumer preferences are shifting towards eco-friendly and health-conscious products, creating a favorable market environment for non-toxic FR PP. This trend is particularly evident in the consumer goods sector, where manufacturers are actively promoting the use of safer materials in household items and children's products.

Despite the positive outlook, challenges remain in the widespread adoption of non-toxic FR PP formulations. These include higher production costs compared to traditional flame retardants and the need for extensive testing to meet various industry-specific standards. However, ongoing research and development efforts are focused on improving the cost-effectiveness and performance of these materials, which is expected to further drive market growth.

In conclusion, the market for non-toxic FR PP formulations shows strong potential for growth, supported by regulatory pressures, environmental concerns, and increasing consumer demand for safer products. As technology advances and production scales up, this segment is likely to capture a larger share of the overall flame retardant plastics market in the coming years.

Current FR PP Tech and Challenges

Fire-retardant polypropylene (FR PP) has become increasingly important in various industries due to stringent safety regulations and growing awareness of fire hazards. The current state of FR PP technology presents both advancements and challenges that need to be addressed for wider adoption and improved performance.

One of the primary challenges in developing non-toxic FR PP formulations is achieving an optimal balance between fire retardancy and mechanical properties. Traditional flame retardants often compromise the material's strength, flexibility, and durability. This trade-off has led researchers to explore novel additives and synergistic combinations that can enhance fire resistance without significantly impacting the polymer's inherent characteristics.

The most common FR PP technologies currently in use include halogenated flame retardants, phosphorus-based compounds, and inorganic fillers. Halogenated flame retardants, while effective, face increasing scrutiny due to environmental and health concerns. This has driven the industry towards more sustainable alternatives, such as phosphorus-based flame retardants and mineral fillers like aluminum hydroxide and magnesium hydroxide.

Phosphorus-based flame retardants have gained traction as a promising non-toxic alternative. These compounds work by promoting char formation and creating a protective layer that inhibits combustion. However, they often require higher loading levels compared to halogenated counterparts, which can affect the polymer's processability and mechanical properties.

Inorganic fillers, particularly metal hydroxides, offer another approach to fire retardancy. These materials release water vapor when heated, cooling the polymer and diluting combustible gases. While effective, they typically require high loading levels, which can lead to increased density and reduced flexibility of the final product.

A significant challenge in the field is the development of synergistic systems that can achieve high fire retardancy at lower additive concentrations. Researchers are exploring combinations of different flame retardants and nano-sized particles to create more efficient and cost-effective solutions. However, optimizing these complex formulations requires extensive testing and fine-tuning.

Another hurdle in FR PP technology is maintaining long-term stability and performance. Some flame retardants can migrate to the surface of the polymer over time, reducing their effectiveness and potentially causing environmental issues. Developing encapsulation techniques or chemically bonding flame retardants to the polymer matrix are areas of ongoing research to address this challenge.

The increasing demand for sustainable and recyclable materials presents an additional challenge for FR PP formulations. Many current flame retardants hinder the recycling process or degrade during multiple recycling cycles. This has spurred interest in developing more environmentally friendly and recyclable FR PP solutions, aligning with circular economy principles.

One of the primary challenges in developing non-toxic FR PP formulations is achieving an optimal balance between fire retardancy and mechanical properties. Traditional flame retardants often compromise the material's strength, flexibility, and durability. This trade-off has led researchers to explore novel additives and synergistic combinations that can enhance fire resistance without significantly impacting the polymer's inherent characteristics.

The most common FR PP technologies currently in use include halogenated flame retardants, phosphorus-based compounds, and inorganic fillers. Halogenated flame retardants, while effective, face increasing scrutiny due to environmental and health concerns. This has driven the industry towards more sustainable alternatives, such as phosphorus-based flame retardants and mineral fillers like aluminum hydroxide and magnesium hydroxide.

Phosphorus-based flame retardants have gained traction as a promising non-toxic alternative. These compounds work by promoting char formation and creating a protective layer that inhibits combustion. However, they often require higher loading levels compared to halogenated counterparts, which can affect the polymer's processability and mechanical properties.

Inorganic fillers, particularly metal hydroxides, offer another approach to fire retardancy. These materials release water vapor when heated, cooling the polymer and diluting combustible gases. While effective, they typically require high loading levels, which can lead to increased density and reduced flexibility of the final product.

A significant challenge in the field is the development of synergistic systems that can achieve high fire retardancy at lower additive concentrations. Researchers are exploring combinations of different flame retardants and nano-sized particles to create more efficient and cost-effective solutions. However, optimizing these complex formulations requires extensive testing and fine-tuning.

Another hurdle in FR PP technology is maintaining long-term stability and performance. Some flame retardants can migrate to the surface of the polymer over time, reducing their effectiveness and potentially causing environmental issues. Developing encapsulation techniques or chemically bonding flame retardants to the polymer matrix are areas of ongoing research to address this challenge.

The increasing demand for sustainable and recyclable materials presents an additional challenge for FR PP formulations. Many current flame retardants hinder the recycling process or degrade during multiple recycling cycles. This has spurred interest in developing more environmentally friendly and recyclable FR PP solutions, aligning with circular economy principles.

Existing Non-Toxic FR PP Solutions

01 Use of halogenated flame retardants

Halogenated compounds are commonly used as flame retardants in polypropylene. These additives work by releasing halogen radicals during combustion, which interfere with the flame propagation process. They are effective in reducing the flammability of polypropylene and improving its fire resistance properties.- Use of halogenated flame retardants: Halogenated compounds are commonly used as flame retardants in polypropylene. These additives work by releasing halogen radicals during combustion, which interfere with the flame propagation process. They are effective in reducing the flammability of polypropylene and improving its fire resistance properties.

- Incorporation of intumescent systems: Intumescent systems are multi-component flame retardant additives that form a protective char layer when exposed to heat. This char layer acts as a barrier, reducing heat transfer and oxygen diffusion to the polymer. Intumescent systems typically consist of an acid source, a carbonization agent, and a blowing agent, which work synergistically to improve the fire retardancy of polypropylene.

- Use of mineral-based flame retardants: Mineral-based flame retardants, such as metal hydroxides and borates, are used to enhance the fire retardancy of polypropylene. These additives work by releasing water or forming a protective layer when exposed to high temperatures. They are often preferred due to their low toxicity and environmentally friendly nature.

- Nanocomposite-based flame retardant systems: Nanocomposites, such as those incorporating clay or graphene, are used to improve the fire retardancy of polypropylene. These nanoparticles can enhance the formation of a protective char layer and reduce heat release rates. The use of nanocomposites can also improve other properties of polypropylene, such as mechanical strength and barrier properties.

- Synergistic flame retardant combinations: Combining different types of flame retardants can lead to synergistic effects, improving the overall fire retardancy of polypropylene. These combinations often include halogenated compounds with antimony trioxide, or phosphorus-based flame retardants with nitrogen-containing compounds. Synergistic systems can achieve better flame retardancy at lower additive loadings, minimizing the impact on other polymer properties.

02 Incorporation of intumescent systems

Intumescent systems are used to enhance the fire retardancy of polypropylene. These systems typically consist of an acid source, a carbon source, and a blowing agent. When exposed to heat, they form a carbonaceous char layer that insulates the underlying material and reduces heat transfer, thus improving fire resistance.Expand Specific Solutions03 Use of mineral-based flame retardants

Mineral-based flame retardants, such as metal hydroxides and borates, are incorporated into polypropylene to improve its fire resistance. These additives work by releasing water or forming a protective layer when exposed to heat, which helps to cool the material and inhibit combustion.Expand Specific Solutions04 Nanocomposite-based flame retardant systems

Nanocomposites, such as those incorporating clay or graphene, are used to enhance the fire retardancy of polypropylene. These materials can improve the thermal stability and barrier properties of the polymer, leading to reduced flammability and improved fire resistance performance.Expand Specific Solutions05 Synergistic flame retardant combinations

Combinations of different flame retardant additives are used to achieve synergistic effects in improving the fire retardancy of polypropylene. These combinations can enhance the overall performance of the flame retardant system, allowing for lower additive loadings while maintaining or improving fire resistance properties.Expand Specific Solutions

Key Players in FR PP Industry

The development of non-toxic fire-retardant polypropylene formulations is in a growth phase, with increasing market demand driven by stringent safety regulations and environmental concerns. The global market for flame retardant plastics is expanding, with a projected CAGR of 6.2% from 2021 to 2026. Technologically, the field is advancing rapidly, with companies like Borealis AG, Polyrocks Chemical Co., Ltd., and SABIC Global Technologies BV leading innovation. These firms are focusing on developing halogen-free solutions and improving the overall performance of fire-retardant polypropylene. The competitive landscape is diverse, with both established chemical companies and specialized manufacturers vying for market share, indicating a mature yet dynamic industry segment.

Borealis AG

Technical Solution: Borealis AG has developed a non-toxic fire-retardant polypropylene formulation using a novel halogen-free flame retardant system. Their approach combines mineral-based flame retardants with intumescent additives to create a synergistic effect. The formulation includes ammonium polyphosphate, pentaerythritol, and melamine as key components[1]. This combination forms a protective char layer when exposed to heat, effectively inhibiting flame spread. Borealis has also incorporated nano-sized particles of metal hydroxides to enhance the overall fire resistance without compromising the mechanical properties of the polypropylene[2]. The company has reported achieving UL94 V-0 ratings at thicknesses as low as 1.6 mm, demonstrating excellent flame retardancy[3].

Strengths: Halogen-free formulation addresses environmental concerns; Achieves high flame retardancy ratings; Maintains good mechanical properties. Weaknesses: Potential for higher cost due to specialized additives; May require fine-tuning for specific applications.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered a non-toxic fire-retardant polypropylene formulation utilizing a proprietary blend of organic phosphorus-based flame retardants and mineral fillers. Their approach focuses on creating a self-extinguishing polymer matrix that prevents sustained combustion. The company has developed a series of compounds under their STAMAX brand, which incorporate long glass fibers for enhanced mechanical strength alongside the flame-retardant additives[4]. SABIC's formulation achieves UL94 V-0 ratings at 1.5 mm thickness while maintaining over 80% of the original tensile strength of unfilled polypropylene[5]. Additionally, they have implemented a surface treatment technology for the mineral fillers to improve dispersion and bonding within the polymer matrix, resulting in better overall performance[6].

Strengths: High flame retardancy with minimal impact on mechanical properties; Versatile formulation suitable for various applications. Weaknesses: Potential for increased production complexity; May have limitations in extreme temperature applications.

Innovative FR Additives for PP

Polypropylene based formulations

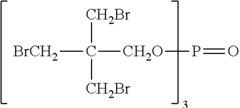

PatentActiveUS20130005880A1

Innovation

- A polypropylene composition comprising tris(tribromoneopentyl) phosphate and a carbon-carbon initiator, with minimal or no antimony trioxide, achieving UL 94 V-0 ratings by maintaining low concentrations of the flame retardant system, thereby preserving the polymer's physical attributes.

Flame retardant polypropylene composition comprising a biopolymer

PatentPendingUS20240352242A1

Innovation

- A flame retardant polypropylene composition comprising a propylene polymer, a nitrogen-containing flame retardant, and an antidripping-agent biopolymer with phenolic hydroxyl groups, specifically lignin, in a weight ratio that replaces fluoropolymers and ensures compliance with UL94 V0 rating without halogens.

Environmental Impact of FR PP

The environmental impact of fire-retardant polypropylene (FR PP) formulations is a critical consideration in the development and application of these materials. As the demand for flame-retardant plastics continues to grow, it is essential to assess the potential ecological consequences throughout their lifecycle.

FR PP formulations typically incorporate various additives to achieve desired fire-retardant properties. Historically, halogenated compounds were widely used due to their effectiveness. However, these substances have raised significant environmental concerns, particularly regarding their persistence in ecosystems and potential for bioaccumulation. This has led to a shift towards more environmentally friendly alternatives.

The production phase of FR PP can have notable environmental implications. The synthesis and incorporation of fire-retardant additives often require additional energy and resources compared to standard polypropylene manufacturing. This increased energy consumption contributes to higher carbon emissions and resource depletion. Moreover, the production of certain fire-retardant additives may involve the use of hazardous chemicals, posing potential risks to workers and local ecosystems if not properly managed.

During the use phase, FR PP products generally have a positive environmental impact by reducing the risk and severity of fires. This can lead to decreased property damage and lower emissions from potential fire incidents. However, the long-term stability of some fire-retardant additives remains a concern, as they may leach out of the polymer matrix over time, potentially contaminating surrounding environments.

End-of-life management of FR PP presents unique challenges. Recycling these materials can be complicated due to the presence of fire-retardant additives, which may interfere with standard recycling processes or degrade the quality of recycled materials. Incineration of FR PP waste can also be problematic, as it may release toxic substances if not conducted under controlled conditions. Landfilling, while sometimes necessary, raises concerns about long-term leaching of additives into soil and groundwater.

Recent research has focused on developing more sustainable FR PP formulations. This includes the use of bio-based fire retardants, which can reduce reliance on petrochemical-derived additives and potentially improve biodegradability. Additionally, efforts are being made to create FR PP composites that maintain their fire-retardant properties while being more amenable to recycling and safer disposal.

The environmental impact of FR PP extends beyond its immediate lifecycle. By improving fire safety in various applications, these materials contribute to reducing the overall environmental damage caused by fires. However, this benefit must be weighed against the potential long-term ecological effects of the additives used.

FR PP formulations typically incorporate various additives to achieve desired fire-retardant properties. Historically, halogenated compounds were widely used due to their effectiveness. However, these substances have raised significant environmental concerns, particularly regarding their persistence in ecosystems and potential for bioaccumulation. This has led to a shift towards more environmentally friendly alternatives.

The production phase of FR PP can have notable environmental implications. The synthesis and incorporation of fire-retardant additives often require additional energy and resources compared to standard polypropylene manufacturing. This increased energy consumption contributes to higher carbon emissions and resource depletion. Moreover, the production of certain fire-retardant additives may involve the use of hazardous chemicals, posing potential risks to workers and local ecosystems if not properly managed.

During the use phase, FR PP products generally have a positive environmental impact by reducing the risk and severity of fires. This can lead to decreased property damage and lower emissions from potential fire incidents. However, the long-term stability of some fire-retardant additives remains a concern, as they may leach out of the polymer matrix over time, potentially contaminating surrounding environments.

End-of-life management of FR PP presents unique challenges. Recycling these materials can be complicated due to the presence of fire-retardant additives, which may interfere with standard recycling processes or degrade the quality of recycled materials. Incineration of FR PP waste can also be problematic, as it may release toxic substances if not conducted under controlled conditions. Landfilling, while sometimes necessary, raises concerns about long-term leaching of additives into soil and groundwater.

Recent research has focused on developing more sustainable FR PP formulations. This includes the use of bio-based fire retardants, which can reduce reliance on petrochemical-derived additives and potentially improve biodegradability. Additionally, efforts are being made to create FR PP composites that maintain their fire-retardant properties while being more amenable to recycling and safer disposal.

The environmental impact of FR PP extends beyond its immediate lifecycle. By improving fire safety in various applications, these materials contribute to reducing the overall environmental damage caused by fires. However, this benefit must be weighed against the potential long-term ecological effects of the additives used.

Regulatory Framework for FR Materials

The regulatory framework for fire-retardant (FR) materials plays a crucial role in shaping the development and adoption of non-toxic fire-retardant polypropylene formulations. This framework encompasses a complex web of international, national, and industry-specific standards and regulations that govern the use, testing, and certification of FR materials.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for fire safety and testing methods. These standards, including ISO 4589 for oxygen index testing and IEC 60695 for fire hazard testing, provide a foundation for consistent evaluation of FR materials across borders.

In the United States, the Consumer Product Safety Commission (CPSC) enforces regulations such as 16 CFR Part 1633 for mattress flammability and the Flammable Fabrics Act. The National Fire Protection Association (NFPA) also develops codes and standards widely adopted by state and local jurisdictions. Of particular relevance is NFPA 701, which outlines test methods for flame-resistant textiles and films.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of certain flame retardants. Additionally, the Construction Products Regulation (CPR) sets requirements for construction materials, including their fire performance.

Industry-specific regulations further refine requirements for FR materials. In the automotive sector, FMVSS 302 in the US and ECE R118 in Europe dictate flammability standards for vehicle interiors. The aviation industry adheres to strict fire safety regulations, such as those outlined in FAR 25.853 for aircraft cabin materials.

Environmental concerns have led to the phasing out of certain halogenated flame retardants, driving the search for non-toxic alternatives. The Stockholm Convention on Persistent Organic Pollutants has been instrumental in restricting the use of some harmful FR chemicals globally.

Compliance with these regulations often requires extensive testing and certification processes. Underwriters Laboratories (UL) and other testing organizations provide standardized methods and certifications that are widely recognized in the industry.

As research into non-toxic fire-retardant polypropylene formulations progresses, developers must navigate this complex regulatory landscape. The challenge lies in creating formulations that not only meet stringent fire safety standards but also comply with evolving environmental and health regulations. This regulatory framework continues to evolve, with a growing emphasis on sustainability and human health, influencing the direction of future FR material development.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for fire safety and testing methods. These standards, including ISO 4589 for oxygen index testing and IEC 60695 for fire hazard testing, provide a foundation for consistent evaluation of FR materials across borders.

In the United States, the Consumer Product Safety Commission (CPSC) enforces regulations such as 16 CFR Part 1633 for mattress flammability and the Flammable Fabrics Act. The National Fire Protection Association (NFPA) also develops codes and standards widely adopted by state and local jurisdictions. Of particular relevance is NFPA 701, which outlines test methods for flame-resistant textiles and films.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of certain flame retardants. Additionally, the Construction Products Regulation (CPR) sets requirements for construction materials, including their fire performance.

Industry-specific regulations further refine requirements for FR materials. In the automotive sector, FMVSS 302 in the US and ECE R118 in Europe dictate flammability standards for vehicle interiors. The aviation industry adheres to strict fire safety regulations, such as those outlined in FAR 25.853 for aircraft cabin materials.

Environmental concerns have led to the phasing out of certain halogenated flame retardants, driving the search for non-toxic alternatives. The Stockholm Convention on Persistent Organic Pollutants has been instrumental in restricting the use of some harmful FR chemicals globally.

Compliance with these regulations often requires extensive testing and certification processes. Underwriters Laboratories (UL) and other testing organizations provide standardized methods and certifications that are widely recognized in the industry.

As research into non-toxic fire-retardant polypropylene formulations progresses, developers must navigate this complex regulatory landscape. The challenge lies in creating formulations that not only meet stringent fire safety standards but also comply with evolving environmental and health regulations. This regulatory framework continues to evolve, with a growing emphasis on sustainability and human health, influencing the direction of future FR material development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!