Investigating Polypropylene Capabilities in High-Temperature Transfer Hoses

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP High-Temp Hose Background and Objectives

Polypropylene (PP) has emerged as a versatile material in various industrial applications, including high-temperature transfer hoses. The evolution of PP in this field stems from the increasing demand for cost-effective, durable, and chemically resistant materials capable of withstanding elevated temperatures in fluid transfer systems.

The development of PP for high-temperature applications can be traced back to the 1950s when isotactic polypropylene was first synthesized. Since then, continuous advancements in polymer science and manufacturing techniques have significantly enhanced PP's thermal and mechanical properties, making it a viable option for high-temperature hoses.

In recent years, the focus has shifted towards improving PP's heat resistance and long-term durability under extreme conditions. This has led to the development of specialized PP grades and composite materials that can maintain their structural integrity and performance at temperatures exceeding 100°C, a crucial requirement for many industrial processes.

The primary objective of investigating PP capabilities in high-temperature transfer hoses is to push the boundaries of material performance and expand its applicability in challenging environments. Researchers and engineers aim to develop PP-based hoses that can compete with or surpass traditional materials like silicone, fluoropolymers, or metal in terms of temperature resistance, flexibility, and cost-effectiveness.

Key technical goals include enhancing PP's thermal stability, improving its resistance to thermal degradation, and maintaining mechanical properties at elevated temperatures. Additionally, there is a focus on developing PP formulations that exhibit excellent chemical resistance to a wide range of fluids, as high-temperature transfer hoses are often exposed to corrosive or aggressive media.

Another critical objective is to optimize the manufacturing processes for PP high-temperature hoses, ensuring consistent quality, reliability, and scalability. This involves refining extrusion techniques, exploring new additives and reinforcement materials, and developing innovative composite structures that leverage PP's inherent properties while addressing its limitations.

The investigation also aims to understand and mitigate the long-term effects of thermal cycling and prolonged exposure to high temperatures on PP hoses. This includes studying the material's creep behavior, thermal fatigue resistance, and potential changes in physical and chemical properties over time.

By achieving these objectives, the industry seeks to expand the use of PP in high-temperature transfer hose applications, potentially revolutionizing sectors such as automotive, chemical processing, and industrial manufacturing. The successful development of PP-based high-temperature hoses could lead to significant cost savings, improved energy efficiency, and enhanced safety in various industrial processes.

The development of PP for high-temperature applications can be traced back to the 1950s when isotactic polypropylene was first synthesized. Since then, continuous advancements in polymer science and manufacturing techniques have significantly enhanced PP's thermal and mechanical properties, making it a viable option for high-temperature hoses.

In recent years, the focus has shifted towards improving PP's heat resistance and long-term durability under extreme conditions. This has led to the development of specialized PP grades and composite materials that can maintain their structural integrity and performance at temperatures exceeding 100°C, a crucial requirement for many industrial processes.

The primary objective of investigating PP capabilities in high-temperature transfer hoses is to push the boundaries of material performance and expand its applicability in challenging environments. Researchers and engineers aim to develop PP-based hoses that can compete with or surpass traditional materials like silicone, fluoropolymers, or metal in terms of temperature resistance, flexibility, and cost-effectiveness.

Key technical goals include enhancing PP's thermal stability, improving its resistance to thermal degradation, and maintaining mechanical properties at elevated temperatures. Additionally, there is a focus on developing PP formulations that exhibit excellent chemical resistance to a wide range of fluids, as high-temperature transfer hoses are often exposed to corrosive or aggressive media.

Another critical objective is to optimize the manufacturing processes for PP high-temperature hoses, ensuring consistent quality, reliability, and scalability. This involves refining extrusion techniques, exploring new additives and reinforcement materials, and developing innovative composite structures that leverage PP's inherent properties while addressing its limitations.

The investigation also aims to understand and mitigate the long-term effects of thermal cycling and prolonged exposure to high temperatures on PP hoses. This includes studying the material's creep behavior, thermal fatigue resistance, and potential changes in physical and chemical properties over time.

By achieving these objectives, the industry seeks to expand the use of PP in high-temperature transfer hose applications, potentially revolutionizing sectors such as automotive, chemical processing, and industrial manufacturing. The successful development of PP-based high-temperature hoses could lead to significant cost savings, improved energy efficiency, and enhanced safety in various industrial processes.

Market Analysis for High-Temp Transfer Hoses

The market for high-temperature transfer hoses, particularly those utilizing polypropylene capabilities, has shown significant growth in recent years. This expansion is driven by increasing demand across various industries, including automotive, chemical processing, and manufacturing. The global market for high-temperature hoses is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong through the next five years.

Key factors contributing to market growth include the rising need for durable and heat-resistant materials in industrial applications, stringent safety regulations in chemical and petrochemical industries, and the automotive sector's push towards more efficient and lightweight components. Polypropylene-based high-temperature hoses are gaining traction due to their excellent balance of thermal resistance, chemical inertness, and cost-effectiveness.

In the automotive industry, the shift towards electric vehicles and the ongoing development of more efficient internal combustion engines have created new opportunities for high-temperature hose applications. These hoses are crucial for managing heat in battery systems and optimizing coolant circulation in advanced powertrains.

The chemical processing sector represents another significant market segment for high-temperature transfer hoses. As chemical manufacturers seek to improve process efficiency and safety, the demand for reliable, heat-resistant hose solutions continues to grow. Polypropylene's resistance to a wide range of chemicals makes it an attractive option for many applications in this field.

Geographically, North America and Europe currently lead the market for high-temperature transfer hoses, owing to their well-established industrial bases and stringent regulatory environments. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization in countries like China and India, and the expansion of automotive and manufacturing sectors.

Market challenges include the volatility of raw material prices, which can impact the cost-effectiveness of polypropylene-based solutions. Additionally, competition from alternative materials such as silicone and fluoropolymers poses a threat to market share. Manufacturers are responding by focusing on product innovation, seeking to enhance the temperature resistance and durability of polypropylene-based hoses while maintaining their cost advantage.

The market is characterized by a mix of large multinational corporations and specialized manufacturers. Key players are investing in research and development to improve product performance and expand their product portfolios. Strategic partnerships and acquisitions are becoming increasingly common as companies seek to strengthen their market positions and access new technologies.

Key factors contributing to market growth include the rising need for durable and heat-resistant materials in industrial applications, stringent safety regulations in chemical and petrochemical industries, and the automotive sector's push towards more efficient and lightweight components. Polypropylene-based high-temperature hoses are gaining traction due to their excellent balance of thermal resistance, chemical inertness, and cost-effectiveness.

In the automotive industry, the shift towards electric vehicles and the ongoing development of more efficient internal combustion engines have created new opportunities for high-temperature hose applications. These hoses are crucial for managing heat in battery systems and optimizing coolant circulation in advanced powertrains.

The chemical processing sector represents another significant market segment for high-temperature transfer hoses. As chemical manufacturers seek to improve process efficiency and safety, the demand for reliable, heat-resistant hose solutions continues to grow. Polypropylene's resistance to a wide range of chemicals makes it an attractive option for many applications in this field.

Geographically, North America and Europe currently lead the market for high-temperature transfer hoses, owing to their well-established industrial bases and stringent regulatory environments. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization in countries like China and India, and the expansion of automotive and manufacturing sectors.

Market challenges include the volatility of raw material prices, which can impact the cost-effectiveness of polypropylene-based solutions. Additionally, competition from alternative materials such as silicone and fluoropolymers poses a threat to market share. Manufacturers are responding by focusing on product innovation, seeking to enhance the temperature resistance and durability of polypropylene-based hoses while maintaining their cost advantage.

The market is characterized by a mix of large multinational corporations and specialized manufacturers. Key players are investing in research and development to improve product performance and expand their product portfolios. Strategic partnerships and acquisitions are becoming increasingly common as companies seek to strengthen their market positions and access new technologies.

PP Limitations in High-Temp Applications

Polypropylene (PP) has been widely used in various industrial applications due to its favorable properties such as low cost, chemical resistance, and ease of processing. However, when it comes to high-temperature transfer hoses, PP exhibits certain limitations that restrict its use in extreme thermal conditions.

One of the primary limitations of PP in high-temperature applications is its relatively low melting point, typically around 160-165°C. This characteristic makes PP unsuitable for continuous use in environments where temperatures exceed 120°C, as the material begins to soften and lose its structural integrity. In transfer hoses subjected to high temperatures, this can lead to deformation, leakage, or complete failure of the hose system.

Another significant limitation is PP's tendency to degrade when exposed to prolonged high temperatures. Thermal oxidation occurs more rapidly at elevated temperatures, causing the polymer chains to break down and leading to a loss of mechanical properties. This degradation process can result in embrittlement, reduced flexibility, and decreased overall performance of the hose over time.

PP also exhibits poor dimensional stability at high temperatures. As the material heats up, it undergoes thermal expansion, which can cause changes in the hose's dimensions and potentially compromise its sealing properties. This thermal expansion can lead to issues such as loosening of fittings, reduced flow capacity, or even separation of hose layers in multi-layer constructions.

The limited heat resistance of PP also affects its ability to maintain pressure ratings at elevated temperatures. As the temperature increases, the material's strength and stiffness decrease, reducing its capacity to withstand internal pressures. This limitation is particularly critical in high-pressure transfer applications where maintaining structural integrity is crucial for safety and performance.

Furthermore, PP's thermal conductivity is relatively low compared to other materials used in high-temperature applications. This property can lead to inefficient heat transfer in scenarios where rapid heating or cooling of the transferred medium is required. In some cases, this limitation may necessitate the use of thinner wall thicknesses or alternative materials to achieve desired thermal performance.

When considering long-term use in high-temperature environments, PP's creep resistance becomes a significant concern. Creep, the tendency of a material to deform permanently under constant stress, is accelerated at elevated temperatures. This can result in gradual deformation of the hose over time, potentially leading to premature failure or reduced service life.

In conclusion, while PP offers many advantages in various applications, its use in high-temperature transfer hoses is limited by its thermal properties. These limitations necessitate careful consideration of operating conditions and the exploration of alternative materials or composite solutions for applications requiring sustained high-temperature performance.

One of the primary limitations of PP in high-temperature applications is its relatively low melting point, typically around 160-165°C. This characteristic makes PP unsuitable for continuous use in environments where temperatures exceed 120°C, as the material begins to soften and lose its structural integrity. In transfer hoses subjected to high temperatures, this can lead to deformation, leakage, or complete failure of the hose system.

Another significant limitation is PP's tendency to degrade when exposed to prolonged high temperatures. Thermal oxidation occurs more rapidly at elevated temperatures, causing the polymer chains to break down and leading to a loss of mechanical properties. This degradation process can result in embrittlement, reduced flexibility, and decreased overall performance of the hose over time.

PP also exhibits poor dimensional stability at high temperatures. As the material heats up, it undergoes thermal expansion, which can cause changes in the hose's dimensions and potentially compromise its sealing properties. This thermal expansion can lead to issues such as loosening of fittings, reduced flow capacity, or even separation of hose layers in multi-layer constructions.

The limited heat resistance of PP also affects its ability to maintain pressure ratings at elevated temperatures. As the temperature increases, the material's strength and stiffness decrease, reducing its capacity to withstand internal pressures. This limitation is particularly critical in high-pressure transfer applications where maintaining structural integrity is crucial for safety and performance.

Furthermore, PP's thermal conductivity is relatively low compared to other materials used in high-temperature applications. This property can lead to inefficient heat transfer in scenarios where rapid heating or cooling of the transferred medium is required. In some cases, this limitation may necessitate the use of thinner wall thicknesses or alternative materials to achieve desired thermal performance.

When considering long-term use in high-temperature environments, PP's creep resistance becomes a significant concern. Creep, the tendency of a material to deform permanently under constant stress, is accelerated at elevated temperatures. This can result in gradual deformation of the hose over time, potentially leading to premature failure or reduced service life.

In conclusion, while PP offers many advantages in various applications, its use in high-temperature transfer hoses is limited by its thermal properties. These limitations necessitate careful consideration of operating conditions and the exploration of alternative materials or composite solutions for applications requiring sustained high-temperature performance.

Current PP High-Temp Hose Solutions

01 Improving temperature resistance of polypropylene

Various methods are employed to enhance the temperature resistance of polypropylene, including the use of additives, modification of the polymer structure, and blending with other materials. These techniques aim to increase the thermal stability and maintain the mechanical properties of polypropylene at elevated temperatures.- Improving temperature resistance of polypropylene: Various methods are employed to enhance the temperature resistance of polypropylene, including the use of additives, modification of the polymer structure, and blending with other materials. These techniques aim to increase the thermal stability and maintain the mechanical properties of polypropylene at elevated temperatures.

- Polypropylene composites for high-temperature applications: Polypropylene composites are developed by incorporating fillers, reinforcing agents, or other polymers to improve temperature resistance. These composites often exhibit enhanced thermal stability, mechanical strength, and dimensional stability at higher temperatures compared to pure polypropylene.

- Heat-resistant polypropylene grades: Specialized grades of polypropylene are developed with improved temperature resistance through modifications in the polymerization process or by using specific catalysts. These grades offer higher melting points, better creep resistance, and improved long-term thermal stability for applications requiring elevated temperature performance.

- Nucleating agents for enhancing thermal properties: Nucleating agents are incorporated into polypropylene to improve its crystallization behavior and overall temperature resistance. These additives can increase the crystallization temperature, enhance the degree of crystallinity, and improve the thermal and mechanical properties of polypropylene at elevated temperatures.

- Surface treatments for improved temperature resistance: Various surface treatment techniques are applied to polypropylene products to enhance their temperature resistance. These treatments can include plasma treatment, chemical modification, or the application of protective coatings, which can improve the thermal stability and performance of polypropylene in high-temperature environments.

02 Polypropylene composites for high-temperature applications

Polypropylene composites are developed by incorporating fillers, reinforcing agents, or other polymers to improve temperature resistance. These composites often exhibit enhanced thermal stability, mechanical strength, and dimensional stability at higher temperatures compared to pure polypropylene.Expand Specific Solutions03 Heat-resistant polypropylene grades

Specialized grades of polypropylene are developed with improved temperature resistance through modifications in the polymerization process or by using specific catalysts. These grades are designed to maintain their properties at higher temperatures and are suitable for applications requiring enhanced thermal stability.Expand Specific Solutions04 Surface treatments for improved temperature resistance

Various surface treatment techniques are applied to polypropylene to enhance its temperature resistance. These treatments may include plasma treatment, chemical modification, or coating with heat-resistant materials, resulting in improved thermal stability of the polymer surface.Expand Specific Solutions05 Testing and characterization of temperature-resistant polypropylene

Methods and equipment are developed for testing and characterizing the temperature resistance of polypropylene materials. These techniques help in evaluating the thermal stability, mechanical properties, and performance of polypropylene at elevated temperatures, ensuring its suitability for specific applications.Expand Specific Solutions

Key Players in PP High-Temp Hose Industry

The investigation into polypropylene capabilities for high-temperature transfer hoses reveals a competitive landscape in a mature market with steady growth. The global market size for industrial hoses is estimated to reach $16 billion by 2025, driven by increasing demand in various industries. Technologically, major players like DuPont, ExxonMobil, and SABIC are at the forefront, continuously improving polypropylene formulations for enhanced heat resistance and durability. Companies such as ContiTech Schlauch GmbH and Parker-Hannifin Corp. are leveraging these advancements to develop high-performance hoses for demanding applications. The industry is characterized by ongoing R&D efforts to push the temperature limits of polypropylene-based hoses, with a focus on maintaining flexibility and chemical resistance at elevated temperatures.

Borealis AG

Technical Solution: Borealis AG has developed advanced polypropylene (PP) compounds specifically designed for high-temperature transfer hoses. Their Bormed™ BJ868MO grade offers excellent heat resistance up to 150°C, making it suitable for automotive and industrial applications[1]. The material incorporates proprietary stabilization technology that enhances long-term thermal stability and prevents degradation under prolonged high-temperature exposure[2]. Additionally, Borealis has implemented a cross-linking process that further improves the material's temperature resistance and mechanical properties, allowing it to maintain structural integrity in demanding environments[3].

Strengths: Superior heat resistance, long-term thermal stability, and improved mechanical properties. Weaknesses: Potentially higher cost compared to standard PP grades, and may require specialized processing equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of high-performance polypropylene materials for high-temperature applications, including transfer hoses. Their Zytel® HTNFR52G30NH BK083 grade is a glass-fiber reinforced, flame-retardant polypropylene that can withstand continuous use temperatures up to 150°C[4]. The material features a unique blend of additives that enhance its thermal stability and chemical resistance, making it ideal for automotive and industrial fluid transfer systems[5]. DuPont has also implemented a proprietary processing technique that optimizes the crystalline structure of the polymer, resulting in improved dimensional stability at elevated temperatures[6].

Strengths: Excellent thermal and chemical resistance, flame-retardant properties, and dimensional stability. Weaknesses: Higher cost compared to standard PP grades, and potential limitations in flexibility for certain hose designs.

Innovations in PP for High-Temp Resistance

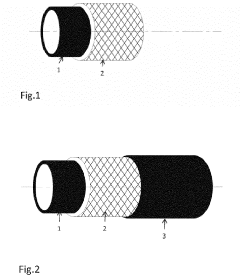

Transfer hose, in particular for use at high temperatures

PatentActiveEP2879865A2

Innovation

- A flexible hose with a cover made of at least 20% by weight polyphenylene sulfide (PPS) and/or polyoxadiazole (POD) and/or aramid (AR) and/or polyetheretherketone (PEEK) and/or polyethylene 2,6-naphthalate (PEN) with reinforcement materials like carbon or metal fibers, combined with suitable elastomers and thermoplastics, providing enhanced temperature resistance and flexibility.

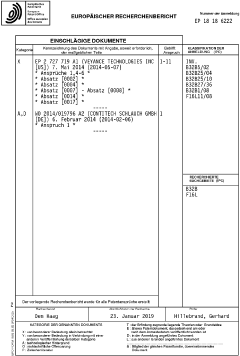

Long-term temperature resistant pes hose for temperatures up to 150°c

PatentActiveEP3482927A1

Innovation

- A transfer hose with an inner layer composed of at least 90% ethylene acrylate rubber (AEM) and/or hydrogenated nitrile rubber (HNBR) and/or acrylate rubber (ACM), combined with a cover layer made of at least 90% polyester (PES), which provides comparable temperature resistance to para-aramid hoses without the need for an additional elastomeric outer layer.

Material Safety and Regulatory Compliance

Material safety and regulatory compliance are critical aspects when considering polypropylene for high-temperature transfer hoses. Polypropylene, a thermoplastic polymer, has gained significant attention in various industrial applications due to its favorable properties. However, its use in high-temperature environments necessitates a thorough examination of safety considerations and adherence to regulatory standards.

From a safety perspective, polypropylene exhibits excellent chemical resistance, making it suitable for transferring a wide range of fluids without degradation or leaching of harmful substances. This characteristic is particularly important in industries such as food processing, pharmaceuticals, and chemical manufacturing, where product purity and contamination prevention are paramount. Additionally, polypropylene's low toxicity and inert nature contribute to its overall safety profile, reducing the risk of adverse health effects for workers and end-users.

Regulatory compliance for polypropylene in high-temperature transfer hoses encompasses various standards and certifications. In the United States, the Food and Drug Administration (FDA) has approved certain grades of polypropylene for food contact applications, provided they meet specific requirements outlined in 21 CFR 177.1520. Similarly, the European Union has established regulations under EU 10/2011 for plastic materials intended to come into contact with food. Manufacturers must ensure their polypropylene formulations comply with these standards when used in food-related applications.

For industrial applications, polypropylene hoses must often meet standards set by organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards typically cover aspects such as mechanical properties, thermal resistance, and chemical compatibility. For instance, ISO 15874 provides specifications for polypropylene piping systems for hot and cold water installations.

When considering high-temperature applications, it is crucial to evaluate the thermal stability of polypropylene. While standard polypropylene has a relatively low melting point (around 160°C), advanced formulations and copolymers have been developed to enhance its heat resistance. Manufacturers must provide detailed temperature ratings and performance data to ensure compliance with safety regulations and industry standards for high-temperature operations.

Environmental regulations also play a role in the use of polypropylene for transfer hoses. The material's recyclability aligns with sustainability initiatives and circular economy principles. However, manufacturers must consider end-of-life disposal and recycling processes to comply with waste management regulations in various jurisdictions.

In conclusion, while polypropylene offers numerous advantages for high-temperature transfer hoses, its implementation requires careful consideration of material safety and regulatory compliance. Manufacturers and end-users must stay informed about relevant standards, conduct thorough testing, and maintain proper documentation to ensure safe and compliant use of polypropylene in demanding industrial applications.

From a safety perspective, polypropylene exhibits excellent chemical resistance, making it suitable for transferring a wide range of fluids without degradation or leaching of harmful substances. This characteristic is particularly important in industries such as food processing, pharmaceuticals, and chemical manufacturing, where product purity and contamination prevention are paramount. Additionally, polypropylene's low toxicity and inert nature contribute to its overall safety profile, reducing the risk of adverse health effects for workers and end-users.

Regulatory compliance for polypropylene in high-temperature transfer hoses encompasses various standards and certifications. In the United States, the Food and Drug Administration (FDA) has approved certain grades of polypropylene for food contact applications, provided they meet specific requirements outlined in 21 CFR 177.1520. Similarly, the European Union has established regulations under EU 10/2011 for plastic materials intended to come into contact with food. Manufacturers must ensure their polypropylene formulations comply with these standards when used in food-related applications.

For industrial applications, polypropylene hoses must often meet standards set by organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards typically cover aspects such as mechanical properties, thermal resistance, and chemical compatibility. For instance, ISO 15874 provides specifications for polypropylene piping systems for hot and cold water installations.

When considering high-temperature applications, it is crucial to evaluate the thermal stability of polypropylene. While standard polypropylene has a relatively low melting point (around 160°C), advanced formulations and copolymers have been developed to enhance its heat resistance. Manufacturers must provide detailed temperature ratings and performance data to ensure compliance with safety regulations and industry standards for high-temperature operations.

Environmental regulations also play a role in the use of polypropylene for transfer hoses. The material's recyclability aligns with sustainability initiatives and circular economy principles. However, manufacturers must consider end-of-life disposal and recycling processes to comply with waste management regulations in various jurisdictions.

In conclusion, while polypropylene offers numerous advantages for high-temperature transfer hoses, its implementation requires careful consideration of material safety and regulatory compliance. Manufacturers and end-users must stay informed about relevant standards, conduct thorough testing, and maintain proper documentation to ensure safe and compliant use of polypropylene in demanding industrial applications.

Environmental Impact of PP High-Temp Hoses

The environmental impact of polypropylene (PP) high-temperature transfer hoses is a critical consideration in their application and lifecycle assessment. These hoses, while offering significant advantages in terms of heat resistance and durability, also present certain environmental challenges that warrant careful examination.

One of the primary environmental concerns associated with PP high-temp hoses is their production process. The manufacturing of polypropylene involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. However, compared to alternative materials used in high-temperature applications, PP often requires less energy-intensive production methods, potentially offsetting some of its environmental impact.

The durability and longevity of PP high-temp hoses play a crucial role in their environmental footprint. These hoses typically exhibit excellent resistance to wear, corrosion, and chemical degradation, leading to extended service life. This longevity reduces the frequency of replacement, thereby minimizing waste generation and the need for additional resource consumption in manufacturing replacement hoses.

End-of-life considerations for PP high-temp hoses are another significant aspect of their environmental impact. While polypropylene is recyclable, the specialized nature of these hoses, often incorporating multiple materials and additives, can complicate the recycling process. Proper disposal and recycling infrastructure are essential to mitigate potential environmental harm and maximize material recovery.

The use phase of PP high-temp hoses also contributes to their environmental profile. These hoses often facilitate more efficient heat transfer processes in industrial applications, potentially leading to energy savings and reduced emissions in the systems where they are employed. This operational efficiency can partially offset the environmental costs associated with their production and disposal.

Leaching and degradation of PP high-temp hoses under extreme conditions is an area of environmental concern. While polypropylene is generally considered chemically stable, prolonged exposure to high temperatures and aggressive substances may lead to the release of microplastics or other degradation products into the environment. This risk necessitates ongoing research into the long-term environmental behavior of these materials under various operational conditions.

Advancements in PP formulations and manufacturing techniques are continually improving the environmental performance of high-temp hoses. Innovations in bio-based polypropylene and the incorporation of recycled content are promising directions for reducing the environmental footprint of these products. Additionally, the development of more easily recyclable designs and improved end-of-life management strategies are key areas of focus in enhancing the overall sustainability of PP high-temp hoses.

One of the primary environmental concerns associated with PP high-temp hoses is their production process. The manufacturing of polypropylene involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. However, compared to alternative materials used in high-temperature applications, PP often requires less energy-intensive production methods, potentially offsetting some of its environmental impact.

The durability and longevity of PP high-temp hoses play a crucial role in their environmental footprint. These hoses typically exhibit excellent resistance to wear, corrosion, and chemical degradation, leading to extended service life. This longevity reduces the frequency of replacement, thereby minimizing waste generation and the need for additional resource consumption in manufacturing replacement hoses.

End-of-life considerations for PP high-temp hoses are another significant aspect of their environmental impact. While polypropylene is recyclable, the specialized nature of these hoses, often incorporating multiple materials and additives, can complicate the recycling process. Proper disposal and recycling infrastructure are essential to mitigate potential environmental harm and maximize material recovery.

The use phase of PP high-temp hoses also contributes to their environmental profile. These hoses often facilitate more efficient heat transfer processes in industrial applications, potentially leading to energy savings and reduced emissions in the systems where they are employed. This operational efficiency can partially offset the environmental costs associated with their production and disposal.

Leaching and degradation of PP high-temp hoses under extreme conditions is an area of environmental concern. While polypropylene is generally considered chemically stable, prolonged exposure to high temperatures and aggressive substances may lead to the release of microplastics or other degradation products into the environment. This risk necessitates ongoing research into the long-term environmental behavior of these materials under various operational conditions.

Advancements in PP formulations and manufacturing techniques are continually improving the environmental performance of high-temp hoses. Innovations in bio-based polypropylene and the incorporation of recycled content are promising directions for reducing the environmental footprint of these products. Additionally, the development of more easily recyclable designs and improved end-of-life management strategies are key areas of focus in enhancing the overall sustainability of PP high-temp hoses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!