Isocyanate Technology: Maximizing Efficiency in Use

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanate technology has undergone significant evolution since its inception in the early 20th century. The journey began with Otto Bayer's groundbreaking discovery of polyurethane in 1937, which laid the foundation for isocyanate chemistry. This innovation sparked a revolution in materials science, leading to the development of versatile polymers with wide-ranging applications.

In the 1950s and 1960s, the focus shifted towards improving the synthesis and production of isocyanates. Researchers developed more efficient methods for producing key isocyanates such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These advancements paved the way for large-scale industrial production, making isocyanates more accessible and cost-effective.

The 1970s and 1980s saw a surge in research aimed at enhancing the performance and versatility of isocyanate-based products. Scientists explored new formulations and additives to improve properties such as durability, flexibility, and fire resistance. This period also witnessed the development of specialized isocyanates for niche applications, including automotive coatings and high-performance adhesives.

Environmental concerns in the 1990s and early 2000s led to a paradigm shift in isocyanate technology. The industry focused on developing low-VOC (volatile organic compound) and water-based systems to reduce environmental impact. Researchers also explored bio-based isocyanates derived from renewable resources, aligning with the growing demand for sustainable materials.

In recent years, the evolution of isocyanate technology has been driven by the need for increased efficiency and sustainability. Advanced catalysts and processing techniques have been developed to optimize reaction kinetics and reduce energy consumption. Additionally, there has been a growing emphasis on improving worker safety through the development of low-emission formulations and enhanced personal protective equipment.

The digital age has also influenced isocyanate evolution, with the integration of smart manufacturing technologies and data analytics. These advancements have enabled more precise control over production processes, leading to improved product consistency and quality. Furthermore, computational modeling and simulation tools have accelerated the development of new isocyanate-based materials by allowing researchers to predict properties and optimize formulations virtually.

Looking ahead, the future of isocyanate technology is likely to focus on further enhancing sustainability and efficiency. This may include the development of fully recyclable isocyanate-based materials, as well as the exploration of novel chemistries that could potentially replace traditional isocyanates while maintaining their desirable properties. The ongoing pursuit of maximizing efficiency in isocyanate use will continue to drive innovation in this dynamic field.

In the 1950s and 1960s, the focus shifted towards improving the synthesis and production of isocyanates. Researchers developed more efficient methods for producing key isocyanates such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These advancements paved the way for large-scale industrial production, making isocyanates more accessible and cost-effective.

The 1970s and 1980s saw a surge in research aimed at enhancing the performance and versatility of isocyanate-based products. Scientists explored new formulations and additives to improve properties such as durability, flexibility, and fire resistance. This period also witnessed the development of specialized isocyanates for niche applications, including automotive coatings and high-performance adhesives.

Environmental concerns in the 1990s and early 2000s led to a paradigm shift in isocyanate technology. The industry focused on developing low-VOC (volatile organic compound) and water-based systems to reduce environmental impact. Researchers also explored bio-based isocyanates derived from renewable resources, aligning with the growing demand for sustainable materials.

In recent years, the evolution of isocyanate technology has been driven by the need for increased efficiency and sustainability. Advanced catalysts and processing techniques have been developed to optimize reaction kinetics and reduce energy consumption. Additionally, there has been a growing emphasis on improving worker safety through the development of low-emission formulations and enhanced personal protective equipment.

The digital age has also influenced isocyanate evolution, with the integration of smart manufacturing technologies and data analytics. These advancements have enabled more precise control over production processes, leading to improved product consistency and quality. Furthermore, computational modeling and simulation tools have accelerated the development of new isocyanate-based materials by allowing researchers to predict properties and optimize formulations virtually.

Looking ahead, the future of isocyanate technology is likely to focus on further enhancing sustainability and efficiency. This may include the development of fully recyclable isocyanate-based materials, as well as the exploration of novel chemistries that could potentially replace traditional isocyanates while maintaining their desirable properties. The ongoing pursuit of maximizing efficiency in isocyanate use will continue to drive innovation in this dynamic field.

Market Demand Analysis

The global market for isocyanates has been experiencing steady growth, driven by increasing demand across various industries. The construction sector, particularly in emerging economies, has been a significant contributor to this growth. Isocyanates are widely used in the production of polyurethane foams, which find extensive applications in insulation materials for buildings. As energy efficiency regulations become more stringent worldwide, the demand for high-performance insulation materials continues to rise, boosting the isocyanate market.

The automotive industry represents another major consumer of isocyanates. With the growing emphasis on lightweight vehicles to improve fuel efficiency and reduce emissions, automakers are increasingly turning to polyurethane-based components. This trend is expected to persist, especially with the rise of electric vehicles, where weight reduction is crucial for extending battery range.

In the furniture and bedding industry, isocyanates are essential in the production of flexible foams for mattresses, cushions, and upholstery. The growing middle class in developing countries, coupled with changing lifestyles and increased disposable income, has led to a surge in demand for furniture and bedding products, indirectly driving the isocyanate market.

The packaging industry has also emerged as a significant consumer of isocyanates, particularly in the production of rigid polyurethane foams for insulation in refrigerated transport and cold storage facilities. As global trade in perishable goods expands, the demand for efficient temperature-controlled packaging solutions is expected to grow, further fueling the isocyanate market.

However, the market faces challenges related to environmental and health concerns associated with certain isocyanates. Regulatory bodies in various countries have imposed strict guidelines on the use and handling of these chemicals, which could potentially impact market growth. This has led to increased research and development efforts focused on developing more environmentally friendly and safer alternatives.

Despite these challenges, the overall market outlook for isocyanates remains positive. The global push towards sustainability and energy efficiency across industries is likely to continue driving demand for isocyanate-based products. Additionally, ongoing technological advancements in isocyanate production and application techniques are expected to open up new market opportunities and improve overall efficiency in use.

The automotive industry represents another major consumer of isocyanates. With the growing emphasis on lightweight vehicles to improve fuel efficiency and reduce emissions, automakers are increasingly turning to polyurethane-based components. This trend is expected to persist, especially with the rise of electric vehicles, where weight reduction is crucial for extending battery range.

In the furniture and bedding industry, isocyanates are essential in the production of flexible foams for mattresses, cushions, and upholstery. The growing middle class in developing countries, coupled with changing lifestyles and increased disposable income, has led to a surge in demand for furniture and bedding products, indirectly driving the isocyanate market.

The packaging industry has also emerged as a significant consumer of isocyanates, particularly in the production of rigid polyurethane foams for insulation in refrigerated transport and cold storage facilities. As global trade in perishable goods expands, the demand for efficient temperature-controlled packaging solutions is expected to grow, further fueling the isocyanate market.

However, the market faces challenges related to environmental and health concerns associated with certain isocyanates. Regulatory bodies in various countries have imposed strict guidelines on the use and handling of these chemicals, which could potentially impact market growth. This has led to increased research and development efforts focused on developing more environmentally friendly and safer alternatives.

Despite these challenges, the overall market outlook for isocyanates remains positive. The global push towards sustainability and energy efficiency across industries is likely to continue driving demand for isocyanate-based products. Additionally, ongoing technological advancements in isocyanate production and application techniques are expected to open up new market opportunities and improve overall efficiency in use.

Technical Challenges

Isocyanate technology, while widely used in various industries, faces several significant technical challenges that hinder its efficiency and broader adoption. One of the primary issues is the high reactivity of isocyanates, which can lead to uncontrolled reactions and reduced product quality. This reactivity also poses safety concerns for workers and necessitates stringent handling procedures, increasing production costs and complexity.

Another major challenge is the environmental impact of isocyanate production and use. Traditional manufacturing processes often involve the use of phosgene, a highly toxic substance, which raises environmental and safety concerns. The industry is under pressure to develop greener, more sustainable production methods that reduce or eliminate the need for hazardous materials.

The sensitivity of isocyanates to moisture presents another significant hurdle. Even trace amounts of water can trigger unwanted side reactions, leading to foam formation, reduced product performance, and increased waste. This sensitivity necessitates careful control of environmental conditions during storage, handling, and application, adding to the overall complexity and cost of isocyanate-based processes.

Achieving consistent product quality is an ongoing challenge in isocyanate technology. Variations in raw materials, reaction conditions, and processing parameters can significantly impact the final product properties. This variability makes it difficult to maintain uniform quality across different batches, especially in large-scale production settings.

The development of bio-based alternatives to petroleum-derived isocyanates is an area of intense research but faces technical hurdles. While promising, these bio-based options often struggle to match the performance characteristics of traditional isocyanates, particularly in terms of reactivity, stability, and end-product properties.

Isocyanate emissions during application and curing processes pose both health and environmental concerns. Developing effective emission control technologies and low-VOC (volatile organic compound) formulations remains a significant challenge for the industry, particularly in sectors like automotive coatings and construction adhesives.

Lastly, the optimization of isocyanate-based formulations for specific applications presents ongoing challenges. Balancing factors such as cure time, strength, flexibility, and durability often requires complex formulation adjustments and extensive testing, making it difficult to rapidly develop new products or adapt existing ones to changing market demands.

Another major challenge is the environmental impact of isocyanate production and use. Traditional manufacturing processes often involve the use of phosgene, a highly toxic substance, which raises environmental and safety concerns. The industry is under pressure to develop greener, more sustainable production methods that reduce or eliminate the need for hazardous materials.

The sensitivity of isocyanates to moisture presents another significant hurdle. Even trace amounts of water can trigger unwanted side reactions, leading to foam formation, reduced product performance, and increased waste. This sensitivity necessitates careful control of environmental conditions during storage, handling, and application, adding to the overall complexity and cost of isocyanate-based processes.

Achieving consistent product quality is an ongoing challenge in isocyanate technology. Variations in raw materials, reaction conditions, and processing parameters can significantly impact the final product properties. This variability makes it difficult to maintain uniform quality across different batches, especially in large-scale production settings.

The development of bio-based alternatives to petroleum-derived isocyanates is an area of intense research but faces technical hurdles. While promising, these bio-based options often struggle to match the performance characteristics of traditional isocyanates, particularly in terms of reactivity, stability, and end-product properties.

Isocyanate emissions during application and curing processes pose both health and environmental concerns. Developing effective emission control technologies and low-VOC (volatile organic compound) formulations remains a significant challenge for the industry, particularly in sectors like automotive coatings and construction adhesives.

Lastly, the optimization of isocyanate-based formulations for specific applications presents ongoing challenges. Balancing factors such as cure time, strength, flexibility, and durability often requires complex formulation adjustments and extensive testing, making it difficult to rapidly develop new products or adapt existing ones to changing market demands.

Current Solutions

01 Catalyst optimization for isocyanate reactions

Improving isocyanate efficiency through the use of optimized catalysts. This involves selecting and developing catalysts that enhance reaction rates, selectivity, and yield in isocyanate-based processes. Optimized catalysts can lead to faster reaction times, reduced side reactions, and improved overall efficiency in the production of polyurethanes and other isocyanate-derived materials.- Catalyst optimization for isocyanate reactions: Improving isocyanate efficiency through the use of optimized catalysts. This involves selecting and developing catalysts that enhance reaction rates, selectivity, and yield in isocyanate-based processes. Optimized catalysts can lead to reduced reaction times, lower energy consumption, and improved product quality.

- Isocyanate formulation and blending techniques: Enhancing isocyanate efficiency through advanced formulation and blending techniques. This includes optimizing the ratio of different isocyanates, incorporating additives, and developing novel blending methods to improve reactivity, stability, and overall performance of isocyanate-based products.

- Process optimization for isocyanate production: Improving isocyanate efficiency through process optimization in manufacturing. This involves refining reaction conditions, implementing advanced process control systems, and developing innovative reactor designs to enhance yield, reduce waste, and improve energy efficiency in isocyanate production.

- Isocyanate modification for enhanced reactivity: Increasing isocyanate efficiency by modifying the chemical structure or properties of isocyanates. This includes developing new isocyanate derivatives, incorporating functional groups, or creating hybrid isocyanate systems to improve reactivity, selectivity, and overall performance in various applications.

- Recycling and recovery of isocyanates: Enhancing isocyanate efficiency through improved recycling and recovery methods. This involves developing techniques for reclaiming unreacted isocyanates, purifying recovered materials, and reintegrating them into production processes, thereby reducing waste and improving overall resource utilization.

02 Isocyanate formulation and blending techniques

Enhancing isocyanate efficiency through advanced formulation and blending techniques. This includes developing optimal mixtures of different isocyanates, adjusting ratios of components, and incorporating additives to improve reactivity and performance. These techniques can lead to improved product properties, reduced material consumption, and increased overall efficiency in isocyanate-based applications.Expand Specific Solutions03 Process optimization for isocyanate production

Improving efficiency in isocyanate production through process optimization. This involves refining reaction conditions, developing new synthesis routes, and implementing advanced process control strategies. Optimized processes can lead to higher yields, reduced energy consumption, and improved product quality in the manufacture of isocyanates.Expand Specific Solutions04 Isocyanate recovery and recycling methods

Enhancing isocyanate efficiency through the development of recovery and recycling methods. This includes techniques for capturing and purifying unreacted isocyanates from process streams, as well as methods for regenerating and reusing isocyanate-based materials. These approaches can lead to reduced waste, improved resource utilization, and increased overall efficiency in isocyanate-based industries.Expand Specific Solutions05 Novel isocyanate chemistries and applications

Improving isocyanate efficiency through the development of novel chemistries and applications. This involves exploring new isocyanate structures, investigating alternative reaction pathways, and identifying innovative uses for isocyanate-based materials. These advancements can lead to improved performance, expanded application areas, and increased overall efficiency in the utilization of isocyanates.Expand Specific Solutions

Industry Leaders

The isocyanate technology market is in a mature growth stage, with a global market size estimated to exceed $30 billion by 2025. Major players like Covestro, BASF, Wanhua Chemical, and Mitsui Chemicals dominate the industry, leveraging their extensive R&D capabilities and production capacities. The technology's maturity is evident in its widespread application across various sectors, including automotive, construction, and electronics. However, ongoing innovation focuses on improving efficiency, sustainability, and developing bio-based alternatives. Emerging companies and research institutions are also contributing to advancements in isocyanate technology, driving competition and fostering new applications in niche markets.

Covestro Deutschland AG

Technical Solution: Covestro has developed a novel gas-phase technology for isocyanate production, which significantly improves efficiency and reduces environmental impact. This process utilizes a gas-phase reaction instead of traditional liquid-phase methods, resulting in up to 60% energy savings and 80% reduction in solvent use[1]. The technology also incorporates advanced catalysts and reactor designs, enabling higher yields and improved product quality. Covestro's approach includes real-time monitoring and control systems to optimize reaction conditions, further enhancing efficiency and consistency in isocyanate production[2].

Strengths: Significant energy and solvent reduction, higher yields, and improved product quality. Weaknesses: May require substantial initial investment for implementation and potential challenges in scaling up the technology for large-scale production.

BASF Corp.

Technical Solution: BASF has developed an innovative continuous flow technology for isocyanate production, which offers improved efficiency and sustainability. This process utilizes microreactor technology, allowing for precise control of reaction conditions and enhanced heat transfer. The continuous flow approach enables a 30% reduction in energy consumption and a 50% decrease in solvent usage compared to traditional batch processes[3]. BASF's technology also incorporates in-line analytics and advanced process control systems, ensuring consistent product quality and enabling real-time optimization of reaction parameters[4].

Strengths: Improved process control, reduced energy and solvent consumption, and enhanced product consistency. Weaknesses: May require significant modifications to existing production facilities and potential challenges in handling high-viscosity materials in continuous flow systems.

Key Innovations

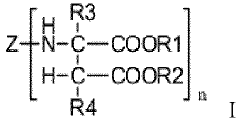

Polyether-modified polyisocyanate composition

PatentInactiveEP3988596A1

Innovation

- A polyether-modified polyisocyanate composition is developed by reacting a polyisocyanate with a polyoxyalkylene monoether alcohol, having a specific molecular weight and oxypropylene content, to achieve a balanced isocyanate functionality and content, which is used as a crosslinking agent in coatings, improving working time and drying efficiency while maintaining high hardness.

Process for preparing isocyanates

PatentWO2013029918A1

Innovation

- Increasing the ratio of phosgene to amine and/or the concentration of inert substances in the reactant streams when operating below nominal capacity, using static mixing elements and adjusting the flow rates to maintain optimized mixing and residence times, allowing for continuous operation at reduced capacity without compromising product quality.

Environmental Impact

The environmental impact of isocyanate technology is a critical consideration in its application and development. Isocyanates, while highly versatile and widely used in various industries, pose significant environmental challenges that require careful management and mitigation strategies.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During production and application processes, volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) can be released into the atmosphere. These emissions contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human health. To address this issue, many manufacturers have implemented advanced emission control technologies and improved production processes to minimize the release of harmful substances.

Water pollution is another significant environmental risk associated with isocyanate technology. Improper disposal of isocyanate-containing waste or accidental spills can lead to contamination of water bodies. Once in aquatic ecosystems, isocyanates can react with water to form potentially toxic compounds, affecting marine life and water quality. To mitigate this risk, strict waste management protocols and spill prevention measures are essential in facilities handling isocyanates.

The production of isocyanates also raises concerns about resource consumption and energy efficiency. The manufacturing process typically requires significant energy inputs and relies on petrochemical feedstocks. This dependence on non-renewable resources contributes to the overall carbon footprint of isocyanate-based products. In response, there is a growing focus on developing more sustainable production methods, including the use of bio-based raw materials and energy-efficient manufacturing processes.

End-of-life considerations for isocyanate-containing products present another environmental challenge. Many products, such as polyurethane foams and coatings, are not easily recyclable due to their complex chemical composition. This leads to increased waste generation and potential environmental contamination when these products are disposed of in landfills. To address this issue, researchers are exploring innovative recycling technologies and developing more environmentally friendly alternatives to traditional isocyanate-based materials.

Despite these challenges, the isocyanate industry has made significant strides in improving its environmental performance. Many companies have adopted green chemistry principles, focusing on reducing waste, improving energy efficiency, and developing safer alternatives. Additionally, regulatory frameworks such as REACH in the European Union have driven improvements in the management of isocyanates throughout their lifecycle, from production to disposal.

As the demand for sustainable solutions grows, the isocyanate industry continues to invest in research and development aimed at minimizing environmental impacts. This includes exploring novel catalysts to reduce energy requirements, developing water-based formulations to decrease VOC emissions, and investigating bio-based isocyanates as alternatives to petrochemical-derived products. These efforts demonstrate the industry's commitment to balancing technological advancement with environmental stewardship.

One of the primary environmental concerns associated with isocyanates is their potential for air pollution. During production and application processes, volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) can be released into the atmosphere. These emissions contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human health. To address this issue, many manufacturers have implemented advanced emission control technologies and improved production processes to minimize the release of harmful substances.

Water pollution is another significant environmental risk associated with isocyanate technology. Improper disposal of isocyanate-containing waste or accidental spills can lead to contamination of water bodies. Once in aquatic ecosystems, isocyanates can react with water to form potentially toxic compounds, affecting marine life and water quality. To mitigate this risk, strict waste management protocols and spill prevention measures are essential in facilities handling isocyanates.

The production of isocyanates also raises concerns about resource consumption and energy efficiency. The manufacturing process typically requires significant energy inputs and relies on petrochemical feedstocks. This dependence on non-renewable resources contributes to the overall carbon footprint of isocyanate-based products. In response, there is a growing focus on developing more sustainable production methods, including the use of bio-based raw materials and energy-efficient manufacturing processes.

End-of-life considerations for isocyanate-containing products present another environmental challenge. Many products, such as polyurethane foams and coatings, are not easily recyclable due to their complex chemical composition. This leads to increased waste generation and potential environmental contamination when these products are disposed of in landfills. To address this issue, researchers are exploring innovative recycling technologies and developing more environmentally friendly alternatives to traditional isocyanate-based materials.

Despite these challenges, the isocyanate industry has made significant strides in improving its environmental performance. Many companies have adopted green chemistry principles, focusing on reducing waste, improving energy efficiency, and developing safer alternatives. Additionally, regulatory frameworks such as REACH in the European Union have driven improvements in the management of isocyanates throughout their lifecycle, from production to disposal.

As the demand for sustainable solutions grows, the isocyanate industry continues to invest in research and development aimed at minimizing environmental impacts. This includes exploring novel catalysts to reduce energy requirements, developing water-based formulations to decrease VOC emissions, and investigating bio-based isocyanates as alternatives to petrochemical-derived products. These efforts demonstrate the industry's commitment to balancing technological advancement with environmental stewardship.

Safety Regulations

Safety regulations play a crucial role in the use and handling of isocyanates, given their potential health and environmental risks. The Occupational Safety and Health Administration (OSHA) in the United States has established stringent guidelines for isocyanate exposure limits in the workplace. These regulations typically set permissible exposure limits (PELs) for different types of isocyanates, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI).

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety information, including exposure scenarios and risk management measures. The regulation also mandates the substitution of substances of very high concern (SVHCs) with safer alternatives when possible.

Personal protective equipment (PPE) is a critical component of isocyanate safety regulations. Workers handling isocyanates are required to wear appropriate respiratory protection, such as air-purifying respirators or supplied-air respirators, depending on the concentration and type of isocyanate. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact.

Ventilation requirements are another key aspect of isocyanate safety regulations. Local exhaust ventilation systems must be installed in areas where isocyanates are used or processed to minimize airborne concentrations. Regular air monitoring is often required to ensure that exposure levels remain below established limits.

Training and education are essential components of isocyanate safety regulations. Workers must receive comprehensive training on the hazards associated with isocyanates, proper handling procedures, emergency response protocols, and the correct use of PPE. Many jurisdictions require employers to maintain detailed records of employee training and exposure monitoring.

Storage and transportation of isocyanates are subject to specific regulations to prevent accidental releases and ensure safe handling. These include requirements for proper labeling, segregation from incompatible materials, and the use of appropriate containment systems. In the United States, the Department of Transportation (DOT) classifies many isocyanates as hazardous materials, subjecting them to special packaging and shipping requirements.

Environmental regulations also govern the use and disposal of isocyanates. Many countries have implemented strict controls on isocyanate emissions to air and water, requiring companies to implement pollution control technologies and monitor their environmental impact. Proper disposal of isocyanate-containing waste is regulated to prevent contamination of soil and groundwater.

As the industry continues to seek ways to maximize efficiency in isocyanate use, compliance with evolving safety regulations remains a critical challenge. Companies must stay informed about regulatory changes and invest in technologies and practices that not only improve efficiency but also enhance safety and environmental protection.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety information, including exposure scenarios and risk management measures. The regulation also mandates the substitution of substances of very high concern (SVHCs) with safer alternatives when possible.

Personal protective equipment (PPE) is a critical component of isocyanate safety regulations. Workers handling isocyanates are required to wear appropriate respiratory protection, such as air-purifying respirators or supplied-air respirators, depending on the concentration and type of isocyanate. Impervious gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact.

Ventilation requirements are another key aspect of isocyanate safety regulations. Local exhaust ventilation systems must be installed in areas where isocyanates are used or processed to minimize airborne concentrations. Regular air monitoring is often required to ensure that exposure levels remain below established limits.

Training and education are essential components of isocyanate safety regulations. Workers must receive comprehensive training on the hazards associated with isocyanates, proper handling procedures, emergency response protocols, and the correct use of PPE. Many jurisdictions require employers to maintain detailed records of employee training and exposure monitoring.

Storage and transportation of isocyanates are subject to specific regulations to prevent accidental releases and ensure safe handling. These include requirements for proper labeling, segregation from incompatible materials, and the use of appropriate containment systems. In the United States, the Department of Transportation (DOT) classifies many isocyanates as hazardous materials, subjecting them to special packaging and shipping requirements.

Environmental regulations also govern the use and disposal of isocyanates. Many countries have implemented strict controls on isocyanate emissions to air and water, requiring companies to implement pollution control technologies and monitor their environmental impact. Proper disposal of isocyanate-containing waste is regulated to prevent contamination of soil and groundwater.

As the industry continues to seek ways to maximize efficiency in isocyanate use, compliance with evolving safety regulations remains a critical challenge. Companies must stay informed about regulatory changes and invest in technologies and practices that not only improve efficiency but also enhance safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!