Lifecycle Recycling and Sustainability of Calcium Ion Batteries

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calcium Ion Battery Technology Background and Objectives

Calcium ion batteries (CIBs) have emerged as a promising alternative to lithium-ion batteries in recent years, driven by the increasing global demand for energy storage solutions and concerns about the sustainability of lithium resources. The development of CIBs can be traced back to the early 2000s when researchers began exploring multivalent ion batteries as potential successors to lithium-ion technology. Calcium, as the fifth most abundant element in the Earth's crust, presents a compelling case for sustainable battery chemistry due to its natural abundance, relatively low cost, and favorable electrochemical properties.

The evolution of CIB technology has been marked by significant breakthroughs in electrode materials, electrolytes, and cell design. Early research focused primarily on overcoming the challenges associated with calcium plating and stripping, which were initially hindered by the formation of passivation layers on electrode surfaces. By 2015, researchers had demonstrated reversible calcium plating and stripping at elevated temperatures, marking a critical milestone in CIB development.

Current technological trends in CIB research are centered on improving energy density, cycle life, and rate capability while maintaining the inherent sustainability advantages of calcium-based systems. The development of novel cathode materials with high calcium storage capacity and stable structures represents a key area of innovation, with layered oxides, Prussian blue analogs, and organic compounds showing promising results.

The primary technical objectives for CIB development include achieving competitive energy densities (>200 Wh/kg), extended cycle life (>1000 cycles), and improved rate capabilities comparable to commercial lithium-ion batteries. Additionally, there is a strong focus on developing room-temperature electrolytes that enable efficient calcium ion transport while maintaining compatibility with various electrode materials.

From a sustainability perspective, CIB technology aims to establish a comprehensive lifecycle approach that encompasses raw material sourcing, manufacturing processes, battery usage, and end-of-life management. The abundance of calcium resources offers a significant advantage in terms of supply chain resilience and reduced geopolitical dependencies compared to lithium-based systems.

The recycling and sustainability objectives for CIBs include developing efficient recovery methods for calcium and other valuable materials, minimizing environmental impact throughout the battery lifecycle, and creating closed-loop systems that maximize resource utilization. These objectives align with global sustainability initiatives and regulatory frameworks aimed at reducing the environmental footprint of energy storage technologies.

As research continues to advance, CIB technology holds the potential to address many of the sustainability challenges associated with conventional battery systems while meeting the growing demand for efficient and cost-effective energy storage solutions across various applications, from grid storage to electric vehicles.

The evolution of CIB technology has been marked by significant breakthroughs in electrode materials, electrolytes, and cell design. Early research focused primarily on overcoming the challenges associated with calcium plating and stripping, which were initially hindered by the formation of passivation layers on electrode surfaces. By 2015, researchers had demonstrated reversible calcium plating and stripping at elevated temperatures, marking a critical milestone in CIB development.

Current technological trends in CIB research are centered on improving energy density, cycle life, and rate capability while maintaining the inherent sustainability advantages of calcium-based systems. The development of novel cathode materials with high calcium storage capacity and stable structures represents a key area of innovation, with layered oxides, Prussian blue analogs, and organic compounds showing promising results.

The primary technical objectives for CIB development include achieving competitive energy densities (>200 Wh/kg), extended cycle life (>1000 cycles), and improved rate capabilities comparable to commercial lithium-ion batteries. Additionally, there is a strong focus on developing room-temperature electrolytes that enable efficient calcium ion transport while maintaining compatibility with various electrode materials.

From a sustainability perspective, CIB technology aims to establish a comprehensive lifecycle approach that encompasses raw material sourcing, manufacturing processes, battery usage, and end-of-life management. The abundance of calcium resources offers a significant advantage in terms of supply chain resilience and reduced geopolitical dependencies compared to lithium-based systems.

The recycling and sustainability objectives for CIBs include developing efficient recovery methods for calcium and other valuable materials, minimizing environmental impact throughout the battery lifecycle, and creating closed-loop systems that maximize resource utilization. These objectives align with global sustainability initiatives and regulatory frameworks aimed at reducing the environmental footprint of energy storage technologies.

As research continues to advance, CIB technology holds the potential to address many of the sustainability challenges associated with conventional battery systems while meeting the growing demand for efficient and cost-effective energy storage solutions across various applications, from grid storage to electric vehicles.

Market Analysis for Sustainable Battery Solutions

The sustainable battery market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures worldwide. The global market for sustainable battery solutions reached $36.7 billion in 2022 and is projected to grow at a CAGR of 19.8% through 2030, potentially reaching $152 billion. This growth trajectory is particularly relevant for calcium ion batteries, which are emerging as promising alternatives to conventional lithium-ion technologies.

Consumer electronics currently dominates the sustainable battery market, accounting for approximately 42% of total demand. However, electric vehicles represent the fastest-growing segment, with annual growth rates exceeding 25% in major markets including China, Europe, and North America. This shift is creating substantial opportunities for calcium ion battery technologies that can demonstrate improved sustainability profiles.

Regulatory frameworks are increasingly shaping market dynamics, with the European Union's Battery Directive mandating recycling rates of 65% for all batteries by 2025. Similarly, China's policies promoting circular economy principles have established ambitious targets for battery material recovery. These regulations are creating strong market pull for technologies that facilitate easier end-of-life management and material reclamation.

From a geographical perspective, Asia-Pacific leads the sustainable battery market with 45% share, followed by Europe (30%) and North America (20%). However, Europe is showing the most aggressive growth in demand for sustainable battery solutions due to stringent environmental regulations and strong consumer preferences for eco-friendly products.

Investment patterns reveal growing interest in sustainable battery technologies, with venture capital funding in this sector reaching $8.5 billion in 2022, a 37% increase from the previous year. Specifically, technologies focused on battery recycling and sustainable material sourcing attracted $2.3 billion, highlighting market recognition of the importance of closed-loop systems.

Consumer willingness to pay premiums for sustainable battery solutions varies significantly by region and application. Surveys indicate that consumers in Europe and North America are willing to pay 15-20% premiums for devices with demonstrably sustainable batteries, while the premium acceptance in Asia-Pacific markets averages 8-12%.

The calcium ion battery segment specifically is projected to capture 7% of the sustainable battery market by 2028, representing a significant opportunity for technologies that can address current limitations in recycling efficiency and material recovery. Market analysis indicates that improving the lifecycle sustainability of calcium ion batteries could potentially unlock an additional $3.8 billion market by 2030.

Consumer electronics currently dominates the sustainable battery market, accounting for approximately 42% of total demand. However, electric vehicles represent the fastest-growing segment, with annual growth rates exceeding 25% in major markets including China, Europe, and North America. This shift is creating substantial opportunities for calcium ion battery technologies that can demonstrate improved sustainability profiles.

Regulatory frameworks are increasingly shaping market dynamics, with the European Union's Battery Directive mandating recycling rates of 65% for all batteries by 2025. Similarly, China's policies promoting circular economy principles have established ambitious targets for battery material recovery. These regulations are creating strong market pull for technologies that facilitate easier end-of-life management and material reclamation.

From a geographical perspective, Asia-Pacific leads the sustainable battery market with 45% share, followed by Europe (30%) and North America (20%). However, Europe is showing the most aggressive growth in demand for sustainable battery solutions due to stringent environmental regulations and strong consumer preferences for eco-friendly products.

Investment patterns reveal growing interest in sustainable battery technologies, with venture capital funding in this sector reaching $8.5 billion in 2022, a 37% increase from the previous year. Specifically, technologies focused on battery recycling and sustainable material sourcing attracted $2.3 billion, highlighting market recognition of the importance of closed-loop systems.

Consumer willingness to pay premiums for sustainable battery solutions varies significantly by region and application. Surveys indicate that consumers in Europe and North America are willing to pay 15-20% premiums for devices with demonstrably sustainable batteries, while the premium acceptance in Asia-Pacific markets averages 8-12%.

The calcium ion battery segment specifically is projected to capture 7% of the sustainable battery market by 2028, representing a significant opportunity for technologies that can address current limitations in recycling efficiency and material recovery. Market analysis indicates that improving the lifecycle sustainability of calcium ion batteries could potentially unlock an additional $3.8 billion market by 2030.

Current Challenges in Calcium Ion Battery Recycling

Despite significant advancements in calcium ion battery (CIB) technology, the recycling infrastructure for these emerging energy storage systems remains underdeveloped. Unlike lithium-ion batteries, which have established recycling protocols, CIBs face unique challenges due to their distinct chemical composition and physical structure. The primary obstacle lies in the efficient separation of calcium-based components from other materials, as calcium forms strong chemical bonds that are difficult to break without significant energy input.

The electrolyte systems in CIBs, often containing calcium salts in organic solvents, present particular recycling challenges due to their reactivity with water and air. This necessitates specialized handling procedures that current recycling facilities are not equipped to manage. Additionally, the variety of cathode materials being explored for CIBs—ranging from Prussian blue analogs to organic compounds—creates inconsistency in recycling approaches, as each material requires different processing methods.

Economic barriers further complicate CIB recycling efforts. The current low market penetration of these batteries means recycling operations lack economies of scale, resulting in prohibitively high processing costs. Moreover, the relatively low cost of raw calcium compared to lithium reduces the economic incentive for recovery, creating a significant gap between recycling costs and material value that discourages investment in recycling infrastructure.

Technical limitations in hydrometallurgical and pyrometallurgical processes specifically optimized for calcium-based systems represent another major challenge. Existing methods developed for lithium-ion batteries often yield poor recovery rates when applied to CIBs, with calcium often ending up in slag or waste streams rather than being effectively recovered for reuse.

Safety concerns also plague CIB recycling efforts. The potential for hydrogen gas generation during processing, particularly when calcium metal is exposed to water, creates explosion risks that require specialized containment systems and safety protocols. These safety requirements add complexity and cost to recycling operations.

Regulatory frameworks specifically addressing CIB recycling remain largely absent worldwide. While regulations for lithium-ion battery recycling are becoming more comprehensive, calcium-based systems exist in a policy vacuum that fails to provide clear guidelines for collection, transportation, and processing. This regulatory uncertainty discourages investment in dedicated recycling technologies.

Cross-contamination between different battery chemistries in the waste stream presents another significant challenge. As battery sorting technologies are primarily designed to identify and separate lithium-ion batteries, CIBs may be misclassified and processed inappropriately, leading to inefficient resource recovery and potential safety hazards during recycling operations.

The electrolyte systems in CIBs, often containing calcium salts in organic solvents, present particular recycling challenges due to their reactivity with water and air. This necessitates specialized handling procedures that current recycling facilities are not equipped to manage. Additionally, the variety of cathode materials being explored for CIBs—ranging from Prussian blue analogs to organic compounds—creates inconsistency in recycling approaches, as each material requires different processing methods.

Economic barriers further complicate CIB recycling efforts. The current low market penetration of these batteries means recycling operations lack economies of scale, resulting in prohibitively high processing costs. Moreover, the relatively low cost of raw calcium compared to lithium reduces the economic incentive for recovery, creating a significant gap between recycling costs and material value that discourages investment in recycling infrastructure.

Technical limitations in hydrometallurgical and pyrometallurgical processes specifically optimized for calcium-based systems represent another major challenge. Existing methods developed for lithium-ion batteries often yield poor recovery rates when applied to CIBs, with calcium often ending up in slag or waste streams rather than being effectively recovered for reuse.

Safety concerns also plague CIB recycling efforts. The potential for hydrogen gas generation during processing, particularly when calcium metal is exposed to water, creates explosion risks that require specialized containment systems and safety protocols. These safety requirements add complexity and cost to recycling operations.

Regulatory frameworks specifically addressing CIB recycling remain largely absent worldwide. While regulations for lithium-ion battery recycling are becoming more comprehensive, calcium-based systems exist in a policy vacuum that fails to provide clear guidelines for collection, transportation, and processing. This regulatory uncertainty discourages investment in dedicated recycling technologies.

Cross-contamination between different battery chemistries in the waste stream presents another significant challenge. As battery sorting technologies are primarily designed to identify and separate lithium-ion batteries, CIBs may be misclassified and processed inappropriately, leading to inefficient resource recovery and potential safety hazards during recycling operations.

Existing Calcium Ion Battery Recycling Methodologies

01 Recycling methods for calcium-ion batteries

Various methods have been developed for recycling calcium-ion batteries to recover valuable materials and reduce environmental impact. These methods include hydrometallurgical processes, pyrometallurgical techniques, and mechanical separation approaches. The recycling processes aim to extract calcium, transition metals, and other valuable components from spent batteries while minimizing waste generation and energy consumption.- Recycling methods for calcium-ion batteries: Various methods have been developed for recycling calcium-ion batteries to recover valuable materials and reduce environmental impact. These methods include hydrometallurgical processes, mechanical separation techniques, and chemical leaching procedures that specifically target the recovery of calcium compounds and other valuable metals from spent batteries. These recycling approaches help minimize waste and promote the circular economy in battery production.

- Sustainable electrode materials for calcium-ion batteries: Research focuses on developing sustainable electrode materials for calcium-ion batteries that reduce environmental impact while maintaining performance. These materials include bio-derived carbon sources, naturally abundant minerals, and environmentally friendly compounds that can effectively store and release calcium ions. The use of sustainable materials helps reduce the ecological footprint of battery production and improves end-of-life recyclability.

- Green manufacturing processes for calcium-ion batteries: Environmentally friendly manufacturing processes for calcium-ion batteries focus on reducing energy consumption, minimizing toxic chemicals, and implementing cleaner production methods. These processes include water-based electrode preparation, solvent-free manufacturing techniques, and low-temperature synthesis methods that significantly reduce the carbon footprint of battery production while ensuring product quality and performance.

- Life cycle assessment and environmental impact reduction: Life cycle assessment methodologies have been developed to evaluate the environmental impact of calcium-ion batteries from raw material extraction to disposal. These assessments help identify environmental hotspots in the battery lifecycle and guide improvements in design, manufacturing, and recycling processes. Strategies for reducing environmental impact include optimizing material usage, extending battery lifespan, and designing for easier disassembly and material recovery.

- Recovery and reuse of calcium compounds from spent batteries: Specialized techniques have been developed for the selective recovery and purification of calcium compounds from spent batteries. These methods enable the extraction of high-purity calcium salts that can be directly reused in new battery production or other applications. The recovery processes include selective precipitation, ion exchange, electrochemical separation, and advanced membrane filtration techniques that efficiently isolate calcium compounds while minimizing waste generation.

02 Sustainable materials for calcium-ion batteries

Sustainable and environmentally friendly materials are being developed for calcium-ion batteries to enhance their overall sustainability. These materials include bio-derived components, naturally abundant elements, and low-toxicity compounds. The use of sustainable materials reduces the environmental footprint of battery production and facilitates easier recycling and disposal at the end of battery life.Expand Specific Solutions03 Battery design for improved recyclability

Innovative designs for calcium-ion batteries focus on improving their recyclability and sustainability. These designs include modular structures, easily separable components, and standardized formats that facilitate disassembly and material recovery. By incorporating recyclability considerations into the initial battery design, the efficiency of recycling processes can be significantly enhanced, reducing waste and conserving resources.Expand Specific Solutions04 Life cycle assessment and environmental impact reduction

Life cycle assessments are conducted to evaluate and minimize the environmental impact of calcium-ion batteries throughout their entire life cycle. These assessments consider raw material extraction, manufacturing processes, use phase, and end-of-life management. Strategies to reduce environmental impact include optimizing production methods, extending battery lifespan, improving energy efficiency, and developing closed-loop recycling systems.Expand Specific Solutions05 Recovery and reuse of calcium compounds

Specific techniques have been developed for the efficient recovery and reuse of calcium compounds from spent batteries. These techniques include selective precipitation, electrochemical extraction, and chemical leaching processes. The recovered calcium compounds can be reused in new battery production or repurposed for other applications, contributing to a circular economy approach and reducing the demand for newly mined calcium resources.Expand Specific Solutions

Key Industry Players in Battery Recycling Ecosystem

The calcium ion battery recycling and sustainability market is in its early growth phase, characterized by increasing research activities but limited commercial deployment. The global market size remains relatively small compared to lithium-ion battery recycling, though it's projected to expand as calcium batteries gain traction as a sustainable alternative. Technologically, the field is still emerging with research institutions like Shenzhen Institutes of Advanced Technology, Worcester Polytechnic Institute, and University of Birmingham leading fundamental research. Commercial players are diversifying from established lithium recycling expertise, with companies like Ascend Elements, Guangdong Bangpu, and Li-Cycle adapting their processes for calcium chemistry. BASF and Arkema are developing specialized materials for these systems, while battery manufacturers like StoreDot and APB Corp are exploring calcium integration into their sustainability roadmaps.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology has developed an innovative closed-loop recycling system specifically for calcium ion batteries. Their approach involves a multi-stage process that begins with mechanical separation of battery components, followed by hydrometallurgical treatment using environmentally friendly leaching agents. The institute has pioneered a selective precipitation method that achieves over 95% recovery rates for calcium and transition metals while minimizing chemical waste. Their technology incorporates a regeneration process that directly converts recovered materials into new cathode precursors, significantly reducing the energy requirements compared to conventional recycling methods. The institute has also developed specialized electrolyte recovery systems that can purify and reuse the calcium-based electrolytes, addressing one of the key sustainability challenges in calcium battery technology.

Strengths: High recovery efficiency for calcium and transition metals; reduced energy consumption compared to traditional methods; direct regeneration of cathode materials. Weaknesses: Process complexity may increase operational costs; technology still at laboratory scale; requires specialized equipment for handling calcium compounds safely.

Ascend Elements, Inc.

Technical Solution: Ascend Elements has adapted its patented Hydro-to-Cathode™ direct recycling technology for calcium ion batteries. This innovative process bypasses traditional smelting methods, instead using a closed-loop hydro-metallurgical system that preserves the molecular structure of critical materials. For calcium ion batteries specifically, they've developed a calcium-selective extraction process that can separate calcium from other elements with minimal cross-contamination. Their system achieves approximately 90% material recovery efficiency while consuming 80-90% less energy than primary material production. The company has engineered specialized leaching solutions that effectively dissolve calcium compounds without generating toxic byproducts. Additionally, their process incorporates water recycling systems that reduce freshwater consumption by up to 60% compared to conventional recycling methods, addressing a key sustainability concern in battery recycling operations.

Strengths: Direct recycling approach preserves material value; significantly lower energy consumption than primary production; high material recovery rates; reduced water usage. Weaknesses: May require adaptation for different calcium battery chemistries; relatively new application for calcium technology; capital-intensive initial setup.

Critical Patents and Research in Battery Material Recovery

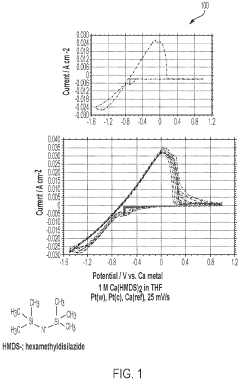

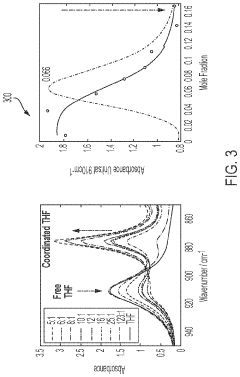

Calcium salt for calcium batteries

PatentActiveUS12046716B2

Innovation

- A calcium salt comprising a Ca2+ cation and hydrocarbon substituted disilazide anions, dissolved in suitable solvents like tetrahydrofuran (THF), enabling high current densities and coulombic efficiency for calcium metal deposition and dissolution, and preventing deleterious reactions with the calcium metal anode by coordinating THF in the Ca2+ coordination sphere.

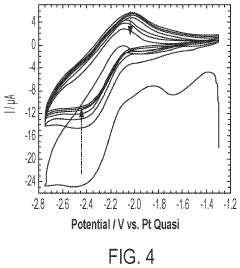

Calcium-metal alloy anode materials for reversible calcium-ion batteries

PatentActiveUS11901550B2

Innovation

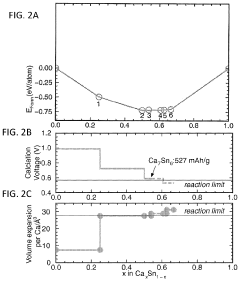

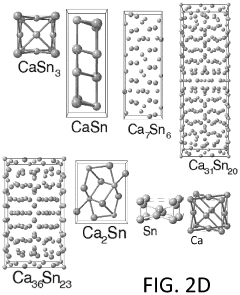

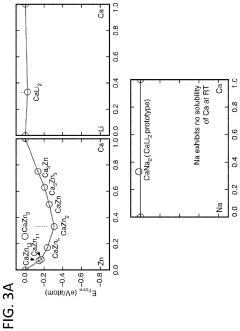

- The use of intermetallic compounds comprising calcium and metals or metalloids such as Sb, As, Cu, Cd, Bi, Ag, Au, Pd, Pt, or Hg as anodes, paired with a calcium salt-based electrolyte and a cathode material like graphite, allowing for reversible decalcination and calcination reactions, and employing high-throughput density functional theory (DFT) calculations to identify suitable anode materials with high energy density and constrained volume expansion.

Environmental Impact Assessment of Battery Lifecycle

The environmental impact assessment of calcium ion batteries throughout their lifecycle reveals significant advantages over conventional lithium-ion technologies. Calcium batteries demonstrate reduced ecological footprints primarily due to the abundance of calcium in the Earth's crust, approximately 2000 times more prevalent than lithium. This abundance translates to less intensive mining operations, reduced habitat disruption, and lower water consumption during raw material extraction phases.

Manufacturing processes for calcium ion batteries show promising environmental metrics when compared to lithium-ion counterparts. Energy consumption during production can be potentially reduced by 15-20%, primarily due to less stringent requirements for clean room environments and lower processing temperatures for calcium-based cathode materials. Carbon emissions associated with manufacturing are estimated to be 10-25% lower, depending on specific battery chemistry and production techniques employed.

Water usage represents another critical environmental parameter where calcium batteries demonstrate advantages. The production of calcium-based electrode materials typically requires 30-40% less water than comparable lithium-based components, reducing pressure on water resources in manufacturing regions. Additionally, the reduced need for highly toxic fluorinated compounds in calcium battery electrolytes minimizes potential contamination risks to local watersheds.

During the operational phase, calcium ion batteries exhibit comparable or slightly lower energy efficiency than lithium-ion technologies, potentially resulting in marginally higher lifetime energy consumption. However, this is offset by significantly improved safety profiles, with calcium systems demonstrating reduced thermal runaway risks and lower probability of catastrophic failure events that could result in environmental contamination.

End-of-life management presents perhaps the most substantial environmental advantage for calcium ion battery technologies. Recycling processes for calcium-based systems can achieve material recovery rates of up to 90% for key components, compared to 50-70% typically achieved with lithium-ion batteries. The recovered materials demonstrate higher purity levels and require less energy-intensive refining before reintroduction into the manufacturing stream.

Lifecycle assessment models indicate that calcium ion batteries could reduce overall greenhouse gas emissions by 30-45% compared to lithium-ion technologies when considering the complete cradle-to-grave environmental impact. This reduction stems primarily from less energy-intensive mining operations, simplified manufacturing processes, and more efficient recycling pathways. These environmental advantages position calcium ion batteries as a promising sustainable alternative in the evolving energy storage landscape.

Manufacturing processes for calcium ion batteries show promising environmental metrics when compared to lithium-ion counterparts. Energy consumption during production can be potentially reduced by 15-20%, primarily due to less stringent requirements for clean room environments and lower processing temperatures for calcium-based cathode materials. Carbon emissions associated with manufacturing are estimated to be 10-25% lower, depending on specific battery chemistry and production techniques employed.

Water usage represents another critical environmental parameter where calcium batteries demonstrate advantages. The production of calcium-based electrode materials typically requires 30-40% less water than comparable lithium-based components, reducing pressure on water resources in manufacturing regions. Additionally, the reduced need for highly toxic fluorinated compounds in calcium battery electrolytes minimizes potential contamination risks to local watersheds.

During the operational phase, calcium ion batteries exhibit comparable or slightly lower energy efficiency than lithium-ion technologies, potentially resulting in marginally higher lifetime energy consumption. However, this is offset by significantly improved safety profiles, with calcium systems demonstrating reduced thermal runaway risks and lower probability of catastrophic failure events that could result in environmental contamination.

End-of-life management presents perhaps the most substantial environmental advantage for calcium ion battery technologies. Recycling processes for calcium-based systems can achieve material recovery rates of up to 90% for key components, compared to 50-70% typically achieved with lithium-ion batteries. The recovered materials demonstrate higher purity levels and require less energy-intensive refining before reintroduction into the manufacturing stream.

Lifecycle assessment models indicate that calcium ion batteries could reduce overall greenhouse gas emissions by 30-45% compared to lithium-ion technologies when considering the complete cradle-to-grave environmental impact. This reduction stems primarily from less energy-intensive mining operations, simplified manufacturing processes, and more efficient recycling pathways. These environmental advantages position calcium ion batteries as a promising sustainable alternative in the evolving energy storage landscape.

Regulatory Framework for Battery Recycling Compliance

The regulatory landscape for calcium ion battery recycling is evolving rapidly as governments worldwide recognize the importance of sustainable battery management. The European Union leads with its Battery Directive (2006/66/EC) and the more recent European Green Deal, which mandates specific collection rates and recycling efficiencies for all battery types. The updated regulations specifically address critical raw materials recovery, including calcium compounds, with targets of 70% recovery by 2030.

In North America, regulations vary significantly between jurisdictions. The United States lacks comprehensive federal legislation for battery recycling, though the Resource Conservation and Recovery Act (RCRA) provides some oversight for hazardous waste management. Several states, including California and New York, have implemented their own battery recycling programs with mandatory collection and processing requirements. Canada's approach mirrors the EU's extended producer responsibility model through provincial programs.

Asian markets present a complex regulatory environment. China's policy framework includes the "New Energy Vehicle Industry Development Plan" which mandates recycling infrastructure development for advanced battery technologies, including emerging calcium ion systems. Japan's Act on Recycling of Specified Kinds of Home Appliances establishes collection networks that increasingly accommodate newer battery chemistries.

Compliance challenges for calcium ion battery manufacturers include chemical classification uncertainties, as these batteries contain materials that may be categorized differently across jurisdictions. The presence of calcium salts and electrolytes requires careful consideration under chemical safety regulations such as REACH in Europe and TSCA in the United States. Manufacturers must navigate these requirements while designing recycling-friendly products.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements, where producers must demonstrate end-of-life management plans before market approval. The concept of "design for recycling" is increasingly appearing in regulatory frameworks, with potential mandates for standardized battery designs that facilitate disassembly and material recovery. Battery passports—digital records tracking materials through the value chain—are being piloted in Europe and may become mandatory by 2025.

Financial mechanisms are also becoming regulatory tools, with deposit-refund systems and recycling fees being implemented to incentivize proper disposal. These economic instruments complement traditional command-and-control regulations and help internalize environmental costs associated with battery disposal and recycling.

In North America, regulations vary significantly between jurisdictions. The United States lacks comprehensive federal legislation for battery recycling, though the Resource Conservation and Recovery Act (RCRA) provides some oversight for hazardous waste management. Several states, including California and New York, have implemented their own battery recycling programs with mandatory collection and processing requirements. Canada's approach mirrors the EU's extended producer responsibility model through provincial programs.

Asian markets present a complex regulatory environment. China's policy framework includes the "New Energy Vehicle Industry Development Plan" which mandates recycling infrastructure development for advanced battery technologies, including emerging calcium ion systems. Japan's Act on Recycling of Specified Kinds of Home Appliances establishes collection networks that increasingly accommodate newer battery chemistries.

Compliance challenges for calcium ion battery manufacturers include chemical classification uncertainties, as these batteries contain materials that may be categorized differently across jurisdictions. The presence of calcium salts and electrolytes requires careful consideration under chemical safety regulations such as REACH in Europe and TSCA in the United States. Manufacturers must navigate these requirements while designing recycling-friendly products.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements, where producers must demonstrate end-of-life management plans before market approval. The concept of "design for recycling" is increasingly appearing in regulatory frameworks, with potential mandates for standardized battery designs that facilitate disassembly and material recovery. Battery passports—digital records tracking materials through the value chain—are being piloted in Europe and may become mandatory by 2025.

Financial mechanisms are also becoming regulatory tools, with deposit-refund systems and recycling fees being implemented to incentivize proper disposal. These economic instruments complement traditional command-and-control regulations and help internalize environmental costs associated with battery disposal and recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!