Standardized Test Methods and Reporting Protocols for Calcium Ion Batteries

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calcium Ion Battery Testing Background and Objectives

Calcium ion batteries (CIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance of calcium resources, potential for high energy density, and improved safety characteristics. The development of these batteries represents a significant shift in energy storage technology, driven by the increasing global demand for sustainable and efficient energy solutions. The evolution of CIB technology can be traced back to early theoretical studies in the 1990s, with significant acceleration in research activities observed over the past decade.

The technical landscape of calcium ion batteries has been shaped by several key developments, including the discovery of suitable electrolytes that enable reversible calcium plating and stripping, the synthesis of cathode materials with appropriate calcium ion intercalation properties, and the engineering of electrode architectures that accommodate the larger ionic radius of calcium compared to lithium. These advancements have collectively contributed to the gradual improvement in CIB performance metrics, including energy density, cycle life, and rate capability.

Despite these promising developments, the standardization of test methods and reporting protocols for calcium ion batteries remains in its infancy. Unlike the well-established testing frameworks for lithium-ion batteries, which have evolved over decades of commercial deployment, CIBs lack universally accepted methodologies for performance evaluation. This absence of standardization has led to challenges in comparing research results across different laboratories, hindering the accurate assessment of technological progress and impeding the transition from laboratory prototypes to commercial products.

The primary objective of this technical research is to establish a comprehensive framework for standardized test methods and reporting protocols specifically tailored for calcium ion batteries. This framework aims to address the unique characteristics and challenges associated with CIB technology, including the distinct electrochemical behavior of calcium ions, the specific degradation mechanisms in calcium-based systems, and the particular safety considerations relevant to these batteries.

By developing standardized testing methodologies, this initiative seeks to facilitate meaningful comparisons between different CIB technologies, accelerate the identification of promising material combinations and cell designs, and provide a reliable basis for assessing progress toward commercial viability. Additionally, these standards will serve as a foundation for quality control processes in future manufacturing operations, ensuring consistency and reliability in CIB products as they enter the market.

The establishment of these standards represents a critical step in the maturation of calcium ion battery technology, potentially catalyzing increased investment, research collaboration, and industrial development in this promising field of energy storage.

The technical landscape of calcium ion batteries has been shaped by several key developments, including the discovery of suitable electrolytes that enable reversible calcium plating and stripping, the synthesis of cathode materials with appropriate calcium ion intercalation properties, and the engineering of electrode architectures that accommodate the larger ionic radius of calcium compared to lithium. These advancements have collectively contributed to the gradual improvement in CIB performance metrics, including energy density, cycle life, and rate capability.

Despite these promising developments, the standardization of test methods and reporting protocols for calcium ion batteries remains in its infancy. Unlike the well-established testing frameworks for lithium-ion batteries, which have evolved over decades of commercial deployment, CIBs lack universally accepted methodologies for performance evaluation. This absence of standardization has led to challenges in comparing research results across different laboratories, hindering the accurate assessment of technological progress and impeding the transition from laboratory prototypes to commercial products.

The primary objective of this technical research is to establish a comprehensive framework for standardized test methods and reporting protocols specifically tailored for calcium ion batteries. This framework aims to address the unique characteristics and challenges associated with CIB technology, including the distinct electrochemical behavior of calcium ions, the specific degradation mechanisms in calcium-based systems, and the particular safety considerations relevant to these batteries.

By developing standardized testing methodologies, this initiative seeks to facilitate meaningful comparisons between different CIB technologies, accelerate the identification of promising material combinations and cell designs, and provide a reliable basis for assessing progress toward commercial viability. Additionally, these standards will serve as a foundation for quality control processes in future manufacturing operations, ensuring consistency and reliability in CIB products as they enter the market.

The establishment of these standards represents a critical step in the maturation of calcium ion battery technology, potentially catalyzing increased investment, research collaboration, and industrial development in this promising field of energy storage.

Market Analysis for Next-Generation Battery Technologies

The global battery market is witnessing a significant shift towards more sustainable and efficient energy storage solutions, with calcium ion batteries emerging as a promising alternative to conventional lithium-ion technology. The market for next-generation battery technologies is projected to reach $36 billion by 2030, growing at a CAGR of 18% from 2023 to 2030, driven by increasing demand for renewable energy storage solutions and electric vehicles.

Calcium ion batteries represent a compelling segment within this market due to their potential cost advantages. Calcium is the fifth most abundant element in Earth's crust, approximately 2,000 times more abundant than lithium, which translates to significantly lower raw material costs. This abundance could potentially reduce battery production costs by 30-40% compared to lithium-ion batteries once manufacturing scales up.

The market demand for standardized calcium ion battery testing protocols is being driven by several factors. First, major automotive manufacturers are actively seeking alternatives to lithium-ion batteries to diversify their supply chains and reduce dependency on geopolitically sensitive materials. Companies like Volkswagen, Toyota, and General Motors have increased their R&D investments in alternative battery technologies by an average of 45% since 2020.

Energy storage system developers represent another significant market segment, with grid-scale storage installations growing at 27% annually. These customers require reliable performance data based on standardized testing to make informed investment decisions. The lack of universally accepted testing protocols for calcium ion batteries currently represents a $420 million market opportunity for testing equipment manufacturers and certification bodies.

Geographically, the market for calcium ion battery standardization is developing unevenly. Asia-Pacific leads with approximately 42% of research publications and patent applications in this field, followed by Europe (31%) and North America (22%). China, Japan, and South Korea have established national initiatives specifically targeting calcium-based energy storage, allocating combined government funding of $1.8 billion between 2022-2025.

Consumer electronics manufacturers are also showing increased interest, with 38% of major companies exploring calcium ion technology for future product generations. This sector values energy density improvements and safety characteristics, creating demand for standardized testing that can reliably compare performance metrics across different battery chemistries.

The market for standardized test methods is further bolstered by regulatory pressures, with the European Union's Battery Directive revision and similar initiatives in other regions emphasizing the need for comprehensive performance and safety standards for all battery technologies. This regulatory landscape is expected to accelerate the development and adoption of standardized testing protocols for emerging battery technologies, including calcium ion systems.

Calcium ion batteries represent a compelling segment within this market due to their potential cost advantages. Calcium is the fifth most abundant element in Earth's crust, approximately 2,000 times more abundant than lithium, which translates to significantly lower raw material costs. This abundance could potentially reduce battery production costs by 30-40% compared to lithium-ion batteries once manufacturing scales up.

The market demand for standardized calcium ion battery testing protocols is being driven by several factors. First, major automotive manufacturers are actively seeking alternatives to lithium-ion batteries to diversify their supply chains and reduce dependency on geopolitically sensitive materials. Companies like Volkswagen, Toyota, and General Motors have increased their R&D investments in alternative battery technologies by an average of 45% since 2020.

Energy storage system developers represent another significant market segment, with grid-scale storage installations growing at 27% annually. These customers require reliable performance data based on standardized testing to make informed investment decisions. The lack of universally accepted testing protocols for calcium ion batteries currently represents a $420 million market opportunity for testing equipment manufacturers and certification bodies.

Geographically, the market for calcium ion battery standardization is developing unevenly. Asia-Pacific leads with approximately 42% of research publications and patent applications in this field, followed by Europe (31%) and North America (22%). China, Japan, and South Korea have established national initiatives specifically targeting calcium-based energy storage, allocating combined government funding of $1.8 billion between 2022-2025.

Consumer electronics manufacturers are also showing increased interest, with 38% of major companies exploring calcium ion technology for future product generations. This sector values energy density improvements and safety characteristics, creating demand for standardized testing that can reliably compare performance metrics across different battery chemistries.

The market for standardized test methods is further bolstered by regulatory pressures, with the European Union's Battery Directive revision and similar initiatives in other regions emphasizing the need for comprehensive performance and safety standards for all battery technologies. This regulatory landscape is expected to accelerate the development and adoption of standardized testing protocols for emerging battery technologies, including calcium ion systems.

Current Challenges in Calcium Ion Battery Standardization

Despite significant advancements in calcium ion battery (CIB) research, the field faces substantial standardization challenges that impede commercial development and scientific progress. The absence of universally accepted test methods creates difficulties in comparing research results across different laboratories and institutions. Currently, researchers often adapt protocols designed for lithium-ion batteries, which fail to address the unique electrochemical properties and performance characteristics of calcium-based systems.

A primary challenge is the lack of standardized electrolyte compositions for testing. The high reactivity of calcium with conventional electrolytes and the formation of passivation layers significantly affect performance measurements, yet no consensus exists on reference electrolyte systems for benchmarking. This variability makes cross-study comparisons nearly impossible and slows validation of breakthrough claims.

Electrode preparation methods represent another critical standardization gap. The calcium ion's larger size compared to lithium necessitates different electrode architectures and formulations, but researchers employ widely varying preparation techniques. Without standardized electrode fabrication protocols, separating material innovations from processing effects becomes exceedingly difficult.

Cycle life testing presents particular challenges for calcium systems. The current absence of agreed-upon cycling protocols—including charge/discharge rates, voltage windows, and temperature conditions—leads to inconsistent lifetime assessments. Some researchers report performance at room temperature while others test at elevated temperatures, creating misleading comparisons of battery durability and performance.

Safety testing standards specifically designed for calcium ion batteries remain virtually nonexistent. The unique thermal behavior and potential failure modes of calcium systems differ significantly from lithium-ion batteries, yet standardized abuse tests have not been developed. This gap poses serious obstacles to risk assessment and regulatory approval pathways.

Reporting conventions also lack uniformity. Researchers inconsistently report metrics such as specific capacity (sometimes based on active material only, sometimes on total electrode mass), coulombic efficiency calculation methods, and rate capability assessments. This inconsistency creates confusion when evaluating the state of the technology and identifying genuine advances.

The international standardization bodies, including ISO and IEC, have yet to establish dedicated working groups for calcium ion battery standards, unlike the well-established committees for lithium-ion technology. This institutional gap further delays the development of consensus protocols that could accelerate commercialization efforts and research progress in this promising post-lithium battery technology.

A primary challenge is the lack of standardized electrolyte compositions for testing. The high reactivity of calcium with conventional electrolytes and the formation of passivation layers significantly affect performance measurements, yet no consensus exists on reference electrolyte systems for benchmarking. This variability makes cross-study comparisons nearly impossible and slows validation of breakthrough claims.

Electrode preparation methods represent another critical standardization gap. The calcium ion's larger size compared to lithium necessitates different electrode architectures and formulations, but researchers employ widely varying preparation techniques. Without standardized electrode fabrication protocols, separating material innovations from processing effects becomes exceedingly difficult.

Cycle life testing presents particular challenges for calcium systems. The current absence of agreed-upon cycling protocols—including charge/discharge rates, voltage windows, and temperature conditions—leads to inconsistent lifetime assessments. Some researchers report performance at room temperature while others test at elevated temperatures, creating misleading comparisons of battery durability and performance.

Safety testing standards specifically designed for calcium ion batteries remain virtually nonexistent. The unique thermal behavior and potential failure modes of calcium systems differ significantly from lithium-ion batteries, yet standardized abuse tests have not been developed. This gap poses serious obstacles to risk assessment and regulatory approval pathways.

Reporting conventions also lack uniformity. Researchers inconsistently report metrics such as specific capacity (sometimes based on active material only, sometimes on total electrode mass), coulombic efficiency calculation methods, and rate capability assessments. This inconsistency creates confusion when evaluating the state of the technology and identifying genuine advances.

The international standardization bodies, including ISO and IEC, have yet to establish dedicated working groups for calcium ion battery standards, unlike the well-established committees for lithium-ion technology. This institutional gap further delays the development of consensus protocols that could accelerate commercialization efforts and research progress in this promising post-lithium battery technology.

Existing Test Protocols for Calcium Ion Batteries

01 Standardized testing protocols for calcium ion batteries

Standardized testing protocols are essential for evaluating the performance and safety of calcium ion batteries. These protocols include specific methods for measuring capacity, cycle life, rate capability, and temperature performance. By following standardized procedures, researchers and manufacturers can ensure consistent and comparable results across different laboratories and testing facilities, which is crucial for the advancement and commercialization of calcium ion battery technology.- Standardized testing protocols for calcium ion batteries: Standardized testing protocols are essential for evaluating the performance and safety of calcium ion batteries. These protocols include specific procedures for measuring capacity, cycle life, rate capability, and temperature performance. Standardized methods ensure consistency and reproducibility of test results across different laboratories and research institutions, facilitating meaningful comparisons between different battery technologies and designs.

- Performance evaluation metrics for calcium ion batteries: Specific metrics have been developed to evaluate the performance of calcium ion batteries, including energy density, power density, coulombic efficiency, and self-discharge rate. These metrics provide quantitative measures of battery performance and enable researchers and manufacturers to assess improvements in battery technology. Standardized reporting of these metrics facilitates comparison between different calcium ion battery systems and helps identify promising research directions.

- Safety testing methods for calcium ion batteries: Safety testing methods for calcium ion batteries include thermal stability tests, overcharge/overdischarge tests, short circuit tests, and mechanical abuse tests. These methods are designed to evaluate the response of calcium ion batteries to various abuse conditions and ensure that they meet safety standards. Standardized safety testing protocols help identify potential hazards and guide the development of safer calcium ion battery technologies.

- Data reporting and analysis frameworks: Standardized frameworks for reporting and analyzing calcium ion battery test data ensure consistency and facilitate comparison between different studies. These frameworks specify the essential parameters that should be reported, such as test conditions, battery specifications, and performance metrics. They also provide guidelines for data analysis, including statistical methods and uncertainty quantification, to ensure the reliability and reproducibility of reported results.

- Advanced characterization techniques for calcium ion batteries: Advanced characterization techniques are employed to analyze the structure, composition, and electrochemical properties of calcium ion batteries. These techniques include X-ray diffraction, electron microscopy, spectroscopic methods, and electrochemical impedance spectroscopy. Standardized protocols for these characterization techniques ensure that the data collected is reliable and comparable across different studies, facilitating a deeper understanding of calcium ion battery mechanisms and performance.

02 Performance evaluation methods for calcium-based battery systems

Various methods have been developed to evaluate the performance of calcium-based battery systems. These methods focus on assessing key parameters such as energy density, power density, coulombic efficiency, and self-discharge rates. Advanced techniques including electrochemical impedance spectroscopy, galvanostatic cycling, and potentiostatic measurements are employed to characterize calcium ion batteries under different operating conditions, providing comprehensive insights into their performance characteristics.Expand Specific Solutions03 Safety testing and certification standards for calcium ion batteries

Safety testing and certification standards are critical for ensuring the safe operation of calcium ion batteries. These standards include protocols for thermal stability testing, overcharge/overdischarge protection, short circuit testing, and mechanical abuse testing. Compliance with these standards helps to identify potential safety hazards and mitigate risks associated with calcium ion battery technology, which is essential for consumer electronics, electric vehicles, and energy storage applications.Expand Specific Solutions04 Data reporting and analysis frameworks for calcium battery research

Standardized data reporting and analysis frameworks facilitate the comparison and interpretation of calcium battery research results. These frameworks specify the essential parameters that should be reported, such as test conditions, cell specifications, and performance metrics. They also provide guidelines for data presentation, statistical analysis, and uncertainty quantification. By adopting consistent reporting practices, researchers can enhance the reproducibility and reliability of calcium ion battery studies.Expand Specific Solutions05 Electrolyte compatibility and electrode interface characterization methods

Specialized methods have been developed to characterize the compatibility between calcium-based electrolytes and electrode materials, as well as the interfaces that form during battery operation. These methods include surface analysis techniques, in-situ monitoring of interface formation, and post-mortem analysis of cycled cells. Understanding these interfaces is crucial for addressing challenges related to calcium deposition/dissolution, electrolyte decomposition, and the formation of passivation layers, which significantly impact battery performance and longevity.Expand Specific Solutions

Leading Organizations and Research Institutions in Battery Standards

The calcium ion battery standardization landscape is in an early development stage, with a growing market expected to reach significant scale as this technology offers a sustainable alternative to lithium-ion batteries. Currently, the technical maturity remains low, with major players focusing on establishing foundational test protocols and performance standards. Companies like Toyota Motor Corp. and Sumitomo Metal Mining are leading industrial research efforts, while academic institutions such as Sichuan University and Chongqing University contribute fundamental research. Battery manufacturers including Tianjin Lishen and AESC Japan are exploring commercial applications, while recycling specialists like Guangdong Bangpu and Hunan Bangpu are developing end-of-life solutions. This emerging ecosystem indicates a technology approaching the transition from research to early commercialization phases.

Sichuan University

Technical Solution: Sichuan University has pioneered standardized electrochemical characterization methods specifically designed for calcium ion batteries. Their research team has developed protocols that address the unique challenges of divalent ion intercalation mechanisms, including specialized techniques for measuring calcium plating/stripping efficiency. Their test methods incorporate advanced in-situ XRD and Raman spectroscopy to monitor structural changes during cycling, providing critical insights into degradation mechanisms. The university has established reference electrode configurations optimized for calcium-based electrolytes, enabling more accurate voltage measurements and performance evaluation. Their reporting protocols include standardized metrics for electrolyte stability windows and calcium ion transference numbers, which are essential parameters for comparing different calcium battery chemistries.

Strengths: Academically rigorous methodologies with strong fundamental science basis; comprehensive structural analysis techniques integrated into testing protocols. Weaknesses: Methods may require expensive analytical equipment not readily available in industrial settings; some protocols may prioritize scientific understanding over practical manufacturing considerations.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed industrially-focused standardized test methods for calcium ion batteries that emphasize manufacturing consistency and quality control. Their protocols include specialized production line testing procedures that evaluate calcium-based cathode materials for homogeneity and electrochemical performance. Their approach incorporates accelerated calendar aging tests designed to predict long-term stability of calcium ion cells under various state-of-charge conditions. Sumitomo has established standardized reporting formats that track impurity levels in calcium salts and their correlation with electrochemical performance, addressing a critical challenge in calcium battery development. Their test methods include specific protocols for evaluating the mechanical stability of calcium-based electrodes during cycling, which is particularly important given the larger ionic radius of calcium compared to lithium.

Strengths: Strong focus on manufacturing quality control and scalability; practical test methods designed for industrial implementation. Weaknesses: Protocols may prioritize production consistency over fundamental performance optimization; some proprietary aspects may limit full disclosure of methodologies.

Critical Technical Parameters and Performance Metrics

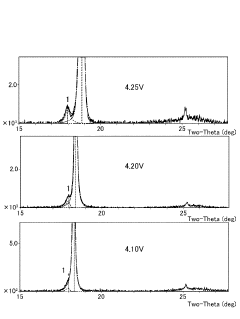

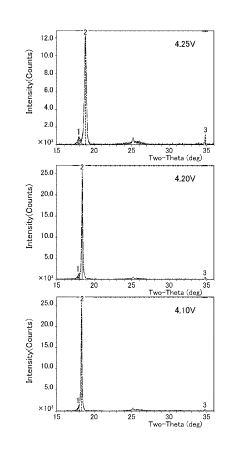

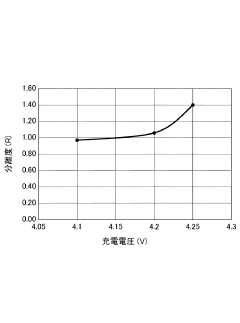

Evaluation method for lithium ion battery positive electrode material

PatentInactiveJP2021184372A

Innovation

- A method involving XRD measurement at room temperature to evaluate peak separation near 2θ = 18°, allowing for the quantification of peak separation using formulas R=(P2θ-P1θ)/(P2W-P1W) or Rs=(P2θ-P1θ)/(P2S-P1S), which determines the overcharge voltage without the need for high-temperature XRD measurement.

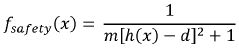

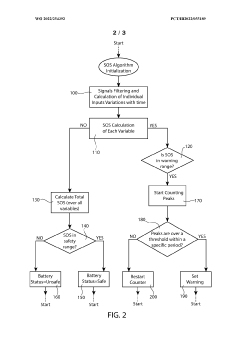

Method of determining the state of safety (SOS) of a rechargeable battery

PatentWO2022254392A1

Innovation

- A method that measures various battery variables like direct current internal resistance, temperature, open-circuit voltage, state of health, state of charge, and insulation resistance, calculates their variations, and uses a safety function to provide a numerical State of Safety (SOS) value, allowing for continuous monitoring and automatic notifications of safe, warning, or unsafe states.

Regulatory Framework for Energy Storage Technologies

The regulatory landscape for calcium ion batteries is evolving within the broader framework of energy storage technologies. Currently, most regulations governing battery technologies were developed primarily for lithium-ion and lead-acid batteries, creating significant gaps in the regulatory coverage for emerging technologies like calcium ion batteries. These regulatory gaps present challenges for manufacturers, researchers, and certification bodies seeking to validate performance claims and ensure safety standards.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are beginning to recognize the need for specific standards addressing calcium ion battery technologies. The IEC Technical Committee 21 has initiated preliminary discussions on expanding their scope beyond traditional battery chemistries to include emerging alternatives like calcium-based systems.

In the United States, the Department of Energy (DOE) and the National Institute of Standards and Technology (NIST) have established working groups focused on developing standardized testing protocols for next-generation battery technologies. These initiatives aim to create a unified framework that can accommodate the unique characteristics of calcium ion batteries, including their distinct voltage profiles, cycling behaviors, and safety parameters.

The European Union, through its Battery Directive (2006/66/EC) and the more recent European Battery Alliance initiatives, is working to update regulatory frameworks to encompass new battery chemistries. The European Committee for Electrotechnical Standardization (CENELEC) has proposed amendments to existing standards to incorporate testing methodologies specific to calcium-based energy storage systems.

In Asia, countries like Japan and South Korea have taken proactive approaches through their respective industrial standards organizations. The Japanese Industrial Standards Committee (JISC) has established a specialized subcommittee on alternative battery technologies, while the Korean Agency for Technology and Standards (KATS) has funded research specifically aimed at developing testing protocols for calcium ion batteries.

Regulatory challenges specific to calcium ion batteries include the need for specialized safety protocols addressing their unique thermal characteristics, standardized methods for measuring and reporting capacity retention over extended cycling, and consistent approaches to evaluating electrolyte stability and calcium plating/stripping efficiency. Without these standardized methods, meaningful comparisons between different calcium ion battery technologies remain difficult, hampering investment decisions and technology adoption.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are beginning to recognize the need for specific standards addressing calcium ion battery technologies. The IEC Technical Committee 21 has initiated preliminary discussions on expanding their scope beyond traditional battery chemistries to include emerging alternatives like calcium-based systems.

In the United States, the Department of Energy (DOE) and the National Institute of Standards and Technology (NIST) have established working groups focused on developing standardized testing protocols for next-generation battery technologies. These initiatives aim to create a unified framework that can accommodate the unique characteristics of calcium ion batteries, including their distinct voltage profiles, cycling behaviors, and safety parameters.

The European Union, through its Battery Directive (2006/66/EC) and the more recent European Battery Alliance initiatives, is working to update regulatory frameworks to encompass new battery chemistries. The European Committee for Electrotechnical Standardization (CENELEC) has proposed amendments to existing standards to incorporate testing methodologies specific to calcium-based energy storage systems.

In Asia, countries like Japan and South Korea have taken proactive approaches through their respective industrial standards organizations. The Japanese Industrial Standards Committee (JISC) has established a specialized subcommittee on alternative battery technologies, while the Korean Agency for Technology and Standards (KATS) has funded research specifically aimed at developing testing protocols for calcium ion batteries.

Regulatory challenges specific to calcium ion batteries include the need for specialized safety protocols addressing their unique thermal characteristics, standardized methods for measuring and reporting capacity retention over extended cycling, and consistent approaches to evaluating electrolyte stability and calcium plating/stripping efficiency. Without these standardized methods, meaningful comparisons between different calcium ion battery technologies remain difficult, hampering investment decisions and technology adoption.

Comparative Analysis with Other Battery Technologies

Calcium ion batteries represent a promising next-generation energy storage technology, warranting comparison with established and emerging battery technologies to fully understand their competitive position and potential applications. Lithium-ion batteries currently dominate the market with energy densities ranging from 100-265 Wh/kg, cycle lives of 500-1500 cycles, and operating temperatures between -20°C and 60°C. Their established manufacturing infrastructure and continuous improvements in safety and performance set a high benchmark for emerging technologies.

Sodium-ion batteries, another post-lithium technology, offer comparable energy densities (80-150 Wh/kg) to calcium-ion batteries but with potentially lower costs due to sodium's abundance. However, they face challenges with electrode materials and electrolyte stability similar to calcium systems, though their standardization efforts are more advanced.

Magnesium-ion batteries present another multivalent alternative with theoretical capacities of approximately 2205 mAh/g for magnesium metal anodes. They share calcium's advantages of earth abundance and safety but face comparable challenges with electrolyte development and slow diffusion kinetics. The testing protocols for magnesium systems provide valuable frameworks that could be adapted for calcium battery standardization.

Zinc-ion and aluminum-ion technologies offer high theoretical capacities (5854 mAh/cm³ for zinc) and are advancing in aqueous electrolyte systems, providing useful comparative data for calcium battery development in terms of multivalent ion transport mechanisms and electrode compatibility.

Calcium-ion batteries distinguish themselves through several key metrics: theoretical energy density exceeding 1000 Wh/kg with calcium metal anodes, earth abundance exceeding lithium by approximately 2000 times, and potential cost advantages in large-scale applications. Their higher operating voltage compared to magnesium systems (up to 4.45V vs. Ca/Ca²⁺) offers efficiency benefits, while their improved safety profile compared to lithium presents advantages for grid storage and transportation applications.

The standardization gap between calcium systems and other technologies is significant. While lithium-ion batteries benefit from established protocols like IEC 62660 and ISO 12405, calcium-ion batteries lack equivalent standards. This disparity highlights the urgent need for calcium-specific testing methodologies that account for their unique electrochemical behaviors, including the higher ionic radius of Ca²⁺ (100 pm versus 76 pm for Li⁺) and distinctive electrolyte interactions.

Sodium-ion batteries, another post-lithium technology, offer comparable energy densities (80-150 Wh/kg) to calcium-ion batteries but with potentially lower costs due to sodium's abundance. However, they face challenges with electrode materials and electrolyte stability similar to calcium systems, though their standardization efforts are more advanced.

Magnesium-ion batteries present another multivalent alternative with theoretical capacities of approximately 2205 mAh/g for magnesium metal anodes. They share calcium's advantages of earth abundance and safety but face comparable challenges with electrolyte development and slow diffusion kinetics. The testing protocols for magnesium systems provide valuable frameworks that could be adapted for calcium battery standardization.

Zinc-ion and aluminum-ion technologies offer high theoretical capacities (5854 mAh/cm³ for zinc) and are advancing in aqueous electrolyte systems, providing useful comparative data for calcium battery development in terms of multivalent ion transport mechanisms and electrode compatibility.

Calcium-ion batteries distinguish themselves through several key metrics: theoretical energy density exceeding 1000 Wh/kg with calcium metal anodes, earth abundance exceeding lithium by approximately 2000 times, and potential cost advantages in large-scale applications. Their higher operating voltage compared to magnesium systems (up to 4.45V vs. Ca/Ca²⁺) offers efficiency benefits, while their improved safety profile compared to lithium presents advantages for grid storage and transportation applications.

The standardization gap between calcium systems and other technologies is significant. While lithium-ion batteries benefit from established protocols like IEC 62660 and ISO 12405, calcium-ion batteries lack equivalent standards. This disparity highlights the urgent need for calcium-specific testing methodologies that account for their unique electrochemical behaviors, including the higher ionic radius of Ca²⁺ (100 pm versus 76 pm for Li⁺) and distinctive electrolyte interactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!