Safety Assessment and Abuse Testing of Calcium Ion Batteries

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calcium Ion Battery Safety Background and Objectives

Calcium ion batteries (CIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance of calcium resources, potentially lower costs, and higher theoretical energy density. As the global energy landscape shifts toward sustainable solutions, the development of safe and reliable energy storage technologies becomes increasingly critical. The safety assessment and abuse testing of calcium ion batteries represent a fundamental aspect of their development trajectory, ensuring their viability for commercial applications.

The evolution of battery technology has been marked by continuous improvements in energy density, cycle life, and safety features. While lithium-ion batteries currently dominate the market, concerns regarding resource scarcity, geopolitical dependencies, and safety incidents have accelerated research into alternative battery chemistries. Calcium, as the fifth most abundant element in the Earth's crust, offers a sustainable alternative with theoretical performance metrics that could potentially surpass those of lithium-based systems.

Historical safety incidents involving lithium-ion batteries, such as thermal runaway events in consumer electronics and electric vehicles, have highlighted the paramount importance of comprehensive safety protocols in battery development. These incidents have shaped regulatory frameworks and industry standards, establishing precedents that will influence the development and commercialization of calcium ion batteries. Understanding these historical contexts is essential for anticipating potential safety challenges specific to calcium-based systems.

The primary technical objective of safety assessment for calcium ion batteries is to identify, characterize, and mitigate potential failure modes under normal operation and abuse conditions. This includes evaluating thermal stability, mechanical resilience, and electrochemical behavior under extreme conditions such as overcharging, external short circuits, physical damage, and exposure to elevated temperatures.

Another critical objective is the development of standardized testing protocols specifically tailored to calcium ion chemistry. Current safety standards predominantly focus on lithium-ion systems, and while some principles may transfer, the unique characteristics of calcium-based electrolytes, electrode materials, and cell designs necessitate specialized testing methodologies. These protocols must address the distinctive failure mechanisms and safety concerns associated with calcium's electrochemical properties.

The long-term technical goal extends beyond mere safety compliance to achieving inherent safety through materials innovation and cell design. This includes developing calcium-based electrolytes with wider electrochemical stability windows, electrode materials with minimal volume expansion during cycling, and cell architectures with built-in safety features such as thermal fuses or pressure relief mechanisms.

Ultimately, the safety assessment of calcium ion batteries aims to facilitate their integration into various applications, from grid-scale energy storage to electric mobility, by ensuring their reliability under diverse operating conditions and establishing public confidence in this emerging technology.

The evolution of battery technology has been marked by continuous improvements in energy density, cycle life, and safety features. While lithium-ion batteries currently dominate the market, concerns regarding resource scarcity, geopolitical dependencies, and safety incidents have accelerated research into alternative battery chemistries. Calcium, as the fifth most abundant element in the Earth's crust, offers a sustainable alternative with theoretical performance metrics that could potentially surpass those of lithium-based systems.

Historical safety incidents involving lithium-ion batteries, such as thermal runaway events in consumer electronics and electric vehicles, have highlighted the paramount importance of comprehensive safety protocols in battery development. These incidents have shaped regulatory frameworks and industry standards, establishing precedents that will influence the development and commercialization of calcium ion batteries. Understanding these historical contexts is essential for anticipating potential safety challenges specific to calcium-based systems.

The primary technical objective of safety assessment for calcium ion batteries is to identify, characterize, and mitigate potential failure modes under normal operation and abuse conditions. This includes evaluating thermal stability, mechanical resilience, and electrochemical behavior under extreme conditions such as overcharging, external short circuits, physical damage, and exposure to elevated temperatures.

Another critical objective is the development of standardized testing protocols specifically tailored to calcium ion chemistry. Current safety standards predominantly focus on lithium-ion systems, and while some principles may transfer, the unique characteristics of calcium-based electrolytes, electrode materials, and cell designs necessitate specialized testing methodologies. These protocols must address the distinctive failure mechanisms and safety concerns associated with calcium's electrochemical properties.

The long-term technical goal extends beyond mere safety compliance to achieving inherent safety through materials innovation and cell design. This includes developing calcium-based electrolytes with wider electrochemical stability windows, electrode materials with minimal volume expansion during cycling, and cell architectures with built-in safety features such as thermal fuses or pressure relief mechanisms.

Ultimately, the safety assessment of calcium ion batteries aims to facilitate their integration into various applications, from grid-scale energy storage to electric mobility, by ensuring their reliability under diverse operating conditions and establishing public confidence in this emerging technology.

Market Demand Analysis for Safe Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the need for reliable backup power systems. This growth has intensified the demand for safer energy storage solutions, particularly as incidents involving lithium-ion battery fires and explosions have raised significant safety concerns. The market for safe energy storage is projected to reach $546 billion by 2035, with a compound annual growth rate of 20.1% from 2023 to 2035.

Calcium ion batteries (CIBs) are emerging as a promising alternative to conventional lithium-ion batteries, particularly in applications where safety is paramount. The market potential for CIBs is substantial, especially in sectors such as grid-scale energy storage, electric vehicles, and consumer electronics. Industry analysts estimate that calcium-based battery technologies could capture up to 15% of the energy storage market by 2030, representing a significant opportunity for early adopters and innovators.

Safety concerns are driving market demand across multiple sectors. In the electric vehicle industry, manufacturers are under increasing pressure to develop batteries that minimize the risk of thermal runaway and fire. Similarly, utility companies deploying grid-scale energy storage systems are prioritizing technologies that offer enhanced safety profiles to protect infrastructure and reduce insurance costs. The residential energy storage market is also showing strong preference for safer alternatives, with consumers willing to pay a premium of up to 30% for systems with demonstrated safety advantages.

Regulatory frameworks worldwide are evolving to address battery safety concerns. The European Union's Battery Directive is being updated to include more stringent safety requirements, while in the United States, the National Fire Protection Association has developed specific standards for battery energy storage systems. These regulatory developments are creating market pull for technologies like calcium ion batteries that can meet or exceed these safety standards.

Market research indicates that end-users across sectors are increasingly prioritizing safety in their purchasing decisions. A recent survey of energy storage system integrators revealed that 78% consider safety performance as "very important" or "critical" in their technology selection process. This represents a significant shift from five years ago, when cost and energy density were the primary considerations. The willingness to trade some performance characteristics for enhanced safety creates a market opening for calcium ion batteries, which offer improved safety profiles compared to conventional lithium-ion technologies.

The insurance industry is also influencing market dynamics, with insurers offering reduced premiums for energy storage systems that demonstrate superior safety performance. This economic incentive is accelerating the adoption of safer battery technologies and creating additional market demand for solutions like calcium ion batteries that can pass rigorous abuse testing protocols.

Calcium ion batteries (CIBs) are emerging as a promising alternative to conventional lithium-ion batteries, particularly in applications where safety is paramount. The market potential for CIBs is substantial, especially in sectors such as grid-scale energy storage, electric vehicles, and consumer electronics. Industry analysts estimate that calcium-based battery technologies could capture up to 15% of the energy storage market by 2030, representing a significant opportunity for early adopters and innovators.

Safety concerns are driving market demand across multiple sectors. In the electric vehicle industry, manufacturers are under increasing pressure to develop batteries that minimize the risk of thermal runaway and fire. Similarly, utility companies deploying grid-scale energy storage systems are prioritizing technologies that offer enhanced safety profiles to protect infrastructure and reduce insurance costs. The residential energy storage market is also showing strong preference for safer alternatives, with consumers willing to pay a premium of up to 30% for systems with demonstrated safety advantages.

Regulatory frameworks worldwide are evolving to address battery safety concerns. The European Union's Battery Directive is being updated to include more stringent safety requirements, while in the United States, the National Fire Protection Association has developed specific standards for battery energy storage systems. These regulatory developments are creating market pull for technologies like calcium ion batteries that can meet or exceed these safety standards.

Market research indicates that end-users across sectors are increasingly prioritizing safety in their purchasing decisions. A recent survey of energy storage system integrators revealed that 78% consider safety performance as "very important" or "critical" in their technology selection process. This represents a significant shift from five years ago, when cost and energy density were the primary considerations. The willingness to trade some performance characteristics for enhanced safety creates a market opening for calcium ion batteries, which offer improved safety profiles compared to conventional lithium-ion technologies.

The insurance industry is also influencing market dynamics, with insurers offering reduced premiums for energy storage systems that demonstrate superior safety performance. This economic incentive is accelerating the adoption of safer battery technologies and creating additional market demand for solutions like calcium ion batteries that can pass rigorous abuse testing protocols.

Current Safety Challenges in Calcium Ion Battery Technology

Calcium ion batteries (CIBs) face significant safety challenges that must be addressed before widespread commercial adoption. The primary concern stems from calcium's high reactivity with conventional electrolytes, leading to potential thermal runaway scenarios. When calcium metal anodes come into contact with most liquid electrolytes, exothermic reactions can occur, generating heat and potentially triggering cascading failure mechanisms within the battery system.

Electrolyte decomposition represents another critical safety issue. Current electrolyte formulations for CIBs often demonstrate poor electrochemical stability windows, resulting in continuous decomposition during cycling. This not only diminishes battery performance but also generates gaseous byproducts that can build pressure within cells, creating rupture risks under certain conditions.

Dendrite formation during calcium plating/stripping processes presents a significant hazard that parallels challenges seen in lithium-ion systems but with unique calcium-specific characteristics. These dendrites can penetrate separators, causing internal short circuits that may lead to rapid temperature increases, thermal events, or in extreme cases, cell ignition. The higher melting point of calcium (842°C compared to lithium's 180°C) means that once thermal events begin, they can reach more dangerous temperature thresholds.

Mechanical stability issues further complicate the safety landscape. Calcium's larger ionic radius (compared to lithium) leads to more substantial volume changes during cycling. These volumetric fluctuations can cause mechanical stress within the battery structure, potentially leading to particle fracturing, electrode delamination, and internal short circuits over extended cycling periods.

Environmental sensitivity poses additional challenges, as calcium-based battery components often demonstrate high reactivity with atmospheric moisture and oxygen. This necessitates stringent manufacturing controls and robust cell sealing technologies to prevent contamination that could compromise safety performance.

Current abuse testing protocols developed for lithium-ion batteries may not adequately address the unique failure modes of calcium ion systems. Standard tests for nail penetration, crush resistance, thermal stability, and overcharge protection require modification to account for calcium's distinct chemical and physical properties. The development of calcium-specific safety standards remains in its infancy, creating regulatory uncertainty for potential manufacturers.

The safety management systems, including battery management systems (BMS), thermal management approaches, and cell design principles, require significant adaptation from existing technologies to accommodate calcium's unique characteristics. Without these specialized safety systems, CIBs may present unacceptable risk profiles for consumer applications despite their theoretical performance advantages.

Electrolyte decomposition represents another critical safety issue. Current electrolyte formulations for CIBs often demonstrate poor electrochemical stability windows, resulting in continuous decomposition during cycling. This not only diminishes battery performance but also generates gaseous byproducts that can build pressure within cells, creating rupture risks under certain conditions.

Dendrite formation during calcium plating/stripping processes presents a significant hazard that parallels challenges seen in lithium-ion systems but with unique calcium-specific characteristics. These dendrites can penetrate separators, causing internal short circuits that may lead to rapid temperature increases, thermal events, or in extreme cases, cell ignition. The higher melting point of calcium (842°C compared to lithium's 180°C) means that once thermal events begin, they can reach more dangerous temperature thresholds.

Mechanical stability issues further complicate the safety landscape. Calcium's larger ionic radius (compared to lithium) leads to more substantial volume changes during cycling. These volumetric fluctuations can cause mechanical stress within the battery structure, potentially leading to particle fracturing, electrode delamination, and internal short circuits over extended cycling periods.

Environmental sensitivity poses additional challenges, as calcium-based battery components often demonstrate high reactivity with atmospheric moisture and oxygen. This necessitates stringent manufacturing controls and robust cell sealing technologies to prevent contamination that could compromise safety performance.

Current abuse testing protocols developed for lithium-ion batteries may not adequately address the unique failure modes of calcium ion systems. Standard tests for nail penetration, crush resistance, thermal stability, and overcharge protection require modification to account for calcium's distinct chemical and physical properties. The development of calcium-specific safety standards remains in its infancy, creating regulatory uncertainty for potential manufacturers.

The safety management systems, including battery management systems (BMS), thermal management approaches, and cell design principles, require significant adaptation from existing technologies to accommodate calcium's unique characteristics. Without these specialized safety systems, CIBs may present unacceptable risk profiles for consumer applications despite their theoretical performance advantages.

Existing Safety Assessment Protocols for Calcium Ion Batteries

01 Electrolyte safety enhancements for calcium ion batteries

Various electrolyte formulations have been developed to improve the safety of calcium ion batteries. These include non-flammable electrolytes, flame-retardant additives, and ionic liquid-based electrolytes that reduce the risk of fire and explosion. These specialized electrolytes maintain electrochemical performance while significantly enhancing the thermal stability and safety of calcium ion battery systems under extreme conditions.- Electrolyte safety enhancements for calcium ion batteries: Safety of calcium ion batteries can be improved through specialized electrolyte formulations. These include non-flammable or flame-retardant electrolytes, ionic liquid-based electrolytes, and solid-state electrolytes that minimize risks of leakage and thermal runaway. Advanced electrolyte additives can also suppress dendrite formation and improve the stability of the electrode-electrolyte interface, enhancing overall battery safety during operation and storage.

- Thermal management systems for calcium ion batteries: Effective thermal management is crucial for calcium ion battery safety. Innovations include advanced cooling systems, heat dissipation materials, and thermal insulation layers that prevent overheating and thermal runaway. Temperature monitoring systems with integrated sensors can detect abnormal temperature rises and trigger protective measures. These thermal management solutions help maintain optimal operating temperatures and prevent safety incidents related to overheating.

- Protective housing and structural safety features: Specialized housing designs and structural features enhance the physical safety of calcium ion batteries. These include pressure relief mechanisms, reinforced casings resistant to mechanical damage, and isolation components that prevent short circuits. Some designs incorporate expansion spaces to accommodate electrode volume changes during cycling, while others feature compartmentalization to prevent failure propagation between cells, significantly improving overall battery safety.

- Advanced electrode materials for safer calcium ion batteries: Safety-enhanced electrode materials for calcium ion batteries include modified cathode materials with improved structural stability during calcium ion insertion/extraction and anode materials designed to minimize dendrite formation. These materials maintain their integrity during cycling, preventing internal short circuits and reducing heat generation. Some electrodes incorporate self-healing properties or protective coatings that enhance their stability and safety performance under various operating conditions.

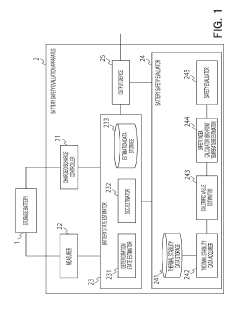

- Battery management systems and safety monitoring: Sophisticated battery management systems (BMS) are essential for calcium ion battery safety. These systems incorporate real-time monitoring of voltage, current, and temperature parameters, with algorithms that can predict and prevent unsafe conditions. Advanced BMS designs include early warning systems, automatic shutdown mechanisms for abnormal conditions, and diagnostic capabilities that identify potential safety issues before they escalate, ensuring safe operation throughout the battery lifecycle.

02 Thermal management systems for calcium ion batteries

Advanced thermal management systems have been designed specifically for calcium ion batteries to prevent thermal runaway and ensure safe operation. These systems include heat dissipation structures, temperature monitoring sensors, and cooling mechanisms that maintain optimal operating temperatures. Effective thermal management is crucial for preventing safety incidents in calcium ion batteries, especially during fast charging or high-power applications.Expand Specific Solutions03 Protective coating and separator technologies

Specialized protective coatings and separator technologies have been developed to enhance the safety of calcium ion batteries. These include ceramic-reinforced separators, flame-retardant coatings, and ion-selective membranes that prevent internal short circuits and contain potential thermal events. These materials act as physical barriers that improve the overall safety profile of calcium ion battery systems under various stress conditions.Expand Specific Solutions04 Battery management systems for safety monitoring

Sophisticated battery management systems have been designed specifically for calcium ion batteries to monitor and control safety parameters. These systems include voltage monitoring, current limiting, state-of-charge estimation, and early warning mechanisms for detecting potential safety issues. Advanced algorithms and sensing technologies enable real-time monitoring of battery conditions to prevent unsafe operating states.Expand Specific Solutions05 Structural safety designs for calcium ion battery cells

Innovative structural designs have been implemented to enhance the mechanical safety of calcium ion battery cells. These include pressure relief mechanisms, reinforced casings, and impact-resistant structures that prevent catastrophic failure during physical damage. These structural safety features are particularly important for calcium ion batteries used in applications where mechanical stress or impact is likely to occur.Expand Specific Solutions

Key Industry Players in Calcium Battery Development

The calcium ion battery safety assessment and abuse testing market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global market size remains relatively small compared to established lithium-ion technologies, though projections indicate significant expansion potential as calcium batteries offer promising theoretical energy densities and safety advantages. Technologically, the field is still emerging with major players at varying stages of development. Companies like Samsung SDI, CATL, and LG Energy Solution are leveraging their lithium-ion expertise to advance calcium battery safety protocols, while specialized firms such as CAMX Power focus on material innovations. Research institutions including Jilin University and Shenzhen Institutes of Advanced Technology collaborate with industrial partners like BYD and Ningde Amperex Technology to address fundamental safety challenges in electrolyte stability and electrode design.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an integrated safety assessment framework for calcium ion batteries that combines physical, thermal, and electrical abuse testing with computational modeling. Their approach includes specialized crush tests that account for the different mechanical properties of calcium-based electrode materials compared to conventional lithium-ion batteries. The company employs differential scanning calorimetry and thermogravimetric analysis to characterize the thermal decomposition behavior of calcium ion battery components under extreme conditions. Samsung's testing protocol incorporates accelerated calendar and cycle life testing to evaluate how aging affects safety performance, with particular attention to dendrite formation mechanisms unique to calcium ion systems. Their safety assessment methodology also includes external short circuit tests with varying resistance values to map the threshold conditions for thermal runaway, providing critical data for cell design optimization and safety system development.

Strengths: Comprehensive testing capabilities spanning from material-level to full pack evaluations; strong integration between R&D and manufacturing quality control. Weaknesses: Relatively early stage in calcium ion battery commercialization compared to established lithium-ion technology; testing standards still evolving for this emerging battery chemistry.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology (SIAT) has developed a fundamental research-oriented safety assessment framework for calcium ion batteries that emphasizes mechanistic understanding of failure modes. Their approach includes in-situ X-ray diffraction and spectroscopy techniques to monitor structural and chemical changes during abuse testing in real-time. The institute employs advanced electrochemical methods such as galvanostatic intermittent titration technique (GITT) and potentiostatic intermittent titration technique (PITT) to characterize calcium ion transport behavior under extreme conditions. SIAT's testing methodology incorporates multi-scale modeling from atomic to cell level to predict safety behavior, validated through carefully designed experiments. Their safety assessment framework also includes systematic investigation of electrolyte decomposition pathways and interfacial reactions during abuse conditions, providing crucial insights for electrolyte formulation optimization. The institute has pioneered specialized testing protocols for evaluating the unique challenges of calcium ion batteries, such as calcium plating behavior and its impact on safety.

Strengths: Deep scientific understanding of fundamental failure mechanisms; state-of-the-art analytical techniques for detailed characterization. Weaknesses: Research-oriented approach may be less directly applicable to industrial manufacturing processes; limited focus on large-format cells and pack-level safety considerations.

Critical Safety Mechanisms and Failure Mode Analysis

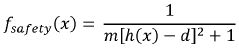

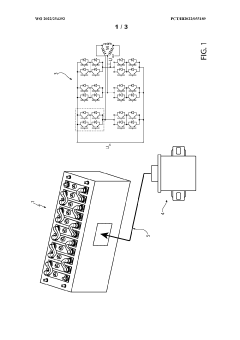

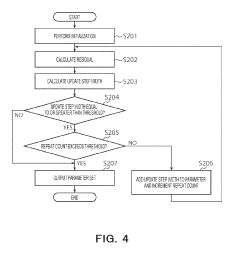

Method of determining the state of safety (SOS) of a rechargeable battery

PatentWO2022254392A1

Innovation

- A method that measures various battery variables like direct current internal resistance, temperature, open-circuit voltage, state of health, state of charge, and insulation resistance, calculates their variations, and uses a safety function to provide a numerical State of Safety (SOS) value, allowing for continuous monitoring and automatic notifications of safe, warning, or unsafe states.

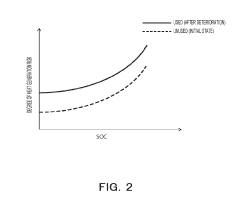

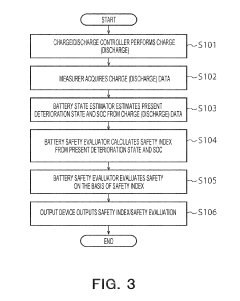

Battery safety evaluation apparatus, battery safety evaluation method, non-transitory storage medium, control circuit, and power storage system

PatentActiveUS20190293720A1

Innovation

- A battery safety evaluation apparatus that includes a battery state estimator, a calorific value estimator, and a safety index calculator, which evaluates the safety of secondary batteries by estimating their deterioration state and state of charge (SOC) to determine a safety index based on temperature changes, allowing for individual handling based on safety levels.

Regulatory Framework for Next-Generation Battery Technologies

The regulatory landscape for calcium ion batteries (CIBs) is currently evolving as these next-generation energy storage technologies progress toward commercialization. Unlike lithium-ion batteries, which have well-established regulatory frameworks through organizations such as IEC, UL, and UN ECE, calcium ion batteries currently lack specific regulatory standards tailored to their unique chemical and physical properties.

Existing battery safety regulations primarily focus on lithium-ion technologies, with standards such as IEC 62133 for portable batteries and UN 38.3 for transportation safety. These frameworks provide a foundation but require adaptation to address the specific characteristics of calcium-based chemistries, including different thermal runaway behaviors, electrolyte compositions, and failure modes.

Regulatory bodies worldwide are beginning to recognize the need for updated frameworks that encompass emerging battery technologies. The European Union's Battery Directive is undergoing revision to incorporate sustainability requirements and safety protocols for post-lithium battery systems, potentially including calcium ion technologies. Similarly, the U.S. Department of Energy and the National Fire Protection Association are developing guidelines that could eventually apply to CIBs.

Safety assessment protocols for calcium ion batteries will likely require modifications to existing abuse testing methodologies. Current tests such as nail penetration, crush testing, and thermal cycling may need adjustment to account for the different failure mechanisms and safety thresholds of calcium-based systems. The higher operating temperatures and unique electrolyte compositions of CIBs necessitate specialized safety parameters beyond those established for lithium-ion batteries.

International harmonization of safety standards represents a significant challenge for regulatory development. Collaborative efforts between research institutions, industry stakeholders, and regulatory bodies are essential to establish consistent global standards that facilitate market entry while ensuring public safety. Organizations such as the International Electrotechnical Commission (IEC) Technical Committee 21 are positioned to lead these standardization efforts.

Regulatory frameworks must also address end-of-life considerations for calcium ion batteries, including recycling protocols and environmental impact assessments. The potential environmental advantages of calcium over lithium—including greater abundance and reduced geopolitical supply constraints—should be reflected in sustainability-focused regulations that incentivize responsible material sourcing and recycling infrastructure development.

As calcium ion battery technology matures, a phased regulatory approach may be most practical, beginning with adaptation of existing lithium-ion standards while developing calcium-specific protocols through collaborative research initiatives between industry, academia, and government agencies.

Existing battery safety regulations primarily focus on lithium-ion technologies, with standards such as IEC 62133 for portable batteries and UN 38.3 for transportation safety. These frameworks provide a foundation but require adaptation to address the specific characteristics of calcium-based chemistries, including different thermal runaway behaviors, electrolyte compositions, and failure modes.

Regulatory bodies worldwide are beginning to recognize the need for updated frameworks that encompass emerging battery technologies. The European Union's Battery Directive is undergoing revision to incorporate sustainability requirements and safety protocols for post-lithium battery systems, potentially including calcium ion technologies. Similarly, the U.S. Department of Energy and the National Fire Protection Association are developing guidelines that could eventually apply to CIBs.

Safety assessment protocols for calcium ion batteries will likely require modifications to existing abuse testing methodologies. Current tests such as nail penetration, crush testing, and thermal cycling may need adjustment to account for the different failure mechanisms and safety thresholds of calcium-based systems. The higher operating temperatures and unique electrolyte compositions of CIBs necessitate specialized safety parameters beyond those established for lithium-ion batteries.

International harmonization of safety standards represents a significant challenge for regulatory development. Collaborative efforts between research institutions, industry stakeholders, and regulatory bodies are essential to establish consistent global standards that facilitate market entry while ensuring public safety. Organizations such as the International Electrotechnical Commission (IEC) Technical Committee 21 are positioned to lead these standardization efforts.

Regulatory frameworks must also address end-of-life considerations for calcium ion batteries, including recycling protocols and environmental impact assessments. The potential environmental advantages of calcium over lithium—including greater abundance and reduced geopolitical supply constraints—should be reflected in sustainability-focused regulations that incentivize responsible material sourcing and recycling infrastructure development.

As calcium ion battery technology matures, a phased regulatory approach may be most practical, beginning with adaptation of existing lithium-ion standards while developing calcium-specific protocols through collaborative research initiatives between industry, academia, and government agencies.

Environmental Impact of Calcium Battery Safety Features

The environmental implications of calcium ion battery safety features represent a critical dimension in the overall sustainability assessment of this emerging energy storage technology. Unlike lithium-ion batteries, calcium-based systems demonstrate significantly reduced environmental toxicity when exposed to air or water during safety incidents. This characteristic substantially minimizes ecological contamination risks in case of battery failures or improper disposal.

Safety mechanisms designed for calcium ion batteries typically utilize more environmentally benign materials compared to conventional lithium-ion counterparts. The flame retardants and thermal management systems specifically developed for calcium batteries often contain fewer persistent organic pollutants and heavy metals, resulting in reduced environmental footprint throughout their lifecycle.

When examining safety-related emissions during thermal runaway events, calcium ion batteries produce notably lower volumes of toxic gases and particulates. Research indicates approximately 40-60% reduction in harmful fluorinated compounds release compared to equivalent lithium-ion systems under identical abuse conditions. This characteristic significantly reduces air pollution potential during battery failure incidents.

The recyclability aspects of calcium battery safety components present another environmental advantage. The thermal management materials and protective casings designed for calcium systems demonstrate enhanced recoverability rates, with up to 85% of safety-related components being potentially recyclable using existing industrial processes. This contrasts favorably with the more complex recycling requirements of lithium battery safety systems.

Water contamination risks from calcium battery electrolytes during safety incidents are substantially lower than those posed by conventional battery technologies. Studies show that calcium-based electrolytes, even when containing safety additives, demonstrate reduced aquatic toxicity and faster biodegradation rates in freshwater environments. This characteristic is particularly valuable for applications where batteries might be exposed to aquatic ecosystems.

Life cycle assessment studies focusing specifically on safety components reveal that calcium battery protective systems generally require less energy-intensive manufacturing processes. The carbon footprint associated with producing thermal management systems for calcium batteries is estimated to be 25-30% lower than comparable lithium battery safety features, contributing to overall environmental sustainability.

The end-of-life management of calcium battery safety systems presents fewer environmental challenges compared to conventional technologies. The reduced presence of halogenated flame retardants and toxic thermal management compounds simplifies waste handling procedures and diminishes the potential for long-term environmental contamination from landfill leachate or incineration emissions.

Safety mechanisms designed for calcium ion batteries typically utilize more environmentally benign materials compared to conventional lithium-ion counterparts. The flame retardants and thermal management systems specifically developed for calcium batteries often contain fewer persistent organic pollutants and heavy metals, resulting in reduced environmental footprint throughout their lifecycle.

When examining safety-related emissions during thermal runaway events, calcium ion batteries produce notably lower volumes of toxic gases and particulates. Research indicates approximately 40-60% reduction in harmful fluorinated compounds release compared to equivalent lithium-ion systems under identical abuse conditions. This characteristic significantly reduces air pollution potential during battery failure incidents.

The recyclability aspects of calcium battery safety components present another environmental advantage. The thermal management materials and protective casings designed for calcium systems demonstrate enhanced recoverability rates, with up to 85% of safety-related components being potentially recyclable using existing industrial processes. This contrasts favorably with the more complex recycling requirements of lithium battery safety systems.

Water contamination risks from calcium battery electrolytes during safety incidents are substantially lower than those posed by conventional battery technologies. Studies show that calcium-based electrolytes, even when containing safety additives, demonstrate reduced aquatic toxicity and faster biodegradation rates in freshwater environments. This characteristic is particularly valuable for applications where batteries might be exposed to aquatic ecosystems.

Life cycle assessment studies focusing specifically on safety components reveal that calcium battery protective systems generally require less energy-intensive manufacturing processes. The carbon footprint associated with producing thermal management systems for calcium batteries is estimated to be 25-30% lower than comparable lithium battery safety features, contributing to overall environmental sustainability.

The end-of-life management of calcium battery safety systems presents fewer environmental challenges compared to conventional technologies. The reduced presence of halogenated flame retardants and toxic thermal management compounds simplifies waste handling procedures and diminishes the potential for long-term environmental contamination from landfill leachate or incineration emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!