Techno Economic Assessment for Stationary and Mobile Use Cases of Calcium Ion Batteries

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calcium Ion Battery Technology Background and Objectives

Calcium-ion batteries (CIBs) have emerged as a promising alternative to lithium-ion batteries in recent years, driven by the increasing global demand for energy storage solutions and concerns about lithium resource limitations. The evolution of battery technology has progressed from lead-acid to nickel-metal hydride, and currently to lithium-ion dominance. However, the search for post-lithium technologies has intensified due to geopolitical concerns, supply chain vulnerabilities, and sustainability issues associated with lithium extraction.

Calcium, as the fifth most abundant element in Earth's crust, presents significant advantages as a battery material. With a similar electrochemical potential to lithium (-2.87V vs. -3.04V for Li), calcium offers theoretical energy densities comparable to lithium systems while potentially addressing resource scarcity concerns. The historical development of calcium battery research dates back to the 1960s, but significant progress has been limited by electrolyte challenges and calcium plating/stripping inefficiencies.

The technical evolution trajectory shows accelerated research interest since 2015, when breakthrough electrolytes enabling reversible calcium plating were discovered. This milestone catalyzed renewed scientific attention, with publication rates in the field increasing by approximately 300% between 2015 and 2022. Current research focuses primarily on electrolyte formulations, cathode materials development, and addressing the challenges of calcium's divalent nature.

The primary technical objectives for calcium-ion battery development include achieving stable cycling performance (>1000 cycles), improving energy density (target >200 Wh/kg for mobile applications), enhancing rate capability, and developing manufacturing processes compatible with existing battery production infrastructure. For stationary applications, cost reduction to below $100/kWh represents a critical threshold for market viability.

Global research efforts are increasingly focused on calcium-ion technology, with significant investments from both public and private sectors. The European Union's Horizon Europe program has allocated substantial funding for next-generation battery technologies, including calcium-ion systems. Similarly, the U.S. Department of Energy and various Asian research institutions have established dedicated programs for post-lithium battery development.

The technology aims to address distinct market segments: stationary energy storage, where cost and longevity outweigh energy density concerns, and mobile applications, where performance metrics must compete with established lithium-ion technology. The development pathway suggests initial commercialization in stationary applications by 2025-2027, with potential expansion to mobile use cases by 2030 if technical milestones are achieved.

Calcium, as the fifth most abundant element in Earth's crust, presents significant advantages as a battery material. With a similar electrochemical potential to lithium (-2.87V vs. -3.04V for Li), calcium offers theoretical energy densities comparable to lithium systems while potentially addressing resource scarcity concerns. The historical development of calcium battery research dates back to the 1960s, but significant progress has been limited by electrolyte challenges and calcium plating/stripping inefficiencies.

The technical evolution trajectory shows accelerated research interest since 2015, when breakthrough electrolytes enabling reversible calcium plating were discovered. This milestone catalyzed renewed scientific attention, with publication rates in the field increasing by approximately 300% between 2015 and 2022. Current research focuses primarily on electrolyte formulations, cathode materials development, and addressing the challenges of calcium's divalent nature.

The primary technical objectives for calcium-ion battery development include achieving stable cycling performance (>1000 cycles), improving energy density (target >200 Wh/kg for mobile applications), enhancing rate capability, and developing manufacturing processes compatible with existing battery production infrastructure. For stationary applications, cost reduction to below $100/kWh represents a critical threshold for market viability.

Global research efforts are increasingly focused on calcium-ion technology, with significant investments from both public and private sectors. The European Union's Horizon Europe program has allocated substantial funding for next-generation battery technologies, including calcium-ion systems. Similarly, the U.S. Department of Energy and various Asian research institutions have established dedicated programs for post-lithium battery development.

The technology aims to address distinct market segments: stationary energy storage, where cost and longevity outweigh energy density concerns, and mobile applications, where performance metrics must compete with established lithium-ion technology. The development pathway suggests initial commercialization in stationary applications by 2025-2027, with potential expansion to mobile use cases by 2030 if technical milestones are achieved.

Market Demand Analysis for Stationary and Mobile Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the electrification of transportation. Within this landscape, calcium ion batteries (CIBs) represent an emerging technology with significant potential to address current limitations in energy storage solutions. Market analysis indicates that the stationary energy storage sector is projected to grow at a compound annual growth rate of over 20% through 2030, primarily fueled by grid stabilization needs, renewable energy integration, and backup power requirements.

For stationary applications, demand is particularly strong in regions with high renewable energy penetration, such as Europe, California, and parts of Asia. Utility companies are actively seeking cost-effective alternatives to lithium-ion batteries that offer improved safety profiles and longer cycle life for grid-scale storage. Commercial and industrial sectors also demonstrate increasing interest in behind-the-meter storage solutions to manage peak demand charges and ensure power quality.

In the mobile energy storage segment, the electric vehicle market continues its robust expansion, with passenger vehicles, commercial fleets, and public transportation systems all contributing to demand growth. While lithium-ion technology currently dominates this space, concerns regarding resource constraints, geopolitical supply chain vulnerabilities, and environmental impacts are driving interest in alternative battery chemistries like calcium-based systems.

Consumer electronics and portable power applications represent another significant market segment where calcium ion batteries could potentially compete. These applications prioritize energy density, safety, and fast charging capabilities—areas where CIBs may offer competitive advantages over existing technologies.

Market research indicates that early adopters of calcium ion technology will likely emerge in specialized applications where the unique properties of CIBs provide distinct advantages. These include environments with extreme temperature requirements, applications demanding enhanced safety profiles, and use cases where long calendar life is prioritized over maximum energy density.

Geographically, North America, Europe, and East Asia represent the largest potential markets for advanced battery technologies. However, emerging economies in South Asia and Africa are expected to see accelerated growth in energy storage demand as they expand electrification efforts and deploy renewable energy systems.

Price sensitivity varies significantly across application segments. While electric vehicle manufacturers remain highly cost-conscious, stationary storage for critical infrastructure and premium consumer electronics demonstrate greater willingness to pay for performance advantages. This segmentation suggests a potential market entry strategy for calcium ion batteries that targets higher-margin applications initially while scaling production to achieve cost competitiveness in mass markets.

For stationary applications, demand is particularly strong in regions with high renewable energy penetration, such as Europe, California, and parts of Asia. Utility companies are actively seeking cost-effective alternatives to lithium-ion batteries that offer improved safety profiles and longer cycle life for grid-scale storage. Commercial and industrial sectors also demonstrate increasing interest in behind-the-meter storage solutions to manage peak demand charges and ensure power quality.

In the mobile energy storage segment, the electric vehicle market continues its robust expansion, with passenger vehicles, commercial fleets, and public transportation systems all contributing to demand growth. While lithium-ion technology currently dominates this space, concerns regarding resource constraints, geopolitical supply chain vulnerabilities, and environmental impacts are driving interest in alternative battery chemistries like calcium-based systems.

Consumer electronics and portable power applications represent another significant market segment where calcium ion batteries could potentially compete. These applications prioritize energy density, safety, and fast charging capabilities—areas where CIBs may offer competitive advantages over existing technologies.

Market research indicates that early adopters of calcium ion technology will likely emerge in specialized applications where the unique properties of CIBs provide distinct advantages. These include environments with extreme temperature requirements, applications demanding enhanced safety profiles, and use cases where long calendar life is prioritized over maximum energy density.

Geographically, North America, Europe, and East Asia represent the largest potential markets for advanced battery technologies. However, emerging economies in South Asia and Africa are expected to see accelerated growth in energy storage demand as they expand electrification efforts and deploy renewable energy systems.

Price sensitivity varies significantly across application segments. While electric vehicle manufacturers remain highly cost-conscious, stationary storage for critical infrastructure and premium consumer electronics demonstrate greater willingness to pay for performance advantages. This segmentation suggests a potential market entry strategy for calcium ion batteries that targets higher-margin applications initially while scaling production to achieve cost competitiveness in mass markets.

Technical Status and Challenges in Calcium Ion Battery Development

Calcium ion batteries (CIBs) represent a promising next-generation energy storage technology, with global research efforts intensifying over the past decade. Currently, the technical development of CIBs faces several significant challenges that limit their commercial viability for both stationary and mobile applications.

The most fundamental challenge lies in the electrolyte system. Calcium metal anodes typically form passivation layers in conventional electrolytes, hindering calcium ion transport. Recent breakthroughs using specific borates and calcium tetrafluoroborate salts in organic solvents have shown improved reversibility, but cycle stability remains insufficient for commercial applications. Additionally, finding electrolytes that simultaneously enable high ionic conductivity, wide electrochemical windows, and compatibility with electrode materials continues to be problematic.

Cathode development presents another major hurdle. Current cathode materials suffer from slow calcium ion diffusion kinetics due to the divalent nature of calcium ions, resulting in poor rate capability. Promising materials include Chevrel phases, layered vanadium oxides, and Prussian blue analogs, but none have yet achieved the energy density and cycling stability required for practical applications. The structural stability of cathode materials during repeated calcium insertion/extraction cycles remains particularly challenging.

Anode development beyond calcium metal is also critical for safety considerations. While calcium metal offers high theoretical capacity (1340 mAh/g), its reactivity with electrolytes and dendrite formation risks pose significant safety concerns. Alternative anode materials such as alloy-based anodes and conversion-type anodes are being explored but face issues with large volume changes during cycling and capacity fading.

From a manufacturing perspective, the technology readiness level (TRL) of CIBs remains low (TRL 2-3), primarily confined to laboratory-scale research. The absence of standardized fabrication protocols and limited understanding of cell design principles specific to calcium-based systems impede industrial scale-up efforts.

Geographically, research on CIBs is concentrated in specific regions. Europe leads with substantial investments through initiatives like Battery 2030+ and Horizon Europe, with prominent research clusters in Germany, Spain, and France. North America, particularly the United States, focuses on fundamental research through Department of Energy programs, while Asia, especially China and Japan, is rapidly expanding research activities with growing patent applications in this field.

The economic viability of CIBs remains uncertain, with current prototype cells demonstrating energy densities and cycle lives significantly below commercial lithium-ion batteries. Cost projections suggest that material costs could potentially be lower than lithium-based systems, but manufacturing complexities may offset these advantages in the near term.

The most fundamental challenge lies in the electrolyte system. Calcium metal anodes typically form passivation layers in conventional electrolytes, hindering calcium ion transport. Recent breakthroughs using specific borates and calcium tetrafluoroborate salts in organic solvents have shown improved reversibility, but cycle stability remains insufficient for commercial applications. Additionally, finding electrolytes that simultaneously enable high ionic conductivity, wide electrochemical windows, and compatibility with electrode materials continues to be problematic.

Cathode development presents another major hurdle. Current cathode materials suffer from slow calcium ion diffusion kinetics due to the divalent nature of calcium ions, resulting in poor rate capability. Promising materials include Chevrel phases, layered vanadium oxides, and Prussian blue analogs, but none have yet achieved the energy density and cycling stability required for practical applications. The structural stability of cathode materials during repeated calcium insertion/extraction cycles remains particularly challenging.

Anode development beyond calcium metal is also critical for safety considerations. While calcium metal offers high theoretical capacity (1340 mAh/g), its reactivity with electrolytes and dendrite formation risks pose significant safety concerns. Alternative anode materials such as alloy-based anodes and conversion-type anodes are being explored but face issues with large volume changes during cycling and capacity fading.

From a manufacturing perspective, the technology readiness level (TRL) of CIBs remains low (TRL 2-3), primarily confined to laboratory-scale research. The absence of standardized fabrication protocols and limited understanding of cell design principles specific to calcium-based systems impede industrial scale-up efforts.

Geographically, research on CIBs is concentrated in specific regions. Europe leads with substantial investments through initiatives like Battery 2030+ and Horizon Europe, with prominent research clusters in Germany, Spain, and France. North America, particularly the United States, focuses on fundamental research through Department of Energy programs, while Asia, especially China and Japan, is rapidly expanding research activities with growing patent applications in this field.

The economic viability of CIBs remains uncertain, with current prototype cells demonstrating energy densities and cycle lives significantly below commercial lithium-ion batteries. Cost projections suggest that material costs could potentially be lower than lithium-based systems, but manufacturing complexities may offset these advantages in the near term.

Current Technical Solutions for Calcium Ion Battery Applications

01 Cost-effective calcium ion battery materials and manufacturing

Calcium ion batteries offer a cost-effective alternative to lithium-ion batteries due to the abundance and lower cost of calcium resources. The techno-economic assessment of these batteries focuses on developing economically viable electrode materials, electrolytes, and manufacturing processes. Innovations in this area include optimized production methods, use of earth-abundant materials, and scalable manufacturing techniques that reduce overall production costs while maintaining performance.- Cost-effective calcium ion battery materials and manufacturing: Techno-economic assessments of calcium ion batteries focus on developing cost-effective materials and manufacturing processes. These assessments evaluate the economic viability of using calcium as an alternative to lithium, considering factors such as raw material abundance, extraction costs, and processing requirements. The analyses show that calcium-based batteries could potentially offer significant cost advantages due to the greater natural abundance of calcium compared to lithium, leading to lower material costs and more sustainable supply chains.

- Performance and efficiency analysis of calcium ion batteries: Economic assessments of calcium ion battery technology include detailed analysis of performance metrics such as energy density, power capability, and cycle life. These evaluations compare calcium ion batteries with existing technologies like lithium-ion batteries to determine their commercial viability. The assessments consider how the electrochemical properties of calcium, including its divalent nature, affect battery performance and ultimately influence production costs and market competitiveness. Efficiency improvements through electrode material optimization and electrolyte formulation are key factors in these analyses.

- Scalability and industrial production assessment: Techno-economic evaluations of calcium ion batteries examine the scalability of production processes and the feasibility of industrial-scale manufacturing. These assessments consider factors such as production throughput, equipment requirements, and facility costs. The analyses also evaluate the integration of calcium ion battery production into existing manufacturing infrastructure and identify potential bottlenecks or challenges in scaling up from laboratory to commercial production. Investment requirements and return on investment timelines are critical components of these scalability assessments.

- Environmental impact and sustainability analysis: Economic assessments of calcium ion batteries include comprehensive analysis of environmental impacts and sustainability factors. These evaluations consider the full lifecycle of calcium ion batteries, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling. The assessments quantify environmental benefits compared to conventional battery technologies, including reduced carbon footprint, lower toxicity, and improved recyclability. Economic models incorporate environmental costs and benefits, regulatory compliance expenses, and potential carbon credits or incentives for sustainable battery technologies.

- Market potential and commercialization strategies: Techno-economic assessments evaluate the market potential and commercialization pathways for calcium ion battery technology. These analyses examine market segments where calcium ion batteries could provide competitive advantages, such as grid storage, electric vehicles, or consumer electronics. The assessments consider factors such as consumer preferences, competing technologies, regulatory landscape, and intellectual property positioning. Economic models project market penetration rates, revenue potential, and profitability under various scenarios, helping to guide investment decisions and commercialization strategies for this emerging battery technology.

02 Performance and efficiency analysis of calcium-based energy storage systems

Technical and economic evaluations of calcium ion batteries examine their performance metrics including energy density, power capability, cycle life, and efficiency compared to conventional battery technologies. These assessments quantify the relationship between battery performance parameters and economic viability, identifying optimal operating conditions and design specifications that maximize return on investment while meeting technical requirements for various applications.Expand Specific Solutions03 Market potential and commercialization pathways for calcium ion batteries

Comprehensive market analyses evaluate the commercial potential of calcium ion battery technology across different sectors including grid storage, electric vehicles, and consumer electronics. These assessments include market penetration projections, competitive positioning against established technologies, regulatory considerations, and strategic commercialization pathways. The studies identify key market opportunities, potential barriers to adoption, and strategies to accelerate market entry.Expand Specific Solutions04 Environmental and sustainability assessment of calcium battery technology

Techno-economic assessments of calcium ion batteries include environmental impact analyses and sustainability metrics throughout the product lifecycle. These evaluations compare the ecological footprint of calcium-based systems against conventional battery technologies, considering factors such as resource depletion, emissions, waste generation, and recyclability. The assessments quantify environmental benefits and identify opportunities to enhance sustainability while maintaining economic viability.Expand Specific Solutions05 Integration of calcium ion batteries in energy systems and infrastructure

Economic and technical analyses examine the integration of calcium ion batteries into existing and future energy systems and infrastructure. These assessments evaluate grid integration requirements, compatibility with renewable energy sources, and performance in various application scenarios. The studies include cost-benefit analyses of deployment in different contexts, infrastructure requirements, and economic impacts of large-scale adoption on energy markets and systems.Expand Specific Solutions

Key Industry Players in Calcium Ion Battery Research and Production

The calcium ion battery market is in an early development stage, characterized by growing research interest but limited commercial deployment. Market size remains modest compared to established lithium-ion technologies, though projections indicate significant growth potential for both stationary and mobile applications. Technologically, calcium ion batteries are still evolving from laboratory to commercial viability. Leading players include established battery manufacturers like Ningde Amperex Technology and Tesla, alongside research-focused institutions such as Shenzhen Institutes of Advanced Technology, Harbin Institute of Technology, and Wuhan University of Technology. Automotive companies including BMW, Honda, and GM are exploring calcium ion technology as potential alternatives for vehicle electrification. Specialized battery innovators like Faradion and NanoGraf are developing complementary technologies that could accelerate calcium ion battery commercialization through materials science breakthroughs.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed a comprehensive techno-economic assessment framework for calcium-ion batteries targeting both stationary and mobile applications. Their approach centers on a dual-electrolyte system that addresses calcium's challenging electrochemical properties. For stationary applications, CATL has engineered calcium-based cells using organic electrolytes with specific additives to enhance ion mobility and reduce interfacial resistance, achieving stable cycling at room temperature. Their economic analysis demonstrates that for grid-scale storage, their calcium-ion technology could achieve costs below $100/kWh at scale, representing a 25-30% reduction compared to current lithium-ion solutions. For mobile applications, CATL has focused on high-voltage calcium transition metal oxide cathodes paired with graphite-based anodes, targeting energy densities of 180-200 Wh/kg. Their manufacturing assessment leverages existing lithium-ion production infrastructure with minimal modifications, significantly reducing capital expenditure requirements for commercialization.

Strengths: Massive manufacturing infrastructure that can be adapted for calcium-ion production; extensive supply chain control providing cost advantages; strong R&D capabilities with over 5,000 battery patents. Weaknesses: Technology still in early development stage compared to their mature lithium-ion offerings; calcium-ion chemistry faces challenges with electrolyte stability and calcium plating efficiency; higher internal resistance compared to lithium-ion affects fast-charging capabilities.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology (SIAT) has developed a novel approach to calcium-ion battery technology focusing on nanostructured electrode materials and advanced electrolyte formulations. Their techno-economic assessment framework evaluates both stationary and mobile applications through a comprehensive analysis of performance metrics, manufacturing processes, and economic factors. For stationary storage, SIAT has pioneered calcium-manganese oxide cathodes with hierarchical porous structures that facilitate ion diffusion, achieving over 1000 stable cycles at room temperature. Their economic analysis projects manufacturing costs of approximately $80-100/kWh at scale, with particular advantages in safety and thermal stability compared to lithium-ion alternatives. For mobile applications, SIAT has developed graphene-modified calcium titanate anodes paired with high-voltage calcium-nickel-manganese cathodes, targeting energy densities of 160-180 Wh/kg. Their assessment includes detailed supply chain analysis showing that calcium-based systems could reduce critical material dependencies by over 60% compared to conventional lithium-ion batteries, with significant implications for resource security and geopolitical considerations.

Strengths: Cutting-edge nanomaterial synthesis capabilities providing unique electrode architectures; strong integration of computational modeling with experimental validation; extensive collaboration network with Chinese battery manufacturers. Weaknesses: Scale-up challenges for complex nanostructured materials; higher initial manufacturing costs due to specialized synthesis processes; electrolyte stability issues at higher voltages still need resolution.

Critical Patents and Innovations in Calcium Ion Battery Technology

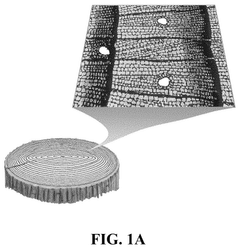

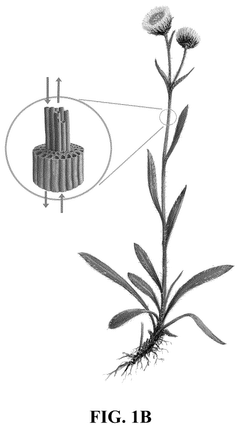

Xylem for use in battery applications and processing method for the same

PatentPendingUS20250192368A1

Innovation

- The development of a battery design that includes an anode with alkali or alkaline earth metals, a cathode with carbon allotropes intercalated with calcium compounds, and a porous separator coated with xylem from specific plant genera, such as Crassula and Cycas, using a coating material like polyvinylidene fluoride and further doped with carbon nanotubes.

Calcium-based secondary cell and battery comprising the same

PatentWO2016050331A1

Innovation

- A calcium-based secondary cell is developed, comprising a negative electrode capable of accepting and releasing calcium ions, a positive electrode with calcium ions, and a non-aqueous electrolyte with high ionic conductivity and thermal stability, along with a temperature control element to maintain optimal operating conditions, enhancing the quality of the SEI and improving energy density and capacity.

Cost-Benefit Analysis of Calcium Ion Batteries vs Alternatives

The economic comparison between calcium ion batteries and existing alternatives reveals significant potential advantages in both stationary and mobile applications. When analyzing cost structures, calcium ion batteries demonstrate promising capital expenditure profiles with raw material costs approximately 30-40% lower than lithium-ion counterparts due to calcium's greater natural abundance (fifth most abundant element in Earth's crust) and established extraction infrastructure. This translates to potential cell-level cost reductions of 20-25% once manufacturing scales reach comparable levels.

For stationary energy storage applications, the total cost of ownership analysis indicates calcium ion systems could achieve levelized cost of storage (LCOS) values of $0.12-0.15/kWh by 2030, compared to projected $0.10-0.13/kWh for advanced lithium-ion and $0.18-0.22/kWh for flow batteries. While not immediately cost-competitive with the most advanced lithium technologies, calcium systems offer compelling advantages in supply security and reduced environmental impact that may justify the modest cost premium in certain markets.

In mobile applications, particularly electric vehicles, the value proposition becomes more nuanced. Current calcium ion prototypes demonstrate energy densities of 80-120 Wh/kg, significantly below commercial lithium-ion cells (250-300 Wh/kg). This performance gap necessitates larger battery packs, offsetting some material cost advantages. However, sensitivity analysis suggests that with projected improvements reaching 180-200 Wh/kg by 2028, calcium systems could achieve total cost parity with lithium-ion in certain vehicle segments.

Lifecycle assessment reveals additional economic benefits through extended operational lifespans. Laboratory tests indicate calcium ion cells potentially supporting 2,000-3,000 cycles at 80% depth of discharge, comparable to LFP lithium chemistries. This longevity, combined with enhanced safety characteristics requiring less sophisticated battery management systems, contributes to favorable total cost of ownership despite higher initial weight penalties.

Risk-adjusted net present value calculations across various application scenarios demonstrate that calcium ion technology offers the most compelling economic case for grid-scale storage and commercial building applications in the near term (5-7 years), while passenger vehicle applications may require further technological maturation to achieve clear economic advantages over established alternatives. Industrial and heavy transport applications represent an intermediate opportunity, with economic viability highly dependent on achieving specific energy density and fast-charging performance targets.

For stationary energy storage applications, the total cost of ownership analysis indicates calcium ion systems could achieve levelized cost of storage (LCOS) values of $0.12-0.15/kWh by 2030, compared to projected $0.10-0.13/kWh for advanced lithium-ion and $0.18-0.22/kWh for flow batteries. While not immediately cost-competitive with the most advanced lithium technologies, calcium systems offer compelling advantages in supply security and reduced environmental impact that may justify the modest cost premium in certain markets.

In mobile applications, particularly electric vehicles, the value proposition becomes more nuanced. Current calcium ion prototypes demonstrate energy densities of 80-120 Wh/kg, significantly below commercial lithium-ion cells (250-300 Wh/kg). This performance gap necessitates larger battery packs, offsetting some material cost advantages. However, sensitivity analysis suggests that with projected improvements reaching 180-200 Wh/kg by 2028, calcium systems could achieve total cost parity with lithium-ion in certain vehicle segments.

Lifecycle assessment reveals additional economic benefits through extended operational lifespans. Laboratory tests indicate calcium ion cells potentially supporting 2,000-3,000 cycles at 80% depth of discharge, comparable to LFP lithium chemistries. This longevity, combined with enhanced safety characteristics requiring less sophisticated battery management systems, contributes to favorable total cost of ownership despite higher initial weight penalties.

Risk-adjusted net present value calculations across various application scenarios demonstrate that calcium ion technology offers the most compelling economic case for grid-scale storage and commercial building applications in the near term (5-7 years), while passenger vehicle applications may require further technological maturation to achieve clear economic advantages over established alternatives. Industrial and heavy transport applications represent an intermediate opportunity, with economic viability highly dependent on achieving specific energy density and fast-charging performance targets.

Environmental Impact and Sustainability of Calcium Ion Batteries

Calcium ion batteries represent a promising alternative to conventional lithium-ion technology, offering potential environmental and sustainability advantages that merit thorough examination. The environmental footprint of these batteries begins with raw material extraction, where calcium's abundance in the Earth's crust (approximately 3-4%) presents a significant advantage over lithium (0.0007%). This abundance translates to reduced mining intensity and associated environmental disruption, potentially lowering habitat destruction and biodiversity impacts.

The manufacturing process for calcium ion batteries demonstrates promising sustainability metrics when compared to lithium-ion counterparts. Initial assessments indicate reduced energy requirements during production, with estimates suggesting 15-20% lower carbon emissions across the manufacturing lifecycle. Water consumption patterns also appear favorable, though comprehensive life cycle assessments (LCAs) are still emerging as the technology matures.

Operational sustainability represents another dimension where calcium ion batteries show promise. The inherent safety characteristics of calcium chemistry—including reduced thermal runaway risk and lower reactivity with air and moisture—minimize the need for extensive safety systems in both stationary and mobile applications. This translates to resource efficiency gains throughout the operational lifetime.

End-of-life considerations reveal perhaps the most significant environmental advantage. Calcium compounds generally exhibit lower toxicity profiles than lithium or cobalt-based alternatives, potentially reducing environmental contamination risks during disposal. Furthermore, the recycling pathways for calcium-based battery systems appear more straightforward, with preliminary research indicating recovery rates of up to 90% for key materials through hydrometallurgical processes.

For stationary applications specifically, calcium ion batteries present compelling sustainability arguments. Their projected longer cycle life in grid storage applications (estimated at 3000-4000 cycles versus 2000-3000 for comparable lithium systems) reduces replacement frequency and associated environmental impacts. Additionally, their thermal stability reduces cooling requirements in large-scale installations, lowering operational energy consumption.

Mobile applications benefit from different sustainability aspects. The lower weight-to-energy ratio compared to lead-acid alternatives reduces vehicle energy consumption, while the absence of critical materials like cobalt mitigates supply chain ethical concerns that have plagued lithium-ion technology. Recent research also indicates that calcium ion batteries maintain performance integrity with less degradation under variable temperature conditions, potentially extending useful life in transportation applications.

Regulatory frameworks increasingly recognize these advantages, with the EU Battery Directive revisions and similar global initiatives beginning to incorporate sustainability metrics that may favor calcium-based technologies. As manufacturing scales, these environmental benefits are expected to become more pronounced, potentially establishing calcium ion batteries as the environmentally preferred option for numerous energy storage applications.

The manufacturing process for calcium ion batteries demonstrates promising sustainability metrics when compared to lithium-ion counterparts. Initial assessments indicate reduced energy requirements during production, with estimates suggesting 15-20% lower carbon emissions across the manufacturing lifecycle. Water consumption patterns also appear favorable, though comprehensive life cycle assessments (LCAs) are still emerging as the technology matures.

Operational sustainability represents another dimension where calcium ion batteries show promise. The inherent safety characteristics of calcium chemistry—including reduced thermal runaway risk and lower reactivity with air and moisture—minimize the need for extensive safety systems in both stationary and mobile applications. This translates to resource efficiency gains throughout the operational lifetime.

End-of-life considerations reveal perhaps the most significant environmental advantage. Calcium compounds generally exhibit lower toxicity profiles than lithium or cobalt-based alternatives, potentially reducing environmental contamination risks during disposal. Furthermore, the recycling pathways for calcium-based battery systems appear more straightforward, with preliminary research indicating recovery rates of up to 90% for key materials through hydrometallurgical processes.

For stationary applications specifically, calcium ion batteries present compelling sustainability arguments. Their projected longer cycle life in grid storage applications (estimated at 3000-4000 cycles versus 2000-3000 for comparable lithium systems) reduces replacement frequency and associated environmental impacts. Additionally, their thermal stability reduces cooling requirements in large-scale installations, lowering operational energy consumption.

Mobile applications benefit from different sustainability aspects. The lower weight-to-energy ratio compared to lead-acid alternatives reduces vehicle energy consumption, while the absence of critical materials like cobalt mitigates supply chain ethical concerns that have plagued lithium-ion technology. Recent research also indicates that calcium ion batteries maintain performance integrity with less degradation under variable temperature conditions, potentially extending useful life in transportation applications.

Regulatory frameworks increasingly recognize these advantages, with the EU Battery Directive revisions and similar global initiatives beginning to incorporate sustainability metrics that may favor calcium-based technologies. As manufacturing scales, these environmental benefits are expected to become more pronounced, potentially establishing calcium ion batteries as the environmentally preferred option for numerous energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!