Manufacturing Readiness Levels and Supply Chain Considerations for Calcium Ion Batteries

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ca-Ion Battery Development Background and Objectives

Calcium-ion batteries (CIBs) have emerged as a promising alternative to lithium-ion batteries in recent years, driven by the increasing global demand for sustainable and cost-effective energy storage solutions. The development of CIBs traces back to early 2010s when researchers began exploring multivalent ion chemistries beyond lithium. Calcium, as the fifth most abundant element in Earth's crust, presents significant advantages in terms of resource availability, with reserves approximately 2,000 times greater than lithium.

The evolution of CIB technology has been marked by several key milestones, including the first reversible calcium plating demonstrated in 2016 and subsequent advancements in electrolyte formulations that enabled improved cycling stability. The fundamental appeal of calcium-ion technology lies in its theoretical capacity of 1,340 mAh/g and standard reduction potential of -2.87V vs. SHE, positioning it competitively against lithium-based systems while offering potential cost advantages.

Current technical objectives for CIB development focus on addressing several critical challenges that have hindered commercial viability. Primary among these is the development of electrolytes that facilitate efficient calcium-ion transport while maintaining stability across wide voltage windows. Researchers aim to achieve calcium plating/stripping coulombic efficiencies exceeding 99.9% at practical current densities, comparable to commercial lithium-ion systems.

Another key objective involves the design of cathode materials capable of accommodating the larger ionic radius of Ca2+ (100 pm versus 76 pm for Li+) while maintaining structural integrity during repeated cycling. The development of host structures that enable rapid calcium-ion diffusion without significant volume changes represents a central research focus, with targets of achieving energy densities above 250 Wh/kg at the cell level.

The manufacturing readiness level (MRL) of calcium-ion batteries currently stands between 3-4 on the 9-point scale, indicating that basic manufacturing implications have been identified but significant process development remains necessary. A primary objective in advancing MRLs involves establishing scalable production methods for specialized electrolytes and electrode materials optimized for calcium-ion chemistry.

Supply chain considerations have become increasingly important in CIB development strategy, with objectives centered on reducing dependence on critical materials and establishing sustainable sourcing pathways. The abundant nature of calcium resources offers potential advantages in supply security, though specialized materials for electrolytes and current collectors may present supply chain vulnerabilities that require strategic planning and alternative material development.

The evolution of CIB technology has been marked by several key milestones, including the first reversible calcium plating demonstrated in 2016 and subsequent advancements in electrolyte formulations that enabled improved cycling stability. The fundamental appeal of calcium-ion technology lies in its theoretical capacity of 1,340 mAh/g and standard reduction potential of -2.87V vs. SHE, positioning it competitively against lithium-based systems while offering potential cost advantages.

Current technical objectives for CIB development focus on addressing several critical challenges that have hindered commercial viability. Primary among these is the development of electrolytes that facilitate efficient calcium-ion transport while maintaining stability across wide voltage windows. Researchers aim to achieve calcium plating/stripping coulombic efficiencies exceeding 99.9% at practical current densities, comparable to commercial lithium-ion systems.

Another key objective involves the design of cathode materials capable of accommodating the larger ionic radius of Ca2+ (100 pm versus 76 pm for Li+) while maintaining structural integrity during repeated cycling. The development of host structures that enable rapid calcium-ion diffusion without significant volume changes represents a central research focus, with targets of achieving energy densities above 250 Wh/kg at the cell level.

The manufacturing readiness level (MRL) of calcium-ion batteries currently stands between 3-4 on the 9-point scale, indicating that basic manufacturing implications have been identified but significant process development remains necessary. A primary objective in advancing MRLs involves establishing scalable production methods for specialized electrolytes and electrode materials optimized for calcium-ion chemistry.

Supply chain considerations have become increasingly important in CIB development strategy, with objectives centered on reducing dependence on critical materials and establishing sustainable sourcing pathways. The abundant nature of calcium resources offers potential advantages in supply security, though specialized materials for electrolytes and current collectors may present supply chain vulnerabilities that require strategic planning and alternative material development.

Market Analysis for Next-Generation Battery Technologies

The global battery market is experiencing a significant shift towards next-generation technologies, with calcium ion batteries emerging as a promising alternative to conventional lithium-ion batteries. Current market projections indicate that the advanced battery sector will reach approximately $240 billion by 2027, growing at a compound annual growth rate of 14.1%. Within this expanding market, calcium ion batteries are positioned to capture increasing market share due to their potential cost advantages and performance characteristics.

Market demand for calcium ion batteries is primarily driven by several key factors. First, the growing concerns about lithium supply chain vulnerabilities and price volatility have accelerated the search for alternative battery chemistries. Calcium is the fifth most abundant element in Earth's crust, offering significant resource advantages over lithium. This abundance translates to potentially lower raw material costs, with calcium carbonate trading at roughly one-fifth the price of lithium carbonate equivalents.

The electric vehicle (EV) sector represents the largest potential market for calcium ion batteries, with global EV sales projected to exceed 30 million units annually by 2030. If calcium ion technology can achieve commercial viability, it could address critical consumer concerns regarding range anxiety, charging times, and vehicle costs. Industry analysts suggest that calcium ion batteries could potentially reduce battery pack costs by 25-30% compared to current lithium-ion technologies, while offering comparable or superior energy density.

Grid-scale energy storage represents another substantial market opportunity, expected to grow to $31.2 billion by 2029. Calcium ion batteries' potential safety advantages—including reduced fire risk and thermal runaway concerns—make them particularly attractive for large-scale stationary applications. Additionally, their projected longer cycle life could significantly reduce the levelized cost of storage, a critical metric for utility-scale adoption.

Consumer electronics manufacturers are also closely monitoring calcium ion battery development, as the technology promises higher energy density and potentially faster charging capabilities. This sector demands approximately 30% of global battery production and continues to seek solutions that extend device runtime while reducing form factor.

Regional market analysis reveals that Asia-Pacific currently dominates battery manufacturing capacity, with China controlling approximately 75% of global lithium-ion production. However, recent geopolitical tensions have accelerated efforts in North America and Europe to develop domestic battery supply chains, creating potential opportunities for new technologies like calcium ion batteries to gain manufacturing footholds in these regions.

Market barriers to adoption include the technology's current manufacturing readiness level (MRL 3-4), indicating significant challenges remain before mass production is feasible. Additionally, the established lithium-ion ecosystem represents substantial inertia, with over $150 billion invested in manufacturing capacity globally over the past decade.

Market demand for calcium ion batteries is primarily driven by several key factors. First, the growing concerns about lithium supply chain vulnerabilities and price volatility have accelerated the search for alternative battery chemistries. Calcium is the fifth most abundant element in Earth's crust, offering significant resource advantages over lithium. This abundance translates to potentially lower raw material costs, with calcium carbonate trading at roughly one-fifth the price of lithium carbonate equivalents.

The electric vehicle (EV) sector represents the largest potential market for calcium ion batteries, with global EV sales projected to exceed 30 million units annually by 2030. If calcium ion technology can achieve commercial viability, it could address critical consumer concerns regarding range anxiety, charging times, and vehicle costs. Industry analysts suggest that calcium ion batteries could potentially reduce battery pack costs by 25-30% compared to current lithium-ion technologies, while offering comparable or superior energy density.

Grid-scale energy storage represents another substantial market opportunity, expected to grow to $31.2 billion by 2029. Calcium ion batteries' potential safety advantages—including reduced fire risk and thermal runaway concerns—make them particularly attractive for large-scale stationary applications. Additionally, their projected longer cycle life could significantly reduce the levelized cost of storage, a critical metric for utility-scale adoption.

Consumer electronics manufacturers are also closely monitoring calcium ion battery development, as the technology promises higher energy density and potentially faster charging capabilities. This sector demands approximately 30% of global battery production and continues to seek solutions that extend device runtime while reducing form factor.

Regional market analysis reveals that Asia-Pacific currently dominates battery manufacturing capacity, with China controlling approximately 75% of global lithium-ion production. However, recent geopolitical tensions have accelerated efforts in North America and Europe to develop domestic battery supply chains, creating potential opportunities for new technologies like calcium ion batteries to gain manufacturing footholds in these regions.

Market barriers to adoption include the technology's current manufacturing readiness level (MRL 3-4), indicating significant challenges remain before mass production is feasible. Additionally, the established lithium-ion ecosystem represents substantial inertia, with over $150 billion invested in manufacturing capacity globally over the past decade.

Current MRL Status and Technical Challenges

Calcium ion batteries (CIBs) currently reside at relatively low Manufacturing Readiness Levels (MRLs), primarily between MRL 3-4, indicating that manufacturing concepts have been identified but significant challenges remain before commercial production can be realized. Laboratory-scale production has demonstrated proof of concept, but the transition to pilot-scale manufacturing faces substantial hurdles. The primary manufacturing challenges stem from calcium's chemical properties, particularly its high reduction potential and tendency to form passivation layers on electrode surfaces.

A critical manufacturing obstacle involves electrolyte compatibility with calcium metal anodes. Current electrolyte formulations struggle to achieve reversible calcium plating and stripping at room temperature, necessitating specialized manufacturing environments and handling protocols. The high reactivity of calcium with conventional electrolyte solvents requires stringent moisture and oxygen control throughout the production process, significantly increasing manufacturing complexity and cost.

Cathode material synthesis represents another significant challenge. Unlike lithium-ion battery cathodes, which benefit from decades of manufacturing optimization, calcium-compatible cathode materials require novel synthesis routes that have not been scaled beyond laboratory quantities. The larger ionic radius of calcium (compared to lithium) necessitates host structures with wider ion channels, demanding precise control over crystal structure formation during manufacturing.

Supply chain considerations present additional complications. The raw material supply chain for CIBs differs from established lithium-ion battery supply chains, requiring new supplier relationships and quality control protocols. While calcium is abundant (the fifth most abundant element in Earth's crust), high-purity calcium metal suitable for battery applications has limited commercial availability, creating potential supply bottlenecks as production scales.

Manufacturing equipment represents another hurdle. Existing battery production lines are optimized for lithium-ion chemistry and require significant modification to accommodate calcium-based materials. The higher reactivity of calcium components necessitates enhanced safety systems and environmental controls throughout the manufacturing process, increasing capital equipment requirements.

Quality control and testing protocols for CIBs remain underdeveloped. The lack of standardized testing methodologies specific to calcium-based systems complicates manufacturing process validation and product qualification. Current battery testing equipment requires recalibration and modification to accurately assess CIB performance parameters, adding another layer of complexity to manufacturing readiness assessment.

Addressing these challenges requires coordinated research efforts across materials science, chemical engineering, and manufacturing technology domains. Recent advances in electrolyte formulations showing improved calcium plating/stripping efficiency suggest pathways toward higher MRLs, but significant investment in manufacturing process development remains necessary before CIBs can approach commercial readiness.

A critical manufacturing obstacle involves electrolyte compatibility with calcium metal anodes. Current electrolyte formulations struggle to achieve reversible calcium plating and stripping at room temperature, necessitating specialized manufacturing environments and handling protocols. The high reactivity of calcium with conventional electrolyte solvents requires stringent moisture and oxygen control throughout the production process, significantly increasing manufacturing complexity and cost.

Cathode material synthesis represents another significant challenge. Unlike lithium-ion battery cathodes, which benefit from decades of manufacturing optimization, calcium-compatible cathode materials require novel synthesis routes that have not been scaled beyond laboratory quantities. The larger ionic radius of calcium (compared to lithium) necessitates host structures with wider ion channels, demanding precise control over crystal structure formation during manufacturing.

Supply chain considerations present additional complications. The raw material supply chain for CIBs differs from established lithium-ion battery supply chains, requiring new supplier relationships and quality control protocols. While calcium is abundant (the fifth most abundant element in Earth's crust), high-purity calcium metal suitable for battery applications has limited commercial availability, creating potential supply bottlenecks as production scales.

Manufacturing equipment represents another hurdle. Existing battery production lines are optimized for lithium-ion chemistry and require significant modification to accommodate calcium-based materials. The higher reactivity of calcium components necessitates enhanced safety systems and environmental controls throughout the manufacturing process, increasing capital equipment requirements.

Quality control and testing protocols for CIBs remain underdeveloped. The lack of standardized testing methodologies specific to calcium-based systems complicates manufacturing process validation and product qualification. Current battery testing equipment requires recalibration and modification to accurately assess CIB performance parameters, adding another layer of complexity to manufacturing readiness assessment.

Addressing these challenges requires coordinated research efforts across materials science, chemical engineering, and manufacturing technology domains. Recent advances in electrolyte formulations showing improved calcium plating/stripping efficiency suggest pathways toward higher MRLs, but significant investment in manufacturing process development remains necessary before CIBs can approach commercial readiness.

Manufacturing Process Solutions for Ca-Ion Batteries

01 Manufacturing processes for calcium ion battery electrodes

Various manufacturing processes have been developed for calcium ion battery electrodes to improve their performance and readiness for commercial production. These processes include specialized coating techniques, electrode preparation methods, and material synthesis approaches that enhance the electrochemical properties of calcium-based battery systems. Advanced manufacturing techniques focus on optimizing electrode structure and composition to address challenges related to calcium ion insertion/extraction kinetics.- Manufacturing processes for calcium ion battery electrodes: Various manufacturing processes are employed to produce electrodes for calcium ion batteries, focusing on improving performance and scalability. These processes include specialized coating techniques, electrode material preparation methods, and assembly procedures that enhance the electrochemical properties of the batteries. Advanced manufacturing techniques help address challenges related to calcium ion insertion/extraction and contribute to higher energy density and longer cycle life.

- Electrolyte formulations for calcium ion batteries: Electrolyte composition plays a crucial role in calcium ion battery performance and manufacturing readiness. Specialized electrolyte formulations are developed to facilitate calcium ion transport while minimizing side reactions. These formulations often include specific solvents, salts, and additives that improve ionic conductivity, interfacial stability, and overall battery performance. The manufacturing readiness of these electrolytes depends on their stability, scalability, and compatibility with mass production techniques.

- Cathode material development and manufacturing: The development and manufacturing of cathode materials for calcium ion batteries focus on structures that can accommodate calcium ion insertion and extraction. Manufacturing processes include synthesis methods like solid-state reactions, sol-gel processes, and hydrothermal techniques. The manufacturing readiness level depends on the scalability of these processes, material stability, and performance consistency. Advanced cathode materials aim to provide high capacity, good rate capability, and long cycle life.

- Anode material processing and fabrication: Anode materials for calcium ion batteries require specific processing and fabrication techniques to achieve optimal performance. Manufacturing processes focus on creating materials with appropriate structure and porosity to accommodate calcium ions. These processes include various synthesis methods, particle size control, and surface modification techniques. The manufacturing readiness level is determined by the scalability of these processes, material stability during cycling, and compatibility with existing battery production infrastructure.

- Cell assembly and quality control for calcium ion batteries: Cell assembly processes and quality control measures are critical for calcium ion battery manufacturing readiness. These include specialized techniques for electrode alignment, electrolyte filling, and sealing that address the unique challenges of calcium ion chemistry. Quality control measures focus on ensuring consistent performance, safety, and reliability. The manufacturing readiness level depends on the development of standardized assembly processes, testing protocols, and quality assurance methods that can be implemented at industrial scale.

02 Electrolyte formulations for calcium ion batteries

Electrolyte formulations play a crucial role in determining the performance and manufacturing readiness of calcium ion batteries. Research has focused on developing electrolytes that enable efficient calcium ion transport while maintaining stability during cycling. These formulations include various calcium salts, solvents, and additives designed to improve ionic conductivity, reduce interfacial resistance, and enhance overall battery performance at different manufacturing readiness levels.Expand Specific Solutions03 Cathode materials development for calcium-based energy storage

The development of suitable cathode materials is critical for advancing calcium ion battery technology toward higher manufacturing readiness levels. Research has focused on materials that can accommodate calcium ion insertion and extraction while maintaining structural stability over multiple cycles. Various cathode compositions, including oxides, phosphates, and organic materials, have been investigated to optimize energy density, power capability, and cycle life of calcium-based energy storage systems.Expand Specific Solutions04 Scale-up and industrial production considerations

Transitioning calcium ion battery technology from laboratory scale to industrial production involves addressing numerous manufacturing readiness challenges. These include process scalability, quality control, cost optimization, and equipment design. Research has focused on developing manufacturing protocols that can be implemented at commercial scale while maintaining performance metrics and ensuring consistency across production batches. Considerations for production line design, material handling, and quality assurance are essential for advancing manufacturing readiness levels.Expand Specific Solutions05 Performance evaluation and testing protocols

Standardized testing protocols and performance evaluation methods are essential for assessing the manufacturing readiness levels of calcium ion batteries. These include electrochemical characterization techniques, accelerated aging tests, safety evaluations, and quality control procedures. Research has focused on developing reliable testing methodologies that can accurately predict battery performance under various operating conditions and throughout the product lifecycle, enabling the advancement of calcium ion battery technology toward commercial readiness.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The calcium ion battery manufacturing landscape is in an early development stage, with market size still limited but showing promising growth potential. Key players like Toyota, BYD, CATL, and Svolt are investing in research and development, though technology readiness levels remain relatively low compared to established lithium-ion batteries. Academic institutions including Shenzhen Institutes of Advanced Technology, Harbin Institute of Technology, and Jilin University are collaborating with industry to overcome technical challenges. Supply chain considerations are particularly critical as companies like Resonac, BTR, and Capchem work to establish reliable material sourcing and processing capabilities. The transition from laboratory to commercial manufacturing requires significant investment in production facilities and quality control systems, with established battery manufacturers leveraging existing infrastructure to accelerate development.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive manufacturing readiness strategy for calcium ion batteries that focuses on scalable production processes and supply chain integration. Their approach includes a multi-phase implementation plan that addresses key manufacturing challenges specific to calcium-based chemistries. Toyota's technical solution incorporates specialized electrode manufacturing techniques to handle the reactivity of calcium materials, utilizing dry coating methods to improve electrode stability and reduce production costs. They've established a vertical integration model for critical materials, securing supplies of calcium salts and electrolyte components through strategic partnerships with mining companies and chemical suppliers. Toyota has also developed proprietary equipment for cell assembly that accommodates the unique characteristics of calcium ion chemistry, including specialized formation protocols that optimize initial cell performance and longevity. Their manufacturing readiness assessment framework includes specific metrics for calcium ion technology that track progress from laboratory to mass production readiness.

Strengths: Toyota's extensive manufacturing expertise and global supply chain network provide significant advantages in scaling calcium ion battery production. Their vertical integration approach reduces supply chain vulnerabilities for critical materials. Weaknesses: The company faces challenges with the limited commercial availability of high-purity calcium materials and specialized electrolytes required for optimal performance, potentially creating production bottlenecks.

BYD Co., Ltd.

Technical Solution: BYD has developed a comprehensive manufacturing readiness strategy for calcium ion batteries that leverages their vertical integration capabilities across the entire battery supply chain. Their technical approach focuses on adapting their Blade Battery manufacturing platform to accommodate calcium ion chemistry, utilizing specialized electrode preparation techniques that address the unique challenges of calcium-based materials. BYD's solution includes proprietary electrolyte formulations designed to enhance calcium ion transport while minimizing side reactions that could impact manufacturing yield and battery performance. They've established a robust supply chain strategy that includes direct investment in calcium material processing facilities and the development of recycling technologies specific to calcium ion batteries. BYD has implemented advanced quality control systems throughout their manufacturing process, utilizing AI-powered inspection systems to identify defects specific to calcium ion cell production. Their manufacturing readiness assessment framework includes detailed cost modeling that projects pathways to price parity with lithium-ion technologies through process optimization and economies of scale.

Strengths: BYD's vertically integrated business model provides exceptional control over the entire supply chain, from raw materials to finished batteries, enabling faster optimization of calcium ion battery manufacturing processes. Their established position as both a battery manufacturer and vehicle OEM creates a guaranteed market for initial production. Weaknesses: The company may face challenges adapting their existing manufacturing equipment to handle the different physical properties of calcium-based materials, potentially requiring significant capital investment for specialized machinery.

Critical Patents and Technical Literature Review

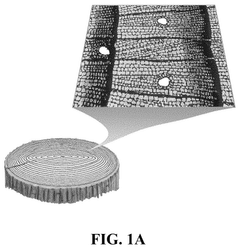

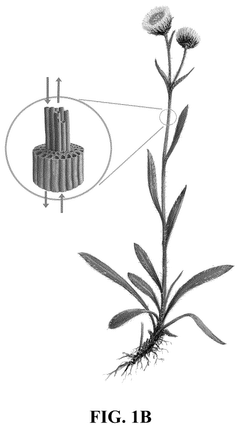

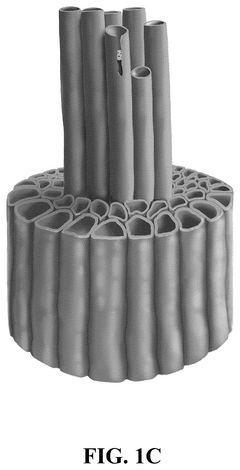

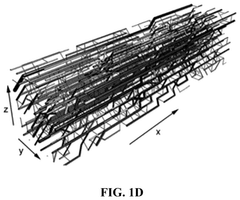

Xylem for use in battery applications and processing method for the same

PatentPendingUS20250192368A1

Innovation

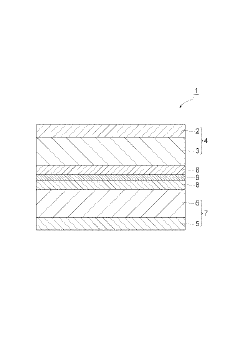

- The development of a battery design that includes an anode with alkali or alkaline earth metals, a cathode with carbon allotropes intercalated with calcium compounds, and a porous separator coated with xylem from specific plant genera, such as Crassula and Cycas, using a coating material like polyvinylidene fluoride and further doped with carbon nanotubes.

Method for manufacturing lithium ion battery

PatentInactiveJP2021096907A

Innovation

- A method for manufacturing lithium-ion batteries involving a specific preliminary charging process with controlled current and voltage, followed by a maintenance phase to form a dense solid electrolyte interface (SEI), using a compound represented by formula (1) in the electrolytic solution, and optimizing temperature and composition.

Supply Chain Risk Assessment and Mitigation Strategies

The calcium ion battery supply chain faces significant vulnerabilities that require systematic assessment and strategic mitigation approaches. Raw material availability represents a primary concern, with calcium resources, though abundant globally, concentrated in specific regions such as China, the United States, and Russia. This geographic concentration creates potential bottlenecks during geopolitical tensions or trade disputes, necessitating diversification strategies and development of alternative sourcing channels.

Manufacturing process dependencies present another critical risk area. The nascent state of calcium ion battery technology means specialized equipment and expertise remain limited to a small number of facilities worldwide. Organizations must implement redundancy planning by qualifying multiple suppliers and establishing parallel production capabilities across different geographic regions to ensure continuity of operations during disruptions.

Quality control inconsistencies across the supply chain pose substantial risks to product performance and safety. Implementing standardized testing protocols and certification requirements throughout the supplier network can help maintain consistent quality levels. Real-time monitoring systems utilizing IoT sensors and blockchain verification can further enhance transparency and traceability across the entire supply chain.

Regulatory compliance variations across different markets create additional complexity. Companies must develop comprehensive regulatory intelligence systems to track evolving standards in target markets. Cross-functional compliance teams should be established to ensure design and manufacturing processes meet all applicable requirements, preventing costly redesigns or market access barriers.

Transportation and logistics vulnerabilities require particular attention for calcium-based battery components, which may have specific handling requirements. Implementing multi-modal transportation options and distributed inventory strategies can reduce dependency on single shipping routes or methods. Advanced logistics planning tools utilizing AI-based predictive analytics can help anticipate potential disruptions and automatically suggest alternative routing.

Strategic supplier partnerships represent a key mitigation approach. Developing long-term collaborative relationships with key suppliers, including joint technology development initiatives and shared investment in specialized manufacturing capabilities, can enhance supply chain resilience. These partnerships should include transparent information sharing protocols and coordinated contingency planning to enable rapid response to emerging supply chain threats.

Manufacturing process dependencies present another critical risk area. The nascent state of calcium ion battery technology means specialized equipment and expertise remain limited to a small number of facilities worldwide. Organizations must implement redundancy planning by qualifying multiple suppliers and establishing parallel production capabilities across different geographic regions to ensure continuity of operations during disruptions.

Quality control inconsistencies across the supply chain pose substantial risks to product performance and safety. Implementing standardized testing protocols and certification requirements throughout the supplier network can help maintain consistent quality levels. Real-time monitoring systems utilizing IoT sensors and blockchain verification can further enhance transparency and traceability across the entire supply chain.

Regulatory compliance variations across different markets create additional complexity. Companies must develop comprehensive regulatory intelligence systems to track evolving standards in target markets. Cross-functional compliance teams should be established to ensure design and manufacturing processes meet all applicable requirements, preventing costly redesigns or market access barriers.

Transportation and logistics vulnerabilities require particular attention for calcium-based battery components, which may have specific handling requirements. Implementing multi-modal transportation options and distributed inventory strategies can reduce dependency on single shipping routes or methods. Advanced logistics planning tools utilizing AI-based predictive analytics can help anticipate potential disruptions and automatically suggest alternative routing.

Strategic supplier partnerships represent a key mitigation approach. Developing long-term collaborative relationships with key suppliers, including joint technology development initiatives and shared investment in specialized manufacturing capabilities, can enhance supply chain resilience. These partnerships should include transparent information sharing protocols and coordinated contingency planning to enable rapid response to emerging supply chain threats.

Raw Material Sourcing and Sustainability Considerations

The sourcing of raw materials for calcium ion batteries presents both challenges and opportunities in the emerging battery technology landscape. Calcium, as the fifth most abundant element in the Earth's crust (approximately 3-4%), offers significant advantages over lithium in terms of resource availability. This abundance translates to potentially lower material costs and reduced geopolitical supply risks compared to lithium-ion battery production chains.

Primary calcium sources include limestone (calcium carbonate), gypsum (calcium sulfate), and fluorite (calcium fluoride), which are widely distributed globally with major deposits in China, the United States, India, and various European countries. This geographical diversity helps mitigate supply concentration risks that currently plague lithium supply chains, where resources are concentrated in the "Lithium Triangle" of South America and a few other regions.

The extraction and processing of calcium compounds generally have lower environmental impacts compared to lithium mining operations. Conventional calcium mining from limestone quarries has established environmental management practices, though challenges remain regarding land use, dust emissions, and water management. The carbon footprint of calcium extraction is primarily associated with energy consumption during processing rather than the extraction itself.

For electrode materials, calcium-based batteries require specialized compounds such as calcium hexacyanoferrate, calcium cobalt oxide, or calcium manganese oxide. The manufacturing readiness level (MRL) for these materials remains relatively low (MRL 3-4), indicating that production processes are still being developed at laboratory scale with limited standardization. Scaling these processes to industrial levels represents a significant challenge in the commercialization pathway.

Sustainability considerations for calcium ion battery supply chains must address several dimensions. Water usage in calcium processing is substantial but generally lower than lithium brine operations. Energy requirements for calcium compound refinement need optimization to reduce the overall carbon footprint. Additionally, the co-extraction of other minerals during calcium mining presents opportunities for integrated resource management that could enhance overall sustainability.

Recycling infrastructure for calcium-based battery materials remains underdeveloped compared to established lithium-ion recycling processes. The development of efficient calcium battery recycling technologies is essential for creating a circular economy approach and reducing long-term environmental impacts. Current research indicates promising recovery rates for calcium compounds, potentially exceeding 90% under optimized conditions.

Strategic partnerships between battery manufacturers, mining companies, and material scientists will be crucial to address these supply chain considerations while advancing the manufacturing readiness level of calcium ion batteries from current prototype stages toward commercial viability.

Primary calcium sources include limestone (calcium carbonate), gypsum (calcium sulfate), and fluorite (calcium fluoride), which are widely distributed globally with major deposits in China, the United States, India, and various European countries. This geographical diversity helps mitigate supply concentration risks that currently plague lithium supply chains, where resources are concentrated in the "Lithium Triangle" of South America and a few other regions.

The extraction and processing of calcium compounds generally have lower environmental impacts compared to lithium mining operations. Conventional calcium mining from limestone quarries has established environmental management practices, though challenges remain regarding land use, dust emissions, and water management. The carbon footprint of calcium extraction is primarily associated with energy consumption during processing rather than the extraction itself.

For electrode materials, calcium-based batteries require specialized compounds such as calcium hexacyanoferrate, calcium cobalt oxide, or calcium manganese oxide. The manufacturing readiness level (MRL) for these materials remains relatively low (MRL 3-4), indicating that production processes are still being developed at laboratory scale with limited standardization. Scaling these processes to industrial levels represents a significant challenge in the commercialization pathway.

Sustainability considerations for calcium ion battery supply chains must address several dimensions. Water usage in calcium processing is substantial but generally lower than lithium brine operations. Energy requirements for calcium compound refinement need optimization to reduce the overall carbon footprint. Additionally, the co-extraction of other minerals during calcium mining presents opportunities for integrated resource management that could enhance overall sustainability.

Recycling infrastructure for calcium-based battery materials remains underdeveloped compared to established lithium-ion recycling processes. The development of efficient calcium battery recycling technologies is essential for creating a circular economy approach and reducing long-term environmental impacts. Current research indicates promising recovery rates for calcium compounds, potentially exceeding 90% under optimized conditions.

Strategic partnerships between battery manufacturers, mining companies, and material scientists will be crucial to address these supply chain considerations while advancing the manufacturing readiness level of calcium ion batteries from current prototype stages toward commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!