Mechanisms of Hydroxyethylcellulose as a Viscosity Modifier in Cosmetics

JUL 31, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in Cosmetics: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a crucial ingredient in the cosmetics industry, serving as an effective viscosity modifier and thickening agent. The evolution of HEC in cosmetic formulations can be traced back to the mid-20th century when the demand for stable, versatile, and safe ingredients in personal care products began to surge. As a cellulose derivative, HEC offers unique properties that align well with the cosmetic industry's requirements for texture enhancement and product stability.

The primary objective of utilizing HEC in cosmetics is to achieve optimal viscosity and texture in various formulations, ranging from lotions and creams to gels and hair care products. This versatility has made HEC an indispensable component in modern cosmetic manufacturing. The technology behind HEC as a viscosity modifier has continuously evolved, driven by the need for improved performance, sustainability, and compatibility with a wide range of cosmetic ingredients.

In recent years, the cosmetics industry has witnessed a significant shift towards natural and eco-friendly ingredients, prompting researchers and formulators to explore new applications and modifications of HEC. This trend has led to the development of novel HEC variants with enhanced properties, such as improved water retention, better stability in the presence of electrolytes, and increased compatibility with natural extracts and oils.

The global market for HEC in cosmetics has experienced steady growth, propelled by the expanding personal care industry and increasing consumer awareness about product quality and ingredients. This growth trajectory is expected to continue, with projections indicating a compound annual growth rate (CAGR) of around 4-5% in the coming years. The Asia-Pacific region, in particular, has emerged as a key market for HEC-based cosmetic products, driven by rising disposable incomes and changing lifestyle preferences.

As the cosmetics industry continues to innovate, the role of HEC as a viscosity modifier is likely to evolve further. Current research focuses on understanding the molecular mechanisms behind HEC's thickening properties and exploring ways to enhance its functionality. This includes investigating the interactions between HEC and other cosmetic ingredients, optimizing its rheological properties, and developing sustainable production methods.

The ongoing technological advancements in HEC production and modification are expected to open up new possibilities for its application in cosmetics. These developments aim to address challenges such as improving the stability of HEC in extreme pH conditions, enhancing its compatibility with a broader range of active ingredients, and reducing its environmental footprint through eco-friendly manufacturing processes.

The primary objective of utilizing HEC in cosmetics is to achieve optimal viscosity and texture in various formulations, ranging from lotions and creams to gels and hair care products. This versatility has made HEC an indispensable component in modern cosmetic manufacturing. The technology behind HEC as a viscosity modifier has continuously evolved, driven by the need for improved performance, sustainability, and compatibility with a wide range of cosmetic ingredients.

In recent years, the cosmetics industry has witnessed a significant shift towards natural and eco-friendly ingredients, prompting researchers and formulators to explore new applications and modifications of HEC. This trend has led to the development of novel HEC variants with enhanced properties, such as improved water retention, better stability in the presence of electrolytes, and increased compatibility with natural extracts and oils.

The global market for HEC in cosmetics has experienced steady growth, propelled by the expanding personal care industry and increasing consumer awareness about product quality and ingredients. This growth trajectory is expected to continue, with projections indicating a compound annual growth rate (CAGR) of around 4-5% in the coming years. The Asia-Pacific region, in particular, has emerged as a key market for HEC-based cosmetic products, driven by rising disposable incomes and changing lifestyle preferences.

As the cosmetics industry continues to innovate, the role of HEC as a viscosity modifier is likely to evolve further. Current research focuses on understanding the molecular mechanisms behind HEC's thickening properties and exploring ways to enhance its functionality. This includes investigating the interactions between HEC and other cosmetic ingredients, optimizing its rheological properties, and developing sustainable production methods.

The ongoing technological advancements in HEC production and modification are expected to open up new possibilities for its application in cosmetics. These developments aim to address challenges such as improving the stability of HEC in extreme pH conditions, enhancing its compatibility with a broader range of active ingredients, and reducing its environmental footprint through eco-friendly manufacturing processes.

Market Analysis for HEC-based Cosmetic Products

The market for hydroxyethylcellulose (HEC) in cosmetics has shown significant growth in recent years, driven by increasing consumer demand for high-performance personal care products. HEC-based cosmetic products have gained popularity due to their excellent viscosity modification properties, which enhance the texture and stability of various formulations.

The global market for HEC in cosmetics is projected to expand at a steady rate, with a particular focus on skincare and hair care applications. Skincare products, including moisturizers, serums, and masks, represent the largest segment for HEC usage. The ability of HEC to create smooth, non-greasy textures while providing hydration makes it a preferred choice for formulators.

Hair care products, such as shampoos, conditioners, and styling gels, form another substantial market for HEC. The polymer's film-forming properties and its capacity to improve product consistency contribute to its widespread adoption in this sector. Additionally, HEC finds applications in color cosmetics, particularly in foundations and mascaras, where it aids in achieving desired viscosity and improving product performance.

Geographically, North America and Europe lead the market for HEC-based cosmetic products, owing to the presence of established cosmetic industries and high consumer awareness. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by rising disposable incomes, changing lifestyles, and increasing beauty consciousness among consumers.

The market is characterized by a growing trend towards natural and sustainable ingredients. This has led to an increased demand for plant-derived HEC, which aligns with the clean beauty movement. Manufacturers are focusing on developing eco-friendly production processes and sourcing methods to meet this demand.

Key market drivers include the rising popularity of multifunctional cosmetic products, which require advanced formulation techniques, and the growing preference for long-lasting, high-performance personal care items. The aging population in developed countries also contributes to market growth, as HEC-based products cater to the specific skincare needs of mature consumers.

However, the market faces challenges such as the availability of alternative thickening agents and stringent regulations regarding cosmetic ingredients in certain regions. Despite these challenges, ongoing research and development efforts are expected to expand the application scope of HEC in cosmetics, potentially opening new market opportunities.

The global market for HEC in cosmetics is projected to expand at a steady rate, with a particular focus on skincare and hair care applications. Skincare products, including moisturizers, serums, and masks, represent the largest segment for HEC usage. The ability of HEC to create smooth, non-greasy textures while providing hydration makes it a preferred choice for formulators.

Hair care products, such as shampoos, conditioners, and styling gels, form another substantial market for HEC. The polymer's film-forming properties and its capacity to improve product consistency contribute to its widespread adoption in this sector. Additionally, HEC finds applications in color cosmetics, particularly in foundations and mascaras, where it aids in achieving desired viscosity and improving product performance.

Geographically, North America and Europe lead the market for HEC-based cosmetic products, owing to the presence of established cosmetic industries and high consumer awareness. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by rising disposable incomes, changing lifestyles, and increasing beauty consciousness among consumers.

The market is characterized by a growing trend towards natural and sustainable ingredients. This has led to an increased demand for plant-derived HEC, which aligns with the clean beauty movement. Manufacturers are focusing on developing eco-friendly production processes and sourcing methods to meet this demand.

Key market drivers include the rising popularity of multifunctional cosmetic products, which require advanced formulation techniques, and the growing preference for long-lasting, high-performance personal care items. The aging population in developed countries also contributes to market growth, as HEC-based products cater to the specific skincare needs of mature consumers.

However, the market faces challenges such as the availability of alternative thickening agents and stringent regulations regarding cosmetic ingredients in certain regions. Despite these challenges, ongoing research and development efforts are expected to expand the application scope of HEC in cosmetics, potentially opening new market opportunities.

Current Challenges in HEC Viscosity Modification

Despite the widespread use of Hydroxyethylcellulose (HEC) as a viscosity modifier in cosmetics, several challenges persist in optimizing its performance and application. One of the primary issues is the sensitivity of HEC to environmental factors, particularly pH and temperature fluctuations. These variations can significantly impact the viscosity and stability of cosmetic formulations, leading to inconsistent product performance across different conditions.

Another challenge lies in achieving the desired rheological properties without compromising other aspects of the formulation. HEC's thickening effect can sometimes interfere with the incorporation of active ingredients or affect the sensory attributes of the final product. Balancing viscosity with other crucial factors such as spreadability, absorption, and skin feel remains a complex task for formulators.

The molecular weight distribution of HEC also presents a challenge in maintaining consistent viscosity across batches. Variations in the polymer chain length can lead to differences in thickening efficiency, requiring careful quality control measures to ensure product uniformity. Additionally, the interaction of HEC with other ingredients in complex cosmetic formulations is not always predictable, necessitating extensive compatibility testing and formulation adjustments.

Biodegradability and sustainability concerns have also emerged as important considerations in the use of HEC. While it is derived from natural cellulose, the chemical modification process raises questions about its environmental impact. Developing more eco-friendly production methods and exploring alternative natural thickeners are ongoing challenges in the industry.

The behavior of HEC in emulsion systems poses another set of challenges. Ensuring stable emulsions while maintaining the desired viscosity profile can be difficult, especially in formulations containing a high oil phase or multiple emollients. Formulators must carefully balance the HEC concentration with emulsifiers and other stabilizing agents to achieve optimal results.

Lastly, the increasing demand for multifunctional ingredients in cosmetics has put pressure on HEC to deliver beyond its primary role as a thickener. Incorporating additional benefits such as moisturization, film-forming properties, or enhanced active delivery while maintaining its viscosity modification capabilities is an ongoing area of research and development in the cosmetic industry.

Another challenge lies in achieving the desired rheological properties without compromising other aspects of the formulation. HEC's thickening effect can sometimes interfere with the incorporation of active ingredients or affect the sensory attributes of the final product. Balancing viscosity with other crucial factors such as spreadability, absorption, and skin feel remains a complex task for formulators.

The molecular weight distribution of HEC also presents a challenge in maintaining consistent viscosity across batches. Variations in the polymer chain length can lead to differences in thickening efficiency, requiring careful quality control measures to ensure product uniformity. Additionally, the interaction of HEC with other ingredients in complex cosmetic formulations is not always predictable, necessitating extensive compatibility testing and formulation adjustments.

Biodegradability and sustainability concerns have also emerged as important considerations in the use of HEC. While it is derived from natural cellulose, the chemical modification process raises questions about its environmental impact. Developing more eco-friendly production methods and exploring alternative natural thickeners are ongoing challenges in the industry.

The behavior of HEC in emulsion systems poses another set of challenges. Ensuring stable emulsions while maintaining the desired viscosity profile can be difficult, especially in formulations containing a high oil phase or multiple emollients. Formulators must carefully balance the HEC concentration with emulsifiers and other stabilizing agents to achieve optimal results.

Lastly, the increasing demand for multifunctional ingredients in cosmetics has put pressure on HEC to deliver beyond its primary role as a thickener. Incorporating additional benefits such as moisturization, film-forming properties, or enhanced active delivery while maintaining its viscosity modification capabilities is an ongoing area of research and development in the cosmetic industry.

Existing HEC Formulation Techniques

01 Viscosity control in aqueous solutions

Hydroxyethylcellulose is used as a thickening agent to control viscosity in aqueous solutions. Its concentration and molecular weight can be adjusted to achieve desired viscosity levels in various applications, such as personal care products, pharmaceuticals, and industrial fluids.- Viscosity control in aqueous solutions: Hydroxyethylcellulose is used as a thickening agent to control viscosity in aqueous solutions. Its concentration and molecular weight can be adjusted to achieve desired viscosity levels in various applications, such as personal care products, pharmaceuticals, and industrial fluids.

- Rheology modification in drilling fluids: Hydroxyethylcellulose is employed as a rheology modifier in drilling fluids. It helps control fluid loss, improve suspension properties, and enhance the overall performance of drilling muds in oil and gas exploration.

- Stabilization of emulsions and suspensions: The viscosity-enhancing properties of hydroxyethylcellulose are utilized to stabilize emulsions and suspensions in various industries. It prevents phase separation and improves the shelf life of products such as cosmetics, paints, and food items.

- Controlled release in pharmaceutical formulations: Hydroxyethylcellulose's viscosity-modifying properties are exploited in pharmaceutical formulations to achieve controlled release of active ingredients. By adjusting its concentration and molecular weight, drug release rates can be tailored for specific therapeutic needs.

- Viscosity measurement techniques: Various methods and apparatus are developed to measure and characterize the viscosity of hydroxyethylcellulose solutions. These techniques help in quality control, product development, and optimization of formulations across different industries.

02 Rheology modification in drilling fluids

Hydroxyethylcellulose is employed as a rheology modifier in drilling fluids. It helps control fluid loss, improve suspension properties, and enhance the overall performance of drilling muds in oil and gas exploration.Expand Specific Solutions03 Stabilization of emulsions and suspensions

The viscosity-enhancing properties of hydroxyethylcellulose are utilized to stabilize emulsions and suspensions in various industries. It prevents phase separation and improves the shelf life of products such as cosmetics, paints, and food items.Expand Specific Solutions04 Controlled release in pharmaceutical formulations

Hydroxyethylcellulose's viscosity-modifying properties are exploited in pharmaceutical formulations to achieve controlled release of active ingredients. By adjusting its concentration and molecular weight, drug release rates can be tailored for specific therapeutic needs.Expand Specific Solutions05 Viscosity enhancement in personal care products

In personal care products, hydroxyethylcellulose is used to enhance viscosity and improve texture. It provides a smooth feel and helps in the even distribution of active ingredients in products such as shampoos, lotions, and gels.Expand Specific Solutions

Key Players in HEC Production and Cosmetic Industry

The market for hydroxyethylcellulose as a viscosity modifier in cosmetics is in a mature growth stage, with a global market size estimated to be in the hundreds of millions of dollars. The technology is well-established, with major players like Dow Global Technologies, Ashland, and Shin-Etsu Chemical (parent of SE Tylose) having developed advanced formulations. Companies such as L'Oréal, Unilever, and Beiersdorf are key end-users, incorporating the technology into various cosmetic products. The competitive landscape is characterized by ongoing research to enhance performance and sustainability, with companies like Shandong Zhongfu Heda New Material Technology and ExoCoBio focusing on innovative applications and bio-based alternatives.

Sumitomo Seika Chemicals Co., Ltd.

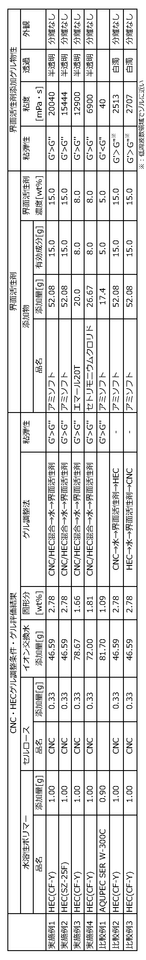

Technical Solution: Sumitomo Seika Chemicals has developed advanced hydroxyethylcellulose (HEC) products specifically for cosmetic applications. Their HEC technology focuses on optimizing molecular weight distribution and degree of substitution to achieve desired viscosity profiles. The company employs a proprietary manufacturing process that ensures consistent quality and purity of HEC, which is crucial for cosmetic formulations. Their HEC products demonstrate excellent thickening efficiency, allowing for the creation of stable emulsions and gels with enhanced texture and sensory properties[1][3]. Sumitomo Seika's HEC also exhibits superior compatibility with various cosmetic ingredients, including electrolytes and surfactants, enabling formulators to create a wide range of products with different viscosities and textures[2].

Strengths: High-quality HEC with consistent performance, excellent thickening efficiency, and broad compatibility with cosmetic ingredients. Weaknesses: Potentially higher cost compared to generic HEC products, and may require specialized formulation knowledge to fully utilize its properties.

Kao Corp.

Technical Solution: Kao Corporation has developed a unique approach to utilizing hydroxyethylcellulose in cosmetics, focusing on synergistic interactions with other ingredients. Their technology involves combining HEC with specific polymers and emollients to create multi-functional viscosity modifiers. This approach not only enhances the thickening effect but also improves the overall stability and sensory properties of cosmetic formulations. Kao's research has shown that their HEC-based systems can provide superior moisture retention and improved skin feel compared to traditional thickeners[4]. The company has also developed methods to control the rheological properties of HEC in various pH conditions, allowing for more versatile application in different cosmetic products, from cleansers to leave-on treatments[5].

Strengths: Innovative HEC-based systems with multi-functional benefits, improved moisture retention, and versatile application across various cosmetic products. Weaknesses: May require more complex formulation processes and potentially higher production costs.

Core Innovations in HEC Molecular Structure

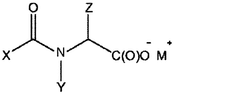

Viscous composition

PatentWO2022071465A1

Innovation

- Incorporating cellulose nanocrystals into a mixture of hydroxyethyl cellulose and water, with optional crosslinking agents and ionic surfactants, to create a stable viscous composition that maintains viscosity even when ionic surfactants are added.

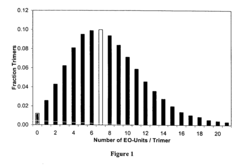

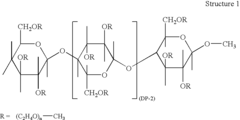

Water-soluble, low substitution hydroxyethylcellulose, derivatives thereof, process of making, and uses thereof

PatentInactiveUS20060199742A1

Innovation

- A new class of lowly substituted HECs with uniformly distributed hydroxyethyl groups, characterized by a hydroxyethyl molar substitution (HE-MS) of 0.7 to 1.3 and an unsubstituted trimer ratio (U3R) less than 0.21, is developed using a continuous caustic reduction hydroxyethylation process, allowing for enhanced water solubility and associative thickening properties.

Environmental Impact of HEC in Cosmetics

The environmental impact of Hydroxyethylcellulose (HEC) in cosmetics is a crucial consideration for manufacturers and consumers alike. As a biodegradable polymer derived from cellulose, HEC generally poses less environmental risk compared to synthetic alternatives. However, its production and disposal still warrant careful examination.

The manufacturing process of HEC involves chemical modifications of cellulose, which can lead to the generation of waste products and the consumption of energy and water resources. While the raw material is renewable, the production methods may contribute to carbon emissions and water pollution if not properly managed. Manufacturers are increasingly adopting cleaner production techniques to mitigate these impacts.

In terms of product use, HEC-containing cosmetics do not typically cause direct environmental harm during application. The polymer is non-toxic to aquatic life and does not bioaccumulate in organisms. However, the disposal of cosmetic products containing HEC can contribute to microplastic pollution in water bodies if not properly treated in wastewater systems.

Biodegradability is a key advantage of HEC over many synthetic viscosity modifiers. Under appropriate conditions, HEC can break down into harmless components, reducing its long-term environmental persistence. This characteristic aligns with the growing demand for eco-friendly cosmetic ingredients.

The potential for HEC to replace less environmentally friendly thickeners in cosmetics presents an opportunity for reducing the overall ecological footprint of personal care products. As consumers become more environmentally conscious, the use of HEC may contribute to the development of greener cosmetic formulations.

However, the increased demand for HEC could lead to expanded cellulose production, potentially impacting forest resources if not managed sustainably. This underscores the importance of responsible sourcing practices in the cosmetic industry's supply chain.

Regulatory bodies are paying closer attention to the environmental implications of cosmetic ingredients, including HEC. Future regulations may require more comprehensive life cycle assessments of such materials, prompting further research into their environmental impacts and driving innovations in production and disposal methods.

In conclusion, while HEC offers several environmental advantages in cosmetic applications, its overall impact depends on responsible manufacturing, usage, and disposal practices. The cosmetic industry's ongoing efforts to improve sustainability are likely to further optimize the environmental profile of HEC and similar biopolymers in the coming years.

The manufacturing process of HEC involves chemical modifications of cellulose, which can lead to the generation of waste products and the consumption of energy and water resources. While the raw material is renewable, the production methods may contribute to carbon emissions and water pollution if not properly managed. Manufacturers are increasingly adopting cleaner production techniques to mitigate these impacts.

In terms of product use, HEC-containing cosmetics do not typically cause direct environmental harm during application. The polymer is non-toxic to aquatic life and does not bioaccumulate in organisms. However, the disposal of cosmetic products containing HEC can contribute to microplastic pollution in water bodies if not properly treated in wastewater systems.

Biodegradability is a key advantage of HEC over many synthetic viscosity modifiers. Under appropriate conditions, HEC can break down into harmless components, reducing its long-term environmental persistence. This characteristic aligns with the growing demand for eco-friendly cosmetic ingredients.

The potential for HEC to replace less environmentally friendly thickeners in cosmetics presents an opportunity for reducing the overall ecological footprint of personal care products. As consumers become more environmentally conscious, the use of HEC may contribute to the development of greener cosmetic formulations.

However, the increased demand for HEC could lead to expanded cellulose production, potentially impacting forest resources if not managed sustainably. This underscores the importance of responsible sourcing practices in the cosmetic industry's supply chain.

Regulatory bodies are paying closer attention to the environmental implications of cosmetic ingredients, including HEC. Future regulations may require more comprehensive life cycle assessments of such materials, prompting further research into their environmental impacts and driving innovations in production and disposal methods.

In conclusion, while HEC offers several environmental advantages in cosmetic applications, its overall impact depends on responsible manufacturing, usage, and disposal practices. The cosmetic industry's ongoing efforts to improve sustainability are likely to further optimize the environmental profile of HEC and similar biopolymers in the coming years.

Regulatory Framework for HEC in Personal Care

The regulatory framework for hydroxyethylcellulose (HEC) in personal care products is governed by various international and regional authorities. In the United States, the Food and Drug Administration (FDA) oversees the use of HEC in cosmetics and personal care items. The FDA classifies HEC as a Generally Recognized as Safe (GRAS) ingredient, allowing its use in food and cosmetic applications without specific limitations.

In the European Union, HEC is regulated under the Cosmetic Regulation (EC) No 1223/2009. The European Commission's Scientific Committee on Consumer Safety (SCCS) has evaluated HEC and deemed it safe for use in cosmetic products. The ingredient is listed in the European Commission's database of cosmetic substances and ingredients (CosIng) with no restrictions on its use in personal care formulations.

Japan's Ministry of Health, Labour and Welfare regulates HEC under the Pharmaceutical Affairs Law. The ingredient is approved for use in cosmetics and quasi-drugs, with specific guidelines outlined in the Japanese Standards of Cosmetic Ingredients (JSCI).

China's National Medical Products Administration (NMPA) regulates the use of HEC in cosmetics. The ingredient is listed in the Inventory of Existing Cosmetic Ingredients in China (IECIC), allowing its use in cosmetic formulations without additional registration requirements.

Globally, the Cosmetic Ingredient Review (CIR) Expert Panel, an independent scientific body, has assessed the safety of HEC for use in cosmetics. Their comprehensive review concluded that HEC is safe in its current practices of use and concentration in cosmetic formulations.

While HEC is generally considered safe, regulatory bodies require manufacturers to ensure product safety and efficacy. This includes conducting stability tests, preservative efficacy testing, and microbial contamination assessments for products containing HEC. Additionally, manufacturers must comply with good manufacturing practices (GMP) and provide accurate labeling information.

As sustainability becomes increasingly important in the cosmetics industry, some regulatory bodies are beginning to consider the environmental impact of ingredients. While HEC is biodegradable, future regulations may address its sourcing and production methods to ensure environmental sustainability.

In summary, the regulatory framework for HEC in personal care products is well-established across major markets, with the ingredient generally recognized as safe for use in cosmetics. However, manufacturers must remain vigilant of potential updates to regulations and emerging concerns related to environmental impact and sustainability.

In the European Union, HEC is regulated under the Cosmetic Regulation (EC) No 1223/2009. The European Commission's Scientific Committee on Consumer Safety (SCCS) has evaluated HEC and deemed it safe for use in cosmetic products. The ingredient is listed in the European Commission's database of cosmetic substances and ingredients (CosIng) with no restrictions on its use in personal care formulations.

Japan's Ministry of Health, Labour and Welfare regulates HEC under the Pharmaceutical Affairs Law. The ingredient is approved for use in cosmetics and quasi-drugs, with specific guidelines outlined in the Japanese Standards of Cosmetic Ingredients (JSCI).

China's National Medical Products Administration (NMPA) regulates the use of HEC in cosmetics. The ingredient is listed in the Inventory of Existing Cosmetic Ingredients in China (IECIC), allowing its use in cosmetic formulations without additional registration requirements.

Globally, the Cosmetic Ingredient Review (CIR) Expert Panel, an independent scientific body, has assessed the safety of HEC for use in cosmetics. Their comprehensive review concluded that HEC is safe in its current practices of use and concentration in cosmetic formulations.

While HEC is generally considered safe, regulatory bodies require manufacturers to ensure product safety and efficacy. This includes conducting stability tests, preservative efficacy testing, and microbial contamination assessments for products containing HEC. Additionally, manufacturers must comply with good manufacturing practices (GMP) and provide accurate labeling information.

As sustainability becomes increasingly important in the cosmetics industry, some regulatory bodies are beginning to consider the environmental impact of ingredients. While HEC is biodegradable, future regulations may address its sourcing and production methods to ensure environmental sustainability.

In summary, the regulatory framework for HEC in personal care products is well-established across major markets, with the ingredient generally recognized as safe for use in cosmetics. However, manufacturers must remain vigilant of potential updates to regulations and emerging concerns related to environmental impact and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!