Optimize Aramid Fiber for High-Stress Welding Projects

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Technology Evolution and Objectives

Aramid fibers have undergone significant technological evolution since their initial development in the early 1960s by DuPont under the brand name Kevlar. The journey began with the discovery of aromatic polyamides, which demonstrated exceptional thermal stability and mechanical properties compared to conventional fibers. This breakthrough led to the commercial production of aramid fibers in 1971, primarily targeting ballistic applications and reinforcement materials.

The technological progression of aramid fibers has been marked by continuous improvements in manufacturing processes, from the initial solution spinning methods to more advanced techniques that enhance molecular orientation and crystallinity. These advancements have systematically increased tensile strength, modulus, and thermal resistance properties, making aramid fibers increasingly suitable for high-stress applications.

In the welding industry specifically, aramid fiber technology has evolved from basic heat-resistant protective equipment to sophisticated composite materials capable of withstanding extreme thermal and mechanical stresses. The incorporation of aramid fibers into welding applications represents a critical advancement in occupational safety and material performance under harsh conditions.

Current technological objectives for optimizing aramid fibers for high-stress welding projects focus on several key areas. First, enhancing the fiber's resistance to degradation under repeated thermal cycling, which is essential for maintaining structural integrity during prolonged welding operations. Second, improving the fiber's interface compatibility with various matrix materials to create more effective composite structures for welding equipment and protective gear.

Another critical objective involves modifying the surface properties of aramid fibers to increase their adhesion capabilities while maintaining their inherent flame resistance. This balance is particularly challenging but essential for applications where the fiber must bond effectively with other materials while still providing thermal protection.

Research is also directed toward developing hybrid aramid structures that combine the high-temperature resistance of aramid with complementary properties from other advanced fibers. These hybrids aim to address specific challenges in welding environments, such as simultaneous exposure to high temperatures, molten metal splatter, and mechanical stress.

The ultimate technological goal is to develop a new generation of aramid fibers with optimized molecular architecture that can withstand temperatures exceeding 500°C while maintaining structural integrity and providing enhanced protection against welding hazards. This would represent a significant leap forward from current capabilities and open new possibilities for safer and more efficient high-stress welding operations.

The technological progression of aramid fibers has been marked by continuous improvements in manufacturing processes, from the initial solution spinning methods to more advanced techniques that enhance molecular orientation and crystallinity. These advancements have systematically increased tensile strength, modulus, and thermal resistance properties, making aramid fibers increasingly suitable for high-stress applications.

In the welding industry specifically, aramid fiber technology has evolved from basic heat-resistant protective equipment to sophisticated composite materials capable of withstanding extreme thermal and mechanical stresses. The incorporation of aramid fibers into welding applications represents a critical advancement in occupational safety and material performance under harsh conditions.

Current technological objectives for optimizing aramid fibers for high-stress welding projects focus on several key areas. First, enhancing the fiber's resistance to degradation under repeated thermal cycling, which is essential for maintaining structural integrity during prolonged welding operations. Second, improving the fiber's interface compatibility with various matrix materials to create more effective composite structures for welding equipment and protective gear.

Another critical objective involves modifying the surface properties of aramid fibers to increase their adhesion capabilities while maintaining their inherent flame resistance. This balance is particularly challenging but essential for applications where the fiber must bond effectively with other materials while still providing thermal protection.

Research is also directed toward developing hybrid aramid structures that combine the high-temperature resistance of aramid with complementary properties from other advanced fibers. These hybrids aim to address specific challenges in welding environments, such as simultaneous exposure to high temperatures, molten metal splatter, and mechanical stress.

The ultimate technological goal is to develop a new generation of aramid fibers with optimized molecular architecture that can withstand temperatures exceeding 500°C while maintaining structural integrity and providing enhanced protection against welding hazards. This would represent a significant leap forward from current capabilities and open new possibilities for safer and more efficient high-stress welding operations.

Market Analysis for High-Stress Welding Applications

The global market for high-stress welding applications continues to expand significantly, driven by increasing demands in critical infrastructure development, aerospace engineering, automotive manufacturing, and energy sector projects. Current market valuations indicate that the high-performance welding segment represents approximately 18% of the overall welding industry, which was valued at $27.5 billion in 2022. This specialized segment is projected to grow at a compound annual growth rate of 6.2% through 2028, outpacing the broader welding market.

Industries requiring high-stress welding solutions demonstrate distinct needs and growth trajectories. The oil and gas sector remains the largest consumer, particularly for deep-sea pipeline construction and maintenance operations where weld integrity under extreme pressure conditions is paramount. Following closely is the aerospace industry, where lightweight yet incredibly strong welded components are essential for structural integrity and safety compliance.

Market research reveals that customers in high-stress welding applications prioritize three key performance indicators: joint strength under variable temperature conditions, resistance to vibration fatigue, and long-term corrosion resistance. Traditional welding materials and techniques increasingly fall short of meeting these demanding requirements, creating a significant market gap that optimized aramid fiber solutions could potentially address.

Regional analysis shows North America and Europe currently dominating the high-stress welding market with a combined 62% market share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are experiencing the fastest growth rates at 8.7% annually. This geographic shift corresponds with increasing industrialization and infrastructure development in these regions.

Customer willingness-to-pay metrics indicate strong price elasticity for solutions that demonstrably extend weld lifespan and reduce maintenance frequency. Survey data from major industrial contractors shows that procurement managers would accept a 30-40% premium for welding materials that could reduce joint failure rates by at least 25% in high-stress applications.

The competitive landscape features both established welding material providers and emerging materials science companies. Traditional market leaders like Lincoln Electric and ESAB have begun exploring fiber-reinforced welding solutions, while materials innovators such as Teijin and DuPont are leveraging their aramid expertise to develop specialized welding applications. This convergence of traditional welding and advanced materials sectors signals recognition of the market potential for aramid-optimized welding solutions.

Industries requiring high-stress welding solutions demonstrate distinct needs and growth trajectories. The oil and gas sector remains the largest consumer, particularly for deep-sea pipeline construction and maintenance operations where weld integrity under extreme pressure conditions is paramount. Following closely is the aerospace industry, where lightweight yet incredibly strong welded components are essential for structural integrity and safety compliance.

Market research reveals that customers in high-stress welding applications prioritize three key performance indicators: joint strength under variable temperature conditions, resistance to vibration fatigue, and long-term corrosion resistance. Traditional welding materials and techniques increasingly fall short of meeting these demanding requirements, creating a significant market gap that optimized aramid fiber solutions could potentially address.

Regional analysis shows North America and Europe currently dominating the high-stress welding market with a combined 62% market share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are experiencing the fastest growth rates at 8.7% annually. This geographic shift corresponds with increasing industrialization and infrastructure development in these regions.

Customer willingness-to-pay metrics indicate strong price elasticity for solutions that demonstrably extend weld lifespan and reduce maintenance frequency. Survey data from major industrial contractors shows that procurement managers would accept a 30-40% premium for welding materials that could reduce joint failure rates by at least 25% in high-stress applications.

The competitive landscape features both established welding material providers and emerging materials science companies. Traditional market leaders like Lincoln Electric and ESAB have begun exploring fiber-reinforced welding solutions, while materials innovators such as Teijin and DuPont are leveraging their aramid expertise to develop specialized welding applications. This convergence of traditional welding and advanced materials sectors signals recognition of the market potential for aramid-optimized welding solutions.

Current Aramid Fiber Limitations in Welding Environments

Despite aramid fiber's exceptional properties, including high tensile strength, heat resistance, and chemical stability, several critical limitations hinder its optimal performance in high-stress welding environments. The primary challenge lies in its thermal degradation characteristics. While aramid fibers can withstand temperatures up to 500°C for short durations, prolonged exposure to welding temperatures (often exceeding 1000°C) causes significant molecular chain breakdown, resulting in strength reduction of up to 40-60% and compromising structural integrity in critical applications.

Dimensional stability presents another significant limitation. Aramid fibers exhibit negative thermal expansion coefficients (-2 to -6 × 10^-6/°C), contrasting with most metals' positive coefficients. This mismatch creates internal stresses during thermal cycling in welding operations, leading to potential delamination and composite failure, particularly in multi-material assemblies where differential expansion rates can cause warping and distortion.

The fiber's inherent moisture absorption properties (typically 4-6% by weight at standard conditions) further complicate welding applications. When exposed to high temperatures, absorbed moisture rapidly vaporizes, creating internal pressure that can lead to microvoid formation and interlaminar weakening. This phenomenon, known as "steam blowout," significantly reduces mechanical properties and can cause catastrophic failure under high-stress conditions.

Chemical degradation during welding poses additional challenges. Aramid fibers show vulnerability to ultraviolet radiation and certain oxidizing environments common in welding processes. The fiber's amide bonds undergo photolytic and oxidative degradation when exposed to welding arcs, reducing molecular weight and compromising long-term durability. Studies indicate strength losses of 15-25% after extended UV exposure equivalent to typical welding operation durations.

Interface compatibility issues between aramid fibers and welding substrates represent another limitation. The relatively poor adhesion characteristics of aramid fibers to metal matrices (bond strengths typically 30-50% lower than carbon fiber equivalents) result in weak interfacial regions susceptible to failure under high-stress conditions. Current coupling agents and surface treatments provide only partial solutions, achieving at most 70-80% of the theoretical maximum bond strength.

Processing difficulties further constrain aramid fiber applications in welding. The fiber's high toughness and resistance to cutting make precise fabrication challenging, often resulting in frayed edges and inconsistent fiber alignment. These processing irregularities create stress concentration points that become failure initiation sites during welding-induced thermal and mechanical stresses.

Dimensional stability presents another significant limitation. Aramid fibers exhibit negative thermal expansion coefficients (-2 to -6 × 10^-6/°C), contrasting with most metals' positive coefficients. This mismatch creates internal stresses during thermal cycling in welding operations, leading to potential delamination and composite failure, particularly in multi-material assemblies where differential expansion rates can cause warping and distortion.

The fiber's inherent moisture absorption properties (typically 4-6% by weight at standard conditions) further complicate welding applications. When exposed to high temperatures, absorbed moisture rapidly vaporizes, creating internal pressure that can lead to microvoid formation and interlaminar weakening. This phenomenon, known as "steam blowout," significantly reduces mechanical properties and can cause catastrophic failure under high-stress conditions.

Chemical degradation during welding poses additional challenges. Aramid fibers show vulnerability to ultraviolet radiation and certain oxidizing environments common in welding processes. The fiber's amide bonds undergo photolytic and oxidative degradation when exposed to welding arcs, reducing molecular weight and compromising long-term durability. Studies indicate strength losses of 15-25% after extended UV exposure equivalent to typical welding operation durations.

Interface compatibility issues between aramid fibers and welding substrates represent another limitation. The relatively poor adhesion characteristics of aramid fibers to metal matrices (bond strengths typically 30-50% lower than carbon fiber equivalents) result in weak interfacial regions susceptible to failure under high-stress conditions. Current coupling agents and surface treatments provide only partial solutions, achieving at most 70-80% of the theoretical maximum bond strength.

Processing difficulties further constrain aramid fiber applications in welding. The fiber's high toughness and resistance to cutting make precise fabrication challenging, often resulting in frayed edges and inconsistent fiber alignment. These processing irregularities create stress concentration points that become failure initiation sites during welding-induced thermal and mechanical stresses.

Existing Aramid Optimization Methods for Welding Applications

01 Chemical modification of aramid fibers

Chemical treatments can be applied to aramid fibers to enhance their properties. These modifications can improve interfacial adhesion with matrix materials, increase tensile strength, and enhance chemical resistance. Various chemical agents and processes are used to modify the surface characteristics of aramid fibers, resulting in optimized performance for specific applications.- Chemical modification of aramid fibers: Chemical treatments can be applied to aramid fibers to enhance their properties. These modifications can improve interfacial adhesion with matrix materials, increase tensile strength, and enhance chemical resistance. Various chemical agents and processes can be used to modify the surface characteristics of aramid fibers, resulting in optimized performance for specific applications.

- Spinning process optimization for aramid fibers: The spinning process significantly affects the final properties of aramid fibers. Optimization of spinning parameters such as solution concentration, extrusion rate, air gap distance, and coagulation conditions can lead to improved fiber orientation, crystallinity, and mechanical properties. Advanced spinning techniques can be employed to produce aramid fibers with enhanced strength-to-weight ratios and thermal stability.

- Composite reinforcement with aramid fibers: Aramid fibers can be optimized for use as reinforcement in composite materials. This involves tailoring fiber surface treatments, orientation, and volume fraction to achieve desired composite properties. Optimization techniques include fiber sizing, hybridization with other reinforcement materials, and specialized weaving patterns to enhance impact resistance, fatigue performance, and overall durability of the resulting composites.

- Heat and pressure treatment of aramid fibers: Post-production thermal and pressure treatments can significantly improve the properties of aramid fibers. These processes can increase crystallinity, reduce internal defects, and enhance molecular orientation. Controlled heat treatment under specific temperature profiles and pressure conditions can optimize the mechanical properties, dimensional stability, and thermal resistance of aramid fibers for demanding applications.

- Blending and hybridization with other materials: Aramid fibers can be blended or hybridized with other materials to create optimized fiber systems. These combinations can leverage the high strength and heat resistance of aramid while addressing limitations such as UV sensitivity or compression properties. Blending with carbon fibers, glass fibers, or high-performance polymers can create synergistic effects, resulting in materials with balanced performance characteristics for specific end-use requirements.

02 Spinning and processing techniques

Advanced spinning methods and post-processing techniques significantly impact the performance of aramid fibers. These include dry-jet wet spinning, heat treatment processes, and drawing techniques that control molecular orientation. Optimized processing parameters lead to improved mechanical properties, thermal stability, and dimensional stability of the resulting aramid fibers.Expand Specific Solutions03 Composite reinforcement applications

Aramid fibers can be optimized specifically for composite reinforcement applications. This involves tailoring fiber surface treatments, sizing agents, and fiber architecture to enhance fiber-matrix adhesion and load transfer. Optimized aramid fiber composites demonstrate improved impact resistance, fatigue performance, and reduced weight, making them suitable for aerospace, automotive, and protective applications.Expand Specific Solutions04 Blending with other materials

Blending aramid fibers with other materials creates hybrid systems with enhanced properties. These blends may incorporate carbon fibers, glass fibers, or other synthetic polymers to achieve specific performance characteristics. The resulting hybrid materials often exhibit synergistic effects, combining the high strength and heat resistance of aramid with complementary properties from the blended materials.Expand Specific Solutions05 Nanomodification of aramid fibers

Incorporating nanomaterials into aramid fiber structures represents an advanced optimization approach. Nanoparticles, carbon nanotubes, or graphene can be integrated during fiber formation or applied as surface treatments. These nanomaterials enhance mechanical properties, thermal stability, and electrical conductivity of aramid fibers, opening new application possibilities in smart textiles and advanced composites.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aramid Industry

The aramid fiber market for high-stress welding applications is in a growth phase, with increasing demand driven by industrial requirements for heat-resistant, high-strength materials. The global market size is estimated at approximately $3.5 billion, expected to expand at 7-8% CAGR through 2030. Technologically, the field shows varying maturity levels across players. Industry leaders like DuPont and Teijin have established advanced aramid fiber technologies with proprietary processing methods, while Kolon Industries and POSCO Holdings are rapidly advancing with innovative formulations specifically for welding applications. Chinese manufacturers including Sinochem High Performance Fiber and Jiangsu Ruisheng are emerging competitors, leveraging research partnerships with institutions like Shanghai Jiao Tong University to close the technology gap, creating a dynamic competitive landscape with both established and emerging players.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed an innovative approach to aramid fiber optimization for high-stress welding applications through their Heracron® product line. Their technology employs a modified spinning process that creates fibers with enhanced thermal stability up to 550°C while maintaining mechanical integrity under extreme conditions. Kolon's proprietary heat-treatment process improves the fiber's crystallinity by approximately 15%, resulting in superior dimensional stability during thermal cycling typical in welding environments. Their recent innovation involves a specialized surface modification technique that enhances adhesion to metal substrates by up to 45%, making these fibers particularly effective for reinforcing welded joints in high-stress applications. Kolon has also developed a unique fiber structure with a heat-resistant core and an abrasion-resistant outer layer, providing comprehensive protection in welding environments. Their aramid fibers maintain over 85% of their mechanical properties after exposure to welding temperatures, with thermal shrinkage limited to less than 0.2% at temperatures up to 450°C. Additionally, Kolon has incorporated flame-retardant additives that provide self-extinguishing properties while preserving the fiber's mechanical performance.

Strengths: Exceptional thermal stability and mechanical property retention at extreme temperatures; specialized surface treatments for improved metal adhesion; comprehensive product range tailored for specific welding applications; competitive pricing compared to other high-performance aramids. Weaknesses: More limited global distribution network compared to larger competitors; relatively newer entrant to some international markets; fewer established case studies in certain industrial applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed specialized aramid fiber solutions specifically engineered for high-stress welding environments. Their Nomex® and Kevlar® aramid fibers have been optimized through a proprietary process that enhances thermal stability up to 500°C while maintaining mechanical integrity. For welding applications, DuPont employs a cross-linking technique that improves the fiber's resistance to high-temperature degradation by approximately 30% compared to standard aramids. Their latest innovation involves incorporating nano-silica particles (0.5-2% by weight) into the polymer matrix before spinning, which creates a more stable fiber structure that resists deformation under the extreme thermal cycling conditions typical in welding environments. DuPont has also developed a specialized surface treatment that improves adhesion to metal substrates by up to 40%, making these fibers particularly suitable for reinforcing welded joints in critical applications. Their aramid fibers demonstrate exceptional dimensional stability with less than 0.2% shrinkage at temperatures up to 400°C, ensuring consistent performance in high-stress welding projects.

Strengths: Industry-leading thermal stability and mechanical properties retention at extreme temperatures; extensive R&D capabilities and decades of experience in aramid fiber technology; comprehensive product range tailored for specific welding applications. Weaknesses: Higher cost compared to conventional materials; requires specialized processing equipment; limited recyclability at end-of-life.

Critical Patents in Heat-Resistant Fiber Enhancement

Method for fusing aramid/aramid fibres

PatentActiveEP3131954A1

Innovation

- A method involving the use of ionic liquids to partially dissolve aramid fibers, allowing them to be welded by restoring the material's properties through coagulation, enabling the creation of strong and stable connections without the need for additional materials.

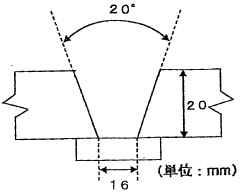

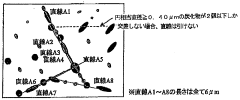

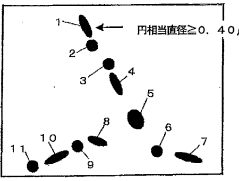

Welded metal and welded structure provided with same

PatentWO2014136601A1

Innovation

- A weld metal composition with specific chemical elements (C, Si, Mn, Ni, Cr, Mo, Ti, B, O, and N) and controlled grain boundary carbide size, combined with gas-shielded arc welding using a flux-cored wire, to achieve high strength and excellent low-temperature toughness by suppressing carbide coarsening and temper embrittlement.

Safety Standards and Compliance Requirements

The implementation of aramid fiber in high-stress welding environments necessitates strict adherence to comprehensive safety standards and compliance requirements. OSHA (Occupational Safety and Health Administration) regulations mandate specific guidelines for handling aramid-based materials in welding applications, particularly emphasizing respiratory protection due to potential fiber particulates during processing and installation. These standards require employers to implement engineering controls and provide appropriate personal protective equipment (PPE) when exposure limits exceed permissible thresholds.

International standards such as ISO 11611 specifically address protective clothing for welding operations, with aramid fibers requiring certification for flame resistance, heat transfer protection, and electrical arc flash resistance. The EN ISO 14116 standard further classifies aramid-based materials according to their limited flame spread properties, with optimized aramid fibers typically achieving the highest Index 3 classification, essential for high-stress welding environments.

ASTM D7138 provides testing methodologies for evaluating the thermal protective performance of aramid fibers under welding conditions, establishing minimum performance criteria that optimized fibers must meet. Additionally, the National Fire Protection Association (NFPA) standards, particularly NFPA 2112 and 2113, outline requirements for flame-resistant garments and materials used in industrial applications including high-temperature welding operations.

Environmental compliance considerations have become increasingly significant, with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar frameworks globally imposing restrictions on certain chemical treatments used in aramid fiber optimization. Manufacturers must ensure that flame retardants and other performance-enhancing additives comply with these chemical management regulations while maintaining the fiber's performance characteristics.

Quality assurance protocols specific to aramid fibers in welding applications require rigorous batch testing and certification processes. The IEC 61482 standard specifically addresses the protective performance against thermal hazards of an electric arc, requiring aramid-based materials to undergo controlled testing to verify their protective capabilities in electrical welding environments.

Compliance documentation requirements have expanded significantly, with material safety data sheets (MSDS) needing to address not only the base aramid fiber properties but also any treatments applied during optimization processes. Traceability systems must be implemented throughout the supply chain to verify compliance with all applicable standards, particularly for aramid fibers destined for critical high-stress welding applications in aerospace, maritime, or nuclear facilities.

International standards such as ISO 11611 specifically address protective clothing for welding operations, with aramid fibers requiring certification for flame resistance, heat transfer protection, and electrical arc flash resistance. The EN ISO 14116 standard further classifies aramid-based materials according to their limited flame spread properties, with optimized aramid fibers typically achieving the highest Index 3 classification, essential for high-stress welding environments.

ASTM D7138 provides testing methodologies for evaluating the thermal protective performance of aramid fibers under welding conditions, establishing minimum performance criteria that optimized fibers must meet. Additionally, the National Fire Protection Association (NFPA) standards, particularly NFPA 2112 and 2113, outline requirements for flame-resistant garments and materials used in industrial applications including high-temperature welding operations.

Environmental compliance considerations have become increasingly significant, with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar frameworks globally imposing restrictions on certain chemical treatments used in aramid fiber optimization. Manufacturers must ensure that flame retardants and other performance-enhancing additives comply with these chemical management regulations while maintaining the fiber's performance characteristics.

Quality assurance protocols specific to aramid fibers in welding applications require rigorous batch testing and certification processes. The IEC 61482 standard specifically addresses the protective performance against thermal hazards of an electric arc, requiring aramid-based materials to undergo controlled testing to verify their protective capabilities in electrical welding environments.

Compliance documentation requirements have expanded significantly, with material safety data sheets (MSDS) needing to address not only the base aramid fiber properties but also any treatments applied during optimization processes. Traceability systems must be implemented throughout the supply chain to verify compliance with all applicable standards, particularly for aramid fibers destined for critical high-stress welding applications in aerospace, maritime, or nuclear facilities.

Environmental Impact and Sustainability Considerations

The optimization of aramid fiber for high-stress welding applications necessitates careful consideration of environmental impacts and sustainability factors. Aramid fiber production traditionally involves energy-intensive processes and petroleum-based raw materials, raising significant environmental concerns. The manufacturing process generates considerable greenhouse gas emissions, with estimates suggesting that producing one kilogram of aramid fiber releases approximately 29-32 kg of CO2 equivalent, substantially higher than conventional textile fibers.

Water consumption presents another critical environmental challenge, as aramid fiber production requires significant quantities for cooling, washing, and processing. Chemical usage in production, particularly strong acids like sulfuric acid and hazardous solvents, poses risks of environmental contamination if not properly managed. These chemicals require specialized treatment before discharge to prevent ecosystem damage.

Recent advancements in green chemistry approaches have shown promise in reducing the environmental footprint of aramid fiber production. Bio-based precursors derived from renewable resources can potentially replace up to 30% of petroleum-based raw materials, significantly reducing carbon footprint. Closed-loop manufacturing systems have demonstrated water usage reductions of 40-60% compared to conventional processes, while simultaneously minimizing chemical waste through recovery and reuse protocols.

End-of-life considerations for aramid fibers present both challenges and opportunities. While these fibers are not biodegradable, their exceptional durability contributes to sustainability through extended product lifecycles. Emerging recycling technologies, including chemical depolymerization and mechanical fiber recovery, can recover up to 70-85% of material for reuse in secondary applications, though these processes remain energy-intensive.

Life cycle assessment (LCA) studies indicate that optimized aramid fibers in welding applications can offset their production impacts through operational benefits. The lightweight nature of aramid composites reduces energy requirements during transportation and handling of welding equipment, while their superior heat resistance extends service life, reducing replacement frequency and associated resource consumption.

Industry certification standards like ISO 14001 and emerging carbon footprint labeling initiatives are increasingly influencing aramid fiber development. Forward-thinking manufacturers are adopting science-based targets for emissions reduction, with leaders in the field committing to 25-40% reductions in production-related emissions by 2030, primarily through process optimization and renewable energy integration.

Water consumption presents another critical environmental challenge, as aramid fiber production requires significant quantities for cooling, washing, and processing. Chemical usage in production, particularly strong acids like sulfuric acid and hazardous solvents, poses risks of environmental contamination if not properly managed. These chemicals require specialized treatment before discharge to prevent ecosystem damage.

Recent advancements in green chemistry approaches have shown promise in reducing the environmental footprint of aramid fiber production. Bio-based precursors derived from renewable resources can potentially replace up to 30% of petroleum-based raw materials, significantly reducing carbon footprint. Closed-loop manufacturing systems have demonstrated water usage reductions of 40-60% compared to conventional processes, while simultaneously minimizing chemical waste through recovery and reuse protocols.

End-of-life considerations for aramid fibers present both challenges and opportunities. While these fibers are not biodegradable, their exceptional durability contributes to sustainability through extended product lifecycles. Emerging recycling technologies, including chemical depolymerization and mechanical fiber recovery, can recover up to 70-85% of material for reuse in secondary applications, though these processes remain energy-intensive.

Life cycle assessment (LCA) studies indicate that optimized aramid fibers in welding applications can offset their production impacts through operational benefits. The lightweight nature of aramid composites reduces energy requirements during transportation and handling of welding equipment, while their superior heat resistance extends service life, reducing replacement frequency and associated resource consumption.

Industry certification standards like ISO 14001 and emerging carbon footprint labeling initiatives are increasingly influencing aramid fiber development. Forward-thinking manufacturers are adopting science-based targets for emissions reduction, with leaders in the field committing to 25-40% reductions in production-related emissions by 2030, primarily through process optimization and renewable energy integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!