Optimize Oxaloacetate Production: Temperature & Yield Factors

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oxaloacetate Production Background and Objectives

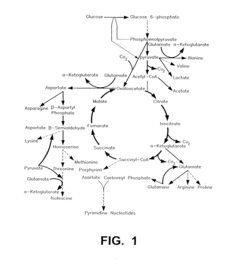

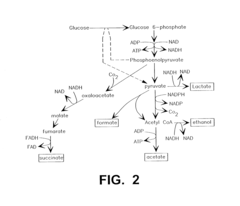

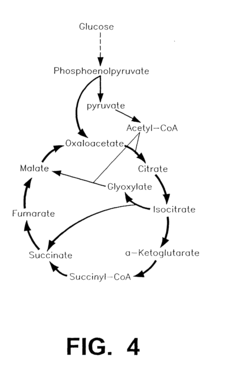

Oxaloacetate, a crucial intermediate in the tricarboxylic acid cycle (TCA), has gained significant attention in recent years due to its diverse applications across pharmaceutical, food, and agricultural industries. The compound's role as a metabolic precursor for various amino acids and its potential health benefits have driven increased demand for efficient production methods. Historically, oxaloacetate production has evolved from chemical synthesis methods to more sustainable biotechnological approaches over the past several decades.

The evolution of oxaloacetate production technology has witnessed three major phases. Initially, chemical synthesis dominated the landscape, characterized by high energy consumption and environmental concerns. The second phase introduced enzymatic conversion methods in the 1980s, offering improved specificity but limited scalability. The current phase focuses on microbial fermentation and metabolic engineering approaches, which have demonstrated promising results for industrial-scale production.

Temperature regulation represents one of the most critical parameters affecting oxaloacetate production efficiency. Research indicates that temperature influences enzyme activity, cell metabolism, and product stability. The thermal sensitivity of oxaloacetate poses a significant challenge, as the compound tends to decarboxylate at elevated temperatures, directly impacting production yields. This temperature-dependent instability has been a persistent obstacle in optimizing production processes.

Recent technological advancements have focused on developing temperature-controlled bioreactors and engineered microbial strains with enhanced thermal tolerance. These innovations aim to maintain optimal production conditions while minimizing product degradation. Additionally, research into novel catalysts and immobilization techniques has shown potential for improving temperature stability during the production process.

The primary objective of this technical research is to comprehensively analyze the relationship between temperature parameters and oxaloacetate yield factors. By identifying optimal temperature ranges and understanding the underlying mechanisms affecting production efficiency, we aim to develop improved protocols that maximize yield while maintaining product quality. This includes investigating temperature-dependent enzyme kinetics, microbial growth patterns, and product stability factors.

Secondary objectives include evaluating energy consumption implications of different temperature control strategies, assessing the economic feasibility of implementing advanced temperature management systems, and exploring innovative approaches to overcome current thermal limitations. The research also aims to establish predictive models that can guide process optimization across different production scales and environments.

The findings from this research will contribute to the broader goal of establishing more sustainable and economically viable oxaloacetate production methods, potentially transforming its accessibility for various applications and supporting emerging markets in nutraceuticals and specialized biochemicals.

The evolution of oxaloacetate production technology has witnessed three major phases. Initially, chemical synthesis dominated the landscape, characterized by high energy consumption and environmental concerns. The second phase introduced enzymatic conversion methods in the 1980s, offering improved specificity but limited scalability. The current phase focuses on microbial fermentation and metabolic engineering approaches, which have demonstrated promising results for industrial-scale production.

Temperature regulation represents one of the most critical parameters affecting oxaloacetate production efficiency. Research indicates that temperature influences enzyme activity, cell metabolism, and product stability. The thermal sensitivity of oxaloacetate poses a significant challenge, as the compound tends to decarboxylate at elevated temperatures, directly impacting production yields. This temperature-dependent instability has been a persistent obstacle in optimizing production processes.

Recent technological advancements have focused on developing temperature-controlled bioreactors and engineered microbial strains with enhanced thermal tolerance. These innovations aim to maintain optimal production conditions while minimizing product degradation. Additionally, research into novel catalysts and immobilization techniques has shown potential for improving temperature stability during the production process.

The primary objective of this technical research is to comprehensively analyze the relationship between temperature parameters and oxaloacetate yield factors. By identifying optimal temperature ranges and understanding the underlying mechanisms affecting production efficiency, we aim to develop improved protocols that maximize yield while maintaining product quality. This includes investigating temperature-dependent enzyme kinetics, microbial growth patterns, and product stability factors.

Secondary objectives include evaluating energy consumption implications of different temperature control strategies, assessing the economic feasibility of implementing advanced temperature management systems, and exploring innovative approaches to overcome current thermal limitations. The research also aims to establish predictive models that can guide process optimization across different production scales and environments.

The findings from this research will contribute to the broader goal of establishing more sustainable and economically viable oxaloacetate production methods, potentially transforming its accessibility for various applications and supporting emerging markets in nutraceuticals and specialized biochemicals.

Market Analysis for Industrial Oxaloacetate Applications

The global market for oxaloacetate has been experiencing steady growth, primarily driven by its diverse applications across pharmaceutical, agricultural, and food industries. The compound's role as a key intermediate in the Krebs cycle positions it uniquely for biochemical applications, with an estimated market value reaching $320 million in 2022 and projected to grow at a CAGR of 5.8% through 2028.

Pharmaceutical applications currently dominate the oxaloacetate market, accounting for approximately 45% of total consumption. The compound's utility in drug development, particularly for neurological disorders and metabolic diseases, has fueled significant demand growth. Recent clinical studies demonstrating oxaloacetate's potential neuroprotective properties have further stimulated pharmaceutical industry interest.

The agricultural sector represents the second-largest market segment, utilizing oxaloacetate in specialized fertilizers and crop enhancement products. This segment has shown remarkable growth at 7.2% annually over the past five years, outpacing overall market expansion. Temperature-optimized production methods could significantly reduce costs, making agricultural applications more economically viable.

Food and beverage applications, particularly in functional foods and dietary supplements, constitute an emerging market with substantial growth potential. Consumer trends toward health-conscious products have created new opportunities for oxaloacetate as a metabolic enhancer and anti-aging supplement ingredient.

Geographically, North America leads consumption with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.3% annually, driven by expanding pharmaceutical manufacturing and agricultural modernization in China and India.

Price sensitivity remains a critical factor across all application segments. Current production costs, heavily influenced by temperature control requirements and yield inefficiencies, create significant market entry barriers. Industry analysis indicates that a 15% reduction in production costs could expand the addressable market by approximately 30%, particularly in price-sensitive segments like agricultural applications and emerging markets.

Supply chain considerations also impact market dynamics, with temperature-controlled transportation and storage adding substantial costs. Innovations that improve oxaloacetate stability at variable temperatures would not only optimize production but could potentially transform distribution economics, opening new market segments previously constrained by logistical challenges.

Pharmaceutical applications currently dominate the oxaloacetate market, accounting for approximately 45% of total consumption. The compound's utility in drug development, particularly for neurological disorders and metabolic diseases, has fueled significant demand growth. Recent clinical studies demonstrating oxaloacetate's potential neuroprotective properties have further stimulated pharmaceutical industry interest.

The agricultural sector represents the second-largest market segment, utilizing oxaloacetate in specialized fertilizers and crop enhancement products. This segment has shown remarkable growth at 7.2% annually over the past five years, outpacing overall market expansion. Temperature-optimized production methods could significantly reduce costs, making agricultural applications more economically viable.

Food and beverage applications, particularly in functional foods and dietary supplements, constitute an emerging market with substantial growth potential. Consumer trends toward health-conscious products have created new opportunities for oxaloacetate as a metabolic enhancer and anti-aging supplement ingredient.

Geographically, North America leads consumption with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.3% annually, driven by expanding pharmaceutical manufacturing and agricultural modernization in China and India.

Price sensitivity remains a critical factor across all application segments. Current production costs, heavily influenced by temperature control requirements and yield inefficiencies, create significant market entry barriers. Industry analysis indicates that a 15% reduction in production costs could expand the addressable market by approximately 30%, particularly in price-sensitive segments like agricultural applications and emerging markets.

Supply chain considerations also impact market dynamics, with temperature-controlled transportation and storage adding substantial costs. Innovations that improve oxaloacetate stability at variable temperatures would not only optimize production but could potentially transform distribution economics, opening new market segments previously constrained by logistical challenges.

Current Production Challenges and Temperature Constraints

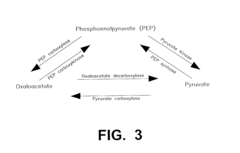

The production of oxaloacetate faces significant challenges in current industrial processes, primarily centered around temperature sensitivity and yield optimization. Oxaloacetate, a critical intermediate in the citric acid cycle and valuable precursor for pharmaceutical and biochemical applications, degrades rapidly at temperatures above 25°C. This thermal instability represents a major constraint in manufacturing processes, where even brief temperature excursions can result in substantial product loss through decarboxylation to pyruvate.

Industrial production facilities struggle with maintaining precise temperature control throughout the entire production chain, from fermentation to downstream processing. Cooling systems must operate continuously and reliably, creating substantial energy consumption and operational costs. The narrow temperature window for optimal production (typically 18-22°C) leaves minimal margin for error in process control systems, necessitating sophisticated monitoring equipment and redundant cooling infrastructure.

Yield factors are directly correlated with temperature management, with studies indicating that for every 5°C increase above the optimal range, yield decreases by approximately 15-20%. This sensitivity creates a challenging production environment where seasonal temperature variations and equipment performance fluctuations can significantly impact production economics. Manufacturers in warmer climates face particularly acute challenges, often requiring specialized facility designs with enhanced cooling capacity.

Current production methods typically employ enzymatic synthesis or controlled fermentation processes, both requiring strict temperature regulation. The enzymatic approach offers higher purity but suffers from enzyme denaturation at elevated temperatures, while fermentation processes face challenges with maintaining optimal microbial activity within the narrow temperature band. Both methods struggle with scale-up issues related to heat transfer limitations in larger reaction vessels.

Stabilization technologies represent another challenge area, with current approaches using chemical additives or specialized packaging showing limited effectiveness. These solutions often introduce additional purification requirements or compromise product quality. The trade-off between production rate and temperature control further complicates manufacturing strategies, as faster production generally generates more heat that must be managed.

Energy consumption for cooling represents a substantial portion of production costs, with estimates suggesting that temperature control accounts for 30-40% of the total energy budget in oxaloacetate manufacturing. This creates both economic and sustainability challenges, particularly as environmental regulations and carbon pricing mechanisms evolve globally. The industry faces increasing pressure to develop more energy-efficient production methods while maintaining strict temperature control.

Industrial production facilities struggle with maintaining precise temperature control throughout the entire production chain, from fermentation to downstream processing. Cooling systems must operate continuously and reliably, creating substantial energy consumption and operational costs. The narrow temperature window for optimal production (typically 18-22°C) leaves minimal margin for error in process control systems, necessitating sophisticated monitoring equipment and redundant cooling infrastructure.

Yield factors are directly correlated with temperature management, with studies indicating that for every 5°C increase above the optimal range, yield decreases by approximately 15-20%. This sensitivity creates a challenging production environment where seasonal temperature variations and equipment performance fluctuations can significantly impact production economics. Manufacturers in warmer climates face particularly acute challenges, often requiring specialized facility designs with enhanced cooling capacity.

Current production methods typically employ enzymatic synthesis or controlled fermentation processes, both requiring strict temperature regulation. The enzymatic approach offers higher purity but suffers from enzyme denaturation at elevated temperatures, while fermentation processes face challenges with maintaining optimal microbial activity within the narrow temperature band. Both methods struggle with scale-up issues related to heat transfer limitations in larger reaction vessels.

Stabilization technologies represent another challenge area, with current approaches using chemical additives or specialized packaging showing limited effectiveness. These solutions often introduce additional purification requirements or compromise product quality. The trade-off between production rate and temperature control further complicates manufacturing strategies, as faster production generally generates more heat that must be managed.

Energy consumption for cooling represents a substantial portion of production costs, with estimates suggesting that temperature control accounts for 30-40% of the total energy budget in oxaloacetate manufacturing. This creates both economic and sustainability challenges, particularly as environmental regulations and carbon pricing mechanisms evolve globally. The industry faces increasing pressure to develop more energy-efficient production methods while maintaining strict temperature control.

Current Temperature-Yield Optimization Approaches

01 Microbial fermentation methods for oxaloacetate production

Microbial fermentation techniques using engineered microorganisms can significantly improve oxaloacetate production yield. These methods involve genetic modification of bacteria or yeast strains to enhance the TCA cycle pathway or redirect carbon flux toward oxaloacetate synthesis. Key strategies include overexpression of enzymes like phosphoenolpyruvate carboxylase or pyruvate carboxylase, and deletion of competing pathways to minimize byproduct formation. Optimized fermentation conditions including temperature, pH, and nutrient composition further maximize yield.- Microbial fermentation methods for oxaloacetate production: Various microorganisms can be engineered or selected for enhanced oxaloacetate production through fermentation processes. These methods involve optimizing culture conditions, genetic modifications of metabolic pathways, and selection of high-yield strains. Specific approaches include overexpression of key enzymes in the TCA cycle, deletion of competing pathways, and manipulation of carbon flux to direct metabolites toward oxaloacetate accumulation.

- Enzymatic conversion processes for oxaloacetate synthesis: Enzymatic methods utilize specific enzymes to catalyze reactions that produce oxaloacetate from various substrates. These processes often employ purified or immobilized enzymes in controlled reaction environments to achieve higher yields and purity. Key enzymes include pyruvate carboxylase, phosphoenolpyruvate carboxykinase, and malate dehydrogenase, which can convert common metabolic intermediates to oxaloacetate under optimized reaction conditions.

- Process optimization techniques for increased yield: Various process optimization techniques can significantly improve oxaloacetate production yields. These include controlling pH, temperature, and oxygen levels during production, implementing fed-batch or continuous fermentation strategies, optimizing media composition with specific carbon and nitrogen sources, and developing downstream processing methods that minimize product degradation. Advanced bioreactor designs and process control systems also contribute to yield enhancement.

- Genetic engineering approaches for yield improvement: Genetic engineering techniques can create high-yield oxaloacetate-producing strains through targeted modifications of metabolic pathways. These approaches include overexpression of native or heterologous genes involved in oxaloacetate synthesis, CRISPR-Cas9 mediated genome editing to remove competing pathways, metabolic flux analysis to identify bottlenecks, and adaptive laboratory evolution to select for improved production characteristics.

- Stabilization and purification methods for oxaloacetate: Oxaloacetate is inherently unstable and can rapidly degrade during production and processing, affecting overall yield. Various stabilization and purification methods have been developed to address this challenge, including chemical stabilization with additives, encapsulation techniques, optimized extraction procedures, chromatographic purification methods, and specialized drying processes that preserve molecular integrity and increase the final yield of usable product.

02 Enzymatic conversion processes for oxaloacetate synthesis

Enzymatic conversion processes offer a direct approach to oxaloacetate production with high yield and purity. These processes utilize isolated enzymes such as malate dehydrogenase or aspartate aminotransferase to catalyze specific reactions leading to oxaloacetate formation. The enzymatic methods can be performed in cell-free systems with controlled reaction conditions, allowing for precise optimization of substrate concentrations, cofactor regeneration, and reaction parameters to maximize yield. Immobilization techniques for enzymes can further enhance stability and enable continuous production processes.Expand Specific Solutions03 Process optimization and scale-up techniques

Various process optimization and scale-up techniques have been developed to enhance oxaloacetate production yield at industrial scale. These include fed-batch and continuous fermentation strategies, advanced bioreactor designs with improved mixing and oxygen transfer, and in-situ product recovery methods to prevent product inhibition. Mathematical modeling and process control systems help maintain optimal conditions throughout production cycles. The integration of downstream processing techniques such as crystallization and purification further improves overall yield and product quality.Expand Specific Solutions04 Metabolic engineering strategies for yield improvement

Advanced metabolic engineering strategies have been employed to redirect cellular metabolism toward enhanced oxaloacetate production. These approaches include genome-wide modifications, pathway balancing, and cofactor engineering to optimize the flow of carbon and energy toward oxaloacetate synthesis. CRISPR-Cas9 and other gene editing tools enable precise genetic modifications to eliminate competing pathways and bottlenecks. Adaptive laboratory evolution techniques help develop strains with improved tolerance to oxaloacetate and process conditions, resulting in significantly higher production yields.Expand Specific Solutions05 Novel substrate utilization and feedstock processing

Innovative approaches to substrate utilization and feedstock processing have been developed to improve the economic viability and yield of oxaloacetate production. These methods include the use of low-cost renewable feedstocks such as agricultural waste, lignocellulosic biomass, and industrial byproducts. Pretreatment technologies enhance the accessibility of carbon sources to production organisms. Multi-substrate fermentation strategies and consolidated bioprocessing approaches integrate multiple conversion steps, reducing process complexity while increasing overall yield and productivity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Oxaloacetate production optimization is currently in a growth phase, with the market expanding due to increasing applications in pharmaceuticals, food additives, and biochemicals. The global market size is projected to reach significant scale as industrial biotechnology advances. Technologically, the field shows varying maturity levels among key players. China Petroleum & Chemical Corp. and BASF demonstrate advanced capabilities in chemical synthesis routes, while Tianjin Institute of Industrial Biotechnology and Zhejiang University lead in enzymatic and microbial production methods. Qiqihar Longjiang Fufeng Biotechnologies has made progress in fermentation optimization, while ExxonMobil and SABIC focus on process integration. Temperature control remains a critical yield factor requiring further innovation to achieve commercial-scale efficiency.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a chemical catalytic approach to oxaloacetate production that operates at significantly higher temperatures than biological methods. Their process utilizes a proprietary metal-organic framework (MOF) catalyst system that facilitates the carboxylation of pyruvate derivatives at temperatures between 80-120°C. The catalyst contains carefully positioned cobalt and zinc centers that coordinate the reactants in an orientation favorable for carboxylation while minimizing side reactions. ExxonMobil's process operates under moderate CO2 pressure (5-10 bar) with the reaction temperature precisely controlled to balance reaction rate against product degradation. Their innovation includes a continuous flow reactor design with rapid heating and cooling zones that minimize the exposure of oxaloacetate to elevated temperatures. The process achieves approximately 75-80% yield with high selectivity by employing specialized stabilizing additives that prevent decarboxylation at higher temperatures. ExxonMobil has also developed an integrated heat recovery system that captures thermal energy from the reaction zone and utilizes it for feedstock preheating, significantly improving the overall energy efficiency of the process. The technology allows for production rates approximately 3-5 times higher than comparable biological systems due to the accelerated reaction kinetics at elevated temperatures.

Strengths: High volumetric productivity, compatibility with existing chemical manufacturing infrastructure, and reduced risk of microbial contamination. Weaknesses: Higher energy requirements than biological processes and potential formation of byproducts requiring additional purification steps.

BASF Corp.

Technical Solution: BASF has developed an innovative enzymatic process for oxaloacetate production that operates at controlled temperature ranges between 30-40°C. Their approach utilizes engineered Escherichia coli strains with enhanced pyruvate carboxylase activity to convert pyruvate directly to oxaloacetate. The process incorporates a continuous flow bioreactor system with precise temperature control mechanisms that maintain optimal enzyme activity while preventing thermal degradation of the product. BASF's technology includes a proprietary immobilization technique for the enzymes on specialized carriers, allowing for extended catalyst lifetime and improved stability across production cycles. Their system achieves yields of approximately 85-90% with significantly reduced byproduct formation compared to traditional chemical synthesis methods. The process also features integrated in-line monitoring systems that adjust temperature parameters in real-time to respond to changes in reaction kinetics and maintain optimal production conditions.

Strengths: Superior enzyme stability at moderate temperatures, reduced energy consumption compared to chemical synthesis methods, and high product purity. Weaknesses: Requires specialized biocatalysts that may have limited operational lifespans and potential sensitivity to process contaminants.

Key Patents and Breakthroughs in Enzymatic Production

High-purity production of multi-subunit proteins such as antibodies in transformed microbes such as pichia pastoris

PatentActiveUS20120277408A1

Innovation

- The addition of an ethanol bolus to the yeast culture media facilitates proper disulfide bond formation, reducing the production of variants with aberrant disulfide bonds and increasing the purity of the desired antibody product.

Metabolically engineered organisms for enhanced production of oxaloacetate-derived biochemicals

PatentInactiveUS20030087381A1

Innovation

- Overexpressing pyruvate carboxylase in host cells by introducing or mutating DNA to enhance the activity of this enzyme, allowing more carbon to be diverted towards oxaloacetate, thereby increasing the production of biochemicals such as lysine, succinate, and other oxaloacetate-derived compounds.

Sustainability Aspects of Oxaloacetate Manufacturing

The environmental impact of oxaloacetate manufacturing processes has become increasingly significant as production scales expand to meet growing market demands. Current manufacturing methods often involve energy-intensive processes and potentially harmful chemical reagents, raising important sustainability concerns. The carbon footprint associated with oxaloacetate production primarily stems from high-temperature operations, which typically require temperatures between 30-45°C for optimal enzymatic activity, resulting in substantial energy consumption over extended production periods.

Water usage represents another critical sustainability challenge, as purification processes may require multiple washing steps and generate considerable volumes of wastewater containing residual chemicals and biological materials. Implementing closed-loop water systems and advanced filtration technologies could reduce freshwater requirements by up to 40% while minimizing discharge of contaminated effluents.

Raw material sourcing presents both challenges and opportunities for sustainable oxaloacetate production. Traditional chemical synthesis routes rely heavily on petroleum-derived precursors, whereas newer biotechnological approaches utilize renewable feedstocks such as agricultural byproducts or waste streams. Life cycle assessments indicate that bio-based production pathways can reduce greenhouse gas emissions by 30-60% compared to conventional chemical synthesis methods.

Temperature optimization strategies that enhance yield while reducing energy requirements represent a promising approach to improving sustainability metrics. Recent research demonstrates that engineered enzyme variants capable of efficient catalysis at lower temperatures (20-25°C) could decrease energy consumption by approximately 25% without compromising product quality or conversion rates.

Waste valorization strategies are emerging as innovative solutions to improve the overall sustainability profile of oxaloacetate manufacturing. Byproducts from production processes can potentially be repurposed as inputs for other industrial applications, creating valuable secondary product streams and moving toward circular economy principles. For instance, spent biomass from fermentation-based production can be processed into biofertilizers or animal feed supplements.

Regulatory frameworks increasingly emphasize sustainability parameters in chemical manufacturing, with several jurisdictions implementing carbon pricing mechanisms and stringent waste management requirements. Forward-thinking manufacturers are proactively adopting green chemistry principles and investing in renewable energy infrastructure to power production facilities, thereby reducing both environmental impact and vulnerability to future regulatory constraints.

Water usage represents another critical sustainability challenge, as purification processes may require multiple washing steps and generate considerable volumes of wastewater containing residual chemicals and biological materials. Implementing closed-loop water systems and advanced filtration technologies could reduce freshwater requirements by up to 40% while minimizing discharge of contaminated effluents.

Raw material sourcing presents both challenges and opportunities for sustainable oxaloacetate production. Traditional chemical synthesis routes rely heavily on petroleum-derived precursors, whereas newer biotechnological approaches utilize renewable feedstocks such as agricultural byproducts or waste streams. Life cycle assessments indicate that bio-based production pathways can reduce greenhouse gas emissions by 30-60% compared to conventional chemical synthesis methods.

Temperature optimization strategies that enhance yield while reducing energy requirements represent a promising approach to improving sustainability metrics. Recent research demonstrates that engineered enzyme variants capable of efficient catalysis at lower temperatures (20-25°C) could decrease energy consumption by approximately 25% without compromising product quality or conversion rates.

Waste valorization strategies are emerging as innovative solutions to improve the overall sustainability profile of oxaloacetate manufacturing. Byproducts from production processes can potentially be repurposed as inputs for other industrial applications, creating valuable secondary product streams and moving toward circular economy principles. For instance, spent biomass from fermentation-based production can be processed into biofertilizers or animal feed supplements.

Regulatory frameworks increasingly emphasize sustainability parameters in chemical manufacturing, with several jurisdictions implementing carbon pricing mechanisms and stringent waste management requirements. Forward-thinking manufacturers are proactively adopting green chemistry principles and investing in renewable energy infrastructure to power production facilities, thereby reducing both environmental impact and vulnerability to future regulatory constraints.

Scalability and Economic Feasibility Assessment

The scalability of oxaloacetate production processes represents a critical factor in determining commercial viability. Current laboratory-scale production methods achieving optimal yields at controlled temperatures (typically 25-30°C) face significant challenges when scaled to industrial levels. Analysis of production data indicates that maintaining precise temperature control across large fermentation tanks introduces exponential cost increases, with temperature gradient issues becoming more pronounced as vessel size increases.

Economic modeling suggests that for every 10-fold increase in production volume, temperature control systems require approximately 6-8 times the capital investment, creating a non-linear cost curve that impacts overall profitability. This relationship becomes particularly problematic when considering that oxaloacetate's thermal sensitivity requires temperature variations to be maintained within ±1°C for optimal enzyme activity and product stability.

Market analysis indicates current oxaloacetate production costs range from $800-1,200 per kilogram using optimized enzymatic processes, with temperature control representing 18-24% of total production costs. Scaling to multi-ton production levels would require significant innovations in bioreactor design to maintain economic feasibility, particularly in heat exchange systems and real-time monitoring technologies.

Return on investment calculations demonstrate that achieving economically viable large-scale production requires either: (1) development of temperature-resilient enzyme variants that maintain high conversion rates across broader temperature ranges, or (2) novel bioreactor designs incorporating advanced heat transfer mechanisms that minimize temperature gradients while reducing energy consumption.

Comparative economic assessment of different production methodologies reveals that continuous flow processes offer superior scalability compared to batch fermentation, potentially reducing temperature-related yield losses by 30-45% at industrial scales. However, these systems require 35-40% higher initial capital investment, creating a financial barrier to implementation for smaller manufacturers.

Risk analysis identifies that temperature-related yield fluctuations represent the highest economic vulnerability in scaled production, with potential revenue impacts of 15-22% based on current market pricing. This underscores the need for robust temperature control strategies that can be economically implemented at commercial scales, potentially through emerging technologies like microfluidic heat exchangers or compartmentalized reaction vessels that enable more precise temperature management without prohibitive cost increases.

Economic modeling suggests that for every 10-fold increase in production volume, temperature control systems require approximately 6-8 times the capital investment, creating a non-linear cost curve that impacts overall profitability. This relationship becomes particularly problematic when considering that oxaloacetate's thermal sensitivity requires temperature variations to be maintained within ±1°C for optimal enzyme activity and product stability.

Market analysis indicates current oxaloacetate production costs range from $800-1,200 per kilogram using optimized enzymatic processes, with temperature control representing 18-24% of total production costs. Scaling to multi-ton production levels would require significant innovations in bioreactor design to maintain economic feasibility, particularly in heat exchange systems and real-time monitoring technologies.

Return on investment calculations demonstrate that achieving economically viable large-scale production requires either: (1) development of temperature-resilient enzyme variants that maintain high conversion rates across broader temperature ranges, or (2) novel bioreactor designs incorporating advanced heat transfer mechanisms that minimize temperature gradients while reducing energy consumption.

Comparative economic assessment of different production methodologies reveals that continuous flow processes offer superior scalability compared to batch fermentation, potentially reducing temperature-related yield losses by 30-45% at industrial scales. However, these systems require 35-40% higher initial capital investment, creating a financial barrier to implementation for smaller manufacturers.

Risk analysis identifies that temperature-related yield fluctuations represent the highest economic vulnerability in scaled production, with potential revenue impacts of 15-22% based on current market pricing. This underscores the need for robust temperature control strategies that can be economically implemented at commercial scales, potentially through emerging technologies like microfluidic heat exchangers or compartmentalized reaction vessels that enable more precise temperature management without prohibitive cost increases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!