Polypropylene’s Part in Polymer Electrolyte Membranes for Fuel Cells

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP in PEM Fuel Cells: Background and Objectives

Polymer electrolyte membrane fuel cells (PEMFCs) have emerged as a promising clean energy technology, offering high efficiency and low environmental impact. The development of PEMFCs has been closely tied to advancements in polymer science, particularly in the realm of electrolyte membranes. Polypropylene (PP), a versatile thermoplastic polymer, has played an increasingly significant role in this field.

The journey of polypropylene in PEM fuel cells began in the late 20th century when researchers started exploring alternatives to traditional perfluorosulfonic acid (PFSA) membranes. The primary goal was to develop membranes with improved performance, durability, and cost-effectiveness. PP's attractive properties, including its chemical stability, mechanical strength, and low cost, made it a candidate of interest for fuel cell applications.

Initially, PP was investigated as a potential base material for composite membranes. Researchers aimed to leverage its structural integrity while addressing its inherent hydrophobicity, which posed challenges for proton conductivity. This led to the development of various modification techniques, such as grafting and blending, to enhance PP's suitability for PEM fuel cells.

As research progressed, the focus shifted towards utilizing PP as a support material in composite membranes. This approach aimed to combine the mechanical strength of PP with the proton conductivity of other polymers or inorganic materials. The objective was to create membranes that could withstand the harsh operating conditions of fuel cells while maintaining high proton conductivity and low gas permeability.

Recent technological advancements have further expanded PP's role in PEM fuel cells. Nanotechnology has opened new avenues for PP modification, enabling the creation of nanostructured membranes with enhanced properties. Additionally, the development of novel synthesis methods has allowed for better control over PP's molecular structure, tailoring it more precisely for fuel cell applications.

The current technological landscape sees PP being explored in various forms within PEM fuel cells, including as a base material, support structure, and component in multi-layer membranes. The overarching goal is to harness PP's beneficial properties while overcoming its limitations, ultimately contributing to the development of more efficient, durable, and cost-effective fuel cell systems.

Looking ahead, the objectives for PP in PEM fuel cells are multifaceted. Researchers aim to further improve PP-based membranes' proton conductivity, mechanical stability, and chemical resistance. There is also a push towards developing environmentally friendly production methods for PP-based fuel cell components, aligning with the overall sustainability goals of fuel cell technology.

The journey of polypropylene in PEM fuel cells began in the late 20th century when researchers started exploring alternatives to traditional perfluorosulfonic acid (PFSA) membranes. The primary goal was to develop membranes with improved performance, durability, and cost-effectiveness. PP's attractive properties, including its chemical stability, mechanical strength, and low cost, made it a candidate of interest for fuel cell applications.

Initially, PP was investigated as a potential base material for composite membranes. Researchers aimed to leverage its structural integrity while addressing its inherent hydrophobicity, which posed challenges for proton conductivity. This led to the development of various modification techniques, such as grafting and blending, to enhance PP's suitability for PEM fuel cells.

As research progressed, the focus shifted towards utilizing PP as a support material in composite membranes. This approach aimed to combine the mechanical strength of PP with the proton conductivity of other polymers or inorganic materials. The objective was to create membranes that could withstand the harsh operating conditions of fuel cells while maintaining high proton conductivity and low gas permeability.

Recent technological advancements have further expanded PP's role in PEM fuel cells. Nanotechnology has opened new avenues for PP modification, enabling the creation of nanostructured membranes with enhanced properties. Additionally, the development of novel synthesis methods has allowed for better control over PP's molecular structure, tailoring it more precisely for fuel cell applications.

The current technological landscape sees PP being explored in various forms within PEM fuel cells, including as a base material, support structure, and component in multi-layer membranes. The overarching goal is to harness PP's beneficial properties while overcoming its limitations, ultimately contributing to the development of more efficient, durable, and cost-effective fuel cell systems.

Looking ahead, the objectives for PP in PEM fuel cells are multifaceted. Researchers aim to further improve PP-based membranes' proton conductivity, mechanical stability, and chemical resistance. There is also a push towards developing environmentally friendly production methods for PP-based fuel cell components, aligning with the overall sustainability goals of fuel cell technology.

Market Analysis for PEM Fuel Cell Applications

The market for Polymer Electrolyte Membrane (PEM) fuel cells has been experiencing significant growth in recent years, driven by the increasing demand for clean energy solutions and the push towards decarbonization across various industries. The automotive sector has emerged as a key driver for PEM fuel cell adoption, with major manufacturers investing heavily in fuel cell electric vehicles (FCEVs) as a complement to battery electric vehicles.

In the transportation sector, PEM fuel cells are gaining traction not only in passenger vehicles but also in heavy-duty applications such as buses, trucks, and trains. The ability of fuel cells to provide longer range and faster refueling times compared to battery-electric alternatives makes them particularly attractive for these applications. Several countries, including Japan, South Korea, and Germany, have announced ambitious targets for FCEV deployment, further stimulating market growth.

The stationary power generation sector represents another significant market for PEM fuel cells. These systems are being increasingly used for backup power in critical infrastructure, such as data centers and telecommunications facilities. The reliability and low-emission characteristics of fuel cells make them an attractive alternative to traditional diesel generators. Additionally, there is growing interest in using PEM fuel cells for distributed power generation and combined heat and power (CHP) applications in both residential and commercial settings.

Material handling equipment, particularly forklifts, has been an early adopter of PEM fuel cell technology. The quick refueling times and consistent power output of fuel cells offer operational advantages over battery-powered alternatives in warehouse environments. This market segment continues to expand as more companies recognize the productivity benefits of fuel cell-powered equipment.

The aerospace and marine industries are also exploring PEM fuel cell applications. In aerospace, fuel cells are being developed for auxiliary power units and potentially for propulsion in small aircraft. In the marine sector, there is increasing interest in fuel cells for both propulsion and onboard power generation, particularly for vessels operating in environmentally sensitive areas.

As the market for PEM fuel cells grows, so does the demand for high-performance, cost-effective membrane materials. Polypropylene, with its potential to enhance the durability and efficiency of PEM fuel cells, could play a crucial role in addressing some of the key challenges facing widespread adoption. The development of polypropylene-based membranes that offer improved performance and reduced costs could significantly impact market dynamics and accelerate the commercialization of PEM fuel cell technologies across various applications.

In the transportation sector, PEM fuel cells are gaining traction not only in passenger vehicles but also in heavy-duty applications such as buses, trucks, and trains. The ability of fuel cells to provide longer range and faster refueling times compared to battery-electric alternatives makes them particularly attractive for these applications. Several countries, including Japan, South Korea, and Germany, have announced ambitious targets for FCEV deployment, further stimulating market growth.

The stationary power generation sector represents another significant market for PEM fuel cells. These systems are being increasingly used for backup power in critical infrastructure, such as data centers and telecommunications facilities. The reliability and low-emission characteristics of fuel cells make them an attractive alternative to traditional diesel generators. Additionally, there is growing interest in using PEM fuel cells for distributed power generation and combined heat and power (CHP) applications in both residential and commercial settings.

Material handling equipment, particularly forklifts, has been an early adopter of PEM fuel cell technology. The quick refueling times and consistent power output of fuel cells offer operational advantages over battery-powered alternatives in warehouse environments. This market segment continues to expand as more companies recognize the productivity benefits of fuel cell-powered equipment.

The aerospace and marine industries are also exploring PEM fuel cell applications. In aerospace, fuel cells are being developed for auxiliary power units and potentially for propulsion in small aircraft. In the marine sector, there is increasing interest in fuel cells for both propulsion and onboard power generation, particularly for vessels operating in environmentally sensitive areas.

As the market for PEM fuel cells grows, so does the demand for high-performance, cost-effective membrane materials. Polypropylene, with its potential to enhance the durability and efficiency of PEM fuel cells, could play a crucial role in addressing some of the key challenges facing widespread adoption. The development of polypropylene-based membranes that offer improved performance and reduced costs could significantly impact market dynamics and accelerate the commercialization of PEM fuel cell technologies across various applications.

Current Challenges in PP-based PEM Development

The development of polypropylene-based polymer electrolyte membranes (PEMs) for fuel cells faces several significant challenges that hinder their widespread adoption and commercial viability. One of the primary obstacles is achieving an optimal balance between proton conductivity and mechanical stability. While polypropylene offers excellent mechanical properties and chemical resistance, its inherent hydrophobicity limits proton conductivity, which is crucial for efficient fuel cell operation.

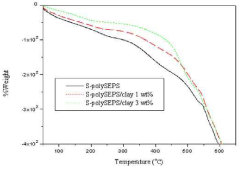

Researchers are grappling with the task of modifying polypropylene to enhance its proton conductivity without compromising its structural integrity. Various approaches, such as grafting hydrophilic functional groups or incorporating inorganic fillers, have shown promise but often lead to trade-offs in other performance aspects. The long-term durability of these modified membranes under fuel cell operating conditions remains a concern, as the harsh chemical environment and temperature fluctuations can degrade the membrane over time.

Another significant challenge lies in the scalability of production processes for PP-based PEMs. While laboratory-scale synthesis methods have demonstrated encouraging results, translating these techniques to industrial-scale manufacturing while maintaining consistent quality and performance is proving to be a formidable task. The cost-effectiveness of large-scale production is also a critical factor that needs to be addressed to make PP-based PEMs economically viable alternatives to existing membrane technologies.

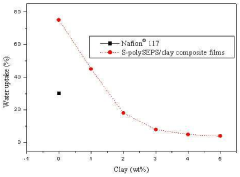

Water management within the membrane is another area of ongoing research and development. Polypropylene's hydrophobic nature makes it challenging to achieve the right balance of water content necessary for optimal proton transport. Excessive water can lead to flooding and reduced efficiency, while insufficient water results in poor conductivity. Developing effective strategies to control water uptake and retention in PP-based PEMs is crucial for maintaining stable performance across varying operating conditions.

The integration of PP-based PEMs into fuel cell systems presents its own set of challenges. Compatibility issues with other fuel cell components, such as catalyst layers and gas diffusion layers, need to be resolved to ensure seamless operation and longevity of the entire system. Additionally, optimizing the interface between the membrane and these components to minimize resistance and maximize performance is an area that requires further investigation and innovation.

Environmental concerns and regulatory compliance pose additional hurdles for PP-based PEM development. As sustainability becomes increasingly important, researchers must consider the entire lifecycle of these membranes, from production to disposal or recycling. Developing environmentally friendly synthesis methods and exploring biodegradable or recyclable alternatives within the polypropylene framework are becoming essential aspects of research in this field.

Researchers are grappling with the task of modifying polypropylene to enhance its proton conductivity without compromising its structural integrity. Various approaches, such as grafting hydrophilic functional groups or incorporating inorganic fillers, have shown promise but often lead to trade-offs in other performance aspects. The long-term durability of these modified membranes under fuel cell operating conditions remains a concern, as the harsh chemical environment and temperature fluctuations can degrade the membrane over time.

Another significant challenge lies in the scalability of production processes for PP-based PEMs. While laboratory-scale synthesis methods have demonstrated encouraging results, translating these techniques to industrial-scale manufacturing while maintaining consistent quality and performance is proving to be a formidable task. The cost-effectiveness of large-scale production is also a critical factor that needs to be addressed to make PP-based PEMs economically viable alternatives to existing membrane technologies.

Water management within the membrane is another area of ongoing research and development. Polypropylene's hydrophobic nature makes it challenging to achieve the right balance of water content necessary for optimal proton transport. Excessive water can lead to flooding and reduced efficiency, while insufficient water results in poor conductivity. Developing effective strategies to control water uptake and retention in PP-based PEMs is crucial for maintaining stable performance across varying operating conditions.

The integration of PP-based PEMs into fuel cell systems presents its own set of challenges. Compatibility issues with other fuel cell components, such as catalyst layers and gas diffusion layers, need to be resolved to ensure seamless operation and longevity of the entire system. Additionally, optimizing the interface between the membrane and these components to minimize resistance and maximize performance is an area that requires further investigation and innovation.

Environmental concerns and regulatory compliance pose additional hurdles for PP-based PEM development. As sustainability becomes increasingly important, researchers must consider the entire lifecycle of these membranes, from production to disposal or recycling. Developing environmentally friendly synthesis methods and exploring biodegradable or recyclable alternatives within the polypropylene framework are becoming essential aspects of research in this field.

Existing PP-based PEM Solutions

01 Composition and preparation of polypropylene-based polymer electrolyte membranes

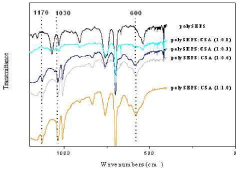

Polypropylene-based polymer electrolyte membranes are developed by incorporating various additives and modifiers to enhance their properties. These membranes are prepared using techniques such as melt extrusion, solution casting, or electrospinning. The composition often includes polypropylene as the base polymer, along with other components to improve ionic conductivity, mechanical strength, and thermal stability.- Preparation methods for polypropylene polymer electrolyte membranes: Various techniques are employed to prepare polypropylene polymer electrolyte membranes, including grafting, crosslinking, and blending methods. These processes aim to improve the membrane's ionic conductivity, mechanical strength, and thermal stability for use in fuel cells and other electrochemical applications.

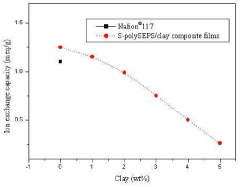

- Modification of polypropylene membranes for enhanced performance: Polypropylene membranes are modified through the incorporation of functional groups, nanoparticles, or other additives to enhance their properties. These modifications can improve proton conductivity, water retention, and overall electrochemical performance of the membranes in fuel cell applications.

- Composite membranes incorporating polypropylene: Composite membranes are developed by combining polypropylene with other polymers or inorganic materials to create hybrid structures. These composites aim to synergize the beneficial properties of different materials, resulting in improved mechanical strength, chemical stability, and ion transport characteristics.

- Surface treatment and functionalization of polypropylene membranes: Various surface treatment techniques are applied to polypropylene membranes to enhance their properties. These methods include plasma treatment, chemical etching, and grafting of functional groups onto the membrane surface, which can improve wettability, ion exchange capacity, and overall performance in electrochemical applications.

- Characterization and performance evaluation of polypropylene electrolyte membranes: Different analytical techniques and testing methods are employed to characterize and evaluate the performance of polypropylene polymer electrolyte membranes. These include measurements of ionic conductivity, mechanical properties, thermal stability, and fuel cell performance under various operating conditions.

02 Surface modification of polypropylene membranes

Surface modification techniques are employed to improve the performance of polypropylene-based polymer electrolyte membranes. These methods include plasma treatment, grafting, and coating with functional materials. Surface modification enhances the membrane's hydrophilicity, ion exchange capacity, and compatibility with other components in fuel cell systems.Expand Specific Solutions03 Crosslinking and blending for improved membrane properties

Crosslinking and blending techniques are utilized to enhance the mechanical, thermal, and electrochemical properties of polypropylene-based polymer electrolyte membranes. These methods involve the incorporation of crosslinking agents or blending with other polymers to create a more robust and efficient membrane structure.Expand Specific Solutions04 Incorporation of inorganic fillers and nanoparticles

Inorganic fillers and nanoparticles are added to polypropylene-based polymer electrolyte membranes to improve their performance. These additives enhance properties such as proton conductivity, water retention, and mechanical strength. Common fillers include silica, titanium dioxide, and various metal oxides.Expand Specific Solutions05 Application in fuel cells and energy storage devices

Polypropylene-based polymer electrolyte membranes find applications in fuel cells and energy storage devices. These membranes serve as separators and electrolytes, facilitating ion transport while maintaining electrical insulation between electrodes. The development of these membranes focuses on improving their performance and durability in various operating conditions.Expand Specific Solutions

Key Players in PEM Fuel Cell Industry

The polymer electrolyte membrane fuel cell market is in a growth phase, with increasing adoption in automotive and stationary power applications. The global market size is projected to reach several billion dollars by 2025, driven by demand for clean energy solutions. Technologically, polypropylene-based membranes are still emerging, with major players like Toyota, Hyundai, and Honda advancing research. Companies such as LG Chem, Toray, and Sumitomo Chemical are developing novel membrane materials and manufacturing processes. While not yet fully mature, the technology is progressing rapidly with collaborations between automakers, chemical companies, and research institutions accelerating innovation and commercialization efforts.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered the use of polypropylene-based composite membranes in their fuel cell vehicles. Their approach involves creating a multi-layer membrane structure, where a thin layer of polypropylene is sandwiched between two layers of sulfonated polymer. This design aims to leverage polypropylene's excellent barrier properties to reduce gas crossover, a common issue in fuel cells[2]. Toyota's membrane also incorporates nanoparticles to enhance proton conductivity and mechanical strength. The company has reported a 20% increase in fuel cell efficiency and a 30% reduction in platinum catalyst usage with this technology[4].

Strengths: Reduced gas crossover, improved fuel cell efficiency, and reduced reliance on expensive catalysts. Weaknesses: Increased complexity in membrane fabrication and potential long-term durability concerns.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel approach to incorporating polypropylene into polymer electrolyte membranes through a grafting technique. Their method involves radiation-induced grafting of styrene onto polypropylene films, followed by sulfonation to introduce proton-conducting groups. This process results in a membrane with a polypropylene backbone and sulfonated polystyrene side chains, combining the mechanical strength of polypropylene with the proton conductivity of sulfonated polymers[5]. LG Chem reports that these membranes exhibit conductivity comparable to Nafion membranes but with improved mechanical properties and lower cost[6].

Strengths: Cost-effective production, good balance of mechanical and electrochemical properties. Weaknesses: Potential degradation of polypropylene during radiation grafting, complexity in controlling grafting density.

Innovations in PP-PEM Technology

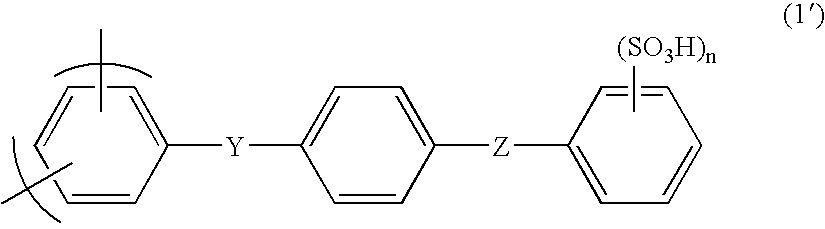

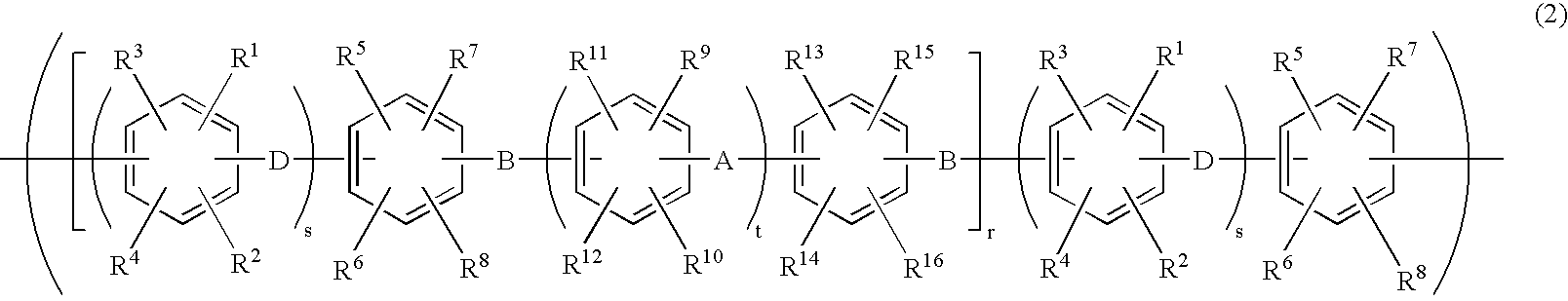

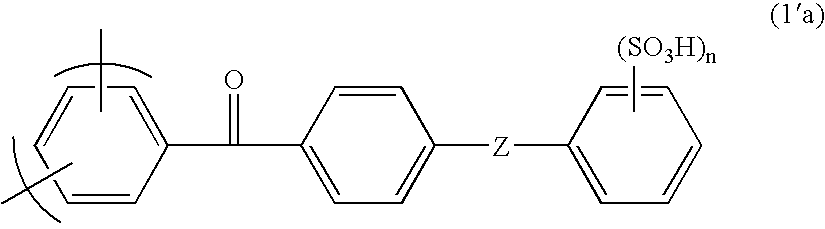

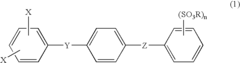

Proton exchange membrane for fuel cell having poly(ethylene-ran-propylene)/styrene block copolymer and preparation method of the same

PatentInactiveKR1020130088280A

Innovation

- Development of a sulfonated polyethylene-propylene/styrene block copolymer as the basic skeleton for electrolyte membranes, incorporating inorganic particles, to enhance ion conductivity and reduce manufacturing costs.

Membrane-electrode assembly for solid polymer electrolyte fuel cell

PatentInactiveUS20080241628A1

Innovation

- A membrane-electrode assembly using sulfonated polyarylene with specific constitutional units as a proton conductive membrane, which includes sulfonic acid groups bonded to an aromatic ring, enhancing proton conductivity and acidity, and maintaining performance under both high-humidity and low-humidity environments.

Environmental Impact of PP-based PEMs

The environmental impact of polypropylene-based polymer electrolyte membranes (PP-based PEMs) in fuel cells is a critical consideration in the development and adoption of this technology. These membranes play a crucial role in the efficiency and performance of fuel cells, but their production, use, and disposal have significant environmental implications.

The manufacturing process of PP-based PEMs involves the use of petrochemical resources, which contributes to carbon emissions and resource depletion. However, compared to traditional energy sources, fuel cells utilizing these membranes offer a cleaner alternative, potentially reducing overall greenhouse gas emissions during operation. The longevity and durability of PP-based PEMs also influence their environmental footprint, as longer-lasting membranes reduce the frequency of replacement and associated waste.

In terms of energy efficiency, fuel cells employing PP-based PEMs demonstrate higher conversion rates compared to conventional combustion engines, leading to reduced fuel consumption and lower emissions. This improved efficiency contributes to a decrease in the overall environmental impact of energy production and utilization.

The end-of-life management of PP-based PEMs presents both challenges and opportunities. While polypropylene is recyclable, the composite nature of these membranes, often containing other materials and chemical treatments, can complicate recycling processes. Developing effective recycling methods for these membranes is crucial to minimize waste and promote a circular economy approach in fuel cell technology.

Water management is another environmental aspect to consider. PP-based PEMs require proper hydration for optimal performance, which may impact water resources in regions where water scarcity is a concern. However, the water produced as a byproduct of fuel cell operation can potentially be recycled or used in other applications, mitigating some of these concerns.

The production of PP-based PEMs may involve the use of certain chemicals and solvents, which could have potential environmental impacts if not properly managed. Efforts to develop greener manufacturing processes and materials for these membranes are ongoing, aiming to reduce the use of harmful substances and minimize environmental risks associated with production.

In the broader context of sustainable energy solutions, the environmental impact of PP-based PEMs must be weighed against the benefits they provide in enabling clean energy technologies. As fuel cell technology continues to advance, ongoing research and development efforts are focused on improving the environmental performance of these membranes throughout their lifecycle, from production to disposal or recycling.

The manufacturing process of PP-based PEMs involves the use of petrochemical resources, which contributes to carbon emissions and resource depletion. However, compared to traditional energy sources, fuel cells utilizing these membranes offer a cleaner alternative, potentially reducing overall greenhouse gas emissions during operation. The longevity and durability of PP-based PEMs also influence their environmental footprint, as longer-lasting membranes reduce the frequency of replacement and associated waste.

In terms of energy efficiency, fuel cells employing PP-based PEMs demonstrate higher conversion rates compared to conventional combustion engines, leading to reduced fuel consumption and lower emissions. This improved efficiency contributes to a decrease in the overall environmental impact of energy production and utilization.

The end-of-life management of PP-based PEMs presents both challenges and opportunities. While polypropylene is recyclable, the composite nature of these membranes, often containing other materials and chemical treatments, can complicate recycling processes. Developing effective recycling methods for these membranes is crucial to minimize waste and promote a circular economy approach in fuel cell technology.

Water management is another environmental aspect to consider. PP-based PEMs require proper hydration for optimal performance, which may impact water resources in regions where water scarcity is a concern. However, the water produced as a byproduct of fuel cell operation can potentially be recycled or used in other applications, mitigating some of these concerns.

The production of PP-based PEMs may involve the use of certain chemicals and solvents, which could have potential environmental impacts if not properly managed. Efforts to develop greener manufacturing processes and materials for these membranes are ongoing, aiming to reduce the use of harmful substances and minimize environmental risks associated with production.

In the broader context of sustainable energy solutions, the environmental impact of PP-based PEMs must be weighed against the benefits they provide in enabling clean energy technologies. As fuel cell technology continues to advance, ongoing research and development efforts are focused on improving the environmental performance of these membranes throughout their lifecycle, from production to disposal or recycling.

Cost-Benefit Analysis of PP in PEM Fuel Cells

The cost-benefit analysis of polypropylene (PP) in polymer electrolyte membrane (PEM) fuel cells reveals a complex interplay of economic and performance factors. PP offers significant cost advantages compared to traditional materials used in PEM fuel cells, such as perfluorosulfonic acid (PFSA) polymers. The lower raw material cost of PP translates to reduced overall production expenses for fuel cell manufacturers.

However, the cost savings must be weighed against potential performance trade-offs. While PP-based membranes generally exhibit lower proton conductivity compared to PFSA membranes, recent advancements in PP modification techniques have narrowed this gap. The improved durability and mechanical strength of PP membranes contribute to extended fuel cell lifetimes, potentially offsetting initial performance differences.

From a manufacturing perspective, PP's ease of processing and compatibility with existing production equipment present additional cost benefits. The ability to leverage established polymer processing techniques reduces the need for specialized equipment investments, lowering barriers to entry for fuel cell production.

Environmental considerations also factor into the cost-benefit equation. PP's recyclability and lower environmental impact during production align with growing sustainability demands, potentially reducing long-term costs associated with waste management and regulatory compliance.

The scalability of PP production offers economies of scale that can further drive down costs as fuel cell adoption increases. This scalability advantage positions PP-based membranes favorably for mass-market applications, particularly in the automotive sector where cost-competitiveness is crucial.

However, the cost-benefit analysis must also account for potential drawbacks. The need for additional treatments or modifications to enhance PP's proton conductivity may partially offset initial cost savings. Furthermore, the long-term performance and durability of PP-based membranes in real-world applications require extensive testing and validation, which incur additional development costs.

In conclusion, while PP offers compelling cost advantages for PEM fuel cells, a comprehensive cost-benefit analysis must consider performance trade-offs, manufacturing efficiencies, environmental impacts, and long-term reliability. As research progresses and PP-based membrane technologies mature, the cost-benefit ratio is likely to improve, potentially accelerating the adoption of this material in commercial fuel cell applications.

However, the cost savings must be weighed against potential performance trade-offs. While PP-based membranes generally exhibit lower proton conductivity compared to PFSA membranes, recent advancements in PP modification techniques have narrowed this gap. The improved durability and mechanical strength of PP membranes contribute to extended fuel cell lifetimes, potentially offsetting initial performance differences.

From a manufacturing perspective, PP's ease of processing and compatibility with existing production equipment present additional cost benefits. The ability to leverage established polymer processing techniques reduces the need for specialized equipment investments, lowering barriers to entry for fuel cell production.

Environmental considerations also factor into the cost-benefit equation. PP's recyclability and lower environmental impact during production align with growing sustainability demands, potentially reducing long-term costs associated with waste management and regulatory compliance.

The scalability of PP production offers economies of scale that can further drive down costs as fuel cell adoption increases. This scalability advantage positions PP-based membranes favorably for mass-market applications, particularly in the automotive sector where cost-competitiveness is crucial.

However, the cost-benefit analysis must also account for potential drawbacks. The need for additional treatments or modifications to enhance PP's proton conductivity may partially offset initial cost savings. Furthermore, the long-term performance and durability of PP-based membranes in real-world applications require extensive testing and validation, which incur additional development costs.

In conclusion, while PP offers compelling cost advantages for PEM fuel cells, a comprehensive cost-benefit analysis must consider performance trade-offs, manufacturing efficiencies, environmental impacts, and long-term reliability. As research progresses and PP-based membrane technologies mature, the cost-benefit ratio is likely to improve, potentially accelerating the adoption of this material in commercial fuel cell applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!