QNED for Redefining Industry Display Standards

JUN 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Technology Evolution

QNED (Quantum Nano Emitting Diode) technology has undergone significant evolution since its inception, marking a series of milestones in the display industry. The journey began with the development of quantum dot technology, which laid the foundation for QNED's emergence. Initially, quantum dots were primarily used to enhance color performance in LCD displays, serving as a color conversion layer.

As research progressed, scientists and engineers focused on integrating quantum dots directly into the light-emitting components of displays. This led to the creation of quantum dot light-emitting diodes (QLEDs), which demonstrated improved color accuracy and efficiency compared to traditional LED displays. However, QLEDs faced challenges in terms of stability and longevity, prompting further innovation.

The next significant leap came with the introduction of nanorod LED technology. Nanorods offered enhanced electron mobility and light emission properties, addressing some of the limitations of earlier quantum dot implementations. This development paved the way for more efficient and brighter displays, setting the stage for QNED's arrival.

QNED technology emerged as a convergence of quantum dot and nanorod LED advancements. By combining the color purity of quantum dots with the efficiency of nanorod LEDs, QNED displays achieved superior performance in terms of brightness, color gamut, and energy efficiency. This hybrid approach allowed for the creation of self-emissive pixels, eliminating the need for a separate backlight system used in traditional LCD displays.

The evolution of QNED also saw improvements in manufacturing processes. Early prototypes faced challenges in mass production due to the complexity of precisely arranging quantum dots and nanorods. However, advancements in nanomaterial synthesis and deposition techniques gradually overcame these hurdles, making large-scale production more feasible.

Recent developments in QNED technology have focused on enhancing durability and reducing production costs. Researchers have explored various encapsulation methods to protect the quantum nano-emitting diodes from environmental factors, thereby extending the lifespan of QNED displays. Additionally, efforts have been made to optimize the materials used, seeking more abundant and cost-effective alternatives without compromising performance.

The latest iterations of QNED technology have also addressed power consumption concerns. By fine-tuning the quantum dot and nanorod compositions, engineers have achieved higher energy efficiency, making QNED displays increasingly suitable for a wide range of applications, from mobile devices to large-format displays and televisions.

As QNED technology continues to mature, it is poised to redefine industry display standards. The ongoing research and development in this field promise further improvements in picture quality, energy efficiency, and production scalability, solidifying QNED's position as a cutting-edge display technology for the future.

As research progressed, scientists and engineers focused on integrating quantum dots directly into the light-emitting components of displays. This led to the creation of quantum dot light-emitting diodes (QLEDs), which demonstrated improved color accuracy and efficiency compared to traditional LED displays. However, QLEDs faced challenges in terms of stability and longevity, prompting further innovation.

The next significant leap came with the introduction of nanorod LED technology. Nanorods offered enhanced electron mobility and light emission properties, addressing some of the limitations of earlier quantum dot implementations. This development paved the way for more efficient and brighter displays, setting the stage for QNED's arrival.

QNED technology emerged as a convergence of quantum dot and nanorod LED advancements. By combining the color purity of quantum dots with the efficiency of nanorod LEDs, QNED displays achieved superior performance in terms of brightness, color gamut, and energy efficiency. This hybrid approach allowed for the creation of self-emissive pixels, eliminating the need for a separate backlight system used in traditional LCD displays.

The evolution of QNED also saw improvements in manufacturing processes. Early prototypes faced challenges in mass production due to the complexity of precisely arranging quantum dots and nanorods. However, advancements in nanomaterial synthesis and deposition techniques gradually overcame these hurdles, making large-scale production more feasible.

Recent developments in QNED technology have focused on enhancing durability and reducing production costs. Researchers have explored various encapsulation methods to protect the quantum nano-emitting diodes from environmental factors, thereby extending the lifespan of QNED displays. Additionally, efforts have been made to optimize the materials used, seeking more abundant and cost-effective alternatives without compromising performance.

The latest iterations of QNED technology have also addressed power consumption concerns. By fine-tuning the quantum dot and nanorod compositions, engineers have achieved higher energy efficiency, making QNED displays increasingly suitable for a wide range of applications, from mobile devices to large-format displays and televisions.

As QNED technology continues to mature, it is poised to redefine industry display standards. The ongoing research and development in this field promise further improvements in picture quality, energy efficiency, and production scalability, solidifying QNED's position as a cutting-edge display technology for the future.

Display Market Dynamics

The display market has witnessed significant transformations in recent years, driven by technological advancements and changing consumer preferences. QNED (Quantum Nano Emitting Diode) technology emerges as a potential game-changer in this dynamic landscape, promising to redefine industry display standards.

The global display market continues to expand, with projections indicating substantial growth in the coming years. This growth is fueled by increasing demand for high-quality displays across various sectors, including consumer electronics, automotive, healthcare, and industrial applications. The proliferation of smart devices, coupled with the rising adoption of advanced display technologies in emerging markets, further contributes to market expansion.

Consumer preferences are shifting towards larger screens with higher resolutions and improved color accuracy. This trend is particularly evident in the television and smartphone segments, where manufacturers are constantly pushing the boundaries of display technology to meet consumer expectations. The demand for immersive viewing experiences has led to the development of technologies that offer enhanced contrast ratios, wider color gamuts, and higher refresh rates.

In the commercial sector, there is a growing need for displays that can deliver superior performance in diverse environments. This includes outdoor displays capable of maintaining visibility in bright sunlight, as well as large-format displays for digital signage and control rooms. The increasing adoption of touch-enabled displays in retail and hospitality sectors also contributes to market growth.

The automotive industry represents a significant growth opportunity for display manufacturers. The integration of advanced driver assistance systems (ADAS) and the trend towards autonomous vehicles are driving demand for high-quality, durable displays that can withstand harsh automotive environments. Head-up displays (HUDs) and digital instrument clusters are becoming standard features in modern vehicles, further expanding the market for automotive displays.

Environmental concerns and energy efficiency regulations are influencing display market dynamics. Manufacturers are focusing on developing eco-friendly display technologies that consume less power and utilize sustainable materials. This shift aligns with global initiatives to reduce carbon footprints and promote energy conservation.

The COVID-19 pandemic has accelerated certain trends in the display market, particularly in the areas of remote work and distance learning. This has led to increased demand for displays suitable for video conferencing and collaborative work environments. The healthcare sector has also seen a surge in demand for medical-grade displays, driven by the need for telemedicine and advanced diagnostic imaging.

As QNED technology enters this competitive landscape, it faces both opportunities and challenges. The technology's potential to offer superior image quality, energy efficiency, and durability positions it as a strong contender in the high-end display market. However, it must compete with established technologies such as OLED and emerging alternatives like microLED. The success of QNED will depend on its ability to deliver tangible benefits to consumers and businesses while addressing the evolving needs of various market segments.

The global display market continues to expand, with projections indicating substantial growth in the coming years. This growth is fueled by increasing demand for high-quality displays across various sectors, including consumer electronics, automotive, healthcare, and industrial applications. The proliferation of smart devices, coupled with the rising adoption of advanced display technologies in emerging markets, further contributes to market expansion.

Consumer preferences are shifting towards larger screens with higher resolutions and improved color accuracy. This trend is particularly evident in the television and smartphone segments, where manufacturers are constantly pushing the boundaries of display technology to meet consumer expectations. The demand for immersive viewing experiences has led to the development of technologies that offer enhanced contrast ratios, wider color gamuts, and higher refresh rates.

In the commercial sector, there is a growing need for displays that can deliver superior performance in diverse environments. This includes outdoor displays capable of maintaining visibility in bright sunlight, as well as large-format displays for digital signage and control rooms. The increasing adoption of touch-enabled displays in retail and hospitality sectors also contributes to market growth.

The automotive industry represents a significant growth opportunity for display manufacturers. The integration of advanced driver assistance systems (ADAS) and the trend towards autonomous vehicles are driving demand for high-quality, durable displays that can withstand harsh automotive environments. Head-up displays (HUDs) and digital instrument clusters are becoming standard features in modern vehicles, further expanding the market for automotive displays.

Environmental concerns and energy efficiency regulations are influencing display market dynamics. Manufacturers are focusing on developing eco-friendly display technologies that consume less power and utilize sustainable materials. This shift aligns with global initiatives to reduce carbon footprints and promote energy conservation.

The COVID-19 pandemic has accelerated certain trends in the display market, particularly in the areas of remote work and distance learning. This has led to increased demand for displays suitable for video conferencing and collaborative work environments. The healthcare sector has also seen a surge in demand for medical-grade displays, driven by the need for telemedicine and advanced diagnostic imaging.

As QNED technology enters this competitive landscape, it faces both opportunities and challenges. The technology's potential to offer superior image quality, energy efficiency, and durability positions it as a strong contender in the high-end display market. However, it must compete with established technologies such as OLED and emerging alternatives like microLED. The success of QNED will depend on its ability to deliver tangible benefits to consumers and businesses while addressing the evolving needs of various market segments.

QNED Technical Challenges

QNED (Quantum Nano Emitting Diode) technology, while promising significant advancements in display quality, faces several technical challenges that need to be addressed for widespread adoption and industry standard redefinition. One of the primary hurdles is the complexity of manufacturing processes required for QNED displays. The precise placement and alignment of quantum dots and nanoparticles demand highly sophisticated and controlled production environments, which can be difficult to scale for mass production.

Another significant challenge lies in the stability and longevity of QNED displays. Quantum dots are known to be sensitive to environmental factors such as heat and moisture, which can affect their performance and lifespan. Developing robust encapsulation techniques to protect these sensitive components from degradation over time is crucial for ensuring the long-term reliability of QNED displays.

Color accuracy and consistency present another set of technical obstacles. While QNED technology promises superior color reproduction, achieving and maintaining precise color calibration across the entire display panel remains a complex task. This challenge is further compounded by the need to ensure uniformity in quantum dot size and distribution, as variations can lead to color inconsistencies across the display.

Power efficiency is an additional area of concern for QNED technology. Although QNEDs are expected to offer improved energy efficiency compared to traditional LED-backlit displays, optimizing power consumption while maintaining high brightness and color performance is a delicate balance that requires innovative solutions in both hardware and software.

The integration of QNED technology with existing display manufacturing infrastructure poses yet another challenge. Adapting current production lines and processes to accommodate the unique requirements of QNED displays may require significant investments and retooling, which could slow down industry-wide adoption.

Furthermore, the development of suitable driving circuits and control systems tailored to the specific characteristics of QNED displays is essential. These systems must be capable of precisely controlling the quantum dot emission to achieve the desired visual output while managing power consumption and heat generation effectively.

Lastly, the cost of production remains a significant barrier to widespread adoption of QNED technology. The materials and processes involved in creating QNED displays are currently more expensive than those used in conventional display technologies. Reducing these costs to a level that makes QNED competitive in the consumer market is a critical challenge that must be overcome to redefine industry display standards.

Another significant challenge lies in the stability and longevity of QNED displays. Quantum dots are known to be sensitive to environmental factors such as heat and moisture, which can affect their performance and lifespan. Developing robust encapsulation techniques to protect these sensitive components from degradation over time is crucial for ensuring the long-term reliability of QNED displays.

Color accuracy and consistency present another set of technical obstacles. While QNED technology promises superior color reproduction, achieving and maintaining precise color calibration across the entire display panel remains a complex task. This challenge is further compounded by the need to ensure uniformity in quantum dot size and distribution, as variations can lead to color inconsistencies across the display.

Power efficiency is an additional area of concern for QNED technology. Although QNEDs are expected to offer improved energy efficiency compared to traditional LED-backlit displays, optimizing power consumption while maintaining high brightness and color performance is a delicate balance that requires innovative solutions in both hardware and software.

The integration of QNED technology with existing display manufacturing infrastructure poses yet another challenge. Adapting current production lines and processes to accommodate the unique requirements of QNED displays may require significant investments and retooling, which could slow down industry-wide adoption.

Furthermore, the development of suitable driving circuits and control systems tailored to the specific characteristics of QNED displays is essential. These systems must be capable of precisely controlling the quantum dot emission to achieve the desired visual output while managing power consumption and heat generation effectively.

Lastly, the cost of production remains a significant barrier to widespread adoption of QNED technology. The materials and processes involved in creating QNED displays are currently more expensive than those used in conventional display technologies. Reducing these costs to a level that makes QNED competitive in the consumer market is a critical challenge that must be overcome to redefine industry display standards.

Current QNED Solutions

01 Quantum dot light-emitting diode structure

QNED displays utilize a structure incorporating quantum dots as the light-emitting material. This structure typically includes layers for electron transport, hole transport, and the quantum dot emissive layer. The quantum dots are engineered to emit specific colors, allowing for precise color control and high color purity in the display.- QNED structure and fabrication: QNED displays utilize quantum nano-emitting diodes, which are typically composed of quantum dots or nanocrystals. The fabrication process involves precise control of nanostructure growth and integration with other display components. This technology aims to improve color accuracy, brightness, and energy efficiency compared to traditional LED displays.

- Color enhancement and light emission control: QNED displays employ advanced techniques for color enhancement and light emission control. This includes the use of specific quantum dot materials, color filters, and light management structures to achieve a wider color gamut and improved contrast. Methods for controlling the emission characteristics of quantum nano-emitting diodes are crucial for display performance.

- Integration with existing display technologies: QNED technology is being integrated with existing display technologies such as LCD and OLED. This integration aims to combine the benefits of quantum nano-emitting diodes with established display architectures. Standards are being developed to ensure compatibility and optimal performance in hybrid display systems.

- Energy efficiency and power management: QNED displays focus on improving energy efficiency through advanced power management techniques. This includes optimizing the electrical characteristics of quantum nano-emitting diodes, developing efficient driving circuits, and implementing intelligent power control algorithms to reduce overall energy consumption while maintaining high display quality.

- Reliability and longevity standards: Standards for QNED displays address reliability and longevity concerns. This includes developing methods to prevent degradation of quantum nano-emitting diodes over time, implementing protective measures against environmental factors, and establishing testing protocols to ensure consistent performance throughout the display's lifespan.

02 Nano-rod LED technology

QNED displays may incorporate nano-rod LED technology, where nanoscale rod-shaped structures are used as the light-emitting elements. These nano-rods can be precisely controlled in terms of size and composition to achieve desired optical properties, potentially offering improvements in efficiency and color quality over traditional LED technologies.Expand Specific Solutions03 Color conversion and enhancement techniques

QNED displays often employ color conversion and enhancement techniques to improve display performance. This may include the use of color filters, quantum dot color converters, or other optical elements to refine the spectral output of the emitted light and achieve a wider color gamut.Expand Specific Solutions04 Driving and control methods for QNED displays

Specific driving and control methods are developed for QNED displays to optimize their performance. These may include specialized circuitry for controlling the quantum dot or nano-rod LEDs, as well as algorithms for color management and image processing tailored to the unique characteristics of QNED technology.Expand Specific Solutions05 Manufacturing processes for QNED displays

The production of QNED displays involves specialized manufacturing processes to create and integrate the quantum dot or nano-rod structures. This may include techniques for depositing quantum dots or growing nano-rods, as well as methods for incorporating these structures into the overall display architecture while maintaining high yield and consistency.Expand Specific Solutions

Key QNED Industry Players

QNED (Quantum Nano Emitting Diode) technology for display standards is in its early development stage, with significant potential to redefine the industry. The market size is expanding rapidly, driven by demand for high-quality, energy-efficient displays. While not yet fully mature, QNED shows promise in bridging the gap between OLED and traditional LCD technologies. Key players like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics are investing heavily in research and development. Other companies such as Sharp, E Ink, and Philips are also exploring QNED applications. As the technology progresses, we can expect increased competition and innovation from both established display manufacturers and emerging tech firms.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed QNED (Quantum Nano Emitting Diode) technology, which combines quantum dot and mini-LED technologies. Their QNED displays use a mini-LED backlight with quantum dot color conversion film to achieve high brightness, wide color gamut, and improved contrast. BOE's QNED panels feature over 10,000 local dimming zones, enabling precise control of brightness and contrast across the screen. This technology allows for deeper blacks and brighter highlights, resulting in enhanced HDR performance.

Strengths: Superior image quality with high brightness and wide color gamut. Improved contrast and HDR performance. Weaknesses: Higher production costs compared to traditional LCD. Potential for blooming effects in high-contrast scenes.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has introduced its own version of QNED technology, which they call QD-OLED. This hybrid display technology combines the benefits of QLED and OLED. Samsung's approach uses blue OLED material as the light source and quantum dots for color conversion. The result is a display that offers the perfect blacks and wide viewing angles of OLED, combined with the high brightness and color volume of QLED. Samsung's QD-OLED panels are capable of producing over 1,000 nits of peak brightness while maintaining OLED's infinite contrast ratio.

Strengths: Excellent color accuracy and wide color gamut. Perfect blacks and wide viewing angles. High brightness levels. Weaknesses: Potential for burn-in, although mitigated compared to traditional OLED. Higher production costs than conventional displays.

QNED Core Innovations

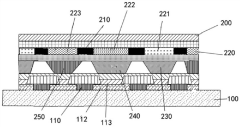

Display panel and display device

PatentActiveCN113488500B

Innovation

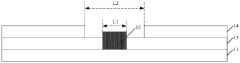

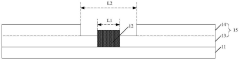

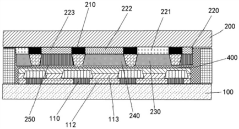

- Design a display panel that ensures that by setting a first opening on the first pixel definition layer that matches the size of the light-emitting unit, and setting a second opening on the second pixel definition layer with a minimum width greater than or equal to the maximum length of the light-emitting unit. The light-emitting unit can perform all-round rotation and alignment in the second opening to avoid random drift and ensure that the light-emitting unit falls back into the corresponding first opening.

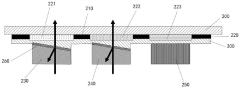

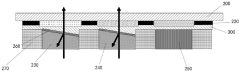

Display panel

PatentPendingCN114914271A

Innovation

- By arranging a wavelength conversion unit and a color filter unit located on the light exit side of the wavelength conversion unit in the display panel, the optical path of the unconverted blue light in the color conversion unit is extended, and the pattern and tilt angle of the color filter unit are used to improve the light conversion efficiency.

QNED Manufacturing Process

The QNED (Quantum Nano Emitting Diode) manufacturing process represents a significant advancement in display technology, combining the best aspects of QLED and Mini-LED technologies. This process involves several key stages, each crucial for achieving the high-quality display standards that QNED promises.

The first stage of QNED manufacturing involves the creation of the quantum dot layer. This process utilizes precision nanotechnology to deposit quantum dots onto a substrate. The quantum dots are typically made from semiconductor materials such as indium phosphide or cadmium selenide, chosen for their specific light-emitting properties. The size and composition of these quantum dots are carefully controlled to ensure precise color output.

Following the quantum dot layer creation, the next critical step is the fabrication of the nano-LED array. This process employs advanced lithography techniques to create an array of extremely small LEDs, typically measuring less than 1 micrometer in diameter. These nano-LEDs serve as the primary light source for the display, offering superior brightness and energy efficiency compared to traditional LED backlights.

The integration of the quantum dot layer with the nano-LED array is a delicate process that requires precise alignment and bonding techniques. This step is crucial for ensuring uniform light distribution and color accuracy across the entire display panel. Advanced robotics and computer vision systems are often employed to achieve the necessary precision in this integration process.

Another essential aspect of QNED manufacturing is the implementation of local dimming zones. This involves dividing the display into numerous independently controllable areas, each capable of adjusting its brightness levels. The creation of these zones requires sophisticated circuitry and control systems, which are integrated into the panel during the manufacturing process.

The final stages of QNED manufacturing involve the assembly of additional display components, such as the color filters, polarizers, and protective layers. These components are carefully layered and bonded to create the complete display panel. Quality control measures are implemented throughout the process, with rigorous testing at each stage to ensure the display meets the high standards expected of QNED technology.

Overall, the QNED manufacturing process is a complex and technologically advanced procedure that requires state-of-the-art facilities and expertise. The combination of quantum dot technology with nano-LED arrays presents unique challenges in terms of precision engineering and quality control. However, the resulting displays offer significant improvements in color accuracy, brightness, and energy efficiency, positioning QNED as a potential game-changer in the display industry.

The first stage of QNED manufacturing involves the creation of the quantum dot layer. This process utilizes precision nanotechnology to deposit quantum dots onto a substrate. The quantum dots are typically made from semiconductor materials such as indium phosphide or cadmium selenide, chosen for their specific light-emitting properties. The size and composition of these quantum dots are carefully controlled to ensure precise color output.

Following the quantum dot layer creation, the next critical step is the fabrication of the nano-LED array. This process employs advanced lithography techniques to create an array of extremely small LEDs, typically measuring less than 1 micrometer in diameter. These nano-LEDs serve as the primary light source for the display, offering superior brightness and energy efficiency compared to traditional LED backlights.

The integration of the quantum dot layer with the nano-LED array is a delicate process that requires precise alignment and bonding techniques. This step is crucial for ensuring uniform light distribution and color accuracy across the entire display panel. Advanced robotics and computer vision systems are often employed to achieve the necessary precision in this integration process.

Another essential aspect of QNED manufacturing is the implementation of local dimming zones. This involves dividing the display into numerous independently controllable areas, each capable of adjusting its brightness levels. The creation of these zones requires sophisticated circuitry and control systems, which are integrated into the panel during the manufacturing process.

The final stages of QNED manufacturing involve the assembly of additional display components, such as the color filters, polarizers, and protective layers. These components are carefully layered and bonded to create the complete display panel. Quality control measures are implemented throughout the process, with rigorous testing at each stage to ensure the display meets the high standards expected of QNED technology.

Overall, the QNED manufacturing process is a complex and technologically advanced procedure that requires state-of-the-art facilities and expertise. The combination of quantum dot technology with nano-LED arrays presents unique challenges in terms of precision engineering and quality control. However, the resulting displays offer significant improvements in color accuracy, brightness, and energy efficiency, positioning QNED as a potential game-changer in the display industry.

QNED Energy Efficiency

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display energy efficiency, addressing the growing demand for more sustainable and eco-friendly display solutions. This innovative technology combines the benefits of quantum dots and mini-LEDs to create a highly efficient light-emitting system.

One of the key factors contributing to QNED's energy efficiency is its superior light conversion efficiency. The quantum dots used in QNED displays can convert blue light from mini-LEDs into precise red and green wavelengths with minimal energy loss. This process results in a more efficient use of the light source, reducing overall power consumption compared to traditional LCD or OLED displays.

The use of mini-LEDs in QNED technology also plays a crucial role in enhancing energy efficiency. These smaller LED chips allow for more precise local dimming, enabling the display to selectively illuminate only the required areas of the screen. This feature significantly reduces power consumption, especially when displaying darker content or when only a portion of the screen needs to be lit.

Furthermore, QNED displays benefit from improved thermal management. The combination of quantum dots and mini-LEDs results in less heat generation compared to conventional display technologies. This reduced heat output not only contributes to energy efficiency but also extends the lifespan of the display, reducing the need for frequent replacements and thus conserving resources in the long term.

Another aspect of QNED's energy efficiency lies in its ability to achieve high brightness levels with lower power input. This characteristic is particularly advantageous in high dynamic range (HDR) content display, where QNED can deliver vibrant and bright images without significantly increasing power consumption. This efficiency is especially notable when compared to OLED technology, which often requires more power to achieve similar brightness levels.

The energy-saving potential of QNED technology extends beyond the display itself. By reducing power consumption, QNED displays can contribute to overall energy savings in various applications, from consumer electronics to large-scale digital signage. This reduction in energy use aligns with global efforts to minimize carbon footprints and promote sustainable technology solutions.

As QNED technology continues to evolve, researchers and manufacturers are focusing on further enhancing its energy efficiency. Ongoing developments include optimizing quantum dot materials for even better light conversion, improving mini-LED design for more precise local dimming, and refining overall system integration to minimize energy losses. These advancements promise to solidify QNED's position as a leading energy-efficient display technology in the coming years.

One of the key factors contributing to QNED's energy efficiency is its superior light conversion efficiency. The quantum dots used in QNED displays can convert blue light from mini-LEDs into precise red and green wavelengths with minimal energy loss. This process results in a more efficient use of the light source, reducing overall power consumption compared to traditional LCD or OLED displays.

The use of mini-LEDs in QNED technology also plays a crucial role in enhancing energy efficiency. These smaller LED chips allow for more precise local dimming, enabling the display to selectively illuminate only the required areas of the screen. This feature significantly reduces power consumption, especially when displaying darker content or when only a portion of the screen needs to be lit.

Furthermore, QNED displays benefit from improved thermal management. The combination of quantum dots and mini-LEDs results in less heat generation compared to conventional display technologies. This reduced heat output not only contributes to energy efficiency but also extends the lifespan of the display, reducing the need for frequent replacements and thus conserving resources in the long term.

Another aspect of QNED's energy efficiency lies in its ability to achieve high brightness levels with lower power input. This characteristic is particularly advantageous in high dynamic range (HDR) content display, where QNED can deliver vibrant and bright images without significantly increasing power consumption. This efficiency is especially notable when compared to OLED technology, which often requires more power to achieve similar brightness levels.

The energy-saving potential of QNED technology extends beyond the display itself. By reducing power consumption, QNED displays can contribute to overall energy savings in various applications, from consumer electronics to large-scale digital signage. This reduction in energy use aligns with global efforts to minimize carbon footprints and promote sustainable technology solutions.

As QNED technology continues to evolve, researchers and manufacturers are focusing on further enhancing its energy efficiency. Ongoing developments include optimizing quantum dot materials for even better light conversion, improving mini-LED design for more precise local dimming, and refining overall system integration to minimize energy losses. These advancements promise to solidify QNED's position as a leading energy-efficient display technology in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!