QNED's Advantages in the Augmentation of Visual Displays

QNED Technology Overview

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display technology, combining the best features of QLED and OLED displays. This innovative approach utilizes quantum dots and nanoLEDs to create a display that offers superior brightness, contrast, and color accuracy compared to existing technologies.

At its core, QNED technology employs a matrix of miniaturized LEDs as the backlight source. These LEDs are significantly smaller than those used in traditional LED-backlit displays, allowing for more precise local dimming and improved contrast ratios. The quantum dots, which are nanoscale semiconductor particles, are then used to convert the blue light emitted by the LEDs into pure red and green light.

The combination of nanoLEDs and quantum dots results in several key advantages for QNED displays. Firstly, they can achieve higher peak brightness levels than OLED displays while maintaining deep black levels, leading to an enhanced dynamic range. This makes QNED displays particularly suitable for HDR content and viewing in brightly lit environments.

Color reproduction is another area where QNED technology excels. The quantum dots used in QNED displays can produce highly saturated and accurate colors across a wide color gamut. This results in more vivid and lifelike images, with better color volume than traditional LCD or OLED displays.

QNED displays also address some of the limitations of OLED technology, such as the potential for burn-in and shorter lifespan. The inorganic nature of the quantum dots and nanoLEDs makes them more resistant to degradation over time, potentially offering longer-lasting displays with consistent performance.

Energy efficiency is another notable aspect of QNED technology. The precise control over the nanoLED backlighting allows for optimized power consumption, as only the necessary areas of the screen are illuminated. This can lead to reduced energy usage compared to traditional LED-backlit displays, especially when displaying darker content.

In terms of manufacturing, QNED technology leverages existing LCD production processes, which could potentially lead to more cost-effective production compared to OLED displays. This factor, combined with the technology's performance benefits, positions QNED as a promising solution for a wide range of display applications, from high-end televisions to professional monitors and even automotive displays.

As QNED technology continues to evolve, it is expected to further improve in areas such as pixel density, response time, and viewing angles. These advancements could solidify QNED's position as a leading display technology in the coming years, offering consumers and professionals alike a superior visual experience across various devices and use cases.

Visual Display Market Analysis

The visual display market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. This market encompasses a wide range of products, including televisions, monitors, smartphones, and other devices with visual displays. The global visual display market size was valued at approximately $150 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 3.5% from 2021 to 2026.

One of the key factors driving market growth is the increasing demand for high-resolution displays with enhanced picture quality. Consumers are increasingly seeking immersive viewing experiences, which has led to the development of technologies such as 4K and 8K displays. The adoption of these high-resolution displays has been particularly strong in the television segment, with 4K TVs becoming increasingly mainstream and 8K TVs gaining traction in the premium market.

Another significant trend in the visual display market is the shift towards larger screen sizes. This trend is evident across various product categories, from smartphones to televisions. In the TV market, for instance, there has been a notable increase in demand for screens larger than 55 inches, particularly in developed markets.

The emergence of new display technologies has also been a key driver of market growth and innovation. OLED (Organic Light-Emitting Diode) displays have gained significant market share, particularly in the high-end smartphone and television segments, due to their superior picture quality and energy efficiency. MicroLED technology is also gaining attention as a potential future display technology, offering the promise of even better picture quality and energy efficiency than OLED.

In terms of regional market dynamics, Asia-Pacific dominates the global visual display market, accounting for the largest market share. This is primarily due to the presence of major display panel manufacturers in countries like South Korea, China, and Japan. North America and Europe follow as significant markets, driven by high consumer spending on electronics and early adoption of new display technologies.

The competitive landscape of the visual display market is characterized by intense competition among major players such as Samsung Electronics, LG Display, Sony Corporation, and TCL Technology. These companies are continuously investing in research and development to introduce innovative display technologies and maintain their market positions.

Looking ahead, the visual display market is expected to continue evolving with the introduction of new technologies and form factors. Flexible and foldable displays are gaining traction, particularly in the smartphone market, and are expected to create new opportunities for growth and innovation in the coming years. Additionally, the integration of advanced features such as artificial intelligence and Internet of Things (IoT) connectivity is likely to further drive market growth and transform the visual display landscape.

QNED Technical Challenges

QNED (Quantum Nano Emitting Diode) technology, while promising, faces several significant technical challenges that need to be addressed for its successful implementation in visual displays. One of the primary hurdles is the precise control and manipulation of quantum dots at the nanoscale level. The uniformity and stability of quantum dot size and distribution are crucial for achieving consistent color output and longevity of the display. Current manufacturing processes struggle to maintain the required level of precision across large-scale production.

Another major challenge lies in the development of efficient and stable blue quantum dots. While red and green quantum dots have shown considerable progress, blue quantum dots continue to lag in terms of efficiency and stability. This imbalance affects the overall color gamut and performance of QNED displays, limiting their ability to produce a full range of accurate colors.

The integration of quantum dots with existing LED technology presents its own set of challenges. Ensuring proper energy transfer from the LED to the quantum dots without significant loss is critical for maintaining high efficiency. Additionally, the interface between the quantum dots and the surrounding materials must be carefully engineered to prevent degradation and maintain long-term stability under various operating conditions.

Heat management is another significant technical hurdle for QNED displays. Quantum dots are sensitive to temperature fluctuations, which can affect their emission properties and lifespan. Developing effective thermal management solutions that can dissipate heat efficiently without compromising the display's form factor or performance is essential for the technology's success.

The encapsulation of quantum dots poses yet another challenge. Protecting these nanoscale particles from environmental factors such as moisture and oxygen is crucial for maintaining their performance and longevity. Current encapsulation methods often struggle to provide adequate protection without negatively impacting the optical properties of the quantum dots.

Scaling up production while maintaining quality and consistency is a significant hurdle for QNED technology. The transition from laboratory-scale production to large-scale manufacturing processes that can produce high-quality QNED displays at competitive costs remains a major challenge for the industry.

Lastly, the environmental impact and potential toxicity of certain quantum dot materials, particularly those containing heavy metals, raise concerns about the long-term sustainability and safety of QNED technology. Developing alternative, eco-friendly quantum dot materials that maintain high performance standards is an ongoing challenge that researchers must address to ensure the widespread adoption of QNED displays.

Current QNED Solutions

01 Quantum dot enhancement for QNED displays

QNED displays utilize quantum dots to enhance color performance and brightness. These nanoscale semiconductor particles emit light of specific wavelengths when excited, resulting in improved color gamut and efficiency. The integration of quantum dots in the display structure allows for better light management and increased visual quality.- QNED structure and composition: QNED displays utilize quantum nano-emitting diodes, which are composed of quantum dots and nanoparticles. These structures are designed to enhance light emission efficiency and color purity. The composition and arrangement of these nanomaterials play a crucial role in determining the overall visual quality of the display.

- Color gamut and brightness enhancement: QNED technology offers improved color gamut and brightness compared to traditional LED displays. The quantum dots used in QNEDs can be tuned to emit specific wavelengths of light, resulting in more vibrant and accurate colors. Additionally, the nano-emitting diodes contribute to enhanced brightness levels, improving overall visual quality.

- Contrast ratio and black level improvement: QNED displays achieve better contrast ratios and deeper black levels through advanced light control mechanisms. The nano-emitting diodes allow for precise control of light emission, enabling local dimming and reducing light leakage. This results in improved contrast and more accurate representation of dark scenes.

- Energy efficiency and heat management: QNED technology offers improved energy efficiency compared to traditional display technologies. The quantum nano-emitting diodes require less power to produce the same level of brightness, resulting in reduced energy consumption. Additionally, advanced heat management techniques are employed to maintain optimal performance and longevity of the display.

- Manufacturing processes and scalability: The manufacturing processes for QNED displays involve advanced techniques for depositing and patterning quantum dots and nanoparticles. These processes are designed to ensure uniformity and consistency across large display areas. Scalability of QNED technology is a key factor in improving visual quality while maintaining cost-effectiveness for various display sizes.

02 Nanostructure design for improved emission

The design and fabrication of nanostructures in QNED displays play a crucial role in enhancing emission properties. Optimized nanostructure geometries, such as nanowires or nanoparticles, can improve light extraction efficiency and directionality. These advancements lead to better brightness, contrast, and overall visual quality in QNED displays.Expand Specific Solutions03 Advanced materials for QNED performance

The development of advanced materials for QNED displays focuses on improving the efficiency and stability of quantum emitters. Novel semiconductor compositions, doping strategies, and surface treatments are explored to enhance the quantum yield and longevity of the emitting diodes. These material innovations contribute to superior visual display quality and device performance.Expand Specific Solutions04 Pixel architecture and driving methods

Innovative pixel architectures and driving methods are crucial for optimizing QNED display performance. Advanced pixel designs incorporate multiple sub-pixels or utilize novel electrode configurations to improve color accuracy and brightness control. Sophisticated driving schemes are developed to enhance refresh rates, reduce motion blur, and increase overall visual quality.Expand Specific Solutions05 Integration with other display technologies

QNED technology can be integrated with other display technologies to further enhance visual quality. Combinations with micro-LED, OLED, or traditional LCD technologies can leverage the strengths of each approach. These hybrid solutions aim to achieve superior color reproduction, contrast ratios, and energy efficiency, resulting in improved overall display performance.Expand Specific Solutions

Key QNED Industry Players

The competitive landscape for QNED's advantages in augmenting visual displays is evolving rapidly, with the industry in a growth phase characterized by significant technological advancements and market expansion. The market size for enhanced visual display technologies is projected to increase substantially, driven by applications in AR/VR, automotive, and consumer electronics. Companies like Meta Platforms, NVIDIA, and Samsung Display are at the forefront, investing heavily in research and development. The technology's maturity varies, with established players like LG Display and BOE Technology Group pushing boundaries, while startups and research institutions like The Hong Kong University of Science & Technology contribute innovative solutions. The competition is fierce, with a mix of tech giants, specialized display manufacturers, and emerging players vying for market share and technological leadership.

NVIDIA Corp.

BOE Technology Group Co., Ltd.

QNED Core Innovations

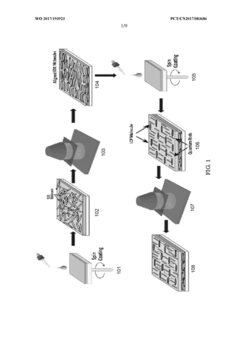

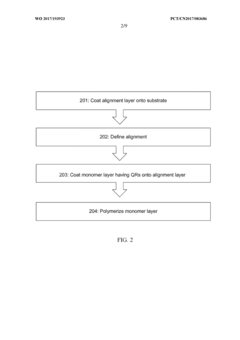

- Photoaligned quantum rod enhancement film (QREF) with aligned quantum rods for improved LCD image quality and efficiency.

- Use of photoalignment layer to control the alignment axis of quantum rods in the polymer layer.

- Integration of QREF in LCDs to reduce light losses associated with color filters and polarizers.

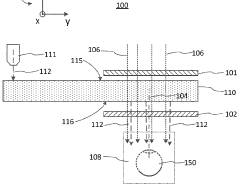

- A near-eye display system incorporating a first polarizer for external light and a see-through lightguide that conveys image light in an orthogonal polarization state, with a second polarizer downstream to adjust the power balance, allowing for mechanical or electrical adjustment of polarization states to accommodate different brightness conditions.

QNED Manufacturing Process

The manufacturing process of QNED (Quantum Nano-Emitting Diode) displays involves several intricate steps that combine advanced nanotechnology with precision engineering. The process begins with the preparation of a substrate, typically made of glass or a flexible material, which serves as the foundation for the display. This substrate is meticulously cleaned and treated to ensure optimal adhesion of subsequent layers.

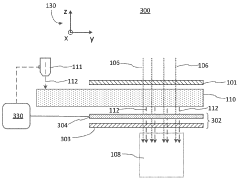

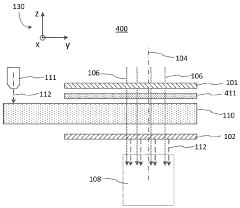

Next, a thin-film transistor (TFT) backplane is deposited onto the substrate. This backplane consists of an array of transistors that control individual pixels, enabling precise control over the display's image quality. The TFT layer is created using photolithography techniques, involving the deposition of various semiconductor materials and conductive layers.

Following the TFT backplane, the quantum dot layer is applied. This layer is crucial for QNED technology, as it contains precisely engineered nanoparticles that emit light when excited. The quantum dots are typically deposited using a solution-based process, such as inkjet printing or photolithography, allowing for precise placement and uniform distribution across the display surface.

The next critical step is the integration of the nano-LED layer. These ultra-small LEDs are positioned above the quantum dot layer and serve as the primary light source. The nano-LEDs are fabricated using advanced semiconductor manufacturing techniques and are carefully aligned with the quantum dot layer to ensure optimal energy transfer and light emission.

A color filter layer is then applied above the nano-LED and quantum dot layers. This filter helps to refine the color output of each pixel, enhancing the overall color accuracy and vibrancy of the display. The color filter is typically created using photolithography or printing techniques, with each sub-pixel precisely aligned with the corresponding quantum dot and nano-LED elements.

The final layers of the QNED display include encapsulation and protective coatings. These layers shield the sensitive internal components from environmental factors such as moisture and oxygen, which can degrade performance over time. Advanced materials like thin-film encapsulation (TFE) or glass-on-glass sealing may be employed to ensure long-term durability and reliability.

Throughout the manufacturing process, stringent quality control measures are implemented to maintain consistency and performance. This includes in-line testing of individual components, as well as comprehensive testing of the completed displays to ensure color accuracy, brightness uniformity, and overall functionality.

QNED Energy Efficiency

QNED (Quantum Nano Emitting Diode) technology demonstrates significant advantages in energy efficiency when applied to visual displays. This innovative approach leverages quantum dot technology to enhance the performance of LED displays, resulting in substantial improvements in power consumption and overall energy efficiency.

One of the primary factors contributing to QNED's energy efficiency is its ability to produce highly saturated colors with minimal energy input. The quantum dots used in QNED displays can emit precise wavelengths of light, allowing for more accurate color reproduction without the need for additional color filters or backlighting systems. This targeted emission of light reduces energy waste and improves overall efficiency.

Furthermore, QNED technology enables better light management within the display. The quantum dots can be precisely controlled, allowing for more efficient use of light output. This means that less energy is required to achieve the same level of brightness compared to traditional LED or OLED displays. The improved light management also contributes to enhanced contrast ratios and deeper blacks, further optimizing the display's performance without increasing power consumption.

Another aspect of QNED's energy efficiency lies in its potential for local dimming capabilities. By utilizing quantum dots in conjunction with mini-LED backlighting, QNED displays can achieve more granular control over individual zones of the screen. This allows for selective dimming or brightening of specific areas, reducing power consumption in darker scenes while maintaining high brightness in brighter areas.

The longevity of QNED displays also contributes to their overall energy efficiency. Quantum dots are known for their stability and resistance to degradation over time. This means that QNED displays can maintain their performance and energy efficiency for longer periods compared to some other display technologies, reducing the need for frequent replacements and the associated energy costs of manufacturing new displays.

Additionally, QNED technology has the potential to improve the energy efficiency of larger displays, such as those used in public spaces or outdoor advertising. The high brightness and color accuracy of QNED displays can be achieved with lower power consumption, making them an attractive option for applications that require large-scale, high-quality visual displays with reduced energy costs.

In summary, QNED technology offers significant advantages in energy efficiency for visual displays through its precise color emission, improved light management, local dimming capabilities, longevity, and scalability to larger display formats. These factors combine to create a display technology that not only enhances visual quality but also contributes to reduced energy consumption and improved sustainability in the field of display technology.