Barium Hydroxide and its Application in Smart Flooring Technologies

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide Smart Flooring Background

Barium hydroxide, a chemical compound with the formula Ba(OH)2, has emerged as a key component in the development of smart flooring technologies. This innovative application represents a significant leap forward in the integration of advanced materials science with everyday infrastructure. The journey of barium hydroxide from a simple industrial chemical to a crucial element in smart flooring systems reflects the broader trend of incorporating reactive and adaptive materials into built environments.

The concept of smart flooring has gained traction in recent years as part of the larger movement towards intelligent buildings and Internet of Things (IoT) integration. Traditional flooring materials have long been passive elements in construction, serving primarily functional and aesthetic purposes. However, the introduction of barium hydroxide-based smart flooring marks a paradigm shift, transforming floors into active, responsive components of building systems.

Barium hydroxide's unique properties make it particularly suitable for smart flooring applications. Its ability to react with carbon dioxide in the air to form barium carbonate creates opportunities for self-healing and air-purifying flooring systems. This chemical reaction not only contributes to improved indoor air quality but also enhances the durability and longevity of flooring materials.

The evolution of barium hydroxide in smart flooring technologies can be traced back to early experiments in self-repairing concrete. Researchers discovered that the incorporation of barium hydroxide into concrete mixtures could lead to the autonomous healing of cracks and fissures, significantly extending the lifespan of concrete structures. This breakthrough laid the foundation for more advanced applications in flooring systems.

As smart building technologies have advanced, the potential applications for barium hydroxide in flooring have expanded. Current research focuses on developing flooring systems that can actively respond to environmental changes, such as temperature fluctuations or humidity levels. These smart floors have the potential to contribute to energy efficiency by regulating heat transfer and moisture levels within buildings.

The integration of barium hydroxide into smart flooring also opens up possibilities for enhanced safety features. For instance, floors could be designed to change color or texture in response to spills or other hazards, providing visual cues to building occupants and potentially preventing accidents. This reactive capability represents a significant advancement in building safety and risk management.

Furthermore, the use of barium hydroxide in smart flooring aligns with growing environmental concerns and sustainability goals. By incorporating materials that can actively purify air and self-repair, the need for frequent replacements and maintenance is reduced, leading to lower environmental impact over the lifecycle of the building.

The concept of smart flooring has gained traction in recent years as part of the larger movement towards intelligent buildings and Internet of Things (IoT) integration. Traditional flooring materials have long been passive elements in construction, serving primarily functional and aesthetic purposes. However, the introduction of barium hydroxide-based smart flooring marks a paradigm shift, transforming floors into active, responsive components of building systems.

Barium hydroxide's unique properties make it particularly suitable for smart flooring applications. Its ability to react with carbon dioxide in the air to form barium carbonate creates opportunities for self-healing and air-purifying flooring systems. This chemical reaction not only contributes to improved indoor air quality but also enhances the durability and longevity of flooring materials.

The evolution of barium hydroxide in smart flooring technologies can be traced back to early experiments in self-repairing concrete. Researchers discovered that the incorporation of barium hydroxide into concrete mixtures could lead to the autonomous healing of cracks and fissures, significantly extending the lifespan of concrete structures. This breakthrough laid the foundation for more advanced applications in flooring systems.

As smart building technologies have advanced, the potential applications for barium hydroxide in flooring have expanded. Current research focuses on developing flooring systems that can actively respond to environmental changes, such as temperature fluctuations or humidity levels. These smart floors have the potential to contribute to energy efficiency by regulating heat transfer and moisture levels within buildings.

The integration of barium hydroxide into smart flooring also opens up possibilities for enhanced safety features. For instance, floors could be designed to change color or texture in response to spills or other hazards, providing visual cues to building occupants and potentially preventing accidents. This reactive capability represents a significant advancement in building safety and risk management.

Furthermore, the use of barium hydroxide in smart flooring aligns with growing environmental concerns and sustainability goals. By incorporating materials that can actively purify air and self-repair, the need for frequent replacements and maintenance is reduced, leading to lower environmental impact over the lifecycle of the building.

Market Analysis for Smart Flooring Solutions

The smart flooring market has been experiencing significant growth in recent years, driven by increasing demand for innovative and technologically advanced building solutions. This market segment is part of the broader smart home and building automation industry, which is projected to reach substantial market value in the coming years. The integration of barium hydroxide in smart flooring technologies represents a novel approach that could potentially disrupt the current market landscape.

Smart flooring solutions encompass a wide range of products and technologies, including pressure-sensitive floors, energy-harvesting surfaces, and interactive floor systems. These solutions cater to various sectors such as residential, commercial, healthcare, and industrial applications. The market is primarily driven by factors such as increasing awareness of energy efficiency, growing adoption of Internet of Things (IoT) technologies, and the rising demand for enhanced user experiences in built environments.

In the residential sector, smart flooring solutions are gaining traction due to their ability to provide safety features, energy management, and personalized comfort. Commercial applications are focusing on improving workspace efficiency and employee well-being through intelligent floor systems that can track movement patterns and optimize space utilization. The healthcare industry is particularly interested in smart flooring technologies for fall detection and patient monitoring in hospitals and care facilities.

The incorporation of barium hydroxide in smart flooring technologies presents unique opportunities for market growth. Barium hydroxide's properties, such as its ability to absorb carbon dioxide and its potential for enhancing the durability and functionality of flooring materials, could address several key market demands. This includes improved indoor air quality, increased floor lifespan, and enhanced thermal properties, all of which are increasingly important to consumers and businesses alike.

Market trends indicate a growing preference for sustainable and eco-friendly building materials. Barium hydroxide's potential role in carbon capture within flooring systems aligns well with this trend, potentially opening new market segments focused on environmentally conscious construction and renovation projects. Additionally, the integration of barium hydroxide in smart flooring could lead to the development of self-healing or self-maintaining floor systems, addressing the market's demand for low-maintenance and long-lasting building solutions.

However, the market for barium hydroxide-enhanced smart flooring faces challenges, including the need for extensive research and development to fully realize its potential applications, potential regulatory hurdles related to the use of barium compounds in building materials, and the need to educate consumers and industry professionals about the benefits and safety of this technology. Overcoming these challenges will be crucial for market penetration and widespread adoption.

Smart flooring solutions encompass a wide range of products and technologies, including pressure-sensitive floors, energy-harvesting surfaces, and interactive floor systems. These solutions cater to various sectors such as residential, commercial, healthcare, and industrial applications. The market is primarily driven by factors such as increasing awareness of energy efficiency, growing adoption of Internet of Things (IoT) technologies, and the rising demand for enhanced user experiences in built environments.

In the residential sector, smart flooring solutions are gaining traction due to their ability to provide safety features, energy management, and personalized comfort. Commercial applications are focusing on improving workspace efficiency and employee well-being through intelligent floor systems that can track movement patterns and optimize space utilization. The healthcare industry is particularly interested in smart flooring technologies for fall detection and patient monitoring in hospitals and care facilities.

The incorporation of barium hydroxide in smart flooring technologies presents unique opportunities for market growth. Barium hydroxide's properties, such as its ability to absorb carbon dioxide and its potential for enhancing the durability and functionality of flooring materials, could address several key market demands. This includes improved indoor air quality, increased floor lifespan, and enhanced thermal properties, all of which are increasingly important to consumers and businesses alike.

Market trends indicate a growing preference for sustainable and eco-friendly building materials. Barium hydroxide's potential role in carbon capture within flooring systems aligns well with this trend, potentially opening new market segments focused on environmentally conscious construction and renovation projects. Additionally, the integration of barium hydroxide in smart flooring could lead to the development of self-healing or self-maintaining floor systems, addressing the market's demand for low-maintenance and long-lasting building solutions.

However, the market for barium hydroxide-enhanced smart flooring faces challenges, including the need for extensive research and development to fully realize its potential applications, potential regulatory hurdles related to the use of barium compounds in building materials, and the need to educate consumers and industry professionals about the benefits and safety of this technology. Overcoming these challenges will be crucial for market penetration and widespread adoption.

Current Challenges in Barium Hydroxide Integration

The integration of barium hydroxide into smart flooring technologies presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is the material's high reactivity with carbon dioxide in the air, which can lead to the formation of barium carbonate. This reaction not only reduces the effectiveness of barium hydroxide but also potentially compromises the structural integrity of the flooring system over time.

Another challenge lies in the moisture sensitivity of barium hydroxide. When exposed to humidity, it tends to form hydrates, which can alter its physical and chemical properties. This characteristic makes it difficult to maintain consistent performance in varying environmental conditions, particularly in areas with fluctuating humidity levels.

The corrosive nature of barium hydroxide poses additional complications for its integration into smart flooring systems. It can potentially degrade other materials used in the flooring construction, such as metals or certain polymers, necessitating careful selection of compatible materials and protective measures.

Furthermore, the relatively high cost of barium hydroxide compared to alternative materials presents an economic challenge for large-scale implementation in smart flooring technologies. This cost factor may limit its adoption, particularly in price-sensitive market segments.

Safety concerns also play a crucial role in the integration process. Barium hydroxide is classified as a hazardous substance, requiring stringent handling and disposal protocols. This classification complicates manufacturing processes and raises potential liability issues for producers and installers of smart flooring systems incorporating this material.

The long-term stability and durability of barium hydroxide in flooring applications remain uncertain. Limited data on its performance over extended periods in real-world conditions creates hesitation among potential adopters and investors in the technology.

Achieving uniform distribution of barium hydroxide within the flooring matrix presents another technical hurdle. Ensuring consistent dispersion is critical for maintaining the desired properties across the entire floor surface, but achieving this uniformity at scale can be challenging.

Lastly, the regulatory landscape surrounding the use of barium compounds in consumer products adds complexity to the integration process. Compliance with varying international standards and regulations may require extensive testing and documentation, potentially slowing down the development and commercialization of barium hydroxide-based smart flooring technologies.

Another challenge lies in the moisture sensitivity of barium hydroxide. When exposed to humidity, it tends to form hydrates, which can alter its physical and chemical properties. This characteristic makes it difficult to maintain consistent performance in varying environmental conditions, particularly in areas with fluctuating humidity levels.

The corrosive nature of barium hydroxide poses additional complications for its integration into smart flooring systems. It can potentially degrade other materials used in the flooring construction, such as metals or certain polymers, necessitating careful selection of compatible materials and protective measures.

Furthermore, the relatively high cost of barium hydroxide compared to alternative materials presents an economic challenge for large-scale implementation in smart flooring technologies. This cost factor may limit its adoption, particularly in price-sensitive market segments.

Safety concerns also play a crucial role in the integration process. Barium hydroxide is classified as a hazardous substance, requiring stringent handling and disposal protocols. This classification complicates manufacturing processes and raises potential liability issues for producers and installers of smart flooring systems incorporating this material.

The long-term stability and durability of barium hydroxide in flooring applications remain uncertain. Limited data on its performance over extended periods in real-world conditions creates hesitation among potential adopters and investors in the technology.

Achieving uniform distribution of barium hydroxide within the flooring matrix presents another technical hurdle. Ensuring consistent dispersion is critical for maintaining the desired properties across the entire floor surface, but achieving this uniformity at scale can be challenging.

Lastly, the regulatory landscape surrounding the use of barium compounds in consumer products adds complexity to the integration process. Compliance with varying international standards and regulations may require extensive testing and documentation, potentially slowing down the development and commercialization of barium hydroxide-based smart flooring technologies.

Existing Barium Hydroxide Applications

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes involve different starting materials and techniques to obtain high-purity barium hydroxide, which is essential for various industrial applications.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes involve different raw materials, reaction conditions, and purification steps to obtain high-quality barium hydroxide for industrial applications.

- Use of barium hydroxide in chemical reactions: Barium hydroxide is utilized in various chemical reactions as a reagent or catalyst. It is particularly useful in organic synthesis, neutralization reactions, and as a strong base in industrial processes.

- Applications in water treatment and environmental remediation: Barium hydroxide finds applications in water treatment processes and environmental remediation. It is used for removing contaminants, adjusting pH levels, and treating industrial wastewater.

- Use in the production of specialty chemicals and materials: Barium hydroxide is employed in the manufacture of various specialty chemicals and materials. It is used in the production of lubricants, plastics, ceramics, and other industrial products.

- Safety considerations and handling of barium hydroxide: Due to its corrosive nature and potential health hazards, proper safety measures and handling procedures are essential when working with barium hydroxide. This includes appropriate storage, personal protective equipment, and disposal methods.

02 Applications of barium hydroxide in chemical processes

Barium hydroxide is utilized in diverse chemical processes, including the production of other barium compounds, water treatment, and as a reagent in organic synthesis. Its alkaline properties make it suitable for neutralization reactions and as a catalyst in certain chemical transformations.Expand Specific Solutions03 Use of barium hydroxide in material science and manufacturing

Barium hydroxide plays a role in various material science applications, including the production of ceramics, glass, and specialty materials. It is also used in the manufacturing of certain types of batteries and electronic components.Expand Specific Solutions04 Environmental and safety considerations for barium hydroxide

The handling, storage, and disposal of barium hydroxide require specific safety measures due to its corrosive nature and potential environmental impact. Proper protocols for its use in industrial settings and methods for treating barium hydroxide-containing waste are discussed.Expand Specific Solutions05 Innovations in barium hydroxide technology

Recent advancements in barium hydroxide technology include improved production methods, novel applications, and enhanced formulations. These innovations aim to increase efficiency, reduce environmental impact, and expand the utility of barium hydroxide in various industries.Expand Specific Solutions

Key Players in Smart Materials Industry

The research on barium hydroxide and its application in smart flooring technologies is in an emerging stage, with the market showing significant growth potential. The global smart flooring market is expected to expand rapidly due to increasing demand for innovative and sustainable building solutions. While the technology is still evolving, several key players are actively developing and commercializing smart flooring solutions. Companies like Shaw Industries Group, Interface, and nora systems are at the forefront, leveraging their expertise in flooring materials and incorporating smart technologies. Other major corporations such as Murata Manufacturing, 3M, and Unilever are also exploring this space, indicating a growing interest from diverse industry sectors in smart flooring applications.

Shaw Industries Group, Inc.

Technical Solution: Shaw Industries Group has developed a smart flooring technology incorporating barium hydroxide for enhanced durability and moisture resistance. Their approach involves integrating barium hydroxide into the flooring material's composition, creating a chemical reaction that forms a protective barrier against water and stains. This technology also includes sensors embedded within the flooring structure to monitor foot traffic, temperature, and humidity levels[1]. The barium hydroxide-infused flooring can self-adjust its properties based on environmental conditions, providing optimal performance and longevity[3].

Strengths: Improved durability, moisture resistance, and adaptive performance. Weaknesses: Potential higher cost and complexity in manufacturing and installation.

3M Innovative Properties Co.

Technical Solution: 3M has developed a novel smart flooring technology utilizing barium hydroxide as a key component. Their approach involves incorporating barium hydroxide into a polymer matrix, creating a responsive flooring material that can change its properties based on environmental conditions. The flooring system includes a network of microsensors that detect pressure, temperature, and humidity[2]. When exposed to moisture or temperature changes, the barium hydroxide-infused polymer undergoes a controlled chemical reaction, altering its structure to provide enhanced grip or insulation as needed[4]. Additionally, 3M has integrated energy harvesting capabilities into the flooring, converting mechanical energy from footsteps into electrical energy to power the smart features[5].

Strengths: Adaptive properties, energy harvesting capabilities, and multifunctional performance. Weaknesses: Potentially high initial costs and complex maintenance requirements.

Innovative Uses of Barium Hydroxide

Manufacture of barium hydroxide

PatentInactiveGB917038A

Innovation

- A process involving the reaction of barium zincate and barium sulphide solutions with controlled additions of zinc oxide and barium sulphide, followed by treatment with hydrogen peroxide and hydrochloric or sulphuric acid to recover barium hydroxide and recycle zinc oxide, minimizing barium loss and maintaining reactivity.

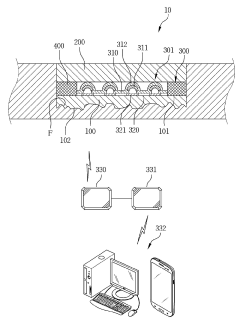

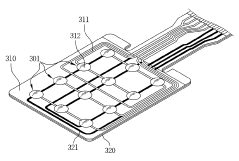

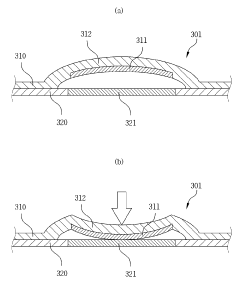

Smart flooring

PatentActiveKR1020210125792A

Innovation

- The smart flooring design includes a pressure sensor unit interposed between upper and lower layers, with a shock absorber for elastic support and a flexible lower layer that distributes load, using ON-OFF type sensors and a pressure analysis unit for efficient pressure sensing.

Environmental Impact Assessment

The environmental impact assessment of barium hydroxide and its application in smart flooring technologies reveals both potential benefits and concerns. Barium hydroxide, when used in smart flooring systems, can contribute to improved energy efficiency and reduced carbon footprint in buildings. These smart floors can regulate temperature and humidity, potentially decreasing the need for traditional heating and cooling systems, thus lowering overall energy consumption.

However, the production and disposal of barium hydroxide raise environmental concerns. The mining and processing of barium ores can lead to habitat disruption and soil contamination if not properly managed. Additionally, the energy-intensive nature of barium hydroxide production contributes to greenhouse gas emissions, offsetting some of the environmental benefits gained from its application in smart flooring.

Water pollution is another significant consideration. Barium compounds, if released into water systems, can be harmful to aquatic life and potentially contaminate drinking water sources. Proper handling and disposal protocols are crucial to mitigate these risks. Furthermore, the long-term durability of smart flooring systems incorporating barium hydroxide needs to be assessed to ensure that frequent replacements do not lead to increased waste generation.

On a positive note, the use of barium hydroxide in smart flooring can potentially reduce the need for certain building materials, leading to a decrease in overall resource consumption. The ability of these floors to regulate indoor environments more efficiently may also result in reduced use of chemical-based cleaning and maintenance products, further minimizing environmental impact.

The recyclability and end-of-life management of smart flooring systems containing barium hydroxide are critical factors in their overall environmental assessment. Research into effective recycling methods and the development of circular economy approaches for these materials could significantly enhance their environmental profile. Additionally, life cycle assessments comparing smart flooring technologies with traditional flooring options are necessary to quantify the net environmental impact accurately.

In conclusion, while barium hydroxide in smart flooring technologies offers promising environmental benefits through energy efficiency and improved indoor environmental quality, careful consideration must be given to its production, use, and disposal to ensure that these benefits are not outweighed by potential negative impacts on ecosystems and human health.

However, the production and disposal of barium hydroxide raise environmental concerns. The mining and processing of barium ores can lead to habitat disruption and soil contamination if not properly managed. Additionally, the energy-intensive nature of barium hydroxide production contributes to greenhouse gas emissions, offsetting some of the environmental benefits gained from its application in smart flooring.

Water pollution is another significant consideration. Barium compounds, if released into water systems, can be harmful to aquatic life and potentially contaminate drinking water sources. Proper handling and disposal protocols are crucial to mitigate these risks. Furthermore, the long-term durability of smart flooring systems incorporating barium hydroxide needs to be assessed to ensure that frequent replacements do not lead to increased waste generation.

On a positive note, the use of barium hydroxide in smart flooring can potentially reduce the need for certain building materials, leading to a decrease in overall resource consumption. The ability of these floors to regulate indoor environments more efficiently may also result in reduced use of chemical-based cleaning and maintenance products, further minimizing environmental impact.

The recyclability and end-of-life management of smart flooring systems containing barium hydroxide are critical factors in their overall environmental assessment. Research into effective recycling methods and the development of circular economy approaches for these materials could significantly enhance their environmental profile. Additionally, life cycle assessments comparing smart flooring technologies with traditional flooring options are necessary to quantify the net environmental impact accurately.

In conclusion, while barium hydroxide in smart flooring technologies offers promising environmental benefits through energy efficiency and improved indoor environmental quality, careful consideration must be given to its production, use, and disposal to ensure that these benefits are not outweighed by potential negative impacts on ecosystems and human health.

Scalability and Cost Analysis

The scalability and cost analysis of barium hydroxide in smart flooring technologies is a critical aspect to consider for widespread adoption and commercial viability. As the demand for smart flooring solutions increases, the ability to scale production and maintain cost-effectiveness becomes paramount.

Barium hydroxide's production process involves the reaction of barium oxide with water or the electrolysis of barium chloride solutions. The scalability of this process is relatively favorable, as the raw materials are readily available and the production methods are well-established. However, the challenge lies in scaling up production to meet potential large-scale demand for smart flooring applications.

One of the key factors affecting scalability is the availability of barium compounds. While barium is not considered a rare earth element, its global production is limited compared to more common industrial chemicals. This could potentially lead to supply chain bottlenecks if demand for barium hydroxide in smart flooring technologies increases significantly.

From a cost perspective, barium hydroxide is generally more expensive than other common alkaline compounds used in construction materials. The current market price for industrial-grade barium hydroxide ranges from $1,000 to $1,500 per metric ton, depending on purity and quantity. This cost factor needs to be carefully considered when integrating barium hydroxide into smart flooring systems, as it could significantly impact the overall product pricing.

The production scale also plays a crucial role in cost analysis. As production volumes increase, economies of scale can be achieved, potentially reducing the per-unit cost of barium hydroxide. However, this would require substantial initial investments in production facilities and equipment, which could pose financial challenges for manufacturers entering the smart flooring market.

Environmental considerations also factor into the scalability and cost analysis. The production of barium hydroxide generates waste products that require proper handling and disposal. As production scales up, the environmental impact and associated costs of waste management would increase proportionally, necessitating efficient and sustainable production processes.

In terms of application in smart flooring, the amount of barium hydroxide required per unit area of flooring is a critical factor. Optimizing the concentration of barium hydroxide to achieve the desired smart properties while minimizing material usage is essential for both scalability and cost-effectiveness. Research into more efficient formulations and application methods could significantly impact the economic viability of barium hydroxide-based smart flooring technologies.

Barium hydroxide's production process involves the reaction of barium oxide with water or the electrolysis of barium chloride solutions. The scalability of this process is relatively favorable, as the raw materials are readily available and the production methods are well-established. However, the challenge lies in scaling up production to meet potential large-scale demand for smart flooring applications.

One of the key factors affecting scalability is the availability of barium compounds. While barium is not considered a rare earth element, its global production is limited compared to more common industrial chemicals. This could potentially lead to supply chain bottlenecks if demand for barium hydroxide in smart flooring technologies increases significantly.

From a cost perspective, barium hydroxide is generally more expensive than other common alkaline compounds used in construction materials. The current market price for industrial-grade barium hydroxide ranges from $1,000 to $1,500 per metric ton, depending on purity and quantity. This cost factor needs to be carefully considered when integrating barium hydroxide into smart flooring systems, as it could significantly impact the overall product pricing.

The production scale also plays a crucial role in cost analysis. As production volumes increase, economies of scale can be achieved, potentially reducing the per-unit cost of barium hydroxide. However, this would require substantial initial investments in production facilities and equipment, which could pose financial challenges for manufacturers entering the smart flooring market.

Environmental considerations also factor into the scalability and cost analysis. The production of barium hydroxide generates waste products that require proper handling and disposal. As production scales up, the environmental impact and associated costs of waste management would increase proportionally, necessitating efficient and sustainable production processes.

In terms of application in smart flooring, the amount of barium hydroxide required per unit area of flooring is a critical factor. Optimizing the concentration of barium hydroxide to achieve the desired smart properties while minimizing material usage is essential for both scalability and cost-effectiveness. Research into more efficient formulations and application methods could significantly impact the economic viability of barium hydroxide-based smart flooring technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!