Barium Hydroxide in Developing Oxygen Barrier Technologies for Plastics

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Oxygen Barrier Tech: Background and Objectives

Oxygen barrier technologies for plastics have become increasingly important in various industries, particularly in food packaging, pharmaceuticals, and electronics. The quest for improved barrier properties has led researchers to explore innovative materials and techniques, with barium hydroxide emerging as a promising candidate in recent years.

The development of oxygen barrier technologies for plastics has a rich history dating back to the mid-20th century. Initially, the focus was on creating multi-layer structures using materials like ethylene vinyl alcohol (EVOH) and polyamides. However, these solutions often came with drawbacks such as high costs, complex processing, and recycling challenges.

As environmental concerns and sustainability goals gained prominence, the industry began seeking more eco-friendly and cost-effective alternatives. This shift in focus paved the way for research into inorganic compounds that could enhance the oxygen barrier properties of plastics without compromising their recyclability or adding significant costs.

Barium hydroxide, a white crystalline compound with the chemical formula Ba(OH)2, has attracted attention due to its unique properties and potential applications in oxygen barrier technologies. Its ability to react with carbon dioxide to form barium carbonate, coupled with its high alkalinity, makes it an intriguing candidate for improving the oxygen barrier properties of plastics.

The primary objective of research into barium hydroxide for oxygen barrier technologies is to develop a novel, efficient, and sustainable solution that can significantly reduce oxygen permeation in plastic materials. This research aims to address several key challenges in the field, including:

1. Enhancing the oxygen barrier properties of common plastics without compromising their mechanical properties or transparency.

2. Developing a cost-effective solution that can be easily integrated into existing manufacturing processes.

3. Creating a barrier technology that is compatible with recycling systems and aligns with circular economy principles.

4. Exploring the potential of barium hydroxide to provide additional benefits, such as improved moisture barrier properties or antimicrobial effects.

By focusing on barium hydroxide, researchers hope to unlock new possibilities in oxygen barrier technologies that can revolutionize packaging solutions across multiple industries. The ultimate goal is to create a versatile, high-performance barrier technology that can be applied to a wide range of plastic materials, offering superior protection against oxygen permeation while maintaining the desirable properties of the base polymer.

The development of oxygen barrier technologies for plastics has a rich history dating back to the mid-20th century. Initially, the focus was on creating multi-layer structures using materials like ethylene vinyl alcohol (EVOH) and polyamides. However, these solutions often came with drawbacks such as high costs, complex processing, and recycling challenges.

As environmental concerns and sustainability goals gained prominence, the industry began seeking more eco-friendly and cost-effective alternatives. This shift in focus paved the way for research into inorganic compounds that could enhance the oxygen barrier properties of plastics without compromising their recyclability or adding significant costs.

Barium hydroxide, a white crystalline compound with the chemical formula Ba(OH)2, has attracted attention due to its unique properties and potential applications in oxygen barrier technologies. Its ability to react with carbon dioxide to form barium carbonate, coupled with its high alkalinity, makes it an intriguing candidate for improving the oxygen barrier properties of plastics.

The primary objective of research into barium hydroxide for oxygen barrier technologies is to develop a novel, efficient, and sustainable solution that can significantly reduce oxygen permeation in plastic materials. This research aims to address several key challenges in the field, including:

1. Enhancing the oxygen barrier properties of common plastics without compromising their mechanical properties or transparency.

2. Developing a cost-effective solution that can be easily integrated into existing manufacturing processes.

3. Creating a barrier technology that is compatible with recycling systems and aligns with circular economy principles.

4. Exploring the potential of barium hydroxide to provide additional benefits, such as improved moisture barrier properties or antimicrobial effects.

By focusing on barium hydroxide, researchers hope to unlock new possibilities in oxygen barrier technologies that can revolutionize packaging solutions across multiple industries. The ultimate goal is to create a versatile, high-performance barrier technology that can be applied to a wide range of plastic materials, offering superior protection against oxygen permeation while maintaining the desirable properties of the base polymer.

Market Analysis for Oxygen Barrier Plastics

The global market for oxygen barrier plastics has been experiencing significant growth, driven by increasing demand in various industries such as food packaging, pharmaceuticals, and electronics. The market size for oxygen barrier plastics was valued at approximately $9.7 billion in 2020 and is projected to reach $15.1 billion by 2026, growing at a CAGR of 7.8% during the forecast period.

The food and beverage industry remains the largest consumer of oxygen barrier plastics, accounting for over 60% of the market share. This dominance is attributed to the rising demand for extended shelf life of packaged foods and beverages, as well as the growing preference for convenience foods in developing economies. The pharmaceutical sector is also emerging as a key growth driver, with increasing requirements for high-performance packaging materials to protect sensitive drugs and medical devices.

Geographically, Asia-Pacific leads the oxygen barrier plastics market, followed by North America and Europe. The rapid industrialization, changing lifestyles, and increasing disposable incomes in countries like China and India are fueling the demand for packaged food products, consequently boosting the market for oxygen barrier plastics in the region.

The market is characterized by intense competition among key players such as Kuraray Co. Ltd., Teijin Limited, Dow Chemical Company, and Mitsubishi Chemical Corporation. These companies are focusing on research and development activities to introduce innovative products with enhanced barrier properties and sustainability features.

One of the emerging trends in the oxygen barrier plastics market is the growing emphasis on sustainable and bio-based materials. Manufacturers are increasingly investing in the development of eco-friendly barrier solutions to address environmental concerns and meet stringent regulations. This shift towards sustainability is expected to create new opportunities for market growth and differentiation.

The COVID-19 pandemic has had a mixed impact on the oxygen barrier plastics market. While it initially disrupted supply chains and manufacturing processes, the increased demand for packaged foods and healthcare products during lockdowns has positively influenced market growth. The pandemic has also accelerated the adoption of e-commerce, further driving the demand for high-performance packaging materials.

Looking ahead, the market for oxygen barrier plastics is poised for continued growth, with technological advancements and increasing applications across various end-use industries. The development of novel barrier technologies, such as those incorporating barium hydroxide, presents opportunities for market expansion and improved product performance.

The food and beverage industry remains the largest consumer of oxygen barrier plastics, accounting for over 60% of the market share. This dominance is attributed to the rising demand for extended shelf life of packaged foods and beverages, as well as the growing preference for convenience foods in developing economies. The pharmaceutical sector is also emerging as a key growth driver, with increasing requirements for high-performance packaging materials to protect sensitive drugs and medical devices.

Geographically, Asia-Pacific leads the oxygen barrier plastics market, followed by North America and Europe. The rapid industrialization, changing lifestyles, and increasing disposable incomes in countries like China and India are fueling the demand for packaged food products, consequently boosting the market for oxygen barrier plastics in the region.

The market is characterized by intense competition among key players such as Kuraray Co. Ltd., Teijin Limited, Dow Chemical Company, and Mitsubishi Chemical Corporation. These companies are focusing on research and development activities to introduce innovative products with enhanced barrier properties and sustainability features.

One of the emerging trends in the oxygen barrier plastics market is the growing emphasis on sustainable and bio-based materials. Manufacturers are increasingly investing in the development of eco-friendly barrier solutions to address environmental concerns and meet stringent regulations. This shift towards sustainability is expected to create new opportunities for market growth and differentiation.

The COVID-19 pandemic has had a mixed impact on the oxygen barrier plastics market. While it initially disrupted supply chains and manufacturing processes, the increased demand for packaged foods and healthcare products during lockdowns has positively influenced market growth. The pandemic has also accelerated the adoption of e-commerce, further driving the demand for high-performance packaging materials.

Looking ahead, the market for oxygen barrier plastics is poised for continued growth, with technological advancements and increasing applications across various end-use industries. The development of novel barrier technologies, such as those incorporating barium hydroxide, presents opportunities for market expansion and improved product performance.

Current Challenges in Oxygen Barrier Technologies

Oxygen barrier technologies for plastics face several significant challenges in their current state of development. One of the primary issues is the trade-off between barrier performance and other material properties. As barrier properties are enhanced, there is often a corresponding decrease in mechanical strength, flexibility, or transparency. This balance is particularly crucial in packaging applications where multiple functionalities are required.

Another challenge lies in the cost-effectiveness of existing barrier solutions. High-performance oxygen barrier materials, such as ethylene vinyl alcohol (EVOH) or polyvinyl alcohol (PVOH), can be expensive, limiting their widespread adoption in cost-sensitive markets. The integration of these materials into multi-layer structures also adds complexity and cost to the manufacturing process.

Environmental concerns pose a significant challenge to current oxygen barrier technologies. Many effective barrier materials are not easily recyclable or biodegradable, conflicting with the growing demand for sustainable packaging solutions. This has led to increased pressure on the industry to develop eco-friendly alternatives that maintain high barrier performance.

The stability and durability of oxygen barrier properties under various environmental conditions remain a challenge. Factors such as humidity, temperature fluctuations, and mechanical stress can significantly impact the long-term effectiveness of barrier materials. This is particularly problematic in applications requiring extended shelf life or exposure to diverse environmental conditions.

Scalability and processability of advanced barrier technologies present another hurdle. While some novel approaches show promise in laboratory settings, translating these into large-scale, economically viable production processes can be challenging. This includes issues related to material compatibility, processing temperatures, and equipment modifications.

The development of active and intelligent packaging systems incorporating oxygen barrier properties adds another layer of complexity. Integrating oxygen scavengers or indicators into barrier materials while maintaining overall performance and safety standards is an ongoing challenge.

Regulatory compliance and safety considerations also pose challenges, particularly in food packaging applications. New barrier materials and technologies must meet stringent food contact regulations and demonstrate long-term safety, which can be a time-consuming and costly process.

In the context of barium hydroxide research for oxygen barrier technologies in plastics, specific challenges include optimizing its incorporation into polymer matrices, ensuring uniform distribution, and maintaining material stability over time. The potential reactivity of barium hydroxide with other components in the plastic formulation or with environmental factors needs careful consideration to prevent unintended effects on barrier performance or material properties.

Another challenge lies in the cost-effectiveness of existing barrier solutions. High-performance oxygen barrier materials, such as ethylene vinyl alcohol (EVOH) or polyvinyl alcohol (PVOH), can be expensive, limiting their widespread adoption in cost-sensitive markets. The integration of these materials into multi-layer structures also adds complexity and cost to the manufacturing process.

Environmental concerns pose a significant challenge to current oxygen barrier technologies. Many effective barrier materials are not easily recyclable or biodegradable, conflicting with the growing demand for sustainable packaging solutions. This has led to increased pressure on the industry to develop eco-friendly alternatives that maintain high barrier performance.

The stability and durability of oxygen barrier properties under various environmental conditions remain a challenge. Factors such as humidity, temperature fluctuations, and mechanical stress can significantly impact the long-term effectiveness of barrier materials. This is particularly problematic in applications requiring extended shelf life or exposure to diverse environmental conditions.

Scalability and processability of advanced barrier technologies present another hurdle. While some novel approaches show promise in laboratory settings, translating these into large-scale, economically viable production processes can be challenging. This includes issues related to material compatibility, processing temperatures, and equipment modifications.

The development of active and intelligent packaging systems incorporating oxygen barrier properties adds another layer of complexity. Integrating oxygen scavengers or indicators into barrier materials while maintaining overall performance and safety standards is an ongoing challenge.

Regulatory compliance and safety considerations also pose challenges, particularly in food packaging applications. New barrier materials and technologies must meet stringent food contact regulations and demonstrate long-term safety, which can be a time-consuming and costly process.

In the context of barium hydroxide research for oxygen barrier technologies in plastics, specific challenges include optimizing its incorporation into polymer matrices, ensuring uniform distribution, and maintaining material stability over time. The potential reactivity of barium hydroxide with other components in the plastic formulation or with environmental factors needs careful consideration to prevent unintended effects on barrier performance or material properties.

Existing Barium Hydroxide-based Barrier Solutions

01 Use of barium hydroxide as an oxygen barrier

Barium hydroxide can be utilized as an effective oxygen barrier in various applications. Its properties allow it to react with and absorb oxygen, preventing oxidation of materials it protects. This makes it useful in packaging, preservation, and industrial processes where oxygen exclusion is crucial.- Use of barium hydroxide as an oxygen barrier: Barium hydroxide can be utilized as an effective oxygen barrier in various applications. Its properties allow it to react with and absorb oxygen, preventing oxidation of materials it protects. This makes it useful in packaging, preservation, and industrial processes where oxygen exclusion is crucial.

- Barium hydroxide in glass manufacturing: In glass manufacturing, barium hydroxide can be used to improve the properties of glass, including its resistance to oxygen permeation. It can be incorporated into the glass composition or applied as a coating, enhancing the glass's ability to act as an oxygen barrier in various applications such as food packaging or electronic displays.

- Barium hydroxide in coating formulations: Barium hydroxide can be incorporated into coating formulations to create oxygen barrier layers on various substrates. These coatings can be applied to materials such as metals, plastics, or paper to enhance their oxygen barrier properties, making them suitable for packaging or protective applications in industries like food, pharmaceuticals, or electronics.

- Barium hydroxide in oxygen scavenging systems: Barium hydroxide can be used as a component in oxygen scavenging systems. These systems actively remove oxygen from enclosed spaces, providing an additional layer of protection beyond passive barrier materials. This approach is particularly useful in packaging applications where long-term oxygen exclusion is required.

- Barium hydroxide in combination with other materials for enhanced oxygen barrier properties: Combining barium hydroxide with other materials can create synergistic effects, enhancing overall oxygen barrier properties. This approach can involve mixing barium hydroxide with polymers, other inorganic compounds, or incorporating it into composite structures. The resulting materials can offer improved oxygen barrier performance compared to single-component systems.

02 Barium hydroxide in glass manufacturing

In glass manufacturing, barium hydroxide can be used to improve the properties of glass, including its resistance to oxygen permeation. It can be incorporated into the glass composition or applied as a coating, enhancing the glass's ability to act as an oxygen barrier in various applications such as food packaging or electronic displays.Expand Specific Solutions03 Barium hydroxide in coating formulations

Barium hydroxide can be incorporated into coating formulations to create oxygen barrier layers on various substrates. These coatings can be applied to materials such as metals, plastics, or paper to enhance their oxygen barrier properties, making them suitable for packaging or protective applications.Expand Specific Solutions04 Barium hydroxide in oxygen scavenging systems

Barium hydroxide can be used as a component in oxygen scavenging systems. These systems actively remove oxygen from enclosed spaces, providing an additional layer of protection beyond passive barrier properties. This is particularly useful in packaging for sensitive products or in industrial processes where oxygen removal is critical.Expand Specific Solutions05 Combination of barium hydroxide with other materials for enhanced oxygen barrier properties

Barium hydroxide can be combined with other materials such as polymers, ceramics, or other chemical compounds to create composite materials with enhanced oxygen barrier properties. These combinations can result in synergistic effects, improving overall performance and expanding the range of potential applications for oxygen barrier materials.Expand Specific Solutions

Key Players in Oxygen Barrier Plastic Industry

The research on barium hydroxide in developing oxygen barrier technologies for plastics is in a nascent stage, with significant potential for growth. The market size is expanding as industries seek improved packaging solutions, driven by the demand for extended shelf life and reduced food waste. Technologically, the field is evolving rapidly, with companies like Toyo Seikan Co., Ltd., Plantic Technologies Ltd., and PPG Industries Ohio, Inc. leading innovation. These firms are exploring various applications of barium hydroxide in plastic barrier technologies, ranging from food packaging to industrial coatings. The competitive landscape is diverse, with both established chemical companies and specialized materials firms vying for market share, indicating a dynamic and promising future for this technology.

Toyo Seikan Co., Ltd.

Technical Solution: Toyo Seikan has developed a novel oxygen barrier technology for plastics using barium hydroxide. Their approach involves incorporating barium hydroxide into a polymer matrix, creating a reactive oxygen scavenging system. This system actively absorbs oxygen molecules that permeate through the plastic, significantly reducing oxygen transmission rates. The company has optimized the dispersion of barium hydroxide particles within the polymer to maximize the barrier effect while maintaining the mechanical properties of the plastic[1]. Additionally, Toyo Seikan has developed a proprietary coating process that applies a thin layer of barium hydroxide-infused material to the surface of plastic containers, further enhancing oxygen barrier properties[3].

Strengths: Highly effective oxygen scavenging, maintains plastic's mechanical properties, versatile application methods. Weaknesses: Potential for barium leaching, higher production costs compared to traditional barriers.

Plantic Technologies Ltd.

Technical Solution: Plantic Technologies has pioneered the use of barium hydroxide in combination with their proprietary biopolymer formulations to create high-performance oxygen barrier plastics. Their approach involves blending barium hydroxide with starch-based polymers, resulting in a biodegradable material with exceptional oxygen barrier properties. The company has developed a patented process that ensures uniform distribution of barium hydroxide within the biopolymer matrix, creating a tortuous path for oxygen molecules[2]. This technology not only provides excellent oxygen barrier properties but also maintains the biodegradability of the base material. Plantic has successfully scaled this technology for use in food packaging applications, particularly for products sensitive to oxygen exposure[4].

Strengths: Biodegradable solution, excellent oxygen barrier properties, suitable for food contact applications. Weaknesses: Limited to certain types of biopolymers, potentially higher cost than conventional plastics.

Core Innovations in Barium Hydroxide Barrier Tech

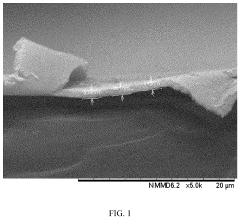

Solvent-based oxygen barrier coating composition

PatentPendingUS20250122385A1

Innovation

- A solvent-based composition for preparing an oxygen barrier coating, comprising a binder polymer with polar functional groups, an acid with reactive acidic groups, and an organic solvent, allowing for faster drying and increased printing speed without adverse effects on the coating's barrier properties.

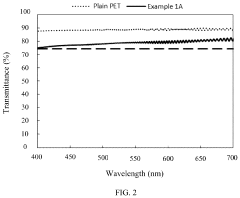

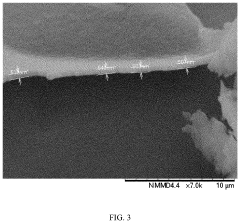

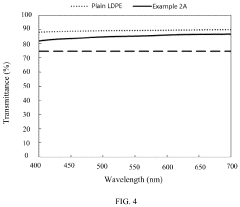

Oxygen barrier coating composition and coating solution, coating layer, and product comprising the same

PatentPendingUS20240059853A1

Innovation

- A translucent antimicrobial oxygen barrier coating composition applied to a substrate polymer film, comprising 15-35% coating polymer, 0.1-5% nanoparticles, 40-75% plasticizer, and 5-20% crosslinking agent, which creates a convoluted path for oxygen and is stretchable, reducing oxygen transmission by at least 90% while maintaining transparency.

Environmental Impact of Barium Hydroxide in Plastics

The use of barium hydroxide in developing oxygen barrier technologies for plastics has raised significant environmental concerns. While this compound offers promising benefits in enhancing the oxygen barrier properties of plastic materials, its potential environmental impact must be carefully considered and addressed.

One of the primary environmental concerns associated with barium hydroxide in plastics is its potential for leaching. When exposed to moisture or acidic conditions, barium ions may leach from the plastic matrix into the surrounding environment. This leaching process can lead to soil and water contamination, potentially affecting ecosystems and posing risks to aquatic life. The extent of leaching depends on various factors, including the concentration of barium hydroxide used, the type of plastic, and environmental conditions.

The toxicity of barium compounds is another critical environmental consideration. Although barium hydroxide itself is not highly toxic, its transformation into other barium compounds in the environment can increase toxicity levels. Prolonged exposure to high concentrations of barium in soil or water can adversely affect plant growth and animal health. Furthermore, the bioaccumulation of barium in the food chain may lead to broader ecological impacts.

The production and disposal of plastics containing barium hydroxide also contribute to environmental concerns. The manufacturing process may release barium-containing waste, requiring proper treatment and disposal to prevent environmental contamination. At the end of the product lifecycle, the presence of barium hydroxide in plastic waste complicates recycling efforts and may lead to increased landfill disposal, exacerbating plastic pollution issues.

However, it is important to note that the use of barium hydroxide in oxygen barrier technologies for plastics may also offer some environmental benefits. By improving the oxygen barrier properties of plastics, these technologies can extend the shelf life of packaged products, potentially reducing food waste and the associated environmental impacts of food production and distribution.

To mitigate the environmental risks associated with barium hydroxide in plastics, several strategies can be employed. These include developing more stable formulations to minimize leaching, implementing strict manufacturing and disposal protocols, and exploring alternative, more environmentally friendly compounds that can provide similar oxygen barrier properties. Additionally, ongoing research into the long-term environmental fate of barium-containing plastics is crucial for informed decision-making and sustainable development in this field.

One of the primary environmental concerns associated with barium hydroxide in plastics is its potential for leaching. When exposed to moisture or acidic conditions, barium ions may leach from the plastic matrix into the surrounding environment. This leaching process can lead to soil and water contamination, potentially affecting ecosystems and posing risks to aquatic life. The extent of leaching depends on various factors, including the concentration of barium hydroxide used, the type of plastic, and environmental conditions.

The toxicity of barium compounds is another critical environmental consideration. Although barium hydroxide itself is not highly toxic, its transformation into other barium compounds in the environment can increase toxicity levels. Prolonged exposure to high concentrations of barium in soil or water can adversely affect plant growth and animal health. Furthermore, the bioaccumulation of barium in the food chain may lead to broader ecological impacts.

The production and disposal of plastics containing barium hydroxide also contribute to environmental concerns. The manufacturing process may release barium-containing waste, requiring proper treatment and disposal to prevent environmental contamination. At the end of the product lifecycle, the presence of barium hydroxide in plastic waste complicates recycling efforts and may lead to increased landfill disposal, exacerbating plastic pollution issues.

However, it is important to note that the use of barium hydroxide in oxygen barrier technologies for plastics may also offer some environmental benefits. By improving the oxygen barrier properties of plastics, these technologies can extend the shelf life of packaged products, potentially reducing food waste and the associated environmental impacts of food production and distribution.

To mitigate the environmental risks associated with barium hydroxide in plastics, several strategies can be employed. These include developing more stable formulations to minimize leaching, implementing strict manufacturing and disposal protocols, and exploring alternative, more environmentally friendly compounds that can provide similar oxygen barrier properties. Additionally, ongoing research into the long-term environmental fate of barium-containing plastics is crucial for informed decision-making and sustainable development in this field.

Regulatory Framework for Barium Hydroxide Use in Packaging

The regulatory framework for barium hydroxide use in packaging is a complex and evolving landscape that significantly impacts the development and implementation of oxygen barrier technologies in plastics. At the global level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for the safe handling and use of barium hydroxide. This system classifies barium hydroxide as a hazardous substance, necessitating specific safety measures and labeling requirements.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating the use of barium hydroxide in food packaging materials. The FDA's Code of Federal Regulations, specifically 21 CFR 175-178, outlines the conditions under which barium compounds, including barium hydroxide, may be used in food-contact materials. These regulations stipulate maximum allowable concentrations and specific use cases, ensuring that any migration of barium into food remains below levels of toxicological concern.

The European Union's regulatory approach is governed by the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU Plastics Regulation (EU) No 10/2011 sets specific migration limits for barium and its compounds in plastic food contact materials. Additionally, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers and importers to register barium hydroxide and provide safety data when annual production or import exceeds one tonne.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Food Sanitation Law and the Positive List System for food contact materials set guidelines for the use of barium compounds in packaging. China's GB 9685 standard specifies the permitted use of additives in food contact materials, including barium hydroxide.

Environmental regulations also play a significant role in shaping the use of barium hydroxide in packaging. Many countries have implemented restrictions on the disposal of barium-containing waste, requiring special handling and treatment procedures. This has led to increased focus on recyclability and sustainability in packaging design, influencing the development of oxygen barrier technologies that incorporate barium hydroxide.

The occupational health and safety aspects of working with barium hydroxide are addressed by various national and international bodies. For instance, the U.S. Occupational Safety and Health Administration (OSHA) has established permissible exposure limits and handling guidelines for barium compounds in industrial settings. Similar regulations exist in other countries, emphasizing the need for proper safety measures in the manufacturing and processing of barium hydroxide-based packaging materials.

As research on barium hydroxide in oxygen barrier technologies progresses, regulatory bodies are likely to update their frameworks to address new findings and applications. This dynamic regulatory environment necessitates ongoing compliance efforts and adaptability from manufacturers and researchers in the field of plastic packaging technologies.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating the use of barium hydroxide in food packaging materials. The FDA's Code of Federal Regulations, specifically 21 CFR 175-178, outlines the conditions under which barium compounds, including barium hydroxide, may be used in food-contact materials. These regulations stipulate maximum allowable concentrations and specific use cases, ensuring that any migration of barium into food remains below levels of toxicological concern.

The European Union's regulatory approach is governed by the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU Plastics Regulation (EU) No 10/2011 sets specific migration limits for barium and its compounds in plastic food contact materials. Additionally, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers and importers to register barium hydroxide and provide safety data when annual production or import exceeds one tonne.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Food Sanitation Law and the Positive List System for food contact materials set guidelines for the use of barium compounds in packaging. China's GB 9685 standard specifies the permitted use of additives in food contact materials, including barium hydroxide.

Environmental regulations also play a significant role in shaping the use of barium hydroxide in packaging. Many countries have implemented restrictions on the disposal of barium-containing waste, requiring special handling and treatment procedures. This has led to increased focus on recyclability and sustainability in packaging design, influencing the development of oxygen barrier technologies that incorporate barium hydroxide.

The occupational health and safety aspects of working with barium hydroxide are addressed by various national and international bodies. For instance, the U.S. Occupational Safety and Health Administration (OSHA) has established permissible exposure limits and handling guidelines for barium compounds in industrial settings. Similar regulations exist in other countries, emphasizing the need for proper safety measures in the manufacturing and processing of barium hydroxide-based packaging materials.

As research on barium hydroxide in oxygen barrier technologies progresses, regulatory bodies are likely to update their frameworks to address new findings and applications. This dynamic regulatory environment necessitates ongoing compliance efforts and adaptability from manufacturers and researchers in the field of plastic packaging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!