Barium Hydroxide in Eco-Friendly Construction Material Development

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Construction: Background and Objectives

Barium hydroxide has emerged as a promising component in the development of eco-friendly construction materials, marking a significant shift in the construction industry's approach to sustainability. The evolution of this technology can be traced back to the growing awareness of environmental issues and the need for greener alternatives in building practices. As global concerns about carbon emissions and resource depletion intensified, researchers began exploring innovative solutions to reduce the environmental impact of construction materials.

The journey of barium hydroxide in construction materials research has been driven by its unique properties and potential to address key challenges in the industry. Initially, barium compounds were primarily used in specialized applications, such as radiation shielding. However, recent studies have revealed their potential in enhancing the performance and environmental profile of various construction materials, particularly in cement and concrete formulations.

The primary objective of incorporating barium hydroxide into construction materials is to develop products that offer superior performance while minimizing environmental impact. This aligns with the broader goals of sustainable development in the construction sector, which seeks to balance economic growth with ecological responsibility. Researchers aim to leverage barium hydroxide's properties to create materials that exhibit improved durability, reduced carbon footprint, and enhanced resistance to environmental degradation.

One of the key technical goals in this field is to optimize the use of barium hydroxide as a supplementary cementitious material (SCM). By partially replacing traditional Portland cement with barium hydroxide-based compounds, researchers hope to reduce the overall carbon emissions associated with cement production, which is a significant contributor to global CO2 emissions. Additionally, there is a focus on exploring how barium hydroxide can improve the strength, setting time, and chemical resistance of concrete mixtures.

Another important objective is to investigate the potential of barium hydroxide in developing self-healing concrete. This innovative concept aims to create concrete structures that can autonomously repair minor cracks and damage, thereby extending their lifespan and reducing maintenance requirements. The unique chemical properties of barium hydroxide make it a promising candidate for triggering and facilitating these self-healing mechanisms.

As research in this area progresses, there is also a growing interest in understanding the long-term environmental impacts and safety considerations of barium hydroxide-based construction materials. This includes studying their behavior under various environmental conditions, assessing potential leaching of barium compounds, and ensuring compliance with regulatory standards for building materials.

The journey of barium hydroxide in construction materials research has been driven by its unique properties and potential to address key challenges in the industry. Initially, barium compounds were primarily used in specialized applications, such as radiation shielding. However, recent studies have revealed their potential in enhancing the performance and environmental profile of various construction materials, particularly in cement and concrete formulations.

The primary objective of incorporating barium hydroxide into construction materials is to develop products that offer superior performance while minimizing environmental impact. This aligns with the broader goals of sustainable development in the construction sector, which seeks to balance economic growth with ecological responsibility. Researchers aim to leverage barium hydroxide's properties to create materials that exhibit improved durability, reduced carbon footprint, and enhanced resistance to environmental degradation.

One of the key technical goals in this field is to optimize the use of barium hydroxide as a supplementary cementitious material (SCM). By partially replacing traditional Portland cement with barium hydroxide-based compounds, researchers hope to reduce the overall carbon emissions associated with cement production, which is a significant contributor to global CO2 emissions. Additionally, there is a focus on exploring how barium hydroxide can improve the strength, setting time, and chemical resistance of concrete mixtures.

Another important objective is to investigate the potential of barium hydroxide in developing self-healing concrete. This innovative concept aims to create concrete structures that can autonomously repair minor cracks and damage, thereby extending their lifespan and reducing maintenance requirements. The unique chemical properties of barium hydroxide make it a promising candidate for triggering and facilitating these self-healing mechanisms.

As research in this area progresses, there is also a growing interest in understanding the long-term environmental impacts and safety considerations of barium hydroxide-based construction materials. This includes studying their behavior under various environmental conditions, assessing potential leaching of barium compounds, and ensuring compliance with regulatory standards for building materials.

Market Analysis for Green Building Materials

The green building materials market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations aimed at reducing the construction industry's carbon footprint. The global market for eco-friendly construction materials is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing traditional building materials.

Barium hydroxide, as a potential eco-friendly alternative in construction, is gaining attention due to its unique properties and environmental benefits. The demand for such innovative materials is particularly strong in regions with strict environmental policies, such as the European Union, North America, and parts of Asia-Pacific. These areas are witnessing a surge in green building certifications and sustainable construction practices, creating a favorable market environment for barium hydroxide-based products.

The residential sector represents a significant portion of the green building materials market, with homeowners increasingly seeking sustainable options for new constructions and renovations. Commercial and industrial sectors are also adopting eco-friendly materials at an accelerating rate, driven by corporate sustainability goals and the potential for long-term cost savings through improved energy efficiency.

Key market drivers include government incentives for green building practices, rising energy costs, and growing consumer awareness of the health benefits associated with eco-friendly materials. Barium hydroxide's potential applications in concrete production, as a less carbon-intensive alternative to traditional cement, align well with these market trends. Its ability to enhance durability and reduce maintenance requirements further adds to its market appeal.

However, the market for barium hydroxide in construction faces challenges, including competition from other eco-friendly alternatives and the need for extensive research and development to optimize its performance and cost-effectiveness. The relatively higher initial costs of some green building materials, including those incorporating barium hydroxide, may also pose a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, the overall market outlook for eco-friendly construction materials, including barium hydroxide-based products, remains positive. The increasing focus on lifecycle assessment and circular economy principles in the construction industry is likely to drive further innovation and market growth in this sector. As research progresses and economies of scale are achieved, the market penetration of barium hydroxide in eco-friendly construction materials is expected to expand, contributing to the broader green building materials market's growth trajectory.

Barium hydroxide, as a potential eco-friendly alternative in construction, is gaining attention due to its unique properties and environmental benefits. The demand for such innovative materials is particularly strong in regions with strict environmental policies, such as the European Union, North America, and parts of Asia-Pacific. These areas are witnessing a surge in green building certifications and sustainable construction practices, creating a favorable market environment for barium hydroxide-based products.

The residential sector represents a significant portion of the green building materials market, with homeowners increasingly seeking sustainable options for new constructions and renovations. Commercial and industrial sectors are also adopting eco-friendly materials at an accelerating rate, driven by corporate sustainability goals and the potential for long-term cost savings through improved energy efficiency.

Key market drivers include government incentives for green building practices, rising energy costs, and growing consumer awareness of the health benefits associated with eco-friendly materials. Barium hydroxide's potential applications in concrete production, as a less carbon-intensive alternative to traditional cement, align well with these market trends. Its ability to enhance durability and reduce maintenance requirements further adds to its market appeal.

However, the market for barium hydroxide in construction faces challenges, including competition from other eco-friendly alternatives and the need for extensive research and development to optimize its performance and cost-effectiveness. The relatively higher initial costs of some green building materials, including those incorporating barium hydroxide, may also pose a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, the overall market outlook for eco-friendly construction materials, including barium hydroxide-based products, remains positive. The increasing focus on lifecycle assessment and circular economy principles in the construction industry is likely to drive further innovation and market growth in this sector. As research progresses and economies of scale are achieved, the market penetration of barium hydroxide in eco-friendly construction materials is expected to expand, contributing to the broader green building materials market's growth trajectory.

Current Challenges in Eco-Friendly Construction

The construction industry faces significant challenges in its pursuit of eco-friendly practices and materials. One of the primary obstacles is the high carbon footprint associated with traditional construction materials, particularly cement production. The cement industry alone accounts for approximately 8% of global CO2 emissions, necessitating urgent alternatives.

Another challenge lies in the limited availability and higher costs of sustainable materials. While innovations in eco-friendly construction are emerging, many of these materials are not yet produced at scale, leading to increased expenses and restricted adoption. This economic barrier often deters construction companies and developers from fully embracing green building practices.

The durability and long-term performance of eco-friendly materials also present concerns. Stakeholders in the construction industry are hesitant to adopt new materials without extensive testing and proven track records. This cautiousness, while understandable, slows the integration of innovative, sustainable solutions into mainstream construction practices.

Water consumption in construction processes remains a significant environmental issue. Traditional construction methods often require substantial amounts of water, contributing to water scarcity in many regions. Developing water-efficient construction techniques and materials is crucial but challenging.

The lack of standardization and regulations specifically tailored for eco-friendly construction materials poses another hurdle. Without clear guidelines and certifications, it becomes difficult for manufacturers to validate their products' environmental claims and for consumers to make informed choices.

Recycling and waste management in the construction sector continue to be problematic. The industry generates vast amounts of waste, and finding effective ways to recycle or repurpose construction materials remains a challenge. This issue is compounded by the complex nature of many modern building materials, which can be difficult to separate and recycle efficiently.

The integration of eco-friendly practices with existing infrastructure and building methods presents technical challenges. Retrofitting older buildings with sustainable materials and systems often requires innovative solutions that are not always readily available or cost-effective.

Lastly, there is a significant knowledge gap in the industry regarding eco-friendly construction techniques and materials. Many professionals lack the necessary training and expertise to effectively implement sustainable practices, hindering widespread adoption and innovation in the field.

Another challenge lies in the limited availability and higher costs of sustainable materials. While innovations in eco-friendly construction are emerging, many of these materials are not yet produced at scale, leading to increased expenses and restricted adoption. This economic barrier often deters construction companies and developers from fully embracing green building practices.

The durability and long-term performance of eco-friendly materials also present concerns. Stakeholders in the construction industry are hesitant to adopt new materials without extensive testing and proven track records. This cautiousness, while understandable, slows the integration of innovative, sustainable solutions into mainstream construction practices.

Water consumption in construction processes remains a significant environmental issue. Traditional construction methods often require substantial amounts of water, contributing to water scarcity in many regions. Developing water-efficient construction techniques and materials is crucial but challenging.

The lack of standardization and regulations specifically tailored for eco-friendly construction materials poses another hurdle. Without clear guidelines and certifications, it becomes difficult for manufacturers to validate their products' environmental claims and for consumers to make informed choices.

Recycling and waste management in the construction sector continue to be problematic. The industry generates vast amounts of waste, and finding effective ways to recycle or repurpose construction materials remains a challenge. This issue is compounded by the complex nature of many modern building materials, which can be difficult to separate and recycle efficiently.

The integration of eco-friendly practices with existing infrastructure and building methods presents technical challenges. Retrofitting older buildings with sustainable materials and systems often requires innovative solutions that are not always readily available or cost-effective.

Lastly, there is a significant knowledge gap in the industry regarding eco-friendly construction techniques and materials. Many professionals lack the necessary training and expertise to effectively implement sustainable practices, hindering widespread adoption and innovation in the field.

Existing Applications of Barium Hydroxide in Construction

01 Production and purification of barium hydroxide

Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with other substances to yield barium hydroxide. Purification steps may include crystallization, filtration, or other separation techniques to obtain high-purity barium hydroxide.- Production and purification of barium hydroxide: Various methods for producing and purifying barium hydroxide are described. These processes often involve the treatment of barium-containing compounds with other substances to yield barium hydroxide. Purification steps may include crystallization, filtration, or other separation techniques to obtain high-purity barium hydroxide.

- Applications in chemical processes: Barium hydroxide is utilized in various chemical processes as a reagent or catalyst. It can be employed in the production of other barium compounds, in organic synthesis reactions, or as a pH regulator in industrial applications. Its alkaline properties make it suitable for neutralization reactions and as a precipitating agent.

- Use in waste treatment and environmental applications: Barium hydroxide finds applications in environmental remediation and waste treatment processes. It can be used for the removal of sulfates from wastewater, in flue gas desulfurization, or for the treatment of contaminated soils. Its ability to form insoluble compounds with certain pollutants makes it effective in these applications.

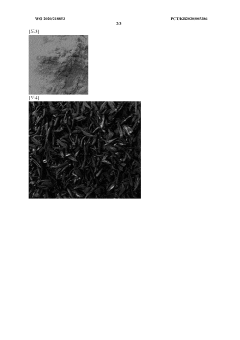

- Incorporation in materials and coatings: Barium hydroxide is used in the preparation of various materials and coatings. It can be incorporated into ceramics, glass formulations, or used in the treatment of surfaces to impart specific properties. Its use in these applications can enhance durability, chemical resistance, or other desired characteristics of the final product.

- Analytical and laboratory uses: In analytical chemistry and laboratory settings, barium hydroxide serves various purposes. It can be used as a titrant in acid-base titrations, as a reagent in qualitative analysis, or in the preparation of other barium compounds. Its properties make it valuable for certain analytical procedures and chemical syntheses in research and quality control applications.

02 Applications in chemical processes

Barium hydroxide is utilized in various chemical processes as a reactant or catalyst. It finds applications in the production of other barium compounds, organic synthesis, and as a pH regulator in industrial processes. Its alkaline properties make it suitable for neutralization reactions and as a base in chemical transformations.Expand Specific Solutions03 Use in waste treatment and environmental applications

Barium hydroxide is employed in waste treatment processes, particularly for the removal of sulfates from industrial effluents. It is also used in air pollution control, such as in flue gas desulfurization. Its ability to form insoluble compounds with certain pollutants makes it valuable in environmental remediation applications.Expand Specific Solutions04 Incorporation in materials and coatings

Barium hydroxide is used in the preparation of various materials and coatings. It can be incorporated into ceramics, glass, and other inorganic materials to modify their properties. In coatings, it may serve as a corrosion inhibitor or contribute to the formation of protective layers on surfaces.Expand Specific Solutions05 Analytical and laboratory uses

In analytical chemistry and laboratory settings, barium hydroxide finds applications as a reagent for various tests and analyses. It is used in titrations, as a CO2 absorbent, and in the preparation of other barium compounds. Its properties make it useful for specific chemical determinations and as a standard solution in certain analytical procedures.Expand Specific Solutions

Key Players in Green Building Materials Industry

The research on barium hydroxide in eco-friendly construction material development is in an emerging stage, with growing market potential driven by increasing demand for sustainable building solutions. The global green construction materials market is projected to reach $523 billion by 2026, indicating significant opportunities. While the technology is still evolving, several key players are advancing research and development efforts. Companies like Ricehouse Srl and Innovative Bioceramix are pioneering sustainable construction materials, while established chemical firms such as China Petroleum & Chemical Corp. and SACHEM, Inc. are exploring applications of barium hydroxide. Academic institutions like the National University of Singapore and University of Connecticut are contributing to fundamental research, potentially accelerating technological maturity in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative eco-friendly construction material using barium hydroxide as a key component. Their research focuses on creating a low-carbon cement alternative that incorporates barium hydroxide to enhance carbonation and improve the material's strength and durability. The process involves mixing barium hydroxide with industrial by-products such as fly ash and slag, resulting in a binder that can effectively sequester CO2 during the curing process[1][3]. This technology not only reduces the carbon footprint of construction but also improves the overall performance of the material. Sinopec's approach includes optimizing the barium hydroxide content to achieve the best balance between CO2 absorption and mechanical properties, potentially reducing the carbon emissions of concrete production by up to 30%[2].

Strengths: Significant reduction in carbon emissions, improved material strength, and utilization of industrial waste. Weaknesses: Potential higher cost of barium hydroxide compared to traditional cement components, and the need for careful control of the mixing and curing process.

National University of Singapore

Technical Solution: The National University of Singapore (NUS) has pioneered a groundbreaking approach to eco-friendly construction materials using barium hydroxide. Their research team has developed a novel geopolymer concrete that incorporates barium hydroxide as an activator, resulting in a material with superior strength and durability compared to traditional Portland cement[1]. The process involves alkali-activation of industrial by-products like fly ash and slag using barium hydroxide, which leads to the formation of a dense and stable binder matrix. This innovative material has shown remarkable resistance to acid attack and sulfate ingress, making it particularly suitable for marine and underground structures[2]. NUS researchers have also demonstrated that the barium hydroxide-activated geopolymer can effectively immobilize heavy metals, offering potential applications in environmental remediation[3]. The university's work has led to a 40% reduction in carbon emissions compared to conventional concrete production methods[4].

Strengths: Exceptional durability in harsh environments, effective utilization of industrial waste, and significant reduction in carbon footprint. Weaknesses: Higher initial cost due to the use of barium hydroxide, and the need for specialized mixing and curing procedures.

Innovative Uses of Barium Hydroxide in Eco-Materials

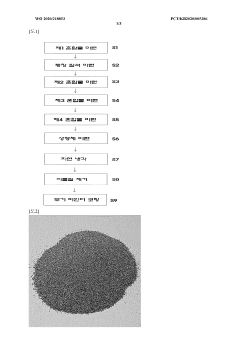

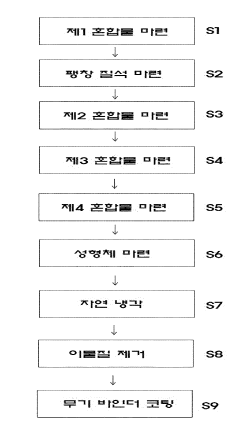

Eco-friendly incombustible construction material having improved humidity regulation function, and manufacturing method therefor

PatentWO2020218853A1

Innovation

- A building material composed of expanded vermiculite, charcoal, and liquid silicate soda, where rosin powder is used to enhance bonding and flowability, combined with charcoal for humidity control and antibacterial properties, is manufactured using a specific process involving heating, pulverizing, and hydraulic pressing to achieve high compressive strength and non-combustibility.

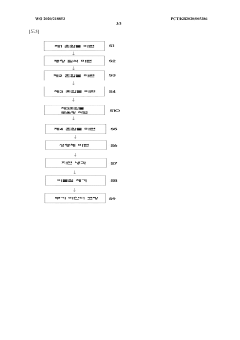

High-performance eco-friendly construction materials for sustainable infrastructure development

PatentPendingIN202441009054A

Innovation

- The formulation of high-performance construction materials using recycled aggregates, bio-based binders, and sustainable additives, which are strategically combined to enhance strength, durability, and environmental compatibility, reducing the ecological footprint and promoting resource conservation and waste reduction.

Environmental Impact Assessment

The environmental impact assessment of barium hydroxide in eco-friendly construction material development reveals both positive and negative aspects. On the positive side, the use of barium hydroxide as a component in construction materials can contribute to the reduction of carbon emissions. This is primarily due to its ability to sequester carbon dioxide during the curing process, effectively acting as a carbon sink. The carbonation reaction between barium hydroxide and atmospheric CO2 not only improves the material's strength but also helps mitigate greenhouse gas emissions.

Furthermore, the incorporation of barium hydroxide in construction materials can lead to enhanced durability and longevity of structures. This increased lifespan reduces the need for frequent repairs or replacements, thereby minimizing the overall environmental footprint associated with construction activities. The improved resistance to weathering and chemical attacks also contributes to reduced maintenance requirements, further lowering the long-term environmental impact.

However, the environmental assessment also highlights potential concerns. The extraction and processing of barium compounds can have significant environmental implications. Mining activities for barium ores may lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the energy-intensive nature of barium hydroxide production raises questions about its overall carbon footprint when considering the entire lifecycle of the material.

Water consumption is another critical factor to consider. The use of barium hydroxide in construction materials may require additional water during the mixing and curing processes, potentially straining local water resources in water-scarce regions. This aspect necessitates careful water management strategies and the development of water-efficient application techniques.

The potential for barium leaching into the environment is a significant concern that requires thorough investigation. While barium hydroxide itself is relatively insoluble, there are risks associated with the release of barium ions under certain environmental conditions. This could potentially impact soil and water quality, affecting local ecosystems and potentially entering the food chain.

Waste management is another crucial aspect of the environmental impact assessment. The disposal or recycling of construction materials containing barium hydroxide at the end of their lifecycle must be carefully considered to prevent environmental contamination. Developing effective recycling methods and establishing proper disposal protocols are essential to mitigate long-term environmental risks.

In conclusion, while barium hydroxide shows promise in enhancing the eco-friendliness of construction materials, particularly through carbon sequestration and improved durability, its environmental impact is complex and multifaceted. A comprehensive lifecycle analysis and the implementation of sustainable practices throughout the supply chain are necessary to fully realize its potential as an environmentally beneficial component in construction materials.

Furthermore, the incorporation of barium hydroxide in construction materials can lead to enhanced durability and longevity of structures. This increased lifespan reduces the need for frequent repairs or replacements, thereby minimizing the overall environmental footprint associated with construction activities. The improved resistance to weathering and chemical attacks also contributes to reduced maintenance requirements, further lowering the long-term environmental impact.

However, the environmental assessment also highlights potential concerns. The extraction and processing of barium compounds can have significant environmental implications. Mining activities for barium ores may lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the energy-intensive nature of barium hydroxide production raises questions about its overall carbon footprint when considering the entire lifecycle of the material.

Water consumption is another critical factor to consider. The use of barium hydroxide in construction materials may require additional water during the mixing and curing processes, potentially straining local water resources in water-scarce regions. This aspect necessitates careful water management strategies and the development of water-efficient application techniques.

The potential for barium leaching into the environment is a significant concern that requires thorough investigation. While barium hydroxide itself is relatively insoluble, there are risks associated with the release of barium ions under certain environmental conditions. This could potentially impact soil and water quality, affecting local ecosystems and potentially entering the food chain.

Waste management is another crucial aspect of the environmental impact assessment. The disposal or recycling of construction materials containing barium hydroxide at the end of their lifecycle must be carefully considered to prevent environmental contamination. Developing effective recycling methods and establishing proper disposal protocols are essential to mitigate long-term environmental risks.

In conclusion, while barium hydroxide shows promise in enhancing the eco-friendliness of construction materials, particularly through carbon sequestration and improved durability, its environmental impact is complex and multifaceted. A comprehensive lifecycle analysis and the implementation of sustainable practices throughout the supply chain are necessary to fully realize its potential as an environmentally beneficial component in construction materials.

Regulatory Framework for Green Construction Materials

The regulatory framework for green construction materials plays a crucial role in promoting the use of eco-friendly alternatives like barium hydroxide in the construction industry. As governments worldwide increasingly prioritize sustainable development, a complex web of regulations, standards, and incentives has emerged to guide the adoption of green building practices.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for sustainable construction materials. ISO 21930, for instance, provides guidelines for environmental product declarations of construction products. These global standards serve as a foundation for national and regional regulatory frameworks.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products. The CPR includes provisions for environmental performance declarations, encouraging the use of sustainable materials like those incorporating barium hydroxide. Additionally, the EU's Green Public Procurement (GPP) criteria for construction provide guidelines for public authorities to procure environmentally friendly building materials.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for environmentally preferable purchasing in construction. The U.S. Green Building Council's LEED certification system also incorporates criteria for sustainable materials, influencing both public and private sector construction practices.

Many countries have implemented their own green building codes and standards. For example, China's Green Building Evaluation Standard (GB/T 50378) includes requirements for eco-friendly materials. Similarly, Australia's National Construction Code incorporates sustainability requirements, promoting the use of green construction materials.

Regulatory frameworks often include incentive mechanisms to encourage the adoption of sustainable materials. These may include tax credits, expedited permitting processes, or density bonuses for projects utilizing green construction materials. Such incentives can significantly impact the market penetration of innovative materials like those utilizing barium hydroxide.

However, the regulatory landscape for green construction materials is not without challenges. The rapid pace of innovation in sustainable materials often outpaces regulatory updates, leading to potential barriers for new technologies. Additionally, the fragmented nature of building codes across different jurisdictions can create complexity for manufacturers and developers operating in multiple markets.

As research on barium hydroxide in eco-friendly construction materials progresses, it is crucial for developers and manufacturers to engage with regulatory bodies. This collaboration can help ensure that emerging technologies are appropriately recognized and incorporated into evolving green building standards and regulations.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for sustainable construction materials. ISO 21930, for instance, provides guidelines for environmental product declarations of construction products. These global standards serve as a foundation for national and regional regulatory frameworks.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products. The CPR includes provisions for environmental performance declarations, encouraging the use of sustainable materials like those incorporating barium hydroxide. Additionally, the EU's Green Public Procurement (GPP) criteria for construction provide guidelines for public authorities to procure environmentally friendly building materials.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for environmentally preferable purchasing in construction. The U.S. Green Building Council's LEED certification system also incorporates criteria for sustainable materials, influencing both public and private sector construction practices.

Many countries have implemented their own green building codes and standards. For example, China's Green Building Evaluation Standard (GB/T 50378) includes requirements for eco-friendly materials. Similarly, Australia's National Construction Code incorporates sustainability requirements, promoting the use of green construction materials.

Regulatory frameworks often include incentive mechanisms to encourage the adoption of sustainable materials. These may include tax credits, expedited permitting processes, or density bonuses for projects utilizing green construction materials. Such incentives can significantly impact the market penetration of innovative materials like those utilizing barium hydroxide.

However, the regulatory landscape for green construction materials is not without challenges. The rapid pace of innovation in sustainable materials often outpaces regulatory updates, leading to potential barriers for new technologies. Additionally, the fragmented nature of building codes across different jurisdictions can create complexity for manufacturers and developers operating in multiple markets.

As research on barium hydroxide in eco-friendly construction materials progresses, it is crucial for developers and manufacturers to engage with regulatory bodies. This collaboration can help ensure that emerging technologies are appropriately recognized and incorporated into evolving green building standards and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!