Sodium Alginate and Silicone Coefficient Improvement

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate-Silicone Blend Research Objectives

The research on improving the coefficient of Sodium Alginate and Silicone aims to enhance the performance and applicability of these materials in various industries. This study is driven by the increasing demand for advanced biomaterials and the need for improved composite materials with enhanced properties.

The primary objective is to optimize the interaction between Sodium Alginate and Silicone, focusing on their compatibility and synergistic effects. By improving their coefficient, we aim to create a blend that combines the best properties of both materials, such as the biocompatibility and biodegradability of Sodium Alginate with the flexibility and durability of Silicone.

One key goal is to develop a method for uniform dispersion of Sodium Alginate within the Silicone matrix. This involves investigating various blending techniques, including mechanical mixing, chemical modification, and the use of compatibilizers. The research will explore how different ratios and processing conditions affect the final properties of the blend.

Another crucial objective is to enhance the mechanical properties of the Sodium Alginate-Silicone blend. This includes improving tensile strength, elongation at break, and overall durability. The study will investigate how the improved coefficient influences these mechanical characteristics and how they can be tailored for specific applications.

The research also aims to evaluate the biocompatibility and biodegradability of the improved blend. This is particularly important for potential applications in biomedical fields, where the material's interaction with biological systems is critical. The study will assess how the enhanced coefficient affects these properties and whether it can lead to new possibilities in tissue engineering and drug delivery systems.

Furthermore, the project seeks to understand the thermal and chemical stability of the improved Sodium Alginate-Silicone blend. This includes studying how the enhanced coefficient impacts the material's resistance to temperature changes and various chemical environments. Such knowledge is crucial for determining the blend's suitability for different industrial applications.

Lastly, the research aims to explore potential applications of the improved blend across various sectors. This includes investigating its use in wound dressings, controlled release systems, flexible electronics, and environmental remediation. The study will assess how the enhanced properties can address current limitations and open up new possibilities in these fields.

The primary objective is to optimize the interaction between Sodium Alginate and Silicone, focusing on their compatibility and synergistic effects. By improving their coefficient, we aim to create a blend that combines the best properties of both materials, such as the biocompatibility and biodegradability of Sodium Alginate with the flexibility and durability of Silicone.

One key goal is to develop a method for uniform dispersion of Sodium Alginate within the Silicone matrix. This involves investigating various blending techniques, including mechanical mixing, chemical modification, and the use of compatibilizers. The research will explore how different ratios and processing conditions affect the final properties of the blend.

Another crucial objective is to enhance the mechanical properties of the Sodium Alginate-Silicone blend. This includes improving tensile strength, elongation at break, and overall durability. The study will investigate how the improved coefficient influences these mechanical characteristics and how they can be tailored for specific applications.

The research also aims to evaluate the biocompatibility and biodegradability of the improved blend. This is particularly important for potential applications in biomedical fields, where the material's interaction with biological systems is critical. The study will assess how the enhanced coefficient affects these properties and whether it can lead to new possibilities in tissue engineering and drug delivery systems.

Furthermore, the project seeks to understand the thermal and chemical stability of the improved Sodium Alginate-Silicone blend. This includes studying how the enhanced coefficient impacts the material's resistance to temperature changes and various chemical environments. Such knowledge is crucial for determining the blend's suitability for different industrial applications.

Lastly, the research aims to explore potential applications of the improved blend across various sectors. This includes investigating its use in wound dressings, controlled release systems, flexible electronics, and environmental remediation. The study will assess how the enhanced properties can address current limitations and open up new possibilities in these fields.

Market Analysis for Enhanced Composite Materials

The market for enhanced composite materials, particularly those involving sodium alginate and silicone, has shown significant growth potential in recent years. This trend is driven by the increasing demand for advanced materials with improved properties across various industries. The global composite materials market, which includes these enhanced materials, is projected to reach a substantial value in the coming years, with a steady compound annual growth rate.

The automotive and aerospace sectors are key drivers of this market growth, as they seek lightweight yet strong materials to improve fuel efficiency and performance. In the automotive industry, there is a growing emphasis on reducing vehicle weight to meet stringent emissions regulations, making enhanced composites an attractive option. The aerospace industry, similarly, requires materials that can withstand extreme conditions while minimizing weight.

Another significant market segment for these enhanced composites is the healthcare and medical devices sector. Sodium alginate, in particular, has found extensive applications in wound dressings, drug delivery systems, and tissue engineering due to its biocompatibility and unique properties. The combination of sodium alginate with silicone offers potential for developing advanced biomaterials with improved mechanical properties and controlled release characteristics.

The construction industry is also showing increased interest in enhanced composite materials. These materials offer advantages such as improved durability, weather resistance, and thermal insulation properties. As sustainable building practices gain traction, the demand for eco-friendly composite materials is expected to rise, creating new opportunities for sodium alginate and silicone-based composites.

In the consumer goods sector, there is a growing trend towards using advanced materials in products ranging from sports equipment to household items. Enhanced composites offer the potential for creating products with superior performance characteristics, such as increased strength-to-weight ratio, flexibility, and durability.

Geographically, North America and Europe currently lead the market for enhanced composite materials, owing to their strong presence in industries such as aerospace, automotive, and healthcare. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in infrastructure, and growing adoption of advanced materials in manufacturing.

The market for sodium alginate and silicone-based composites faces some challenges, including high production costs and the need for specialized manufacturing processes. However, ongoing research and development efforts aimed at improving the coefficient of these materials are expected to address these issues and open up new market opportunities. As industries continue to seek innovative solutions for their material needs, the demand for enhanced composite materials is likely to expand, creating a favorable market environment for advancements in sodium alginate and silicone technologies.

The automotive and aerospace sectors are key drivers of this market growth, as they seek lightweight yet strong materials to improve fuel efficiency and performance. In the automotive industry, there is a growing emphasis on reducing vehicle weight to meet stringent emissions regulations, making enhanced composites an attractive option. The aerospace industry, similarly, requires materials that can withstand extreme conditions while minimizing weight.

Another significant market segment for these enhanced composites is the healthcare and medical devices sector. Sodium alginate, in particular, has found extensive applications in wound dressings, drug delivery systems, and tissue engineering due to its biocompatibility and unique properties. The combination of sodium alginate with silicone offers potential for developing advanced biomaterials with improved mechanical properties and controlled release characteristics.

The construction industry is also showing increased interest in enhanced composite materials. These materials offer advantages such as improved durability, weather resistance, and thermal insulation properties. As sustainable building practices gain traction, the demand for eco-friendly composite materials is expected to rise, creating new opportunities for sodium alginate and silicone-based composites.

In the consumer goods sector, there is a growing trend towards using advanced materials in products ranging from sports equipment to household items. Enhanced composites offer the potential for creating products with superior performance characteristics, such as increased strength-to-weight ratio, flexibility, and durability.

Geographically, North America and Europe currently lead the market for enhanced composite materials, owing to their strong presence in industries such as aerospace, automotive, and healthcare. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in infrastructure, and growing adoption of advanced materials in manufacturing.

The market for sodium alginate and silicone-based composites faces some challenges, including high production costs and the need for specialized manufacturing processes. However, ongoing research and development efforts aimed at improving the coefficient of these materials are expected to address these issues and open up new market opportunities. As industries continue to seek innovative solutions for their material needs, the demand for enhanced composite materials is likely to expand, creating a favorable market environment for advancements in sodium alginate and silicone technologies.

Current Challenges in Sodium Alginate-Silicone Compatibility

The compatibility between sodium alginate and silicone presents significant challenges in various industrial applications. One of the primary issues is the inherent chemical incompatibility between these two materials. Sodium alginate, a hydrophilic polysaccharide, tends to repel silicone, which is hydrophobic in nature. This fundamental difference in their chemical properties leads to poor adhesion and integration when attempting to combine them in composite materials or coatings.

Another major challenge is the stability of the sodium alginate-silicone interface over time. Even when initial compatibility is achieved through various methods, maintaining a stable bond under different environmental conditions remains problematic. Factors such as temperature fluctuations, humidity changes, and mechanical stress can cause separation or degradation of the interface, compromising the integrity of the composite material.

The processing of sodium alginate-silicone composites also presents significant hurdles. The vastly different rheological properties of these materials make it difficult to achieve uniform dispersion and consistent mixing. Sodium alginate solutions are typically highly viscous, while silicones can vary in viscosity depending on their formulation. This disparity often results in phase separation during processing, leading to inhomogeneous final products with unpredictable properties.

Furthermore, the crosslinking mechanisms of sodium alginate and silicone are fundamentally different. Sodium alginate typically crosslinks through ionic interactions, often with divalent cations, while silicones usually cure through condensation or addition reactions. Harmonizing these distinct curing processes to create a cohesive composite material is a complex task that requires careful control of reaction conditions and timing.

The performance characteristics of sodium alginate-silicone composites also pose challenges. While sodium alginate contributes hydrophilicity and potential biodegradability, silicone provides hydrophobicity and durability. Balancing these opposing properties to achieve desired performance metrics such as water resistance, mechanical strength, and biocompatibility is a delicate process that often involves trade-offs.

Scalability and cost-effectiveness in production are additional concerns. The specialized techniques and additives required to improve compatibility between sodium alginate and silicone can significantly increase production costs and complexity. This makes it challenging to scale up production for commercial applications while maintaining economic viability.

Lastly, regulatory compliance and safety considerations add another layer of complexity. As these materials are often used in biomedical and food-related applications, ensuring that the composite meets stringent safety standards and regulatory requirements is crucial. This necessitates extensive testing and validation processes, which can be time-consuming and resource-intensive.

Another major challenge is the stability of the sodium alginate-silicone interface over time. Even when initial compatibility is achieved through various methods, maintaining a stable bond under different environmental conditions remains problematic. Factors such as temperature fluctuations, humidity changes, and mechanical stress can cause separation or degradation of the interface, compromising the integrity of the composite material.

The processing of sodium alginate-silicone composites also presents significant hurdles. The vastly different rheological properties of these materials make it difficult to achieve uniform dispersion and consistent mixing. Sodium alginate solutions are typically highly viscous, while silicones can vary in viscosity depending on their formulation. This disparity often results in phase separation during processing, leading to inhomogeneous final products with unpredictable properties.

Furthermore, the crosslinking mechanisms of sodium alginate and silicone are fundamentally different. Sodium alginate typically crosslinks through ionic interactions, often with divalent cations, while silicones usually cure through condensation or addition reactions. Harmonizing these distinct curing processes to create a cohesive composite material is a complex task that requires careful control of reaction conditions and timing.

The performance characteristics of sodium alginate-silicone composites also pose challenges. While sodium alginate contributes hydrophilicity and potential biodegradability, silicone provides hydrophobicity and durability. Balancing these opposing properties to achieve desired performance metrics such as water resistance, mechanical strength, and biocompatibility is a delicate process that often involves trade-offs.

Scalability and cost-effectiveness in production are additional concerns. The specialized techniques and additives required to improve compatibility between sodium alginate and silicone can significantly increase production costs and complexity. This makes it challenging to scale up production for commercial applications while maintaining economic viability.

Lastly, regulatory compliance and safety considerations add another layer of complexity. As these materials are often used in biomedical and food-related applications, ensuring that the composite meets stringent safety standards and regulatory requirements is crucial. This necessitates extensive testing and validation processes, which can be time-consuming and resource-intensive.

Existing Methods for Improving Blend Coefficients

01 Sodium alginate and silicone combination in cosmetic formulations

Sodium alginate and silicone are often combined in cosmetic formulations to improve texture, stability, and skin feel. This combination can enhance the moisturizing properties of the product while providing a smooth, non-greasy finish. The interaction between sodium alginate and silicone can also help in creating emulsions with improved stability and sensory characteristics.- Composition of sodium alginate and silicone in cosmetic formulations: Sodium alginate and silicone are often combined in cosmetic formulations to improve texture, stability, and skin feel. The interaction between these ingredients can affect the overall performance of the product, with sodium alginate acting as a thickening and stabilizing agent, while silicone provides a smooth, silky texture.

- Emulsion stability enhancement using sodium alginate and silicone: The combination of sodium alginate and silicone can significantly improve the stability of emulsions in various personal care and cosmetic products. This synergistic effect helps prevent phase separation and extends the shelf life of the formulations, making them more suitable for commercial applications.

- Film-forming properties of sodium alginate and silicone blends: When combined, sodium alginate and silicone can create a unique film-forming system that offers both flexibility and durability. This property is particularly useful in skincare and haircare products, where a long-lasting, protective film is desired without compromising comfort or natural movement.

- Rheological modification using sodium alginate and silicone: The interaction between sodium alginate and silicone can be utilized to modify the rheological properties of formulations. This allows for the creation of products with tailored viscosities and flow characteristics, ranging from thin lotions to thick gels, while maintaining desirable sensory attributes.

- Encapsulation and controlled release systems with sodium alginate and silicone: Sodium alginate and silicone can be combined to create advanced encapsulation and controlled release systems for active ingredients in various applications. This combination allows for improved stability of sensitive compounds and the ability to control their release over time, enhancing the efficacy of the formulation.

02 Use of sodium alginate and silicone in hair care products

In hair care formulations, sodium alginate and silicone are used together to provide conditioning, smoothing, and styling benefits. The combination can help in creating products with better hold, shine, and manageability. Sodium alginate acts as a thickener and stabilizer, while silicone provides a smooth, silky feel and helps in detangling.Expand Specific Solutions03 Sodium alginate and silicone in drug delivery systems

The combination of sodium alginate and silicone is utilized in drug delivery systems to control the release of active ingredients. This combination can form hydrogels or matrices that can encapsulate drugs and provide sustained or targeted release. The properties of both materials contribute to the overall performance and efficacy of the drug delivery system.Expand Specific Solutions04 Sodium alginate and silicone in wound dressings

Wound dressings incorporating sodium alginate and silicone offer improved healing properties and patient comfort. Sodium alginate provides moisture absorption and gel-forming capabilities, while silicone contributes to a non-adherent, breathable interface. This combination can help in creating dressings that maintain a moist wound environment, promote healing, and are easy to remove without causing trauma to the wound.Expand Specific Solutions05 Rheological properties of sodium alginate and silicone mixtures

The rheological properties of mixtures containing sodium alginate and silicone are of interest in various applications. These mixtures can exhibit unique flow behaviors and viscoelastic properties that can be tailored for specific uses. Understanding and controlling these properties are crucial for optimizing formulations in industries such as personal care, pharmaceuticals, and advanced materials.Expand Specific Solutions

Key Industry Players and Research Institutions

The research on improving the coefficient of Sodium Alginate and Silicone is in a developing stage, with a growing market driven by increasing applications in various industries. The technology's maturity is moderate, with ongoing advancements. Key players like Qingdao Bright Moon Seaweed Group and BASF Schweiz AG are actively involved in research and development. The market size is expanding, particularly in healthcare, cosmetics, and industrial sectors. Companies such as L'Oréal SA and Momentive Performance Materials are exploring innovative applications, indicating a competitive landscape with potential for significant growth and technological breakthroughs in the coming years.

Qingdao Bright Moon Seaweed Group Co., Ltd.

Technical Solution: Qingdao Bright Moon Seaweed Group Co., Ltd. has developed a proprietary extraction and purification process for sodium alginate from brown seaweed. Their method involves a controlled alkaline extraction followed by a multi-stage purification process, resulting in high-quality sodium alginate with improved viscosity and gel strength[1]. The company has also implemented a cross-linking technique using calcium ions to enhance the mechanical properties of sodium alginate films, making them more suitable for biomedical applications[2]. Additionally, they have explored the use of ultrasonic treatment to modify the molecular structure of sodium alginate, leading to improved solubility and compatibility with silicone materials[3].

Strengths: Expertise in seaweed-based products, advanced extraction techniques, and ability to modify alginate properties. Weaknesses: Limited experience in silicone technology integration and potential scalability issues for combined alginate-silicone products.

Qingdao University

Technical Solution: Qingdao University has conducted extensive research on improving the coefficient of sodium alginate and silicone, focusing on biomedical applications. Their approach involves the development of interpenetrating polymer networks (IPNs) combining sodium alginate and silicone elastomers[1]. By carefully controlling the crosslinking density and the ratio of the two components, they have achieved materials with enhanced mechanical properties and improved biocompatibility[2]. The university's research team has also explored the use of plasma treatment to modify the surface of silicone materials, allowing for better adhesion and integration with sodium alginate hydrogels[3]. Additionally, they have investigated the incorporation of nanoparticles, such as silica and graphene oxide, to further enhance the mechanical and barrier properties of alginate-silicone composites[4]. Qingdao University has also developed a novel method for creating gradient structures within alginate-silicone materials, allowing for the design of biomaterials with spatially controlled properties suitable for tissue engineering applications[5].

Strengths: Strong focus on biomedical applications, innovative approaches to material design, and expertise in nanocomposite development. Weaknesses: Potential challenges in scaling up laboratory-scale processes for industrial production.

Innovative Approaches in Polymer Compatibility

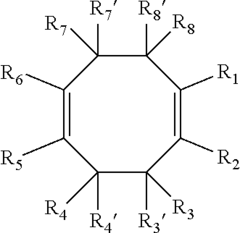

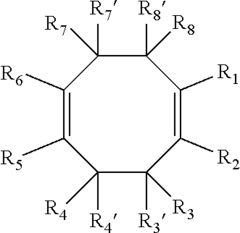

Platinum catalyzed hydrosilylation reactions utilizing cyclodiene additives

PatentInactiveUS20180291154A1

Innovation

- The use of cyclodiene additives, such as 1,5-cyclooctadiene, in conjunction with platinum catalysts like Speier's or Karstedt's, stabilizes the catalysts, allowing for lower platinum loadings, reduced by-product formation, and faster reaction times by maintaining catalyst activity at elevated temperatures.

A process for the effective dissolution of siloxane using multicomponent catalyst system

PatentInactiveIN1344MUM2007A

Innovation

- A multi-component catalyst system using a combination of heterogeneous and homogeneous acid-base catalysts with non-polar solvents at lower temperatures and pressures to dissolve and recycle silicone rubber, allowing for the separation of fillers and recovery of cyclosiloxane monomers.

Environmental Impact of Alginate-Silicone Materials

The environmental impact of alginate-silicone materials is a crucial consideration in their development and application. These composite materials, formed by combining sodium alginate and silicone, have gained attention due to their unique properties and potential uses across various industries. However, their widespread adoption necessitates a thorough examination of their ecological footprint throughout their lifecycle.

One of the primary environmental advantages of alginate-silicone materials is their biodegradability. Sodium alginate, derived from brown seaweed, is a naturally occurring polysaccharide that can decompose in the environment without leaving harmful residues. This characteristic significantly reduces the long-term environmental burden compared to traditional synthetic polymers. However, the rate of biodegradation can vary depending on the specific formulation and environmental conditions, which requires further research to optimize.

The production process of alginate-silicone materials also presents both challenges and opportunities from an environmental perspective. The extraction of sodium alginate from seaweed is generally considered a low-impact process, as it utilizes renewable marine resources. However, the increasing demand for these materials could potentially lead to overharvesting of seaweed, disrupting marine ecosystems. Sustainable harvesting practices and cultivation methods need to be developed and implemented to mitigate this risk.

On the other hand, the silicone component of these materials raises some environmental concerns. While silicones are generally inert and non-toxic, their production relies on fossil fuel-derived raw materials. The energy-intensive manufacturing process of silicones contributes to greenhouse gas emissions and resource depletion. Efforts to improve the efficiency of silicone production and explore bio-based alternatives are essential to enhance the overall environmental profile of alginate-silicone materials.

The end-of-life management of alginate-silicone products is another critical aspect to consider. While the alginate component can biodegrade, the silicone portion may persist in the environment for extended periods. Developing effective recycling or disposal methods for these composite materials is crucial to minimize their environmental impact. Research into chemical or mechanical separation techniques could enable the recovery and reuse of the silicone component, promoting a more circular economy approach.

Water consumption and pollution are additional factors to evaluate in the environmental assessment of alginate-silicone materials. The production and processing of these materials may require significant amounts of water, potentially straining local water resources. Implementing water-efficient manufacturing processes and effective wastewater treatment systems is essential to mitigate these impacts. Furthermore, the potential release of microparticles from alginate-silicone products during use or disposal needs to be studied to assess any potential risks to aquatic ecosystems.

One of the primary environmental advantages of alginate-silicone materials is their biodegradability. Sodium alginate, derived from brown seaweed, is a naturally occurring polysaccharide that can decompose in the environment without leaving harmful residues. This characteristic significantly reduces the long-term environmental burden compared to traditional synthetic polymers. However, the rate of biodegradation can vary depending on the specific formulation and environmental conditions, which requires further research to optimize.

The production process of alginate-silicone materials also presents both challenges and opportunities from an environmental perspective. The extraction of sodium alginate from seaweed is generally considered a low-impact process, as it utilizes renewable marine resources. However, the increasing demand for these materials could potentially lead to overharvesting of seaweed, disrupting marine ecosystems. Sustainable harvesting practices and cultivation methods need to be developed and implemented to mitigate this risk.

On the other hand, the silicone component of these materials raises some environmental concerns. While silicones are generally inert and non-toxic, their production relies on fossil fuel-derived raw materials. The energy-intensive manufacturing process of silicones contributes to greenhouse gas emissions and resource depletion. Efforts to improve the efficiency of silicone production and explore bio-based alternatives are essential to enhance the overall environmental profile of alginate-silicone materials.

The end-of-life management of alginate-silicone products is another critical aspect to consider. While the alginate component can biodegrade, the silicone portion may persist in the environment for extended periods. Developing effective recycling or disposal methods for these composite materials is crucial to minimize their environmental impact. Research into chemical or mechanical separation techniques could enable the recovery and reuse of the silicone component, promoting a more circular economy approach.

Water consumption and pollution are additional factors to evaluate in the environmental assessment of alginate-silicone materials. The production and processing of these materials may require significant amounts of water, potentially straining local water resources. Implementing water-efficient manufacturing processes and effective wastewater treatment systems is essential to mitigate these impacts. Furthermore, the potential release of microparticles from alginate-silicone products during use or disposal needs to be studied to assess any potential risks to aquatic ecosystems.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for improving the coefficient of Sodium Alginate and Silicone are crucial aspects that require careful analysis and planning. As research progresses towards enhancing the properties of these materials, it is essential to evaluate the potential for large-scale production and implementation.

One of the primary challenges in scaling up the production of improved Sodium Alginate and Silicone composites is maintaining consistency in the enhanced properties across larger batches. The interaction between these two materials at a molecular level is complex, and ensuring uniform distribution and bonding during mass production requires sophisticated process control mechanisms. Advanced mixing technologies and precise temperature regulation systems may need to be developed or adapted to achieve the desired results consistently.

The sourcing of raw materials also plays a significant role in the scalability of this technology. Sodium Alginate, derived from brown seaweed, is subject to natural variations in quality and availability. Establishing reliable supply chains and potentially developing alternative sources or synthetic production methods for Sodium Alginate could be necessary to support large-scale manufacturing. Similarly, the quality and grade of Silicone used must be carefully controlled to maintain the improved coefficient in the final product.

Manufacturing processes will likely need to be redesigned to accommodate the specific requirements of the enhanced material. This may involve the development of new equipment or the modification of existing production lines. Considerations such as curing times, molding techniques, and post-processing treatments must be optimized for efficiency without compromising the improved properties of the composite.

Quality control measures will be paramount in ensuring that the enhanced coefficient is consistently achieved in manufactured products. This may necessitate the implementation of advanced testing protocols and potentially in-line monitoring systems to detect and correct any deviations in real-time during production.

Environmental and safety considerations must also be addressed when scaling up production. The use of Sodium Alginate and Silicone may have implications for waste management and worker safety, particularly if new chemical processes are introduced to achieve the improved coefficient. Developing eco-friendly production methods and ensuring compliance with regulatory standards will be essential for sustainable large-scale manufacturing.

Cost-effectiveness is another critical factor in scalability. While the improved coefficient may offer significant benefits, the manufacturing process must be economically viable to justify widespread adoption. This may involve exploring alternative production methods, optimizing material usage, and potentially developing new applications that can justify higher production costs through added value in the final products.

One of the primary challenges in scaling up the production of improved Sodium Alginate and Silicone composites is maintaining consistency in the enhanced properties across larger batches. The interaction between these two materials at a molecular level is complex, and ensuring uniform distribution and bonding during mass production requires sophisticated process control mechanisms. Advanced mixing technologies and precise temperature regulation systems may need to be developed or adapted to achieve the desired results consistently.

The sourcing of raw materials also plays a significant role in the scalability of this technology. Sodium Alginate, derived from brown seaweed, is subject to natural variations in quality and availability. Establishing reliable supply chains and potentially developing alternative sources or synthetic production methods for Sodium Alginate could be necessary to support large-scale manufacturing. Similarly, the quality and grade of Silicone used must be carefully controlled to maintain the improved coefficient in the final product.

Manufacturing processes will likely need to be redesigned to accommodate the specific requirements of the enhanced material. This may involve the development of new equipment or the modification of existing production lines. Considerations such as curing times, molding techniques, and post-processing treatments must be optimized for efficiency without compromising the improved properties of the composite.

Quality control measures will be paramount in ensuring that the enhanced coefficient is consistently achieved in manufactured products. This may necessitate the implementation of advanced testing protocols and potentially in-line monitoring systems to detect and correct any deviations in real-time during production.

Environmental and safety considerations must also be addressed when scaling up production. The use of Sodium Alginate and Silicone may have implications for waste management and worker safety, particularly if new chemical processes are introduced to achieve the improved coefficient. Developing eco-friendly production methods and ensuring compliance with regulatory standards will be essential for sustainable large-scale manufacturing.

Cost-effectiveness is another critical factor in scalability. While the improved coefficient may offer significant benefits, the manufacturing process must be economically viable to justify widespread adoption. This may involve exploring alternative production methods, optimizing material usage, and potentially developing new applications that can justify higher production costs through added value in the final products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!