Improving The Filtering Effect Of Check Valves

Technology Background And Goals

Existing check valves often struggle with effectively filtering out fine particles or contaminants, leading to potential equipment damage and operational inefficiencies. By improving the filtering effect, the research seeks to develop more reliable and efficient check valve systems that can better safeguard critical components and processes. This could involve exploring advanced materials, optimized valve geometries, or integrating additional filtering mechanisms into the valve design.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. Factors such as infrastructure development, urbanization, and the need for efficient fluid control systems contribute to market expansion. - Industry Trends

Key trends shaping the check valve market include the adoption of advanced materials for improved durability and corrosion resistance, the demand for compact and lightweight designs, and the integration of smart technologies for remote monitoring and predictive maintenance. - Application Sectors

Check valves find widespread applications across various sectors, including:- Oil and gas: Upstream, midstream, and downstream operations

- Chemical processing: Handling corrosive and hazardous fluids

- Water and wastewater treatment: Preventing backflow and ensuring directional flow

- Power generation: Steam and cooling systems

- Pharmaceutical and food processing: Maintaining hygiene and preventing contamination

- Regional Dynamics

The Asia-Pacific region is expected to be a significant market for check valves, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold substantial market shares due to established industries and stringent regulations.

Technology Status And Challenges

- Valve Clogging Issues

Check valves are prone to clogging, which reduces flow efficiency and causes pressure drops. Particulates, debris, and scale buildup can obstruct valve openings. - Material Limitations

Conventional valve materials like metals and plastics may corrode, degrade, or react with certain fluids, compromising performance and service life. - Sealing Challenges

Ensuring proper sealing between the valve components is crucial to prevent leakage and backflow. Imperfect sealing can lead to contamination or fluid loss. - Flow Turbulence

Turbulent flow patterns near the valve opening can disrupt smooth fluid flow, reducing efficiency and causing vibrations or noise. - Maintenance Difficulties

Check valves are often installed in hard-to-reach locations, making maintenance, inspection, and replacement challenging and costly.

Technology Evolution Path

Current Technical Solutions

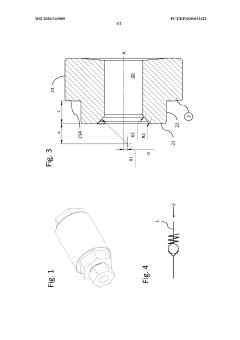

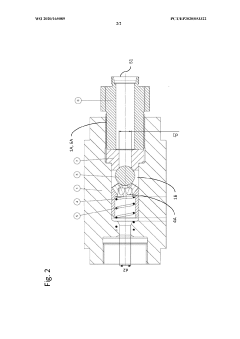

01 Filtering check valves

Valves incorporating filtering elements or mechanisms to remove impurities or contaminants from fluid flow, preventing clogging or damage to downstream components.- Check valves with filtering capabilities: Valves with integrated filters or structures that allow one-way flow while preventing backflow and filtering out contaminants or particles.

- Self-cleaning check valves: Valves with mechanisms to prevent clogging or debris buildup, such as reverse flow flushing, mechanical agitation, or specialized materials/coatings.

- Improved sealing and flow control check valves: Valves with enhanced sealing mechanisms, sealing materials, or flow control geometries for better sealing performance, reduced leakage, and optimized fluid flow.

- Compact or lightweight check valves: Valves designed to be compact, lightweight, or have a reduced footprint, suitable for space-constrained or weight-limited applications, using innovative materials, manufacturing techniques, or optimized geometries.

- Durable and corrosion-resistant check valves: Valves designed to withstand harsh operating conditions, high temperatures, pressures, or corrosive environments, incorporating specialized materials, coatings, or design features for improved durability and corrosion/wear resistance.

02 Check valves with integrated strainers

Valves with built-in strainers or mesh screens acting as filters, preventing solid particles or contaminants from passing through while allowing fluid flow.03 Self-cleaning filtering check valves

Valves with self-cleaning mechanisms like backflushing or reverse flow to periodically remove accumulated debris or contaminants from the filtering element, ensuring continuous and efficient operation.04 Check valves with replaceable filter cartridges

Valves featuring removable or replaceable filter cartridges, allowing easy maintenance and replacement of the filtering element without disassembling the entire valve.05 Multi-stage filtering check valves

Valves incorporating multiple filtering stages, each designed to remove different types or sizes of contaminants, providing a more comprehensive filtering solution.

Technology Main Player Analysis

Honeywell International Technologies Ltd.

Wapro AB

Key Technology Interpretation

- The valve member has a convex-curved contact surface, which improves sealing performance.

- The valve member is pretensioned against the valve seat to seal the passage when not in use, preventing backflow.

- The check valve can be used in an apparatus and method for processing cellulose pulp, improving the overall efficiency and consistency of the process.

Check Valve Potential Innovation Direction

Check Valve Filtering Effect Improvement Environmental Impact

Enhancing the filtering effect of check valves holds environmental significance. Particulate matter and contaminants, if not properly filtered, can adversely impact air and water quality, posing risks to human health and ecological systems. Improved filters in check valves can effectively capture pollutants, reducing emissions and discharges into the environment. Furthermore, efficient filtering extends the lifespan of equipment by preventing internal component corrosion and damage caused by particulates. This not only minimizes waste generation but also contributes to resource conservation and sustainability goals. Overall, enhancing check valve filtering contributes to a cleaner, healthier environment while promoting responsible resource utilization.

Check Valve Filtering Effect Improvement Policy And Regulatory Impact

Improving the filtering effect of check valves is essential for various industries, as it directly impacts system efficiency and safety. Regulatory bodies play a crucial role in setting standards and guidelines for valve performance, ensuring public welfare and environmental protection. The impact of regulations can be multifaceted, influencing design, testing, and certification processes. Compliance with evolving regulations is vital to maintain market access and avoid penalties. Additionally, regulatory changes can drive innovation, prompting manufacturers to develop advanced solutions to meet heightened requirements. A comprehensive assessment of current and anticipated regulations is crucial for strategic planning and maintaining a competitive edge in the check valve industry.