Research on Microreactors in Heterogeneous Catalysis Systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactors represent a revolutionary approach in chemical engineering, characterized by their miniaturized reaction channels with dimensions typically ranging from 10 to 1000 micrometers. The evolution of microreactor technology can be traced back to the early 1990s when the concept of process intensification gained momentum in chemical engineering. Initially developed for simple organic synthesis, microreactors have undergone significant transformation over the past three decades to become sophisticated tools for heterogeneous catalysis applications.

The technological trajectory of microreactors has been shaped by advancements in microfabrication techniques, materials science, and computational fluid dynamics. Early microreactors were primarily constructed from silicon and glass using photolithography and etching techniques borrowed from the semiconductor industry. By the early 2000s, metal microreactors emerged, offering enhanced thermal conductivity and mechanical stability, which proved crucial for catalytic reactions requiring precise temperature control.

A significant milestone in microreactor evolution occurred with the development of 3D printing and additive manufacturing technologies, enabling the creation of complex internal geometries optimized for specific catalytic processes. This advancement facilitated better catalyst integration and more efficient mass transfer, addressing key limitations in heterogeneous catalysis systems. Parallel to hardware developments, sophisticated modeling tools emerged, allowing researchers to simulate and optimize reaction conditions within these miniaturized environments.

The integration of in-situ analytical techniques represents another pivotal advancement in microreactor technology. Real-time monitoring capabilities through spectroscopic methods have transformed microreactors from mere reaction vessels to comprehensive analytical platforms, enabling deeper insights into reaction mechanisms and catalyst behavior under operating conditions. This integration has been particularly valuable for studying transient phenomena in heterogeneous catalysis that were previously difficult to observe.

The primary objectives of current microreactor research in heterogeneous catalysis systems encompass several dimensions. First, enhancing mass and heat transfer efficiency to overcome diffusion limitations that often plague conventional reactors. Second, enabling precise control over reaction parameters to achieve higher selectivity and yield. Third, facilitating rapid screening of catalysts under various conditions to accelerate catalyst development cycles. Fourth, providing a safer platform for studying potentially hazardous reactions through inherent containment features and reduced reagent volumes.

Looking forward, the technological roadmap for microreactors in heterogeneous catalysis aims to address scalability challenges through numbering-up approaches rather than traditional scale-up methods. Additionally, research efforts are focused on developing more robust catalyst immobilization techniques, improving long-term stability, and creating standardized platforms that can bridge the gap between laboratory research and industrial implementation.

The technological trajectory of microreactors has been shaped by advancements in microfabrication techniques, materials science, and computational fluid dynamics. Early microreactors were primarily constructed from silicon and glass using photolithography and etching techniques borrowed from the semiconductor industry. By the early 2000s, metal microreactors emerged, offering enhanced thermal conductivity and mechanical stability, which proved crucial for catalytic reactions requiring precise temperature control.

A significant milestone in microreactor evolution occurred with the development of 3D printing and additive manufacturing technologies, enabling the creation of complex internal geometries optimized for specific catalytic processes. This advancement facilitated better catalyst integration and more efficient mass transfer, addressing key limitations in heterogeneous catalysis systems. Parallel to hardware developments, sophisticated modeling tools emerged, allowing researchers to simulate and optimize reaction conditions within these miniaturized environments.

The integration of in-situ analytical techniques represents another pivotal advancement in microreactor technology. Real-time monitoring capabilities through spectroscopic methods have transformed microreactors from mere reaction vessels to comprehensive analytical platforms, enabling deeper insights into reaction mechanisms and catalyst behavior under operating conditions. This integration has been particularly valuable for studying transient phenomena in heterogeneous catalysis that were previously difficult to observe.

The primary objectives of current microreactor research in heterogeneous catalysis systems encompass several dimensions. First, enhancing mass and heat transfer efficiency to overcome diffusion limitations that often plague conventional reactors. Second, enabling precise control over reaction parameters to achieve higher selectivity and yield. Third, facilitating rapid screening of catalysts under various conditions to accelerate catalyst development cycles. Fourth, providing a safer platform for studying potentially hazardous reactions through inherent containment features and reduced reagent volumes.

Looking forward, the technological roadmap for microreactors in heterogeneous catalysis aims to address scalability challenges through numbering-up approaches rather than traditional scale-up methods. Additionally, research efforts are focused on developing more robust catalyst immobilization techniques, improving long-term stability, and creating standardized platforms that can bridge the gap between laboratory research and industrial implementation.

Market Analysis for Microreactor Catalysis Applications

The global market for microreactor technology in heterogeneous catalysis systems has been experiencing significant growth, driven by increasing demand for more efficient and sustainable chemical processes. The market size for microreactor technologies in chemical processing was valued at approximately $2.5 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate (CAGR) of 11.2%.

Pharmaceutical manufacturing represents the largest application segment, accounting for nearly 35% of the market share. This dominance is attributed to the industry's need for precise reaction control, enhanced safety profiles, and reduced waste generation. The fine chemicals sector follows closely at 28%, while petrochemicals and bulk chemicals collectively represent about 25% of the market.

Regionally, North America and Europe currently lead the market with combined shares exceeding 60%. However, Asia-Pacific is emerging as the fastest-growing region with a projected CAGR of 13.5% through 2028, primarily driven by rapid industrialization in China and India, along with increasing investments in advanced manufacturing technologies.

Key market drivers include stringent environmental regulations promoting greener chemistry approaches, rising pressure to improve resource efficiency, and growing emphasis on process intensification. Microreactors offer compelling advantages in these areas, delivering up to 99% reduction in reagent consumption for certain reactions and energy savings of 30-40% compared to conventional batch processes.

Customer demand patterns indicate a growing preference for modular and scalable microreactor systems that can be easily integrated into existing production lines. End-users are increasingly seeking solutions that offer real-time monitoring capabilities and compatibility with automation systems, reflecting the broader industry trend toward smart manufacturing.

Market challenges include the relatively high initial investment costs, with industrial-scale microreactor systems typically ranging from $500,000 to several million dollars depending on complexity and capacity. Technical barriers to adoption also persist, particularly concerning catalyst deactivation, clogging issues, and scaling limitations for certain reaction types.

The competitive landscape features both established chemical engineering firms and specialized microreactor technology providers. Recent market consolidation through strategic acquisitions suggests that industry players are positioning themselves to offer more comprehensive solution packages that address the entire workflow from laboratory development to full-scale production.

Pharmaceutical manufacturing represents the largest application segment, accounting for nearly 35% of the market share. This dominance is attributed to the industry's need for precise reaction control, enhanced safety profiles, and reduced waste generation. The fine chemicals sector follows closely at 28%, while petrochemicals and bulk chemicals collectively represent about 25% of the market.

Regionally, North America and Europe currently lead the market with combined shares exceeding 60%. However, Asia-Pacific is emerging as the fastest-growing region with a projected CAGR of 13.5% through 2028, primarily driven by rapid industrialization in China and India, along with increasing investments in advanced manufacturing technologies.

Key market drivers include stringent environmental regulations promoting greener chemistry approaches, rising pressure to improve resource efficiency, and growing emphasis on process intensification. Microreactors offer compelling advantages in these areas, delivering up to 99% reduction in reagent consumption for certain reactions and energy savings of 30-40% compared to conventional batch processes.

Customer demand patterns indicate a growing preference for modular and scalable microreactor systems that can be easily integrated into existing production lines. End-users are increasingly seeking solutions that offer real-time monitoring capabilities and compatibility with automation systems, reflecting the broader industry trend toward smart manufacturing.

Market challenges include the relatively high initial investment costs, with industrial-scale microreactor systems typically ranging from $500,000 to several million dollars depending on complexity and capacity. Technical barriers to adoption also persist, particularly concerning catalyst deactivation, clogging issues, and scaling limitations for certain reaction types.

The competitive landscape features both established chemical engineering firms and specialized microreactor technology providers. Recent market consolidation through strategic acquisitions suggests that industry players are positioning themselves to offer more comprehensive solution packages that address the entire workflow from laboratory development to full-scale production.

Current Challenges in Heterogeneous Catalysis Microreactors

Despite significant advancements in microreactor technology for heterogeneous catalysis systems, several critical challenges continue to impede their widespread industrial implementation. Mass and heat transfer limitations remain fundamental obstacles, particularly in gas-liquid-solid reactions where achieving uniform distribution of reactants across catalyst surfaces proves difficult. The miniaturized dimensions of microchannels, while beneficial for enhancing transfer properties, often lead to problematic pressure drops that compromise flow dynamics and reaction efficiency.

Catalyst integration presents another significant hurdle. Current methods for incorporating catalytic materials into microreactors—including wall coating, packed beds, and monolithic structures—each exhibit distinct limitations. Wall coatings often suffer from poor adhesion and limited catalyst loading capacity, while packed beds create excessive pressure drops and flow maldistribution. Monolithic structures, though promising, face manufacturing complexities and challenges in catalyst replacement.

The scaling-up of microreactor systems represents perhaps the most formidable challenge from an industrial perspective. While laboratory-scale demonstrations have shown impressive results, translating these successes to production-scale operations requires complex parallelization strategies that introduce issues of flow distribution, thermal management across multiple units, and increased system complexity. The economic viability of such scaled systems remains questionable for many applications.

Material constraints further complicate microreactor development. The harsh reaction conditions typical in many catalytic processes—including high temperatures, pressures, and corrosive environments—demand exceptional material performance. Current materials often face limitations in thermal stability, chemical compatibility, or mechanical integrity under these demanding conditions, restricting operational parameters and catalyst selection.

Catalyst deactivation and fouling occur more rapidly in microreactors due to their confined geometries. When catalyst particles degrade or channels become blocked, the entire microreactor unit may require replacement, presenting significant operational and economic disadvantages compared to conventional reactors where catalyst replacement is more straightforward.

Monitoring and control systems for microreactors remain underdeveloped. The integration of reliable sensing technologies at the microscale presents unique challenges, limiting real-time process monitoring capabilities essential for quality control and process optimization. This deficiency hampers the implementation of advanced control strategies that could otherwise enhance reaction performance and system reliability.

Addressing these multifaceted challenges requires interdisciplinary approaches combining expertise in materials science, chemical engineering, microfabrication, and process control. Future research directions must focus on developing novel catalyst integration methods, advanced manufacturing techniques for complex geometries, and innovative strategies for effective scale-up while maintaining the inherent advantages of microreactor technology.

Catalyst integration presents another significant hurdle. Current methods for incorporating catalytic materials into microreactors—including wall coating, packed beds, and monolithic structures—each exhibit distinct limitations. Wall coatings often suffer from poor adhesion and limited catalyst loading capacity, while packed beds create excessive pressure drops and flow maldistribution. Monolithic structures, though promising, face manufacturing complexities and challenges in catalyst replacement.

The scaling-up of microreactor systems represents perhaps the most formidable challenge from an industrial perspective. While laboratory-scale demonstrations have shown impressive results, translating these successes to production-scale operations requires complex parallelization strategies that introduce issues of flow distribution, thermal management across multiple units, and increased system complexity. The economic viability of such scaled systems remains questionable for many applications.

Material constraints further complicate microreactor development. The harsh reaction conditions typical in many catalytic processes—including high temperatures, pressures, and corrosive environments—demand exceptional material performance. Current materials often face limitations in thermal stability, chemical compatibility, or mechanical integrity under these demanding conditions, restricting operational parameters and catalyst selection.

Catalyst deactivation and fouling occur more rapidly in microreactors due to their confined geometries. When catalyst particles degrade or channels become blocked, the entire microreactor unit may require replacement, presenting significant operational and economic disadvantages compared to conventional reactors where catalyst replacement is more straightforward.

Monitoring and control systems for microreactors remain underdeveloped. The integration of reliable sensing technologies at the microscale presents unique challenges, limiting real-time process monitoring capabilities essential for quality control and process optimization. This deficiency hampers the implementation of advanced control strategies that could otherwise enhance reaction performance and system reliability.

Addressing these multifaceted challenges requires interdisciplinary approaches combining expertise in materials science, chemical engineering, microfabrication, and process control. Future research directions must focus on developing novel catalyst integration methods, advanced manufacturing techniques for complex geometries, and innovative strategies for effective scale-up while maintaining the inherent advantages of microreactor technology.

State-of-the-Art Microreactor Design Solutions

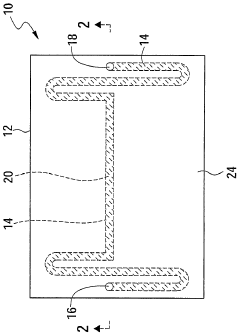

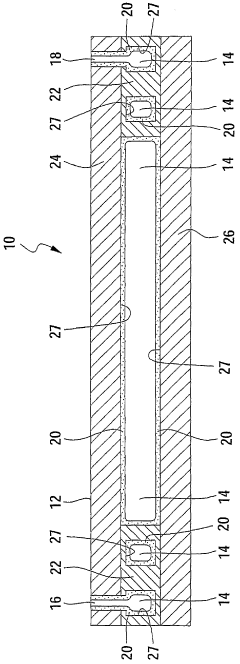

01 Design and structure of microreactors for heterogeneous catalysis

Microreactors designed for heterogeneous catalysis systems feature specialized structures that enhance catalyst performance. These designs include optimized flow channels, catalyst support structures, and integrated monitoring systems. The small dimensions of microreactors provide high surface-to-volume ratios, improving mass and heat transfer during catalytic reactions. Various materials and fabrication techniques are employed to create robust microreactor systems capable of withstanding reaction conditions while maintaining catalyst activity.- Design and structure of microreactors for heterogeneous catalysis: Microreactors designed for heterogeneous catalysis systems feature specialized structures that enhance catalyst performance. These designs include optimized flow channels, catalyst support structures, and integrated heating/cooling systems that improve mass and heat transfer. The miniaturized dimensions allow for precise control of reaction conditions, leading to higher conversion rates and selectivity compared to conventional reactors.

- Catalyst immobilization techniques in microreactor systems: Various methods are employed to immobilize heterogeneous catalysts within microreactors, including wall coating, packed-bed configurations, and monolithic structures. These techniques ensure optimal catalyst distribution and accessibility while minimizing pressure drop. Advanced immobilization approaches incorporate nanomaterials and structured catalyst supports to maximize active surface area and reaction efficiency in the confined microreactor environment.

- Process intensification through microreactor technology: Microreactors enable significant process intensification in heterogeneous catalysis by enhancing mass and heat transfer rates. The high surface-to-volume ratio allows for more efficient catalyst utilization and precise temperature control, resulting in improved reaction kinetics. This intensification leads to higher yields, reduced energy consumption, and smaller equipment footprint compared to conventional reactor systems.

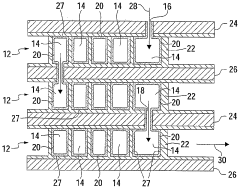

- Continuous flow processing in heterogeneous catalytic microreactors: Continuous flow operation in microreactors offers advantages for heterogeneous catalysis including consistent product quality, reduced reaction times, and improved safety profiles. The controlled residence time distribution enables precise reaction control and facilitates multistep synthesis. These systems can be easily scaled through numbering-up approaches rather than traditional scale-up, maintaining the advantageous characteristics of the microreactor environment.

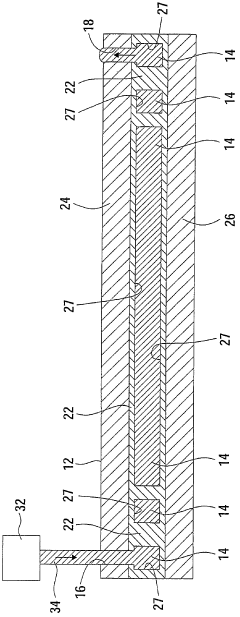

- Integration of monitoring and control systems in catalytic microreactors: Advanced monitoring and control systems integrated into microreactors for heterogeneous catalysis enable real-time analysis and process optimization. These systems incorporate sensors for temperature, pressure, and concentration measurements, along with automated feedback control mechanisms. The integration facilitates rapid screening of reaction conditions, catalyst performance evaluation, and process parameter optimization, accelerating catalyst development and reaction optimization.

02 Process intensification and reaction efficiency in microreactor catalytic systems

Microreactors significantly enhance heterogeneous catalytic processes through process intensification. The controlled environment allows for precise reaction parameters, resulting in improved selectivity, yield, and conversion rates. The enhanced mass and heat transfer characteristics reduce diffusion limitations common in traditional reactors. These systems enable continuous flow operations with shorter residence times while maintaining or improving catalytic performance. Process intensification in microreactors also allows for safer operation of reactions that would be hazardous in conventional reactors.Expand Specific Solutions03 Catalyst immobilization and loading techniques for microreactors

Various methods have been developed for immobilizing heterogeneous catalysts within microreactor channels. These techniques include wall coating, packed-bed configurations, monolithic structures, and membrane integration. The immobilization method affects catalyst stability, activity, and reactor performance. Advanced coating techniques ensure uniform catalyst distribution and strong adhesion to reactor walls. Catalyst loading density and distribution are optimized to balance pressure drop considerations with catalytic efficiency, while preventing channel clogging or catalyst leaching during operation.Expand Specific Solutions04 Monitoring and control systems for microreactor catalytic processes

Sophisticated monitoring and control systems are integrated into microreactors for heterogeneous catalysis to ensure optimal performance. These systems include real-time sensors for temperature, pressure, flow rate, and concentration measurements. Advanced control algorithms enable precise regulation of reaction parameters and rapid response to deviations. Data collection and analysis systems provide insights into catalyst performance and degradation over time. The integration of monitoring technologies allows for automated operation and optimization of catalytic processes in microreactor environments.Expand Specific Solutions05 Scale-up and industrial applications of microreactor catalytic systems

Scaling up microreactor technology for industrial heterogeneous catalysis applications involves numbering-up approaches rather than traditional scale-up methods. Multiple microreactor units are operated in parallel to achieve higher throughput while maintaining the advantages of microscale operations. This approach addresses challenges in maintaining uniform flow distribution, catalyst performance, and heat management across multiple units. Industrial implementations demonstrate the feasibility of microreactor technology for commercial catalytic processes, offering benefits in product quality, energy efficiency, and operational flexibility compared to conventional reactor systems.Expand Specific Solutions

Leading Organizations in Microreactor Technology

The microreactor technology in heterogeneous catalysis systems is currently in a growth phase, with the market expanding rapidly due to increasing demand for efficient chemical processing solutions. The global market size is estimated to reach several billion dollars by 2025, driven by applications in pharmaceuticals, fine chemicals, and petrochemicals. Technologically, the field shows varying maturity levels across different companies. Industry leaders like China Petroleum & Chemical Corp. (Sinopec) and BASF are advancing commercial applications, while research institutions such as Beijing University of Chemical Technology and Fudan University are developing next-generation catalytic microreactor systems. IFP Energies Nouvelles and Eni SpA are focusing on process intensification, while Air Liquide and Corning are pioneering microreactor materials and designs, creating a competitive landscape balanced between established corporations and innovative research entities.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced microreactor technologies for heterogeneous catalysis systems that focus on process intensification in petroleum refining and petrochemical processes. Their microreactor designs incorporate structured catalysts with enhanced surface-to-volume ratios that significantly improve mass and heat transfer characteristics. Sinopec's microreactor technology employs microchannel reactors with catalyst coatings that enable precise control of reaction parameters and residence time distributions. The company has implemented these systems in pilot-scale operations for reactions such as hydrogenation, oxidation, and Fischer-Tropsch synthesis, demonstrating yields up to 15-20% higher than conventional reactors while reducing energy consumption by approximately 30%. Their microreactor designs also feature integrated heat exchangers that allow for isothermal operation even in highly exothermic reactions, preventing hotspot formation and extending catalyst lifetime by up to 40% compared to traditional fixed-bed reactors.

Strengths: Superior heat and mass transfer capabilities, precise reaction control, reduced energy consumption, and integration with existing refinery infrastructure. Weaknesses: Higher capital costs for implementation, potential scaling challenges when transitioning from pilot to industrial scale, and specialized maintenance requirements for microstructured components.

Sinopec Research Institute of Petroleum Processing

Technical Solution: Sinopec Research Institute of Petroleum Processing has pioneered microreactor technology specifically tailored for heterogeneous catalysis in petroleum upgrading processes. Their proprietary microreactor designs feature parallel microchannel arrays with catalyst-coated walls that maximize contact efficiency between reactants and catalytic surfaces. The institute has developed specialized coating techniques that ensure uniform catalyst distribution and strong adhesion to reactor walls, addressing one of the key challenges in microreactor technology. Their systems incorporate advanced flow distribution mechanisms that ensure uniform residence time across all channels, eliminating bypass flows that can reduce conversion efficiency. The institute has successfully demonstrated microreactor applications in hydrodesulfurization processes, achieving sulfur removal efficiencies exceeding 99% while operating at lower temperatures (30-50°C reduction) compared to conventional reactors. Their microreactor technology also features integrated online monitoring systems that enable real-time process optimization and rapid response to changing feedstock characteristics.

Strengths: Specialized expertise in petroleum-specific applications, proven catalyst coating technologies, and integration with refinery control systems. Weaknesses: Limited application range outside petroleum processing, relatively high manufacturing complexity, and challenges in scaling to very large throughput requirements.

Critical Patents in Heterogeneous Catalysis Microreactors

Coated microstructure and method of manufacture

PatentWO2004039490A1

Innovation

- Microreactors with microchannel walls made of glass, ceramic, or glass-ceramic materials coated with a catalyst support and catalyst using a slurry deposition process, providing strong adhesion and resistance to thermal shock and pressure.

Scale-up Strategies for Industrial Implementation

The successful transition of microreactor technology from laboratory to industrial scale requires systematic scale-up strategies that address the unique challenges of heterogeneous catalysis systems. The most promising approach is "numbering-up" (parallel replication) rather than traditional scale-up, which preserves the advantageous characteristics of microreactors while increasing production capacity. This strategy involves connecting multiple microreactor units in parallel configurations, maintaining consistent flow distribution and reaction conditions across all units.

Material selection becomes increasingly critical at industrial scale, with requirements for chemical resistance, thermal stability, and mechanical durability under continuous operation. Advanced manufacturing techniques such as 3D printing, micromachining, and advanced bonding methods are enabling more complex and efficient reactor designs suitable for industrial implementation.

Process intensification techniques complement scale-up efforts by maximizing throughput per unit volume. These include structured catalyst arrangements, multifunctional reactor designs that combine reaction and separation, and advanced flow distribution systems that ensure uniform catalyst contact across parallel channels.

Control systems represent another crucial aspect of industrial implementation, with real-time monitoring and automated feedback mechanisms becoming essential for maintaining optimal performance. Distributed sensor networks throughout the reactor system enable precise temperature, pressure, and concentration monitoring, while advanced control algorithms can adjust operating parameters to maintain consistent product quality.

Economic considerations ultimately determine commercial viability. Capital expenditure for microreactor systems typically exceeds that of conventional reactors, but this is often offset by reduced operating costs, higher yields, and improved product quality. The modular nature of microreactor systems also allows for phased investment and capacity expansion, reducing initial financial risk.

Regulatory compliance presents unique challenges for novel reactor technologies. Working with regulatory bodies early in development can streamline approval processes, particularly for pharmaceutical and fine chemical applications where product quality and consistency are paramount. Standardization efforts across the industry are gradually establishing frameworks for validation and qualification of microreactor systems.

Case studies from chemical, pharmaceutical, and energy sectors demonstrate successful industrial implementation. Notable examples include continuous API manufacturing plants using microreactor technology, which have achieved significant reductions in production footprint and energy consumption while maintaining consistent product quality at commercial scales.

Material selection becomes increasingly critical at industrial scale, with requirements for chemical resistance, thermal stability, and mechanical durability under continuous operation. Advanced manufacturing techniques such as 3D printing, micromachining, and advanced bonding methods are enabling more complex and efficient reactor designs suitable for industrial implementation.

Process intensification techniques complement scale-up efforts by maximizing throughput per unit volume. These include structured catalyst arrangements, multifunctional reactor designs that combine reaction and separation, and advanced flow distribution systems that ensure uniform catalyst contact across parallel channels.

Control systems represent another crucial aspect of industrial implementation, with real-time monitoring and automated feedback mechanisms becoming essential for maintaining optimal performance. Distributed sensor networks throughout the reactor system enable precise temperature, pressure, and concentration monitoring, while advanced control algorithms can adjust operating parameters to maintain consistent product quality.

Economic considerations ultimately determine commercial viability. Capital expenditure for microreactor systems typically exceeds that of conventional reactors, but this is often offset by reduced operating costs, higher yields, and improved product quality. The modular nature of microreactor systems also allows for phased investment and capacity expansion, reducing initial financial risk.

Regulatory compliance presents unique challenges for novel reactor technologies. Working with regulatory bodies early in development can streamline approval processes, particularly for pharmaceutical and fine chemical applications where product quality and consistency are paramount. Standardization efforts across the industry are gradually establishing frameworks for validation and qualification of microreactor systems.

Case studies from chemical, pharmaceutical, and energy sectors demonstrate successful industrial implementation. Notable examples include continuous API manufacturing plants using microreactor technology, which have achieved significant reductions in production footprint and energy consumption while maintaining consistent product quality at commercial scales.

Sustainability Impact of Microreactor Technology

Microreactor technology represents a significant advancement in sustainable chemical processing, offering numerous environmental and economic benefits compared to traditional batch reactors. The inherent characteristics of microreactors—including enhanced heat and mass transfer, precise reaction control, and reduced reagent consumption—directly contribute to greener chemistry practices and reduced environmental footprint.

The implementation of microreactors in heterogeneous catalysis systems substantially reduces energy consumption through improved thermal efficiency. Their high surface-to-volume ratio enables more effective heat transfer, minimizing energy requirements for heating and cooling processes. Studies indicate energy savings of 30-50% compared to conventional reactor systems, directly translating to reduced carbon emissions and operational costs.

Waste reduction constitutes another critical sustainability advantage of microreactor technology. The precise control over reaction parameters minimizes side reactions and unwanted by-products, resulting in higher selectivity and yield. This efficiency reduces waste generation by up to 60% in certain catalytic processes, addressing a fundamental principle of green chemistry by preventing pollution at its source rather than treating waste after production.

Water conservation represents an often-overlooked sustainability benefit of microreactors. Their continuous flow operation requires significantly less solvent and washing agents compared to batch processes. Research demonstrates water usage reductions of 80-90% in pharmaceutical manufacturing processes utilizing microreactor technology, contributing to water conservation efforts in regions facing scarcity challenges.

From a life cycle assessment perspective, microreactors demonstrate favorable environmental profiles. Their compact size reduces material requirements for construction, while their longevity and durability minimize replacement frequency. Additionally, the potential for modular design facilitates easier maintenance and component replacement rather than entire system overhauls, further reducing lifetime resource consumption and waste generation.

The decentralized production capabilities enabled by microreactor technology also contribute to sustainability through reduced transportation requirements. By enabling on-site or near-point-of-use production of chemicals and pharmaceuticals, microreactors can significantly decrease the carbon footprint associated with global supply chains and product distribution networks.

Safety improvements inherent to microreactor design—including reduced chemical inventories and enhanced containment of hazardous materials—minimize the risk and potential environmental impact of industrial accidents. This aspect of sustainability often receives less attention but remains crucial for comprehensive environmental protection strategies in chemical manufacturing.

The implementation of microreactors in heterogeneous catalysis systems substantially reduces energy consumption through improved thermal efficiency. Their high surface-to-volume ratio enables more effective heat transfer, minimizing energy requirements for heating and cooling processes. Studies indicate energy savings of 30-50% compared to conventional reactor systems, directly translating to reduced carbon emissions and operational costs.

Waste reduction constitutes another critical sustainability advantage of microreactor technology. The precise control over reaction parameters minimizes side reactions and unwanted by-products, resulting in higher selectivity and yield. This efficiency reduces waste generation by up to 60% in certain catalytic processes, addressing a fundamental principle of green chemistry by preventing pollution at its source rather than treating waste after production.

Water conservation represents an often-overlooked sustainability benefit of microreactors. Their continuous flow operation requires significantly less solvent and washing agents compared to batch processes. Research demonstrates water usage reductions of 80-90% in pharmaceutical manufacturing processes utilizing microreactor technology, contributing to water conservation efforts in regions facing scarcity challenges.

From a life cycle assessment perspective, microreactors demonstrate favorable environmental profiles. Their compact size reduces material requirements for construction, while their longevity and durability minimize replacement frequency. Additionally, the potential for modular design facilitates easier maintenance and component replacement rather than entire system overhauls, further reducing lifetime resource consumption and waste generation.

The decentralized production capabilities enabled by microreactor technology also contribute to sustainability through reduced transportation requirements. By enabling on-site or near-point-of-use production of chemicals and pharmaceuticals, microreactors can significantly decrease the carbon footprint associated with global supply chains and product distribution networks.

Safety improvements inherent to microreactor design—including reduced chemical inventories and enhanced containment of hazardous materials—minimize the risk and potential environmental impact of industrial accidents. This aspect of sustainability often receives less attention but remains crucial for comprehensive environmental protection strategies in chemical manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!