What Determines Residence Time Distribution in Microreactors

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor RTD Fundamentals and Objectives

Residence Time Distribution (RTD) in microreactors represents a fundamental concept that characterizes the time various fluid elements spend within a reactor system. This distribution significantly impacts reaction performance, selectivity, and yield in chemical processes. The evolution of microreactor technology has transformed chemical engineering practices by offering unprecedented control over reaction conditions at microscale dimensions, typically ranging from 10 to 500 micrometers.

The historical development of RTD analysis dates back to the 1950s when Danckwerts introduced the concept for conventional reactors. However, its application to microreactors gained momentum only in the early 2000s as microfluidic technologies matured. This evolution has been driven by increasing demands for process intensification and the need for more efficient, sustainable chemical manufacturing processes.

Understanding RTD in microreactors requires examining several fundamental physical phenomena. Laminar flow dominates in microchannels due to low Reynolds numbers, creating parabolic velocity profiles that naturally lead to residence time variations. Molecular diffusion becomes particularly significant at microscale, as it can counteract dispersion effects and potentially narrow RTD profiles. Additionally, channel geometry, including aspect ratios, curvatures, and surface roughness, directly influences flow patterns and consequently RTD characteristics.

The primary technical objectives of RTD analysis in microreactors include optimizing reaction performance through precise control of residence times, minimizing unwanted side reactions by reducing RTD spread, and enabling accurate scale-up strategies for industrial implementation. Researchers aim to develop predictive models that can reliably forecast RTD behavior under various operating conditions, thereby facilitating rational design approaches.

Current technical trends in this field include the development of advanced in-situ monitoring techniques for real-time RTD measurement, computational fluid dynamics (CFD) simulations with increasing accuracy for complex geometries, and the integration of artificial intelligence for RTD prediction and control. The emergence of 3D printing technologies has also enabled rapid prototyping of novel microreactor designs with customized flow characteristics.

The ultimate goal of RTD research in microreactors extends beyond fundamental understanding to practical applications. Engineers seek to translate RTD knowledge into design principles that can guide the development of next-generation microreactors with tailored flow properties for specific reaction requirements, thereby unlocking new possibilities in pharmaceutical manufacturing, fine chemicals production, and sustainable chemical processing.

The historical development of RTD analysis dates back to the 1950s when Danckwerts introduced the concept for conventional reactors. However, its application to microreactors gained momentum only in the early 2000s as microfluidic technologies matured. This evolution has been driven by increasing demands for process intensification and the need for more efficient, sustainable chemical manufacturing processes.

Understanding RTD in microreactors requires examining several fundamental physical phenomena. Laminar flow dominates in microchannels due to low Reynolds numbers, creating parabolic velocity profiles that naturally lead to residence time variations. Molecular diffusion becomes particularly significant at microscale, as it can counteract dispersion effects and potentially narrow RTD profiles. Additionally, channel geometry, including aspect ratios, curvatures, and surface roughness, directly influences flow patterns and consequently RTD characteristics.

The primary technical objectives of RTD analysis in microreactors include optimizing reaction performance through precise control of residence times, minimizing unwanted side reactions by reducing RTD spread, and enabling accurate scale-up strategies for industrial implementation. Researchers aim to develop predictive models that can reliably forecast RTD behavior under various operating conditions, thereby facilitating rational design approaches.

Current technical trends in this field include the development of advanced in-situ monitoring techniques for real-time RTD measurement, computational fluid dynamics (CFD) simulations with increasing accuracy for complex geometries, and the integration of artificial intelligence for RTD prediction and control. The emergence of 3D printing technologies has also enabled rapid prototyping of novel microreactor designs with customized flow characteristics.

The ultimate goal of RTD research in microreactors extends beyond fundamental understanding to practical applications. Engineers seek to translate RTD knowledge into design principles that can guide the development of next-generation microreactors with tailored flow properties for specific reaction requirements, thereby unlocking new possibilities in pharmaceutical manufacturing, fine chemicals production, and sustainable chemical processing.

Market Applications and Demand Analysis

The microreactor market has experienced significant growth in recent years, driven by increasing demand for efficient and sustainable chemical processing solutions across multiple industries. The global microreactor technology market was valued at approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 9.8% through 2030, highlighting the expanding commercial interest in this technology.

Pharmaceutical manufacturing represents one of the largest application segments for microreactors, accounting for nearly 35% of the market share. The industry's shift toward continuous manufacturing processes has created substantial demand for microreactors with precisely controlled residence time distributions (RTDs). This demand is particularly strong for the production of active pharmaceutical ingredients (APIs) where reaction selectivity and product purity are directly influenced by RTD characteristics.

The fine chemicals sector constitutes another significant market segment, with companies increasingly adopting microreactor technology to enhance process efficiency and product quality. In this sector, the ability to precisely control RTD enables manufacturers to optimize yield and selectivity in complex multiphase reactions, resulting in higher-value products and reduced waste generation.

Energy and petrochemical industries have also emerged as key adopters of microreactor technology. These sectors require microreactors with specific RTD profiles to maximize conversion efficiency in catalytic processes and ensure uniform heat distribution during highly exothermic reactions. The market demand in this segment is primarily focused on microreactors that can maintain narrow RTD under high-pressure and high-temperature conditions.

From a geographical perspective, North America and Europe currently dominate the microreactor market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization in countries like China, India, and South Korea, along with increasing investments in advanced manufacturing technologies.

Market analysis indicates a growing demand for customizable microreactor systems that allow end-users to modify channel geometries and operating parameters to achieve desired RTD profiles for specific applications. This trend is particularly evident in research institutions and specialty chemical manufacturers where process flexibility is highly valued.

Environmental regulations and sustainability initiatives are further driving market demand for microreactors with optimized RTD characteristics. These systems enable significant reductions in solvent usage, energy consumption, and waste generation compared to conventional batch reactors, aligning with global efforts to develop greener chemical processes.

Pharmaceutical manufacturing represents one of the largest application segments for microreactors, accounting for nearly 35% of the market share. The industry's shift toward continuous manufacturing processes has created substantial demand for microreactors with precisely controlled residence time distributions (RTDs). This demand is particularly strong for the production of active pharmaceutical ingredients (APIs) where reaction selectivity and product purity are directly influenced by RTD characteristics.

The fine chemicals sector constitutes another significant market segment, with companies increasingly adopting microreactor technology to enhance process efficiency and product quality. In this sector, the ability to precisely control RTD enables manufacturers to optimize yield and selectivity in complex multiphase reactions, resulting in higher-value products and reduced waste generation.

Energy and petrochemical industries have also emerged as key adopters of microreactor technology. These sectors require microreactors with specific RTD profiles to maximize conversion efficiency in catalytic processes and ensure uniform heat distribution during highly exothermic reactions. The market demand in this segment is primarily focused on microreactors that can maintain narrow RTD under high-pressure and high-temperature conditions.

From a geographical perspective, North America and Europe currently dominate the microreactor market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization in countries like China, India, and South Korea, along with increasing investments in advanced manufacturing technologies.

Market analysis indicates a growing demand for customizable microreactor systems that allow end-users to modify channel geometries and operating parameters to achieve desired RTD profiles for specific applications. This trend is particularly evident in research institutions and specialty chemical manufacturers where process flexibility is highly valued.

Environmental regulations and sustainability initiatives are further driving market demand for microreactors with optimized RTD characteristics. These systems enable significant reductions in solvent usage, energy consumption, and waste generation compared to conventional batch reactors, aligning with global efforts to develop greener chemical processes.

Current Challenges in RTD Characterization

Despite significant advancements in microreactor technology, Residence Time Distribution (RTD) characterization continues to face substantial challenges that impede both research progress and industrial implementation. The primary obstacle remains the microscale measurement limitations, where conventional RTD measurement techniques become inadequate due to the extremely small volumes and rapid flow rates in microreactors. Traditional sampling methods often disturb the flow patterns they aim to measure, creating a fundamental measurement paradox.

The miniaturization of sensing technologies presents another significant hurdle. Current sensor technologies struggle to achieve the necessary spatial resolution without interfering with the microflow dynamics. Even advanced optical methods like micro-PIV (Particle Image Velocimetry) and confocal microscopy face limitations in capturing the complete three-dimensional flow behavior in complex microreactor geometries.

Data interpretation challenges compound these measurement difficulties. The mathematical models used to interpret RTD data were largely developed for conventional reactors and often fail to account for the unique transport phenomena in microreactors, such as laminar flow dominance, surface tension effects, and wall interactions. This creates a significant gap between experimental measurements and theoretical understanding.

Standardization issues further complicate RTD characterization. The microreactor field lacks universally accepted protocols for RTD measurement and data reporting, making cross-study comparisons difficult and hindering knowledge accumulation. This absence of standardization also impedes the development of reliable simulation tools that could otherwise help predict RTD behavior.

The dynamic nature of microreactor operations introduces additional complexity. Many microreactor applications involve multiphase flows, temperature gradients, or reaction-induced property changes that create time-dependent RTD profiles. Current characterization methods struggle to capture these dynamic behaviors, particularly in real-time industrial settings.

Scale-up considerations present perhaps the most significant industrial challenge. RTD behavior often changes dramatically when scaling from laboratory microreactors to industrial implementations, yet methodologies for predicting these changes remain underdeveloped. This scaling uncertainty creates significant risk for industrial adoption of microreactor technology.

Finally, computational limitations persist despite advances in CFD (Computational Fluid Dynamics). The multi-scale nature of microreactor flows—where molecular diffusion, laminar flow patterns, and sometimes turbulent mixing all play important roles—creates computational models that are either too simplified to be accurate or too complex to be practically solvable with current computing resources.

The miniaturization of sensing technologies presents another significant hurdle. Current sensor technologies struggle to achieve the necessary spatial resolution without interfering with the microflow dynamics. Even advanced optical methods like micro-PIV (Particle Image Velocimetry) and confocal microscopy face limitations in capturing the complete three-dimensional flow behavior in complex microreactor geometries.

Data interpretation challenges compound these measurement difficulties. The mathematical models used to interpret RTD data were largely developed for conventional reactors and often fail to account for the unique transport phenomena in microreactors, such as laminar flow dominance, surface tension effects, and wall interactions. This creates a significant gap between experimental measurements and theoretical understanding.

Standardization issues further complicate RTD characterization. The microreactor field lacks universally accepted protocols for RTD measurement and data reporting, making cross-study comparisons difficult and hindering knowledge accumulation. This absence of standardization also impedes the development of reliable simulation tools that could otherwise help predict RTD behavior.

The dynamic nature of microreactor operations introduces additional complexity. Many microreactor applications involve multiphase flows, temperature gradients, or reaction-induced property changes that create time-dependent RTD profiles. Current characterization methods struggle to capture these dynamic behaviors, particularly in real-time industrial settings.

Scale-up considerations present perhaps the most significant industrial challenge. RTD behavior often changes dramatically when scaling from laboratory microreactors to industrial implementations, yet methodologies for predicting these changes remain underdeveloped. This scaling uncertainty creates significant risk for industrial adoption of microreactor technology.

Finally, computational limitations persist despite advances in CFD (Computational Fluid Dynamics). The multi-scale nature of microreactor flows—where molecular diffusion, laminar flow patterns, and sometimes turbulent mixing all play important roles—creates computational models that are either too simplified to be accurate or too complex to be practically solvable with current computing resources.

Established RTD Modeling Approaches

01 Microreactor design for optimizing residence time distribution

Specific design features in microreactors can be implemented to optimize residence time distribution (RTD), which is crucial for reaction control and product quality. These designs include specialized channel geometries, flow distributors, and mixing elements that ensure uniform flow patterns and minimize dead zones. By carefully engineering the microreactor architecture, more precise control over reaction kinetics and improved product consistency can be achieved.- Microreactor design for optimizing residence time distribution: Specific design features in microreactors can be implemented to optimize residence time distribution, including channel geometry, flow patterns, and mixing elements. These designs help achieve more uniform residence time distribution by minimizing dead zones and ensuring proper mixing. Optimized designs can include structured channels, baffles, and specialized flow distributors that enhance the overall efficiency of chemical reactions by providing consistent processing conditions.

- Measurement and monitoring techniques for residence time distribution: Various techniques are employed to measure and monitor residence time distribution in microreactors, including tracer methods, sensor integration, and real-time analysis systems. These measurement approaches allow for accurate characterization of flow behavior and residence time profiles within microreactor systems. Advanced monitoring techniques enable process optimization by providing data on flow patterns, mixing efficiency, and reaction progress throughout the microreactor channels.

- Control systems for residence time management: Automated control systems can be implemented to manage and adjust residence time distribution in microreactors. These systems utilize feedback mechanisms, flow controllers, and temperature regulators to maintain optimal residence time profiles. By continuously monitoring process parameters and making real-time adjustments, these control systems ensure consistent product quality and reaction efficiency despite variations in operating conditions or feedstock properties.

- Multi-phase flow management in microreactors: Specialized techniques for managing multi-phase flows (gas-liquid, liquid-liquid, or solid-liquid) in microreactors help control residence time distribution. These approaches include phase separators, specialized channel designs, and surface modifications that influence flow behavior. Effective management of multiple phases ensures uniform contact time between reactants and catalysts, leading to improved reaction selectivity and yield in complex chemical processes.

- Scale-up strategies maintaining residence time distribution: Methods for scaling up microreactor systems while preserving desired residence time distribution characteristics include numbering-up approaches, modular designs, and flow distribution systems. These strategies ensure that the advantages of controlled residence time distribution observed at laboratory scale are maintained during industrial implementation. Proper scale-up techniques address challenges related to flow distribution, pressure drop, and heat transfer to maintain reaction performance at larger production volumes.

02 Measurement and monitoring techniques for residence time distribution

Various techniques and apparatus have been developed to measure and monitor residence time distribution in microreactors. These include tracer methods, optical detection systems, and specialized sensors that can provide real-time data on flow behavior within the microchannels. Accurate measurement of RTD is essential for validating reactor performance, optimizing process parameters, and ensuring consistent product quality in continuous flow processes.Expand Specific Solutions03 Flow control strategies to manipulate residence time distribution

Advanced flow control strategies can be employed to manipulate residence time distribution in microreactors. These include the use of pulsed flows, pressure modulation, and variable flow rates to achieve desired RTD profiles. By implementing precise flow control mechanisms, operators can tailor the residence time to specific reaction requirements, enhance mixing efficiency, and improve overall process performance.Expand Specific Solutions04 Mathematical modeling and simulation of residence time distribution

Mathematical models and simulation techniques have been developed to predict and analyze residence time distribution in microreactors. These computational approaches help in understanding flow behavior, identifying potential issues, and optimizing reactor design without extensive experimental work. Models range from simple analytical expressions to complex computational fluid dynamics simulations that account for various factors affecting RTD in microchannels.Expand Specific Solutions05 Integration of residence time control in continuous manufacturing processes

Microreactors with controlled residence time distribution are increasingly being integrated into continuous manufacturing processes across various industries. This integration enables precise reaction control, improved product quality, and enhanced process efficiency. The ability to maintain consistent RTD profiles at different production scales facilitates smoother scale-up from laboratory to industrial production while maintaining product specifications.Expand Specific Solutions

Leading Research Groups and Industrial Players

The residence time distribution (RTD) in microreactors is shaped by a competitive landscape currently in the growth phase of industry development. The global microreactor technology market is expanding rapidly, with projections reaching $1-2 billion by 2025. Technical maturity varies significantly among key players, with established petrochemical companies like ExxonMobil Chemical and Sinopec focusing on industrial-scale implementation, while specialized firms such as Ehrfeld Mikrotechnik BTS and Anellotech drive innovation in reactor design. Research institutions including Michigan State University collaborate with corporations like IBM and Thermo Fisher Scientific to advance computational modeling and analytical techniques. The field is witnessing convergence between chemical engineering expertise from traditional players and microfluidic innovations from newer entrants, creating a dynamic ecosystem where RTD optimization represents a critical competitive advantage.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed proprietary microreactor technology focused on optimizing residence time distribution for petrochemical applications. Their approach centers on structured catalyst bed microreactors with precisely engineered flow distributors that ensure uniform residence time across reaction channels. The company's technology incorporates variable channel geometries that can be adjusted to achieve near-plug flow behavior or controlled dispersion based on reaction requirements. ExxonMobil's systems feature integrated heat management solutions that maintain isothermal conditions throughout the reaction zone, preventing temperature gradients that could distort residence time distributions. Their microreactors employ advanced inlet distribution systems with fractal-inspired manifold designs to ensure equal pressure drop across parallel channels, minimizing flow maldistribution that would otherwise broaden RTD profiles.

Strengths: Extensive experience with high-pressure, high-temperature reactions relevant to petrochemical processing; robust designs suitable for industrial deployment; sophisticated modeling capabilities for RTD prediction. Weaknesses: Technologies primarily optimized for hydrocarbon processing with less versatility for other chemical classes; significant capital investment requirements; complex maintenance procedures for some system components.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed microreactor technology with specific focus on residence time distribution optimization for petroleum refining and chemical synthesis applications. Their approach integrates microchannel arrays with precisely controlled dimensions and surface characteristics to manipulate fluid dynamics at the microscale. Sinopec's technology incorporates variable cross-section channels that create controlled acceleration and deceleration zones to narrow residence time distribution curves. Their systems feature specially designed static mixers positioned at strategic intervals to disrupt laminar flow patterns and minimize axial dispersion effects. The company has implemented advanced process control systems that continuously monitor and adjust flow parameters to maintain target residence time distributions despite variations in feedstock properties or operating conditions.

Strengths: Extensive experience with catalytic processes requiring precise residence time control; robust designs suitable for continuous operation in industrial environments; integration capabilities with existing refinery infrastructure. Weaknesses: Less flexibility for non-petroleum applications; higher energy consumption for certain mixing configurations; potential for fouling in long-duration operations with certain feedstocks.

Key Parameters Influencing Residence Time Distribution

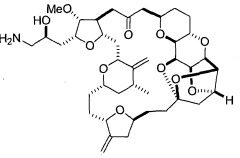

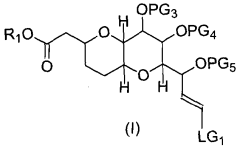

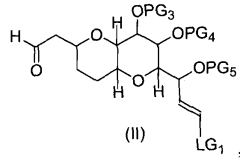

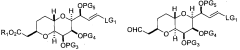

Microreactor process for halichondrin b analog synthesis

PatentWO2012147900A1

Innovation

- The use of microreactors to control reaction temperature and time, allowing for higher temperature processing and continuous flow synthesis of eribulin by reducing a carboalkoxyester to an aldehyde and coupling a C14-C35 fragment with a C1-C13 fragment, using aluminum hydride or borohydride reagents and organometallic bases.

Scale-up Considerations for Industrial Implementation

Scaling up microreactor technology from laboratory to industrial scale presents unique challenges that must be addressed systematically. The transition requires careful consideration of how residence time distribution (RTD) characteristics change with increased dimensions and throughput. Industrial implementation typically follows either a numbering-up approach (parallel operation of multiple small units) or scale-out strategy (increasing channel dimensions while maintaining key performance parameters).

When scaling microreactor systems, maintaining consistent RTD profiles becomes increasingly difficult as flow patterns may shift from laminar to transitional or turbulent regimes. This shift can significantly alter mixing efficiency, heat transfer capabilities, and ultimately reaction performance. Engineers must develop comprehensive computational fluid dynamics (CFD) models that accurately predict RTD behavior across different scales to ensure process reliability.

Material selection becomes more critical at industrial scale, as thermal expansion, chemical compatibility, and mechanical stability under prolonged operation must be thoroughly evaluated. Advanced manufacturing techniques such as 3D printing, precision machining, or microfabrication methods must be adapted for larger-scale production while maintaining the precise channel geometries that influence RTD characteristics.

Process control systems require substantial enhancement when scaling up microreactor networks. Real-time monitoring of flow distribution across parallel channels becomes essential to detect and correct flow maldistribution that could lead to RTD variations. Implementation of advanced sensors at strategic locations throughout the reactor network enables continuous verification of uniform residence time profiles.

Economic considerations play a decisive role in scale-up decisions. The capital investment for microreactor technology must be justified through improved yield, selectivity, safety, or operational flexibility compared to conventional batch processes. A detailed techno-economic analysis should quantify the relationship between RTD precision and process economics to determine the optimal scale-up strategy.

Regulatory compliance presents additional challenges, particularly for pharmaceutical and fine chemical applications. Validation protocols must demonstrate that the scaled-up system maintains the same RTD characteristics that were established during development phases. Documentation of flow patterns, mixing efficiency, and temperature uniformity across all channels becomes part of the qualification process required by regulatory authorities.

Integration with existing plant infrastructure requires careful planning to ensure compatibility with upstream and downstream processes. Buffer systems may be necessary to manage the continuous output from microreactor systems when connecting to batch-oriented downstream operations, with RTD considerations extending beyond the reactor itself to the entire process train.

When scaling microreactor systems, maintaining consistent RTD profiles becomes increasingly difficult as flow patterns may shift from laminar to transitional or turbulent regimes. This shift can significantly alter mixing efficiency, heat transfer capabilities, and ultimately reaction performance. Engineers must develop comprehensive computational fluid dynamics (CFD) models that accurately predict RTD behavior across different scales to ensure process reliability.

Material selection becomes more critical at industrial scale, as thermal expansion, chemical compatibility, and mechanical stability under prolonged operation must be thoroughly evaluated. Advanced manufacturing techniques such as 3D printing, precision machining, or microfabrication methods must be adapted for larger-scale production while maintaining the precise channel geometries that influence RTD characteristics.

Process control systems require substantial enhancement when scaling up microreactor networks. Real-time monitoring of flow distribution across parallel channels becomes essential to detect and correct flow maldistribution that could lead to RTD variations. Implementation of advanced sensors at strategic locations throughout the reactor network enables continuous verification of uniform residence time profiles.

Economic considerations play a decisive role in scale-up decisions. The capital investment for microreactor technology must be justified through improved yield, selectivity, safety, or operational flexibility compared to conventional batch processes. A detailed techno-economic analysis should quantify the relationship between RTD precision and process economics to determine the optimal scale-up strategy.

Regulatory compliance presents additional challenges, particularly for pharmaceutical and fine chemical applications. Validation protocols must demonstrate that the scaled-up system maintains the same RTD characteristics that were established during development phases. Documentation of flow patterns, mixing efficiency, and temperature uniformity across all channels becomes part of the qualification process required by regulatory authorities.

Integration with existing plant infrastructure requires careful planning to ensure compatibility with upstream and downstream processes. Buffer systems may be necessary to manage the continuous output from microreactor systems when connecting to batch-oriented downstream operations, with RTD considerations extending beyond the reactor itself to the entire process train.

Process Intensification Opportunities through RTD Control

Process intensification through Residence Time Distribution (RTD) control represents a significant frontier in microreactor technology advancement. By strategically manipulating RTD characteristics, engineers can unlock substantial improvements in reaction efficiency, selectivity, and yield. The narrow channels and precise flow patterns in microreactors create unique opportunities to tailor residence time profiles that would be impossible in conventional reactors.

One key intensification opportunity lies in the ability to minimize RTD spread, creating near plug-flow conditions that maximize conversion for consecutive reactions. This approach proves particularly valuable for pharmaceutical processes where side reactions must be minimized while maintaining high product purity. Companies implementing tight RTD control have reported yield improvements of 15-30% compared to batch processes.

The integration of static mixers and structured internals within microchannels offers another avenue for process intensification. These elements can be strategically positioned to create controlled micromixing zones that reshape the RTD curve, enabling precise reaction staging. This capability allows for sequential reaction steps to occur within a single continuous flow system, dramatically reducing equipment footprint and processing time.

Temperature control through RTD manipulation presents additional intensification opportunities. By designing microreactors with specific heat transfer characteristics that complement the desired residence time profile, researchers have demonstrated the ability to conduct highly exothermic reactions safely at intensified conditions. This synergistic approach enables operation at higher concentrations and temperatures than conventional systems would allow.

Advanced manufacturing techniques like 3D printing and micromachining are expanding the design space for RTD-optimized microreactors. These fabrication methods enable complex internal geometries that can create tailored flow patterns, including split-and-recombine structures that enhance mixing while maintaining narrow residence time distributions. Such precision engineering allows for process-specific reactor designs that maximize intensification benefits.

Real-time RTD monitoring and control systems represent the cutting edge of process intensification opportunities. By incorporating inline sensors and feedback control algorithms, next-generation microreactor systems can dynamically adjust flow conditions to maintain optimal RTD profiles despite variations in feed composition or catalyst activity. This adaptive approach ensures consistent performance even under changing process conditions.

One key intensification opportunity lies in the ability to minimize RTD spread, creating near plug-flow conditions that maximize conversion for consecutive reactions. This approach proves particularly valuable for pharmaceutical processes where side reactions must be minimized while maintaining high product purity. Companies implementing tight RTD control have reported yield improvements of 15-30% compared to batch processes.

The integration of static mixers and structured internals within microchannels offers another avenue for process intensification. These elements can be strategically positioned to create controlled micromixing zones that reshape the RTD curve, enabling precise reaction staging. This capability allows for sequential reaction steps to occur within a single continuous flow system, dramatically reducing equipment footprint and processing time.

Temperature control through RTD manipulation presents additional intensification opportunities. By designing microreactors with specific heat transfer characteristics that complement the desired residence time profile, researchers have demonstrated the ability to conduct highly exothermic reactions safely at intensified conditions. This synergistic approach enables operation at higher concentrations and temperatures than conventional systems would allow.

Advanced manufacturing techniques like 3D printing and micromachining are expanding the design space for RTD-optimized microreactors. These fabrication methods enable complex internal geometries that can create tailored flow patterns, including split-and-recombine structures that enhance mixing while maintaining narrow residence time distributions. Such precision engineering allows for process-specific reactor designs that maximize intensification benefits.

Real-time RTD monitoring and control systems represent the cutting edge of process intensification opportunities. By incorporating inline sensors and feedback control algorithms, next-generation microreactor systems can dynamically adjust flow conditions to maintain optimal RTD profiles despite variations in feed composition or catalyst activity. This adaptive approach ensures consistent performance even under changing process conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!