Analysis of Microreactors for Hydrogen Production and Storage

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Hydrogen Technology Background and Objectives

Hydrogen has emerged as a pivotal element in the global transition towards sustainable energy systems, offering a clean alternative to fossil fuels with zero carbon emissions at point of use. The concept of microreactors for hydrogen production represents a significant technological advancement that has evolved over the past two decades, moving from laboratory-scale experiments to commercially viable solutions. These compact systems leverage various chemical processes including steam methane reforming, water electrolysis, and thermochemical cycles to generate hydrogen efficiently at distributed locations.

The evolution of microreactor technology has been driven by the increasing demand for decentralized energy production systems and the need to overcome the logistical challenges associated with hydrogen transportation and storage. Early developments in the 2000s focused primarily on proof-of-concept designs, while the 2010s saw significant improvements in catalyst efficiency, reactor materials, and process integration that substantially enhanced production rates and energy efficiency.

Current technological trends indicate a convergence toward modular, scalable microreactor designs that can be deployed in various settings from industrial facilities to residential areas. These systems are increasingly incorporating renewable energy inputs, such as solar or wind power, to drive electrolysis processes, thereby creating truly sustainable hydrogen production pathways. Additionally, advances in materials science have enabled the development of more durable components capable of withstanding the harsh conditions associated with hydrogen production.

The primary objective of microreactor technology development is to establish economically viable, energy-efficient systems for distributed hydrogen production that can operate reliably with minimal maintenance requirements. This includes achieving cost parity with centralized production methods while offering the advantages of reduced transportation needs and enhanced energy security through localized production.

Technical goals in this field encompass several dimensions: increasing hydrogen production efficiency to exceed 75% conversion rates, reducing capital costs by at least 30% compared to conventional systems, enhancing operational flexibility to accommodate variable renewable energy inputs, and developing integrated storage solutions that address hydrogen's low volumetric energy density. Additionally, there is a strong focus on improving safety features and developing standardized designs that can facilitate regulatory approval and market adoption.

The trajectory of microreactor technology is closely aligned with broader hydrogen economy initiatives worldwide, including major investments in hydrogen infrastructure in Europe, Asia, and North America. As these technologies mature, they are expected to play a crucial role in enabling the transition to hydrogen as a mainstream energy carrier across multiple sectors including transportation, industrial processes, and grid-scale energy storage.

The evolution of microreactor technology has been driven by the increasing demand for decentralized energy production systems and the need to overcome the logistical challenges associated with hydrogen transportation and storage. Early developments in the 2000s focused primarily on proof-of-concept designs, while the 2010s saw significant improvements in catalyst efficiency, reactor materials, and process integration that substantially enhanced production rates and energy efficiency.

Current technological trends indicate a convergence toward modular, scalable microreactor designs that can be deployed in various settings from industrial facilities to residential areas. These systems are increasingly incorporating renewable energy inputs, such as solar or wind power, to drive electrolysis processes, thereby creating truly sustainable hydrogen production pathways. Additionally, advances in materials science have enabled the development of more durable components capable of withstanding the harsh conditions associated with hydrogen production.

The primary objective of microreactor technology development is to establish economically viable, energy-efficient systems for distributed hydrogen production that can operate reliably with minimal maintenance requirements. This includes achieving cost parity with centralized production methods while offering the advantages of reduced transportation needs and enhanced energy security through localized production.

Technical goals in this field encompass several dimensions: increasing hydrogen production efficiency to exceed 75% conversion rates, reducing capital costs by at least 30% compared to conventional systems, enhancing operational flexibility to accommodate variable renewable energy inputs, and developing integrated storage solutions that address hydrogen's low volumetric energy density. Additionally, there is a strong focus on improving safety features and developing standardized designs that can facilitate regulatory approval and market adoption.

The trajectory of microreactor technology is closely aligned with broader hydrogen economy initiatives worldwide, including major investments in hydrogen infrastructure in Europe, Asia, and North America. As these technologies mature, they are expected to play a crucial role in enabling the transition to hydrogen as a mainstream energy carrier across multiple sectors including transportation, industrial processes, and grid-scale energy storage.

Market Analysis for Hydrogen Production Microreactors

The global market for hydrogen production microreactors is experiencing significant growth, driven by increasing demand for clean energy solutions and the transition away from fossil fuels. Current market valuations indicate that the hydrogen production sector is expanding at a compound annual growth rate of 9.2%, with microreactor technologies representing one of the fastest-growing segments within this market. This growth is particularly pronounced in regions with strong renewable energy initiatives, including Europe, Japan, and parts of North America.

Market demand for hydrogen production microreactors stems from multiple sectors. The transportation industry represents the largest current market, with fuel cell vehicles requiring efficient hydrogen production and storage solutions. Industrial applications form the second-largest market segment, where hydrogen is utilized as both a feedstock and energy carrier. Additionally, the power generation sector is emerging as a significant market driver, with hydrogen increasingly viewed as a viable medium for energy storage and grid stabilization.

Consumer preferences are shifting toward decentralized energy production systems, which aligns perfectly with the distributed nature of microreactor technology. This trend is reinforced by governmental policies in many countries that incentivize localized clean energy production and storage solutions. Market research indicates that end-users prioritize efficiency, reliability, and scalability when evaluating hydrogen production technologies.

Regional market analysis reveals varying adoption rates and market maturity. Asia-Pacific leads in market size, with Japan and South Korea demonstrating the highest adoption rates for hydrogen technologies. Europe follows closely, driven by aggressive carbon reduction targets and substantial government investment in hydrogen infrastructure. The North American market shows strong growth potential, particularly in California and other states with progressive energy policies.

Price sensitivity analysis indicates that while initial capital costs remain a barrier to widespread adoption, the total cost of ownership is becoming increasingly competitive with conventional energy systems as production scales and technology advances. Market forecasts suggest that price parity with traditional hydrogen production methods could be achieved within 5-7 years in optimal regulatory environments.

Market barriers include infrastructure limitations, regulatory uncertainties, and competition from alternative energy storage technologies. However, these barriers are gradually diminishing as hydrogen ecosystems develop and supportive policies are implemented. The competitive landscape features both established energy companies pivoting toward hydrogen solutions and innovative startups focused specifically on microreactor technology, creating a dynamic market environment with significant opportunity for technological differentiation and market specialization.

Market demand for hydrogen production microreactors stems from multiple sectors. The transportation industry represents the largest current market, with fuel cell vehicles requiring efficient hydrogen production and storage solutions. Industrial applications form the second-largest market segment, where hydrogen is utilized as both a feedstock and energy carrier. Additionally, the power generation sector is emerging as a significant market driver, with hydrogen increasingly viewed as a viable medium for energy storage and grid stabilization.

Consumer preferences are shifting toward decentralized energy production systems, which aligns perfectly with the distributed nature of microreactor technology. This trend is reinforced by governmental policies in many countries that incentivize localized clean energy production and storage solutions. Market research indicates that end-users prioritize efficiency, reliability, and scalability when evaluating hydrogen production technologies.

Regional market analysis reveals varying adoption rates and market maturity. Asia-Pacific leads in market size, with Japan and South Korea demonstrating the highest adoption rates for hydrogen technologies. Europe follows closely, driven by aggressive carbon reduction targets and substantial government investment in hydrogen infrastructure. The North American market shows strong growth potential, particularly in California and other states with progressive energy policies.

Price sensitivity analysis indicates that while initial capital costs remain a barrier to widespread adoption, the total cost of ownership is becoming increasingly competitive with conventional energy systems as production scales and technology advances. Market forecasts suggest that price parity with traditional hydrogen production methods could be achieved within 5-7 years in optimal regulatory environments.

Market barriers include infrastructure limitations, regulatory uncertainties, and competition from alternative energy storage technologies. However, these barriers are gradually diminishing as hydrogen ecosystems develop and supportive policies are implemented. The competitive landscape features both established energy companies pivoting toward hydrogen solutions and innovative startups focused specifically on microreactor technology, creating a dynamic market environment with significant opportunity for technological differentiation and market specialization.

Current Challenges in Microreactor Hydrogen Systems

Despite significant advancements in microreactor technology for hydrogen systems, several critical challenges continue to impede widespread implementation and commercialization. Material durability represents a fundamental obstacle, as reactor components must withstand extreme operating conditions including high temperatures (often exceeding 800°C), pressure fluctuations, and exposure to highly reactive substances. Current materials frequently experience accelerated degradation, compromising system integrity and necessitating costly maintenance cycles.

Thermal management presents another significant challenge, particularly in steam reforming and water-gas shift reactions where precise temperature control is essential for optimal hydrogen production. The compact nature of microreactors creates steep thermal gradients that can lead to hotspots, catalyst deactivation, and structural stress. Existing heat exchange mechanisms often struggle to maintain uniform temperature profiles across the entire reaction zone.

Catalyst performance and longevity remain problematic in microreactor environments. While high surface-area-to-volume ratios theoretically enhance reaction efficiency, catalyst deactivation occurs more rapidly than in conventional systems due to intensified operating conditions. Coking, sintering, and poisoning mechanisms frequently reduce catalyst effectiveness within shorter timeframes, necessitating more frequent replacement or regeneration cycles.

Scale-up challenges persist when transitioning from laboratory prototypes to industrial implementation. The non-linear scaling behavior of fluid dynamics, heat transfer, and reaction kinetics complicates the design of larger systems. Manufacturers struggle to maintain the advantageous characteristics of microreactors when increasing production capacity, often encountering unexpected performance degradation.

Integration complexity represents a substantial hurdle for system designers. Microreactors must seamlessly connect with upstream feedstock preparation, downstream separation processes, and control systems. The miniaturized nature of components creates connection challenges, potential leak points, and monitoring difficulties that conventional systems avoid through their larger scale.

Economic viability remains questionable for many applications due to high manufacturing costs associated with precision fabrication techniques and specialized materials. While operational benefits exist, the capital expenditure often exceeds traditional hydrogen production methods, creating market entry barriers despite technical advantages.

Safety concerns persist regarding the handling of hydrogen at microscale. The combination of high pressure, elevated temperatures, and hydrogen's inherent flammability creates unique risk profiles that require specialized containment strategies and monitoring systems beyond those used in conventional hydrogen production facilities.

Thermal management presents another significant challenge, particularly in steam reforming and water-gas shift reactions where precise temperature control is essential for optimal hydrogen production. The compact nature of microreactors creates steep thermal gradients that can lead to hotspots, catalyst deactivation, and structural stress. Existing heat exchange mechanisms often struggle to maintain uniform temperature profiles across the entire reaction zone.

Catalyst performance and longevity remain problematic in microreactor environments. While high surface-area-to-volume ratios theoretically enhance reaction efficiency, catalyst deactivation occurs more rapidly than in conventional systems due to intensified operating conditions. Coking, sintering, and poisoning mechanisms frequently reduce catalyst effectiveness within shorter timeframes, necessitating more frequent replacement or regeneration cycles.

Scale-up challenges persist when transitioning from laboratory prototypes to industrial implementation. The non-linear scaling behavior of fluid dynamics, heat transfer, and reaction kinetics complicates the design of larger systems. Manufacturers struggle to maintain the advantageous characteristics of microreactors when increasing production capacity, often encountering unexpected performance degradation.

Integration complexity represents a substantial hurdle for system designers. Microreactors must seamlessly connect with upstream feedstock preparation, downstream separation processes, and control systems. The miniaturized nature of components creates connection challenges, potential leak points, and monitoring difficulties that conventional systems avoid through their larger scale.

Economic viability remains questionable for many applications due to high manufacturing costs associated with precision fabrication techniques and specialized materials. While operational benefits exist, the capital expenditure often exceeds traditional hydrogen production methods, creating market entry barriers despite technical advantages.

Safety concerns persist regarding the handling of hydrogen at microscale. The combination of high pressure, elevated temperatures, and hydrogen's inherent flammability creates unique risk profiles that require specialized containment strategies and monitoring systems beyond those used in conventional hydrogen production facilities.

Current Microreactor Solutions for H2 Production

01 Microreactor design and fabrication techniques

Various methods and materials are used for manufacturing microreactors, including microfabrication techniques, etching processes, and advanced materials. These techniques enable the creation of precise microchannels, mixing zones, and reaction chambers necessary for efficient microreactor operation. The design considerations include channel geometry, surface properties, and integration of sensors or catalysts to enhance reaction control and monitoring capabilities.- Microreactor design and fabrication techniques: Various methods and materials are used in the design and fabrication of microreactors, including microfabrication techniques, specialized materials, and integration of components. These approaches enable the creation of microreactors with precise channel geometries, controlled flow patterns, and optimized reaction conditions. Advanced fabrication methods allow for the incorporation of catalysts, sensors, and other functional elements directly into the microreactor structure.

- Storage and handling systems for microreactors: Specialized storage and handling systems are developed for microreactors to maintain their integrity, prevent contamination, and ensure proper functioning. These systems include protective enclosures, temperature-controlled environments, and automated handling mechanisms. Proper storage conditions are essential for preserving the microreactor's performance characteristics and extending its operational lifespan, particularly for applications requiring sterile or controlled environments.

- Continuous flow processes in microreactors: Continuous flow processes implemented in microreactors offer advantages over batch processing, including improved reaction control, enhanced heat and mass transfer, and increased productivity. These systems enable precise residence time control, efficient mixing, and rapid scale-up through numbering-up approaches. Continuous flow microreactors are particularly valuable for reactions requiring strict temperature control, handling hazardous materials, or producing high-value chemicals.

- Integration of monitoring and control systems: Advanced monitoring and control systems are integrated into microreactors to enable real-time process monitoring, automated operation, and quality control. These systems incorporate sensors for temperature, pressure, flow rate, and chemical composition, along with feedback control mechanisms. The integration of monitoring and control systems enhances process reliability, product consistency, and operational safety while reducing the need for manual intervention.

- Scale-up and industrial implementation: Methods for scaling up microreactor technology from laboratory to industrial scale involve parallel operation of multiple units, modular designs, and integrated production systems. These approaches address challenges related to throughput, reliability, and economic viability while maintaining the inherent advantages of microreactor technology. Industrial implementation strategies focus on optimizing production efficiency, minimizing downtime, and ensuring consistent product quality across multiple microreactor units.

02 Storage and preservation of microreactors

Specialized storage solutions are developed for microreactors to maintain their integrity and functionality during periods of non-use. These include protective coatings, controlled atmosphere storage systems, and packaging technologies that prevent contamination or degradation. Proper storage conditions are essential to preserve catalyst activity, prevent channel blockage, and ensure consistent performance when the microreactors are returned to service.Expand Specific Solutions03 Continuous flow production using microreactors

Microreactors enable continuous flow production processes that offer advantages over batch processing, including better heat transfer, improved mixing, and more precise reaction control. These systems can be scaled through numbering-up approaches rather than traditional scale-up, maintaining the efficiency benefits of microreaction technology. Continuous flow microreactors allow for consistent product quality, reduced waste, and enhanced safety for hazardous reactions.Expand Specific Solutions04 Integration of monitoring and control systems

Advanced monitoring and control systems are integrated into microreactor setups to enable real-time process optimization. These include sensors for temperature, pressure, flow rate, and reaction progress monitoring, coupled with automated control systems. The integration of these technologies allows for precise reaction parameter adjustment, fault detection, and data collection for process improvement and quality assurance.Expand Specific Solutions05 Specialized microreactor applications

Microreactors are designed for specific applications across various industries, including pharmaceuticals, fine chemicals, and energy production. These specialized designs incorporate features tailored to particular reaction requirements, such as catalytic surfaces, specific temperature control mechanisms, or materials resistant to corrosive reagents. Application-specific microreactors optimize performance for their intended use cases while addressing unique challenges in different production environments.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The hydrogen production and storage microreactor market is in an early growth phase, characterized by significant R&D activity but limited commercial deployment. The global market is projected to expand rapidly as hydrogen gains importance in clean energy transitions, with estimates suggesting a CAGR of 15-20% through 2030. Technologically, the field shows varying maturity levels across different approaches. Leading players include established industrial giants like Air Products & Chemicals and LG Chem providing commercial solutions, while companies like Hydrogenious LOHC Technologies and GRZ Technologies are advancing innovative storage methods. Research institutions such as Fraunhofer-Gesellschaft, Zhejiang University, and California Institute of Technology are driving fundamental breakthroughs. The competitive landscape features collaboration between academic institutions and industry partners to overcome efficiency, cost, and scalability challenges.

Nanologix, Inc.

Technical Solution: Nanologix has pioneered microreactor technology for biological hydrogen production utilizing specialized microorganisms in controlled microenvironments. Their innovative approach combines biofilm-based hydrogen production with microfluidic reactor designs that optimize nutrient delivery and hydrogen collection. The company's microreactors feature nanoporous membranes that separate the biological production zone from hydrogen collection channels, allowing for continuous hydrogen harvesting while maintaining optimal conditions for the microorganisms. Nanologix's proprietary biocatalyst formulations achieve hydrogen production rates of up to 11.2 mmol H₂/L·h under optimized conditions, representing a significant improvement over conventional bioreactors. Their microreactor systems incorporate real-time monitoring of key parameters including pH, temperature, and nutrient levels, with automated feedback control systems maintaining optimal production conditions. The technology operates at ambient temperatures and pressures, utilizing renewable feedstocks such as organic waste streams or specifically designed growth media. Nanologix has demonstrated continuous hydrogen production for periods exceeding 2000 hours with stable output in their advanced microreactor systems.

Strengths: Renewable and sustainable hydrogen production pathway; ambient operating conditions requiring minimal energy input; potential for carbon-negative hydrogen production when utilizing waste feedstocks; highly selective hydrogen production with minimal byproducts. Weaknesses: Lower production rates compared to thermochemical methods; sensitivity to contamination requiring sterile operating conditions; complexity in maintaining optimal biological conditions; challenges in scaling to industrial production volumes.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced microreactor technology for hydrogen production and storage, focusing on process intensification through miniaturized reaction systems. Their microreactor designs incorporate catalytic membrane reactors that combine reaction and separation in a single unit, significantly enhancing hydrogen yield and purity. The company's microreactor systems utilize structured catalysts with precise control over reaction parameters, enabling operation at higher temperatures and pressures than conventional systems. Air Products has pioneered the integration of microreactor technology with pressure swing adsorption (PSA) systems for immediate hydrogen purification. Their systems achieve conversion efficiencies exceeding 80% with reduced energy consumption compared to traditional steam methane reforming processes. The company has also developed modular microreactor arrays that can be scaled according to production requirements, making the technology suitable for both distributed and centralized hydrogen production scenarios.

Strengths: Superior process control with enhanced heat and mass transfer capabilities; modular design allowing flexible scaling; reduced footprint compared to conventional reformers; improved safety through smaller inventories of hazardous materials. Weaknesses: Higher capital costs per unit of production capacity; potential challenges with catalyst deactivation in compact systems; complexity in manufacturing precision components for microreactor assemblies.

Critical Patents and Technical Literature Review

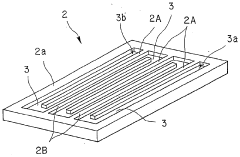

Microreactor and method for producing hydrogen by using the same

PatentInactiveJP2007237044A

Innovation

- A microreactor design where the catalyst is insertable and removable through an opening in the channel structure, allowing for simplified catalyst replacement without disassembling the flow path, and a temperature control section for optimizing reaction conditions.

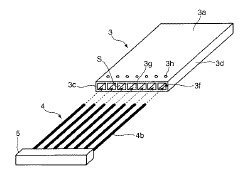

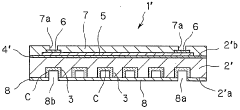

Microreactor and method of producing the same

PatentWO2004069738A1

Innovation

- A microreactor design featuring a metal substrate with fine grooves, a heating element supported by an insulating film, and a catalyst supported within the grooves, allowing for efficient heat transfer and easy manufacturing through etching processes, with a cover member incorporating a raw material inlet and gas outlet to enhance reaction efficiency and reduce costs.

Safety and Regulatory Framework for H2 Microreactors

The regulatory landscape for hydrogen microreactors presents a complex framework that varies significantly across jurisdictions. Current safety regulations for hydrogen production and storage systems were primarily designed for large-scale industrial facilities, creating challenges for the emerging microreactor sector. These smaller-scale technologies often operate under different risk profiles and technical parameters, necessitating adapted regulatory approaches.

In the United States, the Department of Energy (DOE) and the Nuclear Regulatory Commission (NRC) have begun developing specific guidelines for hydrogen microreactors, focusing on containment requirements, pressure management, and catalyst safety protocols. The European Union, through its Hydrogen Strategy, has established the European Clean Hydrogen Alliance which is working to harmonize safety standards across member states, with particular emphasis on residential and commercial applications of microreactor technology.

Risk assessment methodologies for hydrogen microreactors must address several critical safety concerns. Hydrogen's wide flammability range (4-75% concentration in air) and low ignition energy (0.02 mJ) create unique hazard profiles compared to conventional fuels. Microreactor designs must incorporate multiple redundant safety systems, including advanced leak detection, automatic shutdown mechanisms, and pressure relief systems calibrated for small-scale operations.

Material compatibility represents another significant regulatory challenge. Hydrogen embrittlement can compromise structural integrity in certain metals, requiring specific material certification processes. Current standards from organizations like ASME and ISO provide guidance on material selection, but specialized protocols for microreactor applications remain under development.

Certification pathways for hydrogen microreactors typically involve a multi-stage process including design review, prototype testing, and operational validation. The International Electrotechnical Commission (IEC) has published standards (IEC 62282 series) addressing fuel cell technologies that partially cover microreactor applications, though regulatory gaps remain for newer production methodologies such as photocatalytic and plasmonic systems.

Local permitting requirements add another layer of complexity, with significant variation between urban and rural deployment scenarios. Many jurisdictions are developing expedited permitting processes for small-scale hydrogen systems to facilitate market adoption while maintaining safety standards. These frameworks typically incorporate setback requirements, ventilation specifications, and emergency response protocols tailored to the unique characteristics of hydrogen microreactors.

In the United States, the Department of Energy (DOE) and the Nuclear Regulatory Commission (NRC) have begun developing specific guidelines for hydrogen microreactors, focusing on containment requirements, pressure management, and catalyst safety protocols. The European Union, through its Hydrogen Strategy, has established the European Clean Hydrogen Alliance which is working to harmonize safety standards across member states, with particular emphasis on residential and commercial applications of microreactor technology.

Risk assessment methodologies for hydrogen microreactors must address several critical safety concerns. Hydrogen's wide flammability range (4-75% concentration in air) and low ignition energy (0.02 mJ) create unique hazard profiles compared to conventional fuels. Microreactor designs must incorporate multiple redundant safety systems, including advanced leak detection, automatic shutdown mechanisms, and pressure relief systems calibrated for small-scale operations.

Material compatibility represents another significant regulatory challenge. Hydrogen embrittlement can compromise structural integrity in certain metals, requiring specific material certification processes. Current standards from organizations like ASME and ISO provide guidance on material selection, but specialized protocols for microreactor applications remain under development.

Certification pathways for hydrogen microreactors typically involve a multi-stage process including design review, prototype testing, and operational validation. The International Electrotechnical Commission (IEC) has published standards (IEC 62282 series) addressing fuel cell technologies that partially cover microreactor applications, though regulatory gaps remain for newer production methodologies such as photocatalytic and plasmonic systems.

Local permitting requirements add another layer of complexity, with significant variation between urban and rural deployment scenarios. Many jurisdictions are developing expedited permitting processes for small-scale hydrogen systems to facilitate market adoption while maintaining safety standards. These frameworks typically incorporate setback requirements, ventilation specifications, and emergency response protocols tailored to the unique characteristics of hydrogen microreactors.

Scalability and Integration with Existing Infrastructure

The scalability of microreactor technology for hydrogen production represents a critical factor in determining its commercial viability and widespread adoption. Current microreactor systems demonstrate exceptional performance at laboratory and pilot scales, but significant engineering challenges emerge when considering industrial-scale implementation. The modular nature of microreactors offers a promising pathway to scalability through a "numbering-up" approach rather than traditional "scaling-up," allowing for incremental capacity expansion while maintaining the inherent advantages of microreactor design.

Integration with existing hydrogen infrastructure presents both opportunities and challenges. Microreactors must interface with current hydrogen compression, storage, and distribution systems, which were primarily designed for centralized production models. The distributed production capability of microreactors necessitates rethinking infrastructure connections, particularly regarding pressure management, purification requirements, and safety protocols. Standardization of connection interfaces will be essential for seamless integration across various deployment scenarios.

From a physical footprint perspective, microreactor systems offer substantial advantages over conventional hydrogen production facilities. Their compact design enables deployment in space-constrained environments, including urban settings, industrial parks, and transportation hubs. This distributed production model could significantly reduce the need for long-distance hydrogen transport, addressing one of the major cost and efficiency barriers in the hydrogen economy.

Grid integration considerations vary depending on the energy source powering the microreactors. For electrically-driven systems, smart grid compatibility and load management capabilities will be crucial for optimizing operation during periods of renewable energy abundance. For thermal energy-driven microreactors, waste heat recovery and integration with district heating systems present opportunities for improving overall system efficiency.

Regulatory frameworks and permitting processes currently pose significant barriers to rapid deployment, as most existing regulations were developed for conventional large-scale hydrogen production facilities. Streamlined approval pathways specifically designed for microreactor technology will be necessary to enable widespread implementation. Several jurisdictions are beginning to develop specialized regulatory approaches for distributed hydrogen production, which may serve as models for broader adoption.

Cost scaling analysis indicates that microreactor systems may achieve economic viability at smaller production volumes compared to conventional technologies, potentially enabling hydrogen production in markets previously considered uneconomical. However, manufacturing economies of scale for microreactor components remain a critical factor in achieving cost competitiveness with established centralized production methods.

Integration with existing hydrogen infrastructure presents both opportunities and challenges. Microreactors must interface with current hydrogen compression, storage, and distribution systems, which were primarily designed for centralized production models. The distributed production capability of microreactors necessitates rethinking infrastructure connections, particularly regarding pressure management, purification requirements, and safety protocols. Standardization of connection interfaces will be essential for seamless integration across various deployment scenarios.

From a physical footprint perspective, microreactor systems offer substantial advantages over conventional hydrogen production facilities. Their compact design enables deployment in space-constrained environments, including urban settings, industrial parks, and transportation hubs. This distributed production model could significantly reduce the need for long-distance hydrogen transport, addressing one of the major cost and efficiency barriers in the hydrogen economy.

Grid integration considerations vary depending on the energy source powering the microreactors. For electrically-driven systems, smart grid compatibility and load management capabilities will be crucial for optimizing operation during periods of renewable energy abundance. For thermal energy-driven microreactors, waste heat recovery and integration with district heating systems present opportunities for improving overall system efficiency.

Regulatory frameworks and permitting processes currently pose significant barriers to rapid deployment, as most existing regulations were developed for conventional large-scale hydrogen production facilities. Streamlined approval pathways specifically designed for microreactor technology will be necessary to enable widespread implementation. Several jurisdictions are beginning to develop specialized regulatory approaches for distributed hydrogen production, which may serve as models for broader adoption.

Cost scaling analysis indicates that microreactor systems may achieve economic viability at smaller production volumes compared to conventional technologies, potentially enabling hydrogen production in markets previously considered uneconomical. However, manufacturing economies of scale for microreactor components remain a critical factor in achieving cost competitiveness with established centralized production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!