Microreactors with 3D Printing Fabrication Methods and Design Flexibility

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Microreactor Technology Evolution

The evolution of 3D printing microreactor technology represents a significant paradigm shift in chemical engineering and process intensification. The journey began in the early 2000s with rudimentary attempts to fabricate simple microfluidic channels using stereolithography (SLA) techniques. These initial efforts were primarily focused on proof-of-concept demonstrations with limited practical applications due to material constraints and resolution limitations.

By 2010, the field witnessed substantial progress with the introduction of multi-material printing capabilities, enabling the integration of catalytic materials directly into reactor structures. This period marked the transition from purely academic research to early industrial applications, particularly in pharmaceutical research for rapid prototyping of reaction pathways.

The years 2013-2016 saw a critical technological leap with the development of high-resolution printing techniques such as two-photon polymerization and micro-stereolithography, which enabled feature sizes below 100 microns. This advancement allowed for the creation of intricate internal geometries that significantly enhanced mixing efficiency and heat transfer capabilities within microreactors.

Between 2017 and 2019, material science innovations expanded the range of printable materials to include chemically resistant polymers, ceramics, and metal alloys. This diversification addressed previous limitations regarding chemical compatibility, temperature resistance, and pressure handling capabilities, broadening the application scope of 3D printed microreactors to more demanding chemical processes.

The period from 2020 to present has been characterized by the convergence of 3D printing with computational fluid dynamics (CFD) and artificial intelligence. This integration has enabled topology optimization of reactor designs, leading to unprecedented performance improvements in terms of reaction efficiency, selectivity, and yield. Advanced software tools now allow for the simulation and optimization of complex flow patterns before physical fabrication.

Most recently, hybrid manufacturing approaches combining multiple 3D printing technologies (such as material extrusion with inkjet printing) have emerged, enabling multi-functional microreactors with integrated sensing, heating, and catalytic elements. These systems represent a significant step toward fully autonomous chemical processing units.

The current technological frontier involves the development of 4D printing techniques, where printed microreactors can dynamically change their configuration in response to external stimuli or reaction conditions, offering unprecedented control over reaction parameters and pathways. This capability promises to revolutionize on-demand manufacturing of pharmaceuticals and fine chemicals.

By 2010, the field witnessed substantial progress with the introduction of multi-material printing capabilities, enabling the integration of catalytic materials directly into reactor structures. This period marked the transition from purely academic research to early industrial applications, particularly in pharmaceutical research for rapid prototyping of reaction pathways.

The years 2013-2016 saw a critical technological leap with the development of high-resolution printing techniques such as two-photon polymerization and micro-stereolithography, which enabled feature sizes below 100 microns. This advancement allowed for the creation of intricate internal geometries that significantly enhanced mixing efficiency and heat transfer capabilities within microreactors.

Between 2017 and 2019, material science innovations expanded the range of printable materials to include chemically resistant polymers, ceramics, and metal alloys. This diversification addressed previous limitations regarding chemical compatibility, temperature resistance, and pressure handling capabilities, broadening the application scope of 3D printed microreactors to more demanding chemical processes.

The period from 2020 to present has been characterized by the convergence of 3D printing with computational fluid dynamics (CFD) and artificial intelligence. This integration has enabled topology optimization of reactor designs, leading to unprecedented performance improvements in terms of reaction efficiency, selectivity, and yield. Advanced software tools now allow for the simulation and optimization of complex flow patterns before physical fabrication.

Most recently, hybrid manufacturing approaches combining multiple 3D printing technologies (such as material extrusion with inkjet printing) have emerged, enabling multi-functional microreactors with integrated sensing, heating, and catalytic elements. These systems represent a significant step toward fully autonomous chemical processing units.

The current technological frontier involves the development of 4D printing techniques, where printed microreactors can dynamically change their configuration in response to external stimuli or reaction conditions, offering unprecedented control over reaction parameters and pathways. This capability promises to revolutionize on-demand manufacturing of pharmaceuticals and fine chemicals.

Market Applications and Demand Analysis

The market for microreactors fabricated using 3D printing technologies has witnessed substantial growth in recent years, driven by increasing demand across multiple industries seeking more efficient, customizable, and sustainable chemical processing solutions. The global microreactor technology market is projected to reach $1.2 billion by 2027, with a compound annual growth rate of 9.8% from 2022 to 2027, according to recent market research reports.

Pharmaceutical and fine chemical industries represent the largest market segments, collectively accounting for approximately 40% of the total market share. These sectors particularly value the enhanced reaction control, reduced waste generation, and improved safety profiles offered by 3D-printed microreactors. The ability to rapidly prototype and customize reactor designs for specific chemical processes has significantly reduced drug development timelines and costs, creating strong market pull from major pharmaceutical companies.

The energy sector presents another rapidly expanding application area, particularly in the development of decentralized energy systems and alternative fuel production. Microreactors with tailored catalytic surfaces fabricated through advanced 3D printing methods have demonstrated superior performance in hydrogen generation, CO2 conversion, and synthetic fuel production processes. This market segment is expected to grow at 12.5% annually through 2027, outpacing the overall market growth rate.

Academic and research institutions constitute a significant customer base, representing approximately 25% of current market demand. The design flexibility offered by 3D printing enables researchers to rapidly test novel reactor configurations without the constraints of traditional manufacturing methods. This has accelerated innovation in fields ranging from biomedicine to materials science.

Geographically, North America and Europe currently dominate the market with combined market share exceeding 65%. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.2% annually, driven by expanding chemical manufacturing capabilities in China, Japan, and South Korea, coupled with increasing R&D investments in microreactor technologies.

Key market drivers include increasing pressure for process intensification, growing emphasis on sustainable manufacturing practices, and the push toward modular and decentralized production systems. The ability of 3D-printed microreactors to enable continuous flow chemistry while reducing energy consumption, waste generation, and physical footprint aligns perfectly with these industry trends.

Market barriers include concerns about material compatibility for certain aggressive chemical processes, scaling challenges for high-volume production, and regulatory uncertainties regarding validation and qualification of 3D-printed components in regulated industries. Despite these challenges, the unique advantages of design flexibility, rapid prototyping capabilities, and enhanced performance characteristics continue to drive strong market demand across multiple sectors.

Pharmaceutical and fine chemical industries represent the largest market segments, collectively accounting for approximately 40% of the total market share. These sectors particularly value the enhanced reaction control, reduced waste generation, and improved safety profiles offered by 3D-printed microreactors. The ability to rapidly prototype and customize reactor designs for specific chemical processes has significantly reduced drug development timelines and costs, creating strong market pull from major pharmaceutical companies.

The energy sector presents another rapidly expanding application area, particularly in the development of decentralized energy systems and alternative fuel production. Microreactors with tailored catalytic surfaces fabricated through advanced 3D printing methods have demonstrated superior performance in hydrogen generation, CO2 conversion, and synthetic fuel production processes. This market segment is expected to grow at 12.5% annually through 2027, outpacing the overall market growth rate.

Academic and research institutions constitute a significant customer base, representing approximately 25% of current market demand. The design flexibility offered by 3D printing enables researchers to rapidly test novel reactor configurations without the constraints of traditional manufacturing methods. This has accelerated innovation in fields ranging from biomedicine to materials science.

Geographically, North America and Europe currently dominate the market with combined market share exceeding 65%. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.2% annually, driven by expanding chemical manufacturing capabilities in China, Japan, and South Korea, coupled with increasing R&D investments in microreactor technologies.

Key market drivers include increasing pressure for process intensification, growing emphasis on sustainable manufacturing practices, and the push toward modular and decentralized production systems. The ability of 3D-printed microreactors to enable continuous flow chemistry while reducing energy consumption, waste generation, and physical footprint aligns perfectly with these industry trends.

Market barriers include concerns about material compatibility for certain aggressive chemical processes, scaling challenges for high-volume production, and regulatory uncertainties regarding validation and qualification of 3D-printed components in regulated industries. Despite these challenges, the unique advantages of design flexibility, rapid prototyping capabilities, and enhanced performance characteristics continue to drive strong market demand across multiple sectors.

Technical Challenges in 3D Printed Microreactors

Despite significant advancements in 3D printing technologies for microreactor fabrication, several technical challenges persist that limit their widespread industrial adoption. Material compatibility represents a primary concern, as many conventional 3D printing materials lack the chemical resistance necessary for handling aggressive reagents and solvents commonly used in chemical reactions. Additionally, these materials often demonstrate insufficient thermal stability to withstand the temperature ranges required for various chemical processes, limiting application scope.

Resolution limitations of current 3D printing technologies present another significant obstacle. While microreactors demand precise internal channel geometries with dimensions in the sub-millimeter range, many accessible 3D printing methods struggle to consistently achieve the necessary resolution. This limitation becomes particularly problematic when fabricating complex internal structures with high aspect ratios or intricate mixing elements essential for efficient reaction control.

Surface quality issues further complicate microreactor performance. The layer-by-layer deposition inherent to most 3D printing processes creates surface roughness that can cause irregular flow patterns, promote fouling, and catalyze unwanted side reactions. Post-processing techniques to smooth these surfaces often prove challenging due to the enclosed nature of microreactor channels, making internal surface treatment particularly difficult.

Long-term reliability and durability concerns also plague 3D printed microreactors. Material degradation over time, especially when exposed to reaction conditions, can lead to performance deterioration, leaching of printing materials into reaction media, and potential structural failures. The absence of standardized testing protocols for evaluating the longevity of these devices under various operating conditions further complicates reliability assessment.

Scaling challenges represent another significant hurdle. While 3D printing excels at producing customized, one-off prototypes, transitioning to high-volume production while maintaining consistent quality remains problematic. Current printing speeds and build volumes limit production throughput, while quality variations between printed batches introduce reproducibility concerns that are unacceptable in regulated industries.

Integration difficulties with existing analytical and process control systems also impede adoption. Many 3D printed microreactors lack standardized connections or interfaces, complicating their incorporation into broader process systems. Additionally, embedding sensors or monitoring capabilities within the printed structures presents significant design and fabrication challenges that have yet to be fully resolved.

Regulatory uncertainties further complicate commercial deployment, particularly in pharmaceutical and biomedical applications. The novelty of 3D printed microreactors means that regulatory frameworks for their validation and qualification remain underdeveloped, creating barriers to implementation in highly regulated industries where process validation is essential.

Resolution limitations of current 3D printing technologies present another significant obstacle. While microreactors demand precise internal channel geometries with dimensions in the sub-millimeter range, many accessible 3D printing methods struggle to consistently achieve the necessary resolution. This limitation becomes particularly problematic when fabricating complex internal structures with high aspect ratios or intricate mixing elements essential for efficient reaction control.

Surface quality issues further complicate microreactor performance. The layer-by-layer deposition inherent to most 3D printing processes creates surface roughness that can cause irregular flow patterns, promote fouling, and catalyze unwanted side reactions. Post-processing techniques to smooth these surfaces often prove challenging due to the enclosed nature of microreactor channels, making internal surface treatment particularly difficult.

Long-term reliability and durability concerns also plague 3D printed microreactors. Material degradation over time, especially when exposed to reaction conditions, can lead to performance deterioration, leaching of printing materials into reaction media, and potential structural failures. The absence of standardized testing protocols for evaluating the longevity of these devices under various operating conditions further complicates reliability assessment.

Scaling challenges represent another significant hurdle. While 3D printing excels at producing customized, one-off prototypes, transitioning to high-volume production while maintaining consistent quality remains problematic. Current printing speeds and build volumes limit production throughput, while quality variations between printed batches introduce reproducibility concerns that are unacceptable in regulated industries.

Integration difficulties with existing analytical and process control systems also impede adoption. Many 3D printed microreactors lack standardized connections or interfaces, complicating their incorporation into broader process systems. Additionally, embedding sensors or monitoring capabilities within the printed structures presents significant design and fabrication challenges that have yet to be fully resolved.

Regulatory uncertainties further complicate commercial deployment, particularly in pharmaceutical and biomedical applications. The novelty of 3D printed microreactors means that regulatory frameworks for their validation and qualification remain underdeveloped, creating barriers to implementation in highly regulated industries where process validation is essential.

Current Fabrication Methods and Materials

01 Modular design for customizable configurations

Microreactors with modular designs allow for flexible configurations to meet various process requirements. These systems feature interchangeable components that can be assembled in different arrangements, enabling adaptation to different reaction conditions, throughputs, and chemistries. The modular approach facilitates scaling, maintenance, and process optimization by allowing individual components to be modified or replaced without redesigning the entire system.- Modular design for microreactors: Microreactors can be designed with modular components that allow for easy reconfiguration and adaptation to different chemical processes. This modular approach enables researchers and engineers to customize reaction conditions, scale production, and modify reactor configurations without redesigning the entire system. The flexibility in assembly and disassembly of components facilitates maintenance, cleaning, and optimization of reaction parameters for various applications.

- Automated control systems for microreactors: Integration of automated control systems in microreactors enhances design flexibility by allowing precise regulation of reaction parameters. These systems enable real-time monitoring and adjustment of flow rates, temperature, pressure, and mixing conditions. Advanced control algorithms can optimize reaction conditions automatically, adapt to changing requirements, and implement complex reaction sequences. This automation capability makes microreactors adaptable to various chemical processes without physical redesign.

- Scalable microreactor architectures: Scalable microreactor designs allow for flexible production capacity by enabling parallel operation of multiple reactor units. This numbering-up approach maintains the advantages of microreactors while increasing throughput. The architecture permits adding or removing reactor units as needed, facilitating both laboratory-scale experimentation and industrial-scale production. Scalable designs can incorporate interconnected flow paths that can be reconfigured to accommodate different reaction sequences or processing requirements.

- Multi-functional microreactor channels: Microreactors can be designed with channels that serve multiple functions, enhancing flexibility in chemical processing. These channels can incorporate various features such as mixing zones, heat exchange surfaces, catalyst supports, and separation membranes. The multi-functionality allows a single microreactor to perform sequential operations that would traditionally require separate equipment. Channel geometries can be optimized for specific reactions or modified to accommodate different reaction mechanisms and kinetics.

- Materials and fabrication techniques for flexible microreactor design: Advanced materials and fabrication techniques enable greater flexibility in microreactor design. Materials such as polymers, ceramics, metals, and composites offer different properties suitable for various chemical environments. 3D printing, micromachining, and lithography techniques allow for rapid prototyping and customization of complex microreactor geometries. These manufacturing approaches facilitate the creation of specialized features like embedded sensors, catalytic surfaces, and variable channel dimensions that can be tailored to specific reaction requirements.

02 Integration of monitoring and control systems

Advanced microreactors incorporate integrated monitoring and control systems that enhance operational flexibility. These systems include sensors, automated feedback mechanisms, and real-time analytics that allow precise control over reaction parameters. The integration enables dynamic adjustment of process conditions, automated response to deviations, and collection of comprehensive data for process optimization, making microreactors adaptable to changing requirements and suitable for complex reaction sequences.Expand Specific Solutions03 Scalable microreactor architectures

Scalable microreactor architectures provide flexibility in production capacity while maintaining reaction efficiency. These designs allow for parallel operation of multiple reactor units, numbering-up instead of traditional scale-up, which preserves the advantageous characteristics of microscale processing. The scalable approach enables gradual capacity increases, efficient use of space, and the ability to adjust production volumes according to demand without significant redesign or capital investment.Expand Specific Solutions04 Multi-functional reaction chambers

Microreactors with multi-functional reaction chambers offer versatility for different types of chemical processes. These chambers can be configured to accommodate various reaction types, including catalytic, enzymatic, photochemical, and electrochemical reactions. The adaptable design features include adjustable residence times, variable mixing intensities, and interchangeable catalyst supports, allowing a single microreactor system to be used for diverse applications and reducing the need for dedicated equipment.Expand Specific Solutions05 Customizable flow patterns and mixing mechanisms

Microreactors with customizable flow patterns and mixing mechanisms provide flexibility in controlling reaction kinetics and mass transfer. These designs incorporate adjustable channel geometries, variable flow restrictors, and interchangeable mixing elements that can be tailored to specific reaction requirements. The ability to modify flow characteristics enables optimization of residence time distribution, mixing efficiency, and heat transfer, making the microreactors adaptable to reactions with different kinetic profiles and mixing needs.Expand Specific Solutions

Leading Companies in 3D Printed Microreactor Industry

The microreactor market with 3D printing fabrication is currently in an early growth phase, characterized by rapid technological advancement and expanding applications. Market size is projected to increase significantly as industries recognize the benefits of enhanced design flexibility, reduced material waste, and improved efficiency. Technologically, academic institutions like MIT, Dalian University of Technology, and RWTH Aachen University are leading fundamental research, while companies including Fraunhofer-Gesellschaft, Illumina, and Corning are developing commercial applications. Government entities such as the US Government and research organizations like CSIC are providing crucial funding and infrastructure. The field is witnessing convergence between academic innovation and industrial implementation, with increasing focus on scalable manufacturing processes and standardization.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed a comprehensive suite of 3D printing technologies specifically tailored for microreactor fabrication, including selective laser melting (SLM) for metal microreactors and multi-photon polymerization for high-resolution polymer systems. Their metal-based microreactors feature integrated cooling channels and catalyst support structures printed simultaneously with the reactor body, achieving thermal management capabilities impossible with conventional manufacturing[1]. Fraunhofer's approach includes specialized post-processing techniques such as electrochemical polishing and surface functionalization to optimize flow characteristics and catalytic performance. Their microreactor designs incorporate computational fluid dynamics (CFD) optimization, resulting in structures that minimize pressure drop while maximizing mixing efficiency and heat transfer[3]. Fraunhofer has also pioneered hybrid manufacturing approaches that combine 3D printing with precision machining and assembly techniques, enabling the integration of sensors, actuators, and control systems directly into the microreactor structure during fabrication.

Strengths: Exceptional material versatility spanning metals, ceramics, and polymers; advanced design optimization through integrated simulation capabilities; established scale-up methodologies for industrial implementation. Weaknesses: Higher complexity in manufacturing workflow requiring specialized expertise; longer production times for multi-material systems; challenges in quality control and reproducibility for highly complex geometries.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced 3D printing techniques for microreactor fabrication, developing stereolithography (SLA) and digital light processing (DLP) methods that enable the creation of complex internal geometries with feature sizes down to 100 microns[1]. Their approach combines multi-material printing capabilities with post-processing treatments to enhance chemical resistance and thermal stability. MIT researchers have demonstrated microreactors with integrated mixing elements, heat exchangers, and catalyst supports in a single printed structure, significantly reducing assembly steps and potential leak points[3]. Their platform allows for rapid prototyping cycles—reducing design-to-testing time from months to days—and enables the production of microreactors with previously impossible geometries, such as fractal-based flow distributors and three-dimensional reaction zones that maximize surface-to-volume ratios[5]. MIT has also developed specialized resins and composite materials specifically formulated for chemical compatibility with various reaction media.

Strengths: Exceptional design flexibility allowing complex geometries impossible with traditional manufacturing; rapid prototyping capabilities enabling iterative design optimization; advanced multi-material printing for functional integration. Weaknesses: Limited scalability for mass production; potential material constraints for high-temperature or highly corrosive reactions; higher unit costs compared to conventional manufacturing methods for large-scale production.

Key Patents and Research Breakthroughs

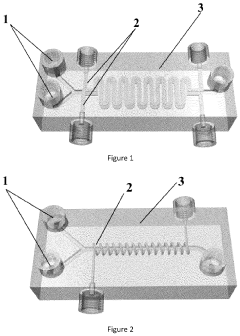

General-purpose fluorescent fluid photochemical microreactor and manufacturing method therefor by 3D printing

PatentActiveUS11872556B2

Innovation

- A 3D printed fluorescent fluid microreactor with serpentine or spiral channels, using transparent photosensitive resin and replaceable fluorescent fluids, allowing for flexible wavelength conversion and simplified production.

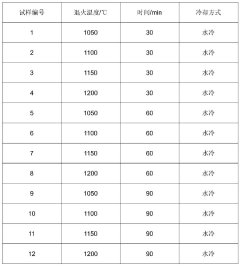

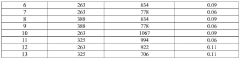

Alloy manufacturing process based on 3D printing and microreactor

PatentPendingCN117733185A

Innovation

- Using an alloy manufacturing process based on 3D printing, microreactors are manufactured through selective laser melting technology, including selecting alloy powder formulas, designing and optimizing microreactor models, performing 3D printing and heat treatment, and optimizing printing parameters such as preheating temperature, laser power and Scanning speed, using high-pressure gas atomization method to produce powder to reduce oxygen content, optimizing channel structure and connection parts to reduce inter-layer gaps and internal surface roughness.

Scalability and Manufacturing Considerations

The scalability of microreactor technology with 3D printing fabrication methods presents both significant opportunities and challenges for industrial implementation. Current manufacturing capabilities allow for the production of microreactors at laboratory and small pilot scales, but transitioning to full commercial production requires addressing several critical factors. The inherent precision of 3D printing technologies, particularly stereolithography (SLA) and digital light processing (DLP), enables the creation of complex internal geometries with feature sizes down to 25-50 microns, which is essential for efficient microreactor performance.

Material selection significantly impacts scalability considerations. While polymeric materials offer excellent design flexibility and cost-effectiveness for prototyping, they often lack the chemical resistance and thermal stability required for industrial applications. Advanced ceramic and metal printing techniques are emerging as viable alternatives, with silicon carbide and stainless steel demonstrating promising results in high-throughput applications. However, these materials typically require more sophisticated printing equipment and post-processing steps, increasing production complexity and cost.

Production throughput represents another critical consideration. Current state-of-the-art 3D printers can fabricate microreactors with volumes of 10-100 mL in timeframes ranging from hours to days, depending on complexity. This production rate remains insufficient for large-scale industrial deployment. Parallel manufacturing approaches, where multiple printing systems operate simultaneously, offer one potential solution but introduce challenges in quality consistency and process validation.

Post-processing requirements further impact manufacturing scalability. Most 3D-printed microreactors require surface treatment to achieve appropriate channel smoothness and chemical compatibility. These processes, including solvent polishing for polymers and thermal sintering for ceramics, add significant time and complexity to the manufacturing workflow. Standardization of these post-processing techniques remains an ongoing challenge for consistent quality at scale.

Economic considerations also play a crucial role in scalability assessment. The current cost structure for 3D-printed microreactors shows an inverse relationship between production volume and unit cost, with significant economies of scale becoming apparent at moderate production volumes. Material costs typically represent 30-40% of total manufacturing expenses, with equipment depreciation and labor accounting for most of the remainder. As printing technologies mature and material options expand, these cost structures are expected to evolve favorably.

Regulatory considerations present additional challenges for scaled manufacturing, particularly for applications in pharmaceutical and food processing industries. Validation protocols for 3D-printed components remain less established than for conventional manufacturing methods, potentially extending timelines for regulatory approval and commercial implementation. Industry-specific standards are beginning to emerge but require further development to facilitate widespread adoption.

Material selection significantly impacts scalability considerations. While polymeric materials offer excellent design flexibility and cost-effectiveness for prototyping, they often lack the chemical resistance and thermal stability required for industrial applications. Advanced ceramic and metal printing techniques are emerging as viable alternatives, with silicon carbide and stainless steel demonstrating promising results in high-throughput applications. However, these materials typically require more sophisticated printing equipment and post-processing steps, increasing production complexity and cost.

Production throughput represents another critical consideration. Current state-of-the-art 3D printers can fabricate microreactors with volumes of 10-100 mL in timeframes ranging from hours to days, depending on complexity. This production rate remains insufficient for large-scale industrial deployment. Parallel manufacturing approaches, where multiple printing systems operate simultaneously, offer one potential solution but introduce challenges in quality consistency and process validation.

Post-processing requirements further impact manufacturing scalability. Most 3D-printed microreactors require surface treatment to achieve appropriate channel smoothness and chemical compatibility. These processes, including solvent polishing for polymers and thermal sintering for ceramics, add significant time and complexity to the manufacturing workflow. Standardization of these post-processing techniques remains an ongoing challenge for consistent quality at scale.

Economic considerations also play a crucial role in scalability assessment. The current cost structure for 3D-printed microreactors shows an inverse relationship between production volume and unit cost, with significant economies of scale becoming apparent at moderate production volumes. Material costs typically represent 30-40% of total manufacturing expenses, with equipment depreciation and labor accounting for most of the remainder. As printing technologies mature and material options expand, these cost structures are expected to evolve favorably.

Regulatory considerations present additional challenges for scaled manufacturing, particularly for applications in pharmaceutical and food processing industries. Validation protocols for 3D-printed components remain less established than for conventional manufacturing methods, potentially extending timelines for regulatory approval and commercial implementation. Industry-specific standards are beginning to emerge but require further development to facilitate widespread adoption.

Sustainability and Green Chemistry Integration

The integration of sustainability principles and green chemistry concepts into microreactor technology represents a significant advancement in responsible manufacturing practices. Microreactors with 3D printing fabrication methods inherently align with green chemistry principles through their precise control over reaction conditions, minimized waste generation, and reduced energy consumption compared to traditional batch processes. The ability to optimize reaction parameters in real-time leads to higher conversion rates and selectivity, substantially decreasing the formation of unwanted by-products.

3D printing fabrication methods further enhance sustainability by enabling material-efficient manufacturing processes. Unlike traditional subtractive manufacturing techniques that generate considerable waste, additive manufacturing approaches utilize only the necessary materials for construction. This reduction in material consumption directly translates to decreased environmental impact throughout the product lifecycle. Additionally, the design flexibility afforded by 3D printing allows for the incorporation of complex internal structures that maximize heat transfer efficiency and reaction surface area, further improving energy utilization.

The combination of microreactor technology and 3D printing facilitates the implementation of continuous flow chemistry, which represents a paradigm shift toward greener chemical processing. Continuous flow systems enable precise dosing of reagents, minimizing excess chemical usage and reducing hazardous waste generation. The enhanced mixing capabilities and improved mass transfer characteristics of 3D-printed microreactors also contribute to more efficient reactions under milder conditions, often eliminating the need for harsh solvents or extreme temperatures.

From a lifecycle perspective, 3D-printed microreactors offer significant advantages in terms of sustainability. Their modular nature allows for easier maintenance, repair, and eventual recycling of components. The ability to rapidly prototype and iterate designs also reduces development waste compared to traditional manufacturing methods. Furthermore, the localized production capabilities of 3D printing technology can reduce transportation-related carbon emissions in the supply chain.

Recent innovations have focused on incorporating biodegradable and bio-based materials into 3D printing feedstocks for microreactor fabrication. These developments align with circular economy principles and further reduce the environmental footprint of microreactor systems. Research into recyclable photopolymers and sustainable ceramic composites shows particular promise for creating environmentally responsible microreactor platforms that maintain the necessary chemical resistance and thermal stability for diverse applications.

The integration of digital monitoring and control systems with 3D-printed microreactors also contributes to sustainability through process optimization and predictive maintenance capabilities. These systems enable real-time adjustments to maximize resource efficiency and minimize waste generation throughout the operational lifetime of the microreactor systems.

3D printing fabrication methods further enhance sustainability by enabling material-efficient manufacturing processes. Unlike traditional subtractive manufacturing techniques that generate considerable waste, additive manufacturing approaches utilize only the necessary materials for construction. This reduction in material consumption directly translates to decreased environmental impact throughout the product lifecycle. Additionally, the design flexibility afforded by 3D printing allows for the incorporation of complex internal structures that maximize heat transfer efficiency and reaction surface area, further improving energy utilization.

The combination of microreactor technology and 3D printing facilitates the implementation of continuous flow chemistry, which represents a paradigm shift toward greener chemical processing. Continuous flow systems enable precise dosing of reagents, minimizing excess chemical usage and reducing hazardous waste generation. The enhanced mixing capabilities and improved mass transfer characteristics of 3D-printed microreactors also contribute to more efficient reactions under milder conditions, often eliminating the need for harsh solvents or extreme temperatures.

From a lifecycle perspective, 3D-printed microreactors offer significant advantages in terms of sustainability. Their modular nature allows for easier maintenance, repair, and eventual recycling of components. The ability to rapidly prototype and iterate designs also reduces development waste compared to traditional manufacturing methods. Furthermore, the localized production capabilities of 3D printing technology can reduce transportation-related carbon emissions in the supply chain.

Recent innovations have focused on incorporating biodegradable and bio-based materials into 3D printing feedstocks for microreactor fabrication. These developments align with circular economy principles and further reduce the environmental footprint of microreactor systems. Research into recyclable photopolymers and sustainable ceramic composites shows particular promise for creating environmentally responsible microreactor platforms that maintain the necessary chemical resistance and thermal stability for diverse applications.

The integration of digital monitoring and control systems with 3D-printed microreactors also contributes to sustainability through process optimization and predictive maintenance capabilities. These systems enable real-time adjustments to maximize resource efficiency and minimize waste generation throughout the operational lifetime of the microreactor systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!