Microreactors in Polymerization Processes and Molecular Weight Control

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology has evolved significantly since its inception in the late 1990s, transforming from laboratory curiosities to sophisticated engineering tools with precise control capabilities. Initially, these miniaturized reaction vessels were primarily used for simple organic synthesis, but their application in polymer chemistry began gaining traction in the early 2000s as researchers recognized their potential for enhanced heat and mass transfer properties.

The evolution of microreactors in polymerization processes has followed a clear trajectory, moving from basic proof-of-concept studies to increasingly complex implementations. Early designs focused on simple channel geometries, while modern microreactors incorporate advanced features such as static mixers, integrated sensors, and automated control systems. This technological progression has been driven by the fundamental limitations of conventional batch polymerization processes, particularly regarding molecular weight distribution control and reaction exotherm management.

Material science advancements have played a crucial role in microreactor development. The transition from glass and silicon substrates to more chemically resistant materials like stainless steel, ceramic, and specialized polymers has expanded the range of viable polymerization chemistries. Concurrently, microfabrication techniques have evolved from basic photolithography to sophisticated 3D printing and laser ablation methods, enabling more complex reactor designs with feature sizes approaching the submicron scale.

The integration of real-time monitoring capabilities represents another significant evolutionary milestone. Early microreactor systems relied on offline analysis, whereas contemporary platforms incorporate in-line spectroscopic techniques (FTIR, Raman, UV-Vis) and physical property measurements, enabling unprecedented reaction monitoring and control. This capability is particularly valuable for controlling molecular weight distributions in polymerization processes, where reaction kinetics must be precisely managed.

The primary technological objectives in this field center on achieving precise control over polymer architecture while maintaining industrial relevance. Specifically, researchers aim to develop microreactor systems capable of producing polymers with predetermined molecular weights, narrow polydispersity indices, and specific end-group functionalities at commercially viable throughputs. Additional objectives include enhancing operational flexibility to accommodate diverse monomer chemistries and polymerization mechanisms, from free radical to controlled radical, anionic, cationic, and step-growth polymerizations.

Looking forward, the field is moving toward fully integrated, autonomous microreactor systems that combine artificial intelligence with advanced process control. These systems promise to revolutionize polymer synthesis by enabling real-time optimization of reaction parameters based on desired product specifications, potentially unlocking novel polymer architectures and properties previously unattainable through conventional methods.

The evolution of microreactors in polymerization processes has followed a clear trajectory, moving from basic proof-of-concept studies to increasingly complex implementations. Early designs focused on simple channel geometries, while modern microreactors incorporate advanced features such as static mixers, integrated sensors, and automated control systems. This technological progression has been driven by the fundamental limitations of conventional batch polymerization processes, particularly regarding molecular weight distribution control and reaction exotherm management.

Material science advancements have played a crucial role in microreactor development. The transition from glass and silicon substrates to more chemically resistant materials like stainless steel, ceramic, and specialized polymers has expanded the range of viable polymerization chemistries. Concurrently, microfabrication techniques have evolved from basic photolithography to sophisticated 3D printing and laser ablation methods, enabling more complex reactor designs with feature sizes approaching the submicron scale.

The integration of real-time monitoring capabilities represents another significant evolutionary milestone. Early microreactor systems relied on offline analysis, whereas contemporary platforms incorporate in-line spectroscopic techniques (FTIR, Raman, UV-Vis) and physical property measurements, enabling unprecedented reaction monitoring and control. This capability is particularly valuable for controlling molecular weight distributions in polymerization processes, where reaction kinetics must be precisely managed.

The primary technological objectives in this field center on achieving precise control over polymer architecture while maintaining industrial relevance. Specifically, researchers aim to develop microreactor systems capable of producing polymers with predetermined molecular weights, narrow polydispersity indices, and specific end-group functionalities at commercially viable throughputs. Additional objectives include enhancing operational flexibility to accommodate diverse monomer chemistries and polymerization mechanisms, from free radical to controlled radical, anionic, cationic, and step-growth polymerizations.

Looking forward, the field is moving toward fully integrated, autonomous microreactor systems that combine artificial intelligence with advanced process control. These systems promise to revolutionize polymer synthesis by enabling real-time optimization of reaction parameters based on desired product specifications, potentially unlocking novel polymer architectures and properties previously unattainable through conventional methods.

Market Analysis for Precision Polymer Manufacturing

The precision polymer manufacturing market is experiencing significant growth driven by increasing demand for tailored polymeric materials across various industries. The global market for precision polymers was valued at approximately $125 billion in 2022 and is projected to reach $189 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is primarily fueled by advancements in microreactor technology that enable unprecedented control over molecular weight distribution and polymer architecture.

Healthcare and pharmaceutical sectors constitute the largest market segment, accounting for nearly 32% of the total market share. The demand for precision polymers in drug delivery systems, medical devices, and diagnostic applications continues to rise due to stringent regulatory requirements and the growing trend toward personalized medicine. Microreactor-based polymerization processes are particularly valuable in these sectors as they ensure batch-to-batch consistency and meet strict quality standards.

The electronics industry represents another significant market segment, with approximately 28% market share. The miniaturization trend in electronic devices necessitates polymers with precisely controlled properties for applications in flexible displays, semiconductors, and advanced packaging materials. Microreactor technology offers substantial advantages in producing these high-performance materials with the required specifications.

Automotive and aerospace industries collectively account for about 21% of the market, with growing adoption of lightweight, high-strength polymeric materials. The ability to fine-tune molecular weight distribution using microreactors directly translates to enhanced mechanical properties, making these materials increasingly attractive for replacing traditional components.

Regional analysis indicates that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate of 9.1% during the forecast period, primarily due to rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Customer requirements are evolving toward higher performance specifications, with 76% of end-users citing molecular weight control as a critical parameter for their applications. This trend aligns perfectly with the capabilities of microreactor technology, which offers superior control over reaction parameters compared to conventional batch processes.

Market challenges include high initial investment costs for microreactor systems and the technical expertise required for operation. However, the long-term benefits of reduced waste, higher product quality, and operational efficiency are driving adoption despite these barriers. The return on investment period for microreactor implementation in polymer manufacturing typically ranges from 18 to 36 months, depending on production scale and application complexity.

Healthcare and pharmaceutical sectors constitute the largest market segment, accounting for nearly 32% of the total market share. The demand for precision polymers in drug delivery systems, medical devices, and diagnostic applications continues to rise due to stringent regulatory requirements and the growing trend toward personalized medicine. Microreactor-based polymerization processes are particularly valuable in these sectors as they ensure batch-to-batch consistency and meet strict quality standards.

The electronics industry represents another significant market segment, with approximately 28% market share. The miniaturization trend in electronic devices necessitates polymers with precisely controlled properties for applications in flexible displays, semiconductors, and advanced packaging materials. Microreactor technology offers substantial advantages in producing these high-performance materials with the required specifications.

Automotive and aerospace industries collectively account for about 21% of the market, with growing adoption of lightweight, high-strength polymeric materials. The ability to fine-tune molecular weight distribution using microreactors directly translates to enhanced mechanical properties, making these materials increasingly attractive for replacing traditional components.

Regional analysis indicates that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate of 9.1% during the forecast period, primarily due to rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Customer requirements are evolving toward higher performance specifications, with 76% of end-users citing molecular weight control as a critical parameter for their applications. This trend aligns perfectly with the capabilities of microreactor technology, which offers superior control over reaction parameters compared to conventional batch processes.

Market challenges include high initial investment costs for microreactor systems and the technical expertise required for operation. However, the long-term benefits of reduced waste, higher product quality, and operational efficiency are driving adoption despite these barriers. The return on investment period for microreactor implementation in polymer manufacturing typically ranges from 18 to 36 months, depending on production scale and application complexity.

Current Microreactor Limitations in Polymerization

Despite the promising advantages of microreactors in polymerization processes, several significant limitations currently hinder their widespread industrial adoption. One of the primary challenges is scaling up production while maintaining the benefits of microreactor technology. While microreactors excel at small-scale synthesis with precise control, transitioning to commercial production volumes remains problematic due to the inherent throughput constraints of individual microreactor units.

Material compatibility presents another substantial hurdle, particularly for high-viscosity polymer systems. As polymerization progresses, the increasing viscosity of the reaction medium can lead to channel clogging and pressure buildup, potentially causing system failure. This limitation is especially pronounced in step-growth and condensation polymerizations where high molecular weight polymers are desired.

Heat transfer efficiency, while generally superior in microreactors compared to batch systems, becomes compromised when dealing with highly exothermic polymerization reactions. The high surface-to-volume ratio that typically facilitates excellent heat dissipation may prove insufficient for controlling thermal runaway in certain polymerization processes, particularly those involving rapid chain propagation.

Molecular weight distribution control, a critical parameter in polymer quality, faces challenges in microreactor environments. The residence time distribution, which directly impacts polymer chain length uniformity, can be difficult to maintain consistently across parallel microreactor channels, leading to broadened molecular weight distributions in the final product.

Monitoring and in-situ characterization capabilities remain limited in current microreactor designs. Real-time analysis of polymerization kinetics, conversion rates, and molecular weight evolution is challenging due to the confined spaces and rapid reaction rates, making process optimization difficult without adequate feedback mechanisms.

Fouling and surface interactions between the polymer and reactor walls represent another significant limitation. As polymerization proceeds, polymer chains can adsorb onto channel surfaces, altering flow dynamics and potentially catalyzing unwanted side reactions, which affects both process stability and product purity.

Cost considerations also impede widespread adoption, as specialized microreactor systems with appropriate materials of construction, precise flow control, and monitoring capabilities require significant capital investment compared to conventional batch reactors. The economic viability becomes questionable when considering the throughput limitations alongside these higher initial costs.

Technical expertise requirements present an additional barrier, as operating microreactor systems for polymerization demands specialized knowledge spanning fluid dynamics, polymer chemistry, and process control that may not be readily available in traditional manufacturing settings.

Material compatibility presents another substantial hurdle, particularly for high-viscosity polymer systems. As polymerization progresses, the increasing viscosity of the reaction medium can lead to channel clogging and pressure buildup, potentially causing system failure. This limitation is especially pronounced in step-growth and condensation polymerizations where high molecular weight polymers are desired.

Heat transfer efficiency, while generally superior in microreactors compared to batch systems, becomes compromised when dealing with highly exothermic polymerization reactions. The high surface-to-volume ratio that typically facilitates excellent heat dissipation may prove insufficient for controlling thermal runaway in certain polymerization processes, particularly those involving rapid chain propagation.

Molecular weight distribution control, a critical parameter in polymer quality, faces challenges in microreactor environments. The residence time distribution, which directly impacts polymer chain length uniformity, can be difficult to maintain consistently across parallel microreactor channels, leading to broadened molecular weight distributions in the final product.

Monitoring and in-situ characterization capabilities remain limited in current microreactor designs. Real-time analysis of polymerization kinetics, conversion rates, and molecular weight evolution is challenging due to the confined spaces and rapid reaction rates, making process optimization difficult without adequate feedback mechanisms.

Fouling and surface interactions between the polymer and reactor walls represent another significant limitation. As polymerization proceeds, polymer chains can adsorb onto channel surfaces, altering flow dynamics and potentially catalyzing unwanted side reactions, which affects both process stability and product purity.

Cost considerations also impede widespread adoption, as specialized microreactor systems with appropriate materials of construction, precise flow control, and monitoring capabilities require significant capital investment compared to conventional batch reactors. The economic viability becomes questionable when considering the throughput limitations alongside these higher initial costs.

Technical expertise requirements present an additional barrier, as operating microreactor systems for polymerization demands specialized knowledge spanning fluid dynamics, polymer chemistry, and process control that may not be readily available in traditional manufacturing settings.

Molecular Weight Control Strategies in Microreactors

01 Microreactors for molecular weight control in polymer synthesis

Microreactors provide precise control over reaction conditions, allowing for the synthesis of polymers with targeted molecular weights. These systems enable better temperature control, mixing efficiency, and residence time distribution, resulting in polymers with narrower molecular weight distributions. The controlled environment of microreactors facilitates the production of polymers with specific molecular weights for various applications.- Microreactors for molecular weight control in polymer synthesis: Microreactors provide precise control over reaction conditions, allowing for the synthesis of polymers with targeted molecular weights. The controlled environment enables better regulation of polymerization kinetics, resulting in narrower molecular weight distributions and more uniform polymer properties. These systems offer advantages in producing specialty polymers with specific molecular weight ranges for various applications.

- Separation and analysis of compounds by molecular weight in microreactors: Microreactors can be used for the separation and analysis of compounds based on their molecular weight. These systems incorporate specialized membranes or filtration mechanisms that allow for the selective passage of molecules based on size. This technology enables the purification of compounds, removal of impurities, and isolation of specific molecular weight fractions for analytical or production purposes.

- Catalytic processes in microreactors affecting molecular weight distribution: Catalytic processes implemented in microreactors can significantly influence the molecular weight distribution of reaction products. The enhanced mass and heat transfer characteristics of microreactors allow for more efficient catalyst utilization and better control over reaction pathways. This results in the ability to selectively produce compounds with desired molecular weight profiles while minimizing unwanted byproducts.

- Continuous flow microreactors for high molecular weight compound synthesis: Continuous flow microreactors offer advantages for synthesizing high molecular weight compounds that would be challenging in batch processes. The continuous nature of these systems allows for better control of reaction parameters, reduced side reactions, and improved scalability. These microreactors can maintain consistent product quality while producing complex high molecular weight compounds for pharmaceutical, material science, and specialty chemical applications.

- Microreactor design optimization for molecular weight-dependent processes: The design of microreactors can be optimized specifically for processes where molecular weight plays a critical role. Features such as channel geometry, mixing elements, residence time distribution, and surface properties can be tailored to accommodate molecules of different sizes and weights. These optimized designs enhance reaction efficiency, selectivity, and yield when working with molecular weight-dependent chemical transformations.

02 Separation and analysis of compounds by molecular weight in microreactors

Microreactors can be used for the separation and analysis of compounds based on their molecular weight. These systems incorporate specialized membranes or filtration mechanisms that allow for the selective passage of molecules based on size. This capability is particularly useful for purification processes, analytical applications, and the isolation of specific molecular weight fractions from complex mixtures.Expand Specific Solutions03 Catalytic processes in microreactors affecting molecular weight distribution

Catalytic processes implemented in microreactors can significantly influence the molecular weight distribution of reaction products. The enhanced surface-to-volume ratio in microreactors improves catalyst efficiency and accessibility. This leads to more uniform catalytic activity throughout the reaction medium, resulting in products with more consistent molecular weights and reduced polydispersity.Expand Specific Solutions04 Flow chemistry in microreactors for high molecular weight compounds

Flow chemistry techniques in microreactors enable the synthesis of high molecular weight compounds with improved efficiency. Continuous flow processes allow for better control over reaction parameters, reducing side reactions that can limit molecular weight growth. These systems can be designed with multiple reaction zones to facilitate step-growth polymerization or controlled chain extension, resulting in higher molecular weight products than would be possible in batch reactors.Expand Specific Solutions05 Microreactor design considerations for molecular weight-dependent processes

The design of microreactors can be optimized for processes where molecular weight plays a critical role. Features such as channel dimensions, mixing structures, and residence time distribution can be tailored to accommodate the changing viscosity and diffusion characteristics of growing polymer chains. Advanced microreactor designs incorporate in-line monitoring of molecular weight and feedback control systems to maintain desired product specifications throughout the production process.Expand Specific Solutions

Leading Companies in Microreactor Technology

The microreactor technology in polymerization processes is currently in a transitional phase from early adoption to commercial implementation, with the global market estimated at $2-3 billion and growing at 15-20% annually. Major players like ExxonMobil Chemical, Dow Global Technologies, and SABIC are leading innovation through extensive patent portfolios focusing on precise molecular weight control. Chinese entities including Sinopec and Chinese Academy of Sciences are rapidly advancing their capabilities, while specialized companies like Yokogawa Fluence Analytics provide real-time monitoring solutions. Academic institutions such as Carnegie Mellon University and Zhejiang University contribute fundamental research. The technology is approaching maturity in specialty polymers but remains in development for large-scale commodity polymer production, with increasing focus on sustainability and process intensification.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed proprietary microreactor technology specifically designed for metallocene-catalyzed polyolefin synthesis with precise molecular weight control. Their systems employ segmented flow microreactors with specialized catalyst injection ports that enable controlled living polymerization[2]. The company's approach features temperature-controlled microchannels with exceptional heat transfer coefficients (>1000 W/m²K) that prevent hotspot formation, ensuring uniform chain growth and molecular weight consistency. ExxonMobil's microreactors incorporate proprietary surface treatments that minimize wall effects and catalyst deactivation, extending catalyst lifetime by up to 300% compared to conventional reactors[4]. Their technology enables rapid screening of reaction conditions, with the ability to test multiple catalyst systems and co-monomer combinations in parallel, accelerating polymer development while maintaining precise molecular weight targets.

Strengths: Exceptional temperature control preventing molecular weight deviations; specialized surface treatments minimizing catalyst deactivation; high throughput capability for industrial-scale production. Weaknesses: Complex system integration requirements; higher sensitivity to impurities requiring ultra-pure feedstocks; limited application to certain polymer chemistries.

Korea Research Institute of Chemical Technology

Technical Solution: The Korea Research Institute of Chemical Technology (KRICT) has developed innovative microreactor platforms specifically designed for controlled/living radical polymerization with precise molecular weight regulation. Their approach combines specially designed microreactor geometries with advanced catalyst systems to achieve unprecedented control over polymer chain growth. KRICT's microreactors feature unique channel configurations that create controlled mixing patterns, enabling uniform initiation and propagation rates across the reaction volume[7]. Their systems incorporate proprietary surface modifications that minimize unwanted termination reactions at channel walls, significantly improving molecular weight control compared to conventional reactors. KRICT has pioneered the integration of in-line monitoring techniques, including spectroscopic methods that provide real-time data on monomer conversion and molecular weight evolution, enabling automated feedback control systems[8]. Their technology has demonstrated exceptional results in producing well-defined polymers with polydispersity indices consistently below 1.2 across various monomer systems.

Strengths: Cutting-edge integration of advanced monitoring techniques; exceptional control over polymer microstructure; versatility across multiple polymerization mechanisms. Weaknesses: Less developed commercial-scale implementation compared to industry leaders; higher complexity in system operation; requires specialized expertise for optimal performance.

Key Patents in Microreactor Polymerization Control

Process for preparation of polymers

PatentInactiveEP1676632A1

Innovation

- Conducting transition metal-catalyzed polycondensation reactions in a microreactor with precise control over reaction conditions, such as temperature, flow rate, and residence time, to produce polymers with improved properties and reduced solvent usage.

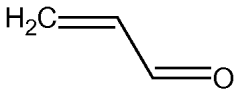

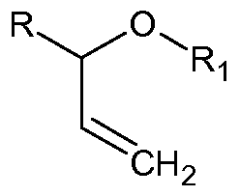

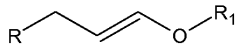

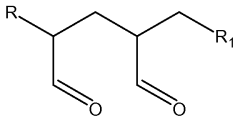

Method for obtaining acrolein polymers, polymers, and uses thereof

PatentWO2011098706A1

Innovation

- A process involving polymerization of acrolein in an aqueous medium using a thermostatically controlled microreactor or micromixer, followed by separation, washing, and chemical modification to enhance solubility and molecular weight control, with specific conditions for catalysts, temperatures, and reaction times to achieve consistent polymer properties.

Scale-up Challenges for Industrial Implementation

The transition from laboratory-scale microreactors to industrial production presents significant challenges that must be addressed for successful implementation. One of the primary obstacles is maintaining consistent reaction conditions across multiple parallel microreactor units. While a single microreactor can achieve precise control over molecular weight distribution, scaling up requires numerous reactors operating in parallel, introducing potential variability between units that can compromise product uniformity.

Heat management becomes increasingly complex at industrial scale. Although microreactors excel at heat transfer due to their high surface-to-volume ratio, the cumulative heat generated by multiple units demands sophisticated cooling systems. For exothermic polymerization reactions, even minor cooling inefficiencies can lead to thermal runaway scenarios, affecting molecular weight control and potentially creating safety hazards.

Material considerations also present substantial challenges. Microreactor channels are susceptible to fouling and clogging, particularly with high-viscosity polymer solutions. This issue becomes more pronounced at industrial scale, where continuous operation for extended periods is necessary for economic viability. Advanced materials with non-stick properties and innovative channel designs are being developed to address these concerns, but implementation costs remain high.

Economic factors significantly impact scale-up decisions. The capital investment required for multiple parallel microreactor units often exceeds that of conventional batch reactors with equivalent production capacity. This financial barrier is compounded by the need for specialized monitoring equipment, precise flow controllers, and advanced automation systems to maintain the molecular weight control advantages of microreactor technology.

Regulatory compliance adds another layer of complexity. Pharmaceutical and specialty polymer manufacturers must validate that scaled-up microreactor processes maintain the same product quality attributes as those demonstrated in development. This validation process is particularly challenging when transitioning from single to multiple parallel units, requiring extensive documentation and testing.

Despite these challenges, several companies have successfully implemented industrial-scale microreactor systems for polymerization processes. These implementations typically begin with modular approaches, gradually increasing capacity while continuously monitoring product quality. The development of standardized microreactor modules with predictable scaling behavior has emerged as a promising strategy to overcome the technical and economic barriers to industrial adoption.

Heat management becomes increasingly complex at industrial scale. Although microreactors excel at heat transfer due to their high surface-to-volume ratio, the cumulative heat generated by multiple units demands sophisticated cooling systems. For exothermic polymerization reactions, even minor cooling inefficiencies can lead to thermal runaway scenarios, affecting molecular weight control and potentially creating safety hazards.

Material considerations also present substantial challenges. Microreactor channels are susceptible to fouling and clogging, particularly with high-viscosity polymer solutions. This issue becomes more pronounced at industrial scale, where continuous operation for extended periods is necessary for economic viability. Advanced materials with non-stick properties and innovative channel designs are being developed to address these concerns, but implementation costs remain high.

Economic factors significantly impact scale-up decisions. The capital investment required for multiple parallel microreactor units often exceeds that of conventional batch reactors with equivalent production capacity. This financial barrier is compounded by the need for specialized monitoring equipment, precise flow controllers, and advanced automation systems to maintain the molecular weight control advantages of microreactor technology.

Regulatory compliance adds another layer of complexity. Pharmaceutical and specialty polymer manufacturers must validate that scaled-up microreactor processes maintain the same product quality attributes as those demonstrated in development. This validation process is particularly challenging when transitioning from single to multiple parallel units, requiring extensive documentation and testing.

Despite these challenges, several companies have successfully implemented industrial-scale microreactor systems for polymerization processes. These implementations typically begin with modular approaches, gradually increasing capacity while continuously monitoring product quality. The development of standardized microreactor modules with predictable scaling behavior has emerged as a promising strategy to overcome the technical and economic barriers to industrial adoption.

Sustainability Aspects of Microreactor Polymerization

Microreactor technology represents a significant advancement in sustainable polymerization processes, offering numerous environmental benefits compared to conventional batch reactors. The enhanced heat and mass transfer capabilities of microreactors enable more precise temperature control, resulting in substantial energy savings of up to 30-50% compared to traditional polymerization methods. This energy efficiency directly translates to reduced carbon footprint across the polymer production lifecycle.

Water consumption in microreactor polymerization systems is markedly lower, with studies demonstrating reductions of 40-60% compared to conventional processes. This conservation is particularly significant in water-intensive polymer manufacturing sectors, addressing growing concerns about industrial water usage in regions facing scarcity challenges.

The precise reaction control afforded by microreactors substantially reduces waste generation through several mechanisms. By minimizing side reactions and improving conversion rates, these systems can achieve waste reduction of 25-45% compared to batch processes. Additionally, the ability to operate with higher concentrations and reduced solvent volumes contributes to greener chemistry practices, aligning with principles of atom economy and process intensification.

From a life cycle assessment perspective, microreactor polymerization demonstrates favorable environmental performance across multiple impact categories. Research indicates reductions in global warming potential (15-35%), acidification potential (20-40%), and resource depletion metrics when compared to conventional polymerization technologies. These improvements stem from both direct process efficiencies and indirect benefits in the supply chain.

The scalability of microreactor technology through numbering-up rather than scaling-up presents unique sustainability advantages. This approach maintains process efficiency while expanding production capacity, avoiding the diminishing returns often observed in traditional scale-up operations. Furthermore, the modular nature of microreactor systems enables more flexible manufacturing footprints, potentially reducing transportation impacts in distributed production models.

Regulatory frameworks increasingly recognize these sustainability benefits, with microreactor polymerization technologies gaining favorable consideration under green chemistry initiatives in Europe, North America, and parts of Asia. Industry adoption is accelerating as companies seek to meet sustainability targets and comply with evolving environmental regulations while maintaining economic competitiveness.

Water consumption in microreactor polymerization systems is markedly lower, with studies demonstrating reductions of 40-60% compared to conventional processes. This conservation is particularly significant in water-intensive polymer manufacturing sectors, addressing growing concerns about industrial water usage in regions facing scarcity challenges.

The precise reaction control afforded by microreactors substantially reduces waste generation through several mechanisms. By minimizing side reactions and improving conversion rates, these systems can achieve waste reduction of 25-45% compared to batch processes. Additionally, the ability to operate with higher concentrations and reduced solvent volumes contributes to greener chemistry practices, aligning with principles of atom economy and process intensification.

From a life cycle assessment perspective, microreactor polymerization demonstrates favorable environmental performance across multiple impact categories. Research indicates reductions in global warming potential (15-35%), acidification potential (20-40%), and resource depletion metrics when compared to conventional polymerization technologies. These improvements stem from both direct process efficiencies and indirect benefits in the supply chain.

The scalability of microreactor technology through numbering-up rather than scaling-up presents unique sustainability advantages. This approach maintains process efficiency while expanding production capacity, avoiding the diminishing returns often observed in traditional scale-up operations. Furthermore, the modular nature of microreactor systems enables more flexible manufacturing footprints, potentially reducing transportation impacts in distributed production models.

Regulatory frameworks increasingly recognize these sustainability benefits, with microreactor polymerization technologies gaining favorable consideration under green chemistry initiatives in Europe, North America, and parts of Asia. Industry adoption is accelerating as companies seek to meet sustainability targets and comply with evolving environmental regulations while maintaining economic competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!