Comparison of Microreactors vs Batch Reactors in Fine Chemical Synthesis

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology represents a paradigm shift in chemical processing, evolving from laboratory curiosities in the 1990s to sophisticated industrial tools in the 21st century. The initial development focused on simple channel designs etched in glass or silicon, primarily for analytical applications. By the early 2000s, researchers began exploring their potential for synthetic chemistry, recognizing advantages in heat and mass transfer efficiency compared to traditional batch reactors.

The evolution accelerated with materials innovation, moving from glass and silicon to more versatile polymers, ceramics, and metals. This transition enabled wider adoption across various chemical sectors, particularly in fine chemical synthesis where reaction control is paramount. The integration of advanced fabrication techniques, including 3D printing and micromachining, has further expanded design possibilities and reduced production costs.

A significant milestone occurred around 2010 when continuous flow chemistry principles became more widely integrated with microreactor technology, establishing the foundation for flow chemistry as a distinct discipline. This convergence enabled precise control over reaction parameters including temperature, pressure, and residence time—critical factors for fine chemical synthesis that often involves highly exothermic or sensitive reactions.

Recent technological advancements have focused on modularity and scalability, addressing the historical limitation of production volume. Modern microreactor systems employ numbering-up approaches rather than traditional scale-up, maintaining reaction efficiency while increasing throughput. This approach preserves the inherent advantages of microreactors while meeting industrial production demands.

The primary objective of microreactor technology in fine chemical synthesis is to overcome the limitations of batch processing, particularly for reactions requiring precise control of reaction conditions. Specific goals include enhancing reaction selectivity, improving yield, reducing waste generation, and enabling safer handling of hazardous intermediates through contained processing environments.

Looking forward, microreactor technology aims to revolutionize pharmaceutical and specialty chemical manufacturing by enabling continuous production models that reduce time-to-market and capital investment. The technology seeks to facilitate greener chemistry through intensified processes that minimize solvent use and energy consumption. Additionally, there is growing interest in developing integrated systems that combine reaction, separation, and purification steps in continuous processes, potentially transforming traditional manufacturing paradigms in the fine chemicals industry.

The evolution accelerated with materials innovation, moving from glass and silicon to more versatile polymers, ceramics, and metals. This transition enabled wider adoption across various chemical sectors, particularly in fine chemical synthesis where reaction control is paramount. The integration of advanced fabrication techniques, including 3D printing and micromachining, has further expanded design possibilities and reduced production costs.

A significant milestone occurred around 2010 when continuous flow chemistry principles became more widely integrated with microreactor technology, establishing the foundation for flow chemistry as a distinct discipline. This convergence enabled precise control over reaction parameters including temperature, pressure, and residence time—critical factors for fine chemical synthesis that often involves highly exothermic or sensitive reactions.

Recent technological advancements have focused on modularity and scalability, addressing the historical limitation of production volume. Modern microreactor systems employ numbering-up approaches rather than traditional scale-up, maintaining reaction efficiency while increasing throughput. This approach preserves the inherent advantages of microreactors while meeting industrial production demands.

The primary objective of microreactor technology in fine chemical synthesis is to overcome the limitations of batch processing, particularly for reactions requiring precise control of reaction conditions. Specific goals include enhancing reaction selectivity, improving yield, reducing waste generation, and enabling safer handling of hazardous intermediates through contained processing environments.

Looking forward, microreactor technology aims to revolutionize pharmaceutical and specialty chemical manufacturing by enabling continuous production models that reduce time-to-market and capital investment. The technology seeks to facilitate greener chemistry through intensified processes that minimize solvent use and energy consumption. Additionally, there is growing interest in developing integrated systems that combine reaction, separation, and purification steps in continuous processes, potentially transforming traditional manufacturing paradigms in the fine chemicals industry.

Market Analysis for Continuous Flow Chemistry

The continuous flow chemistry market is experiencing significant growth, driven by the increasing demand for more efficient and sustainable chemical synthesis methods. The global market for continuous flow chemistry technology was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2028, representing a compound annual growth rate (CAGR) of 13.2% during the forecast period.

Fine chemical synthesis represents one of the largest application segments for continuous flow technology, accounting for roughly 35% of the total market share. This is primarily due to the advantages microreactors offer over traditional batch processes, including enhanced reaction control, improved safety profiles, and reduced environmental impact.

Pharmaceutical companies are the leading end-users of continuous flow chemistry, constituting approximately 42% of the market. The stringent regulatory requirements for drug manufacturing, coupled with the need for process intensification and cost reduction, have accelerated the adoption of microreactor technology in this sector. Major pharmaceutical companies like Novartis, GSK, and Pfizer have already implemented continuous manufacturing lines for several approved drugs.

The agrochemical industry follows as the second-largest market segment at 28%, where continuous flow processes are increasingly utilized for the synthesis of complex pesticides and fertilizers. The specialty chemicals sector accounts for 18% of the market, with applications in flavors, fragrances, and electronic materials.

Geographically, North America dominates the continuous flow chemistry market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.8% during the forecast period, primarily driven by the expanding pharmaceutical and chemical manufacturing sectors in China and India.

Contract manufacturing organizations (CMOs) and contract research organizations (CROs) are emerging as significant adopters of continuous flow technology, as they seek to differentiate their service offerings and improve operational efficiency. This trend is expected to further accelerate market growth in the coming years.

Despite the promising outlook, market penetration of continuous flow chemistry remains relatively low at approximately 15% of potential applications. This indicates substantial growth opportunities, particularly as technological advancements continue to address current limitations such as high initial investment costs and the need for specialized expertise.

Fine chemical synthesis represents one of the largest application segments for continuous flow technology, accounting for roughly 35% of the total market share. This is primarily due to the advantages microreactors offer over traditional batch processes, including enhanced reaction control, improved safety profiles, and reduced environmental impact.

Pharmaceutical companies are the leading end-users of continuous flow chemistry, constituting approximately 42% of the market. The stringent regulatory requirements for drug manufacturing, coupled with the need for process intensification and cost reduction, have accelerated the adoption of microreactor technology in this sector. Major pharmaceutical companies like Novartis, GSK, and Pfizer have already implemented continuous manufacturing lines for several approved drugs.

The agrochemical industry follows as the second-largest market segment at 28%, where continuous flow processes are increasingly utilized for the synthesis of complex pesticides and fertilizers. The specialty chemicals sector accounts for 18% of the market, with applications in flavors, fragrances, and electronic materials.

Geographically, North America dominates the continuous flow chemistry market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.8% during the forecast period, primarily driven by the expanding pharmaceutical and chemical manufacturing sectors in China and India.

Contract manufacturing organizations (CMOs) and contract research organizations (CROs) are emerging as significant adopters of continuous flow technology, as they seek to differentiate their service offerings and improve operational efficiency. This trend is expected to further accelerate market growth in the coming years.

Despite the promising outlook, market penetration of continuous flow chemistry remains relatively low at approximately 15% of potential applications. This indicates substantial growth opportunities, particularly as technological advancements continue to address current limitations such as high initial investment costs and the need for specialized expertise.

Technical Challenges in Microreactor Implementation

Despite the numerous advantages of microreactors in fine chemical synthesis, their implementation faces several significant technical challenges that must be addressed for widespread industrial adoption. The miniaturization of reaction systems introduces complex engineering problems related to fluid dynamics, material compatibility, and process control that differ substantially from traditional batch reactor operations.

Flow control and clogging represent primary obstacles in microreactor technology. The narrow channels (typically 10-1000 μm) are susceptible to blockages from particulates, precipitates, or high-viscosity fluids. This issue becomes particularly problematic in multiphase reactions or when dealing with solid-forming reactions common in fine chemical synthesis. Advanced strategies such as ultrasonic integration, specialized surface treatments, and pulsed flow techniques are being developed to mitigate these challenges, but they add complexity to system design.

Heat and mass transfer, while generally enhanced in microreactors, present unique challenges at microscale. Temperature gradients can be difficult to control precisely across the entire reactor volume, especially for highly exothermic reactions characteristic of many fine chemical processes. Additionally, achieving uniform mixing in laminar flow conditions requires specialized micromixer designs that add complexity to fabrication processes.

Scaling up microreactor technology presents a fundamental challenge different from batch reactors. Rather than increasing vessel size, microreactors require "numbering up" – operating multiple reactors in parallel. This approach introduces complex distribution systems to ensure uniform flow across all channels and sophisticated control systems to monitor and regulate numerous parallel processes simultaneously. The engineering complexity increases exponentially with scale, creating barriers to industrial implementation.

Material compatibility issues are particularly acute in microreactors due to the high surface-to-volume ratio. Channel walls can catalyze unwanted side reactions or adsorb reactants/products, affecting reaction outcomes. Selection of construction materials must balance chemical resistance, thermal conductivity, optical transparency (for monitoring), and fabrication feasibility, often requiring compromises that limit application scope.

Process monitoring and control at microscale present significant technical hurdles. Traditional sampling methods are impractical, necessitating the development of specialized in-line analytical techniques. Integration of sensors without disrupting flow patterns or creating dead zones requires sophisticated engineering solutions. Real-time process analytical technology (PAT) implementation is essential but technically challenging due to the small volumes and rapid residence times involved.

Fabrication techniques for microreactors with complex internal geometries demand advanced manufacturing capabilities. Precision requirements for channel dimensions, surface roughness, and junction designs often necessitate specialized microfabrication techniques that increase production costs and limit material options, creating barriers to widespread adoption in cost-sensitive fine chemical manufacturing environments.

Flow control and clogging represent primary obstacles in microreactor technology. The narrow channels (typically 10-1000 μm) are susceptible to blockages from particulates, precipitates, or high-viscosity fluids. This issue becomes particularly problematic in multiphase reactions or when dealing with solid-forming reactions common in fine chemical synthesis. Advanced strategies such as ultrasonic integration, specialized surface treatments, and pulsed flow techniques are being developed to mitigate these challenges, but they add complexity to system design.

Heat and mass transfer, while generally enhanced in microreactors, present unique challenges at microscale. Temperature gradients can be difficult to control precisely across the entire reactor volume, especially for highly exothermic reactions characteristic of many fine chemical processes. Additionally, achieving uniform mixing in laminar flow conditions requires specialized micromixer designs that add complexity to fabrication processes.

Scaling up microreactor technology presents a fundamental challenge different from batch reactors. Rather than increasing vessel size, microreactors require "numbering up" – operating multiple reactors in parallel. This approach introduces complex distribution systems to ensure uniform flow across all channels and sophisticated control systems to monitor and regulate numerous parallel processes simultaneously. The engineering complexity increases exponentially with scale, creating barriers to industrial implementation.

Material compatibility issues are particularly acute in microreactors due to the high surface-to-volume ratio. Channel walls can catalyze unwanted side reactions or adsorb reactants/products, affecting reaction outcomes. Selection of construction materials must balance chemical resistance, thermal conductivity, optical transparency (for monitoring), and fabrication feasibility, often requiring compromises that limit application scope.

Process monitoring and control at microscale present significant technical hurdles. Traditional sampling methods are impractical, necessitating the development of specialized in-line analytical techniques. Integration of sensors without disrupting flow patterns or creating dead zones requires sophisticated engineering solutions. Real-time process analytical technology (PAT) implementation is essential but technically challenging due to the small volumes and rapid residence times involved.

Fabrication techniques for microreactors with complex internal geometries demand advanced manufacturing capabilities. Precision requirements for channel dimensions, surface roughness, and junction designs often necessitate specialized microfabrication techniques that increase production costs and limit material options, creating barriers to widespread adoption in cost-sensitive fine chemical manufacturing environments.

Current Microreactor vs Batch Reactor Solutions

01 Enhanced efficiency in microreactors compared to batch reactors

Microreactors offer significantly improved efficiency over traditional batch reactors due to their superior heat and mass transfer capabilities. The high surface-to-volume ratio in microreactors allows for better temperature control, faster mixing, and more uniform reaction conditions. This leads to reduced reaction times, lower energy consumption, and more consistent product quality. The continuous flow nature of microreactors also enables real-time monitoring and adjustment of reaction parameters, further enhancing process efficiency.- Enhanced efficiency in microreactors compared to batch reactors: Microreactors offer significantly improved efficiency over traditional batch reactors due to their superior heat and mass transfer capabilities. The high surface-to-volume ratio in microreactors allows for better temperature control, faster mixing, and more uniform reaction conditions. This results in reduced reaction times, lower energy consumption, and more consistent product quality. The continuous flow nature of microreactors also enables easier scale-up while maintaining reaction parameters.

- Improved yield and selectivity in microreactor systems: Microreactors demonstrate superior yield and selectivity compared to conventional batch processes due to precise control over reaction parameters. The enhanced mixing efficiency and uniform temperature distribution minimize unwanted side reactions and by-product formation. This precise control allows for optimization of reaction conditions to maximize desired product formation. Additionally, the short residence times in microreactors can prevent degradation of sensitive intermediates, further improving overall yield and product purity.

- Process intensification through microreactor technology: Microreactor technology enables significant process intensification by allowing reactions to be conducted under more extreme conditions that would be unsafe or impractical in batch reactors. These systems can operate at higher pressures, temperatures, and concentrations while maintaining safety due to their small internal volumes. The improved heat transfer capabilities also permit highly exothermic reactions to be performed with minimal risk. This intensification leads to smaller equipment footprints, reduced solvent usage, and overall more sustainable chemical processing.

- Continuous flow processing advantages over batch operations: Continuous flow processing in microreactors offers numerous advantages over batch operations, including consistent product quality, reduced labor requirements, and improved process control. The steady-state operation eliminates batch-to-batch variations and allows for real-time monitoring and adjustment of reaction parameters. Continuous systems also facilitate easier integration with downstream processing steps, creating more efficient end-to-end manufacturing processes. Additionally, the ability to operate continuously reduces startup and shutdown waste typically associated with batch processing.

- Hybrid and parallel reactor configurations for optimized production: Hybrid systems combining microreactors with batch reactors, as well as parallel microreactor configurations, offer optimized solutions for various production scenarios. These hybrid approaches leverage the advantages of both reactor types: microreactors for fast, highly exothermic reaction steps requiring precise control, and batch reactors for slower reactions or those involving solids. Parallel microreactor arrangements enable high-throughput experimentation for rapid process development and optimization. These configurations also provide flexible manufacturing capabilities that can adapt to changing production demands while maintaining efficiency and product quality.

02 Improved yield and selectivity in microreactor systems

Microreactors demonstrate superior yield and selectivity compared to conventional batch reactors by providing precise control over reaction parameters. The enhanced mixing efficiency and uniform temperature distribution minimize unwanted side reactions and by-product formation. The controlled residence time in microreactors allows for optimal reaction completion, resulting in higher product yields. Additionally, the ability to rapidly screen reaction conditions in microreactors facilitates process optimization, further improving both yield and selectivity for complex chemical transformations.Expand Specific Solutions03 Process intensification and scale-up strategies

Process intensification through microreactor technology offers a novel approach to chemical manufacturing by enabling efficient scale-up through numbering-up rather than traditional scaling-up. This approach maintains the advantageous characteristics of microreactors while increasing production capacity. Parallel operation of multiple microreactor units preserves the high heat and mass transfer rates, precise reaction control, and safety benefits. This strategy overcomes the limitations of conventional batch reactor scale-up, where efficiency and selectivity often decrease with increasing reactor size due to mixing and heat transfer challenges.Expand Specific Solutions04 Safety and environmental benefits of microreactors

Microreactors offer significant safety and environmental advantages over batch reactors by minimizing reagent volumes and enhancing containment of hazardous materials. The small reaction volumes reduce the potential impact of runaway reactions and minimize waste generation. Continuous processing in microreactors allows for immediate quenching of reactions, reducing the risk of accumulation of unstable intermediates. These safety features enable the use of more intensive reaction conditions (higher temperatures and pressures) that can improve efficiency and yield while maintaining a safer operating environment compared to batch processes.Expand Specific Solutions05 Integration of monitoring and control systems

Advanced monitoring and control systems integrated with microreactors enable real-time process optimization that significantly outperforms batch reactor capabilities. In-line analytical techniques such as spectroscopy and chromatography provide immediate feedback on reaction progress, allowing for automated adjustments to reaction parameters. This integration facilitates quality-by-design approaches and continuous process verification, resulting in more consistent product quality. The combination of microreactor technology with sophisticated control systems creates smart manufacturing platforms that can adapt to changing conditions and optimize efficiency, yield, and selectivity dynamically.Expand Specific Solutions

Leading Companies in Microreactor Manufacturing

Microreactors versus batch reactors in fine chemical synthesis represents an evolving technological landscape currently in a growth phase. The global market for microreactor technology is expanding rapidly, projected to reach approximately $1.2 billion by 2026, driven by demands for process intensification and sustainable manufacturing. Leading companies like Corning, Inc., Lonza Ltd., and Fraunhofer-Gesellschaft are advancing microreactor technology through continuous flow chemistry innovations, while traditional batch reactor manufacturers such as Hitachi Ltd., SINOPEC Engineering, and LG Chem Ltd. maintain significant market presence. Academic institutions including Stevens Institute of Technology, Technical University of Denmark, and Zhejiang University are contributing breakthrough research in this field. The technology is approaching maturity in pharmaceutical applications but remains in development for broader fine chemical synthesis, with industry-academic collaborations accelerating commercialization pathways.

Corning, Inc.

Technical Solution: Corning has pioneered the Advanced-Flow™ Reactor (AFR) technology specifically designed for fine chemical synthesis applications. Their microreactors utilize proprietary glass and ceramic materials that offer exceptional chemical resistance and thermal stability, allowing operation under harsh reaction conditions up to 200°C and 30 bar[2]. The heart of Corning's technology is their unique "heart cell" design featuring specialized flow patterns that create intense mixing while maintaining laminar flow, achieving mixing times in milliseconds rather than minutes or hours in conventional batch reactors. This results in reaction selectivity improvements of up to 50% for complex fine chemical syntheses[4]. Corning's AFR systems are modular and scalable, with production capacities ranging from grams to tons per day using the same fundamental technology. The transparent nature of their glass reactors also enables visual process monitoring, while integrated sensors provide comprehensive data on temperature, pressure, and flow parameters for precise process control and optimization.

Strengths: Exceptional chemical compatibility with corrosive reagents; superior heat transfer capabilities (10-100 times better than batch); transparent reactors allow visual process monitoring; proven scalability from lab to commercial production. Weaknesses: Higher upfront investment costs; potential challenges with reactions involving solids or high viscosity materials; requires process redesign when converting from batch to continuous flow.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced microreactor technology specifically designed for fine chemical synthesis applications. Their microreactor systems feature precision-engineered stainless steel and specialized alloy constructions with microchannel dimensions ranging from 100-500 μm, enabling exceptional control over reaction parameters. Sinopec's technology incorporates innovative static mixing elements within the microchannels that create controlled turbulence patterns, achieving mixing times in milliseconds rather than minutes in conventional batch reactors[9]. For temperature-sensitive fine chemical reactions, their systems utilize advanced thermal management with multiple independently controlled temperature zones allowing for precise temperature gradients throughout the reaction pathway. Sinopec has successfully implemented this technology for various high-value fine chemical intermediates, demonstrating yield improvements of 10-30% while reducing reaction times by up to 80%[10]. Their microreactor systems also feature integrated pressure control mechanisms that enable safe operation under elevated pressures (up to 100 bar), expanding the range of possible reaction conditions beyond what is safely achievable in batch reactors.

Strengths: Superior heat and mass transfer capabilities allowing for safer handling of highly exothermic reactions; significant reduction in reaction times and solvent usage; improved product quality consistency; enhanced process control with integrated monitoring systems. Weaknesses: Higher initial capital investment compared to batch systems; requires specialized expertise for operation and maintenance; potential challenges with reactions involving solids or high viscosity materials.

Key Patents in Microreactor Technology

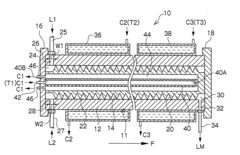

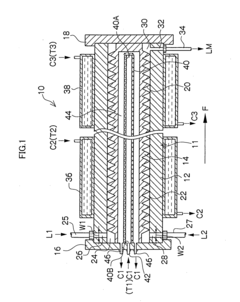

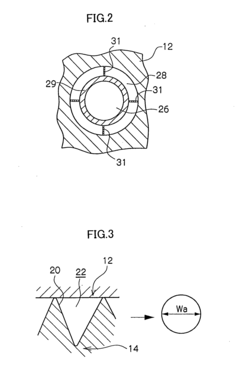

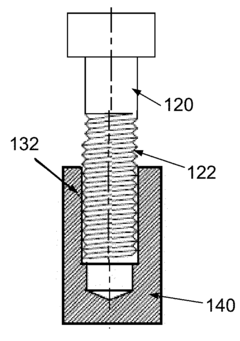

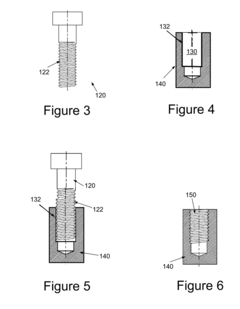

Microreactor

PatentInactiveUS20050031507A1

Innovation

- A microreactor with a spiral reaction channel formed by cutting a spiral screw thread on a round-bar-shaped core member or an outer cylindrical member, allowing for easy and robust manufacturing using general machining technologies, eliminating the need for special precision micro processing techniques.

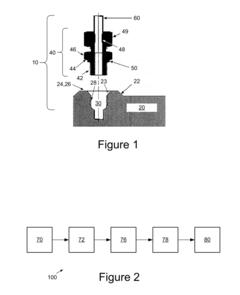

Complex structures in refractory bodies and methods of forming

PatentActiveUS20180010718A1

Innovation

- A method involving a green-state refractory-material structure with a removable carbon insert having a negative surface of the desired shape, which is machined into the ceramic body, fired together, and then removed to form internal threads, using graphite as a suitable insert material to match thermal expansion and prevent chemical reactions.

Scale-up Strategies for Microreactor Processes

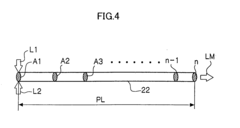

Scaling up microreactor processes presents unique challenges and opportunities compared to traditional batch reactor scale-up. The fundamental approach to microreactor scale-up follows two primary strategies: numbering-up (external scale-up) and equipment sizing (internal scale-up), each with distinct advantages for fine chemical synthesis applications.

Numbering-up involves replicating identical microreactor units in parallel configurations, maintaining the same channel dimensions and flow characteristics across all units. This approach preserves the excellent heat and mass transfer properties observed at laboratory scale, ensuring consistent product quality during production expansion. For fine chemicals requiring precise reaction control, this strategy minimizes the risk of quality variations that typically plague batch scale-up operations.

Equipment sizing, alternatively, focuses on increasing the dimensions of microreactor channels while maintaining laminar flow regimes. This approach requires sophisticated computational fluid dynamics modeling to ensure that the enhanced throughput doesn't compromise the mixing efficiency and heat transfer capabilities that make microreactors advantageous for sensitive fine chemical syntheses.

Hybrid approaches combining both strategies have emerged as particularly effective for complex multi-step syntheses. These systems utilize modular designs where reaction stages with different requirements can be optimized independently, allowing for targeted scale-up solutions at each process step. This flexibility proves especially valuable for fine chemicals with sequential reaction pathways.

Process intensification techniques complement these scale-up strategies by enhancing throughput without proportional increases in equipment size. Advanced microstructured designs incorporating static mixers, flow distributors, and integrated heat exchangers can significantly boost productivity while maintaining the superior reaction control that distinguishes microreactors from batch systems.

Commercial implementation considerations must address practical challenges including pressure drop management across parallel systems, flow distribution uniformity, and robust control systems capable of monitoring multiple process streams simultaneously. Manufacturers have developed specialized manifold designs and distribution systems to ensure balanced flow across numbered-up units, critical for maintaining product consistency.

Economic analysis reveals that while initial capital investment for microreactor scale-up typically exceeds batch alternatives, the reduced development time, improved yield, and decreased waste generation often result in superior long-term return on investment, particularly for high-value fine chemicals where product quality commands premium pricing.

Numbering-up involves replicating identical microreactor units in parallel configurations, maintaining the same channel dimensions and flow characteristics across all units. This approach preserves the excellent heat and mass transfer properties observed at laboratory scale, ensuring consistent product quality during production expansion. For fine chemicals requiring precise reaction control, this strategy minimizes the risk of quality variations that typically plague batch scale-up operations.

Equipment sizing, alternatively, focuses on increasing the dimensions of microreactor channels while maintaining laminar flow regimes. This approach requires sophisticated computational fluid dynamics modeling to ensure that the enhanced throughput doesn't compromise the mixing efficiency and heat transfer capabilities that make microreactors advantageous for sensitive fine chemical syntheses.

Hybrid approaches combining both strategies have emerged as particularly effective for complex multi-step syntheses. These systems utilize modular designs where reaction stages with different requirements can be optimized independently, allowing for targeted scale-up solutions at each process step. This flexibility proves especially valuable for fine chemicals with sequential reaction pathways.

Process intensification techniques complement these scale-up strategies by enhancing throughput without proportional increases in equipment size. Advanced microstructured designs incorporating static mixers, flow distributors, and integrated heat exchangers can significantly boost productivity while maintaining the superior reaction control that distinguishes microreactors from batch systems.

Commercial implementation considerations must address practical challenges including pressure drop management across parallel systems, flow distribution uniformity, and robust control systems capable of monitoring multiple process streams simultaneously. Manufacturers have developed specialized manifold designs and distribution systems to ensure balanced flow across numbered-up units, critical for maintaining product consistency.

Economic analysis reveals that while initial capital investment for microreactor scale-up typically exceeds batch alternatives, the reduced development time, improved yield, and decreased waste generation often result in superior long-term return on investment, particularly for high-value fine chemicals where product quality commands premium pricing.

Sustainability Impact of Microreactor Technology

The adoption of microreactor technology represents a significant paradigm shift in chemical manufacturing with profound implications for sustainability. Microreactors demonstrate superior energy efficiency compared to traditional batch reactors, with studies indicating energy consumption reductions of 30-50% in various fine chemical synthesis processes. This efficiency stems from improved heat transfer capabilities, precise temperature control, and the elimination of energy-intensive heating and cooling cycles characteristic of batch operations.

Water conservation constitutes another critical sustainability advantage of microreactor systems. The continuous flow nature of microreactors typically requires 40-70% less process water than equivalent batch processes. This reduction becomes particularly significant in water-stressed regions where chemical manufacturing facilities operate, contributing to reduced industrial water footprints.

Waste generation metrics further highlight microreactors' sustainability credentials. The enhanced reaction selectivity achieved through superior mixing and precise residence time control results in fewer side reactions and byproducts. Quantitative analyses across multiple fine chemical synthesis case studies demonstrate waste reduction ranging from 20-80% compared to batch equivalents, directly translating to decreased environmental impact and reduced waste treatment requirements.

From a life cycle assessment perspective, microreactor technology offers compelling advantages. The smaller physical footprint of microreactor installations reduces construction material requirements by up to 75% compared to traditional batch facilities of equivalent production capacity. Additionally, the modular nature of microreactor systems facilitates equipment reuse and reconfiguration, extending operational lifespans and reducing manufacturing-related environmental impacts.

Chemical safety improvements represent an often-overlooked sustainability benefit. Microreactors' inherently smaller reaction volumes minimize hazardous material inventories, reducing potential environmental release scenarios by orders of magnitude. This safety-by-design approach aligns with green chemistry principles while simultaneously reducing insurance costs and regulatory compliance burdens.

Looking forward, microreactor technology enables more sustainable manufacturing models through decentralized production capabilities. By facilitating distributed manufacturing closer to end markets, microreactors can significantly reduce transportation-related carbon emissions in chemical supply chains. Early adopters report logistics-related emissions reductions of 15-30% through implementation of distributed manufacturing strategies enabled by microreactor technology.

Water conservation constitutes another critical sustainability advantage of microreactor systems. The continuous flow nature of microreactors typically requires 40-70% less process water than equivalent batch processes. This reduction becomes particularly significant in water-stressed regions where chemical manufacturing facilities operate, contributing to reduced industrial water footprints.

Waste generation metrics further highlight microreactors' sustainability credentials. The enhanced reaction selectivity achieved through superior mixing and precise residence time control results in fewer side reactions and byproducts. Quantitative analyses across multiple fine chemical synthesis case studies demonstrate waste reduction ranging from 20-80% compared to batch equivalents, directly translating to decreased environmental impact and reduced waste treatment requirements.

From a life cycle assessment perspective, microreactor technology offers compelling advantages. The smaller physical footprint of microreactor installations reduces construction material requirements by up to 75% compared to traditional batch facilities of equivalent production capacity. Additionally, the modular nature of microreactor systems facilitates equipment reuse and reconfiguration, extending operational lifespans and reducing manufacturing-related environmental impacts.

Chemical safety improvements represent an often-overlooked sustainability benefit. Microreactors' inherently smaller reaction volumes minimize hazardous material inventories, reducing potential environmental release scenarios by orders of magnitude. This safety-by-design approach aligns with green chemistry principles while simultaneously reducing insurance costs and regulatory compliance burdens.

Looking forward, microreactor technology enables more sustainable manufacturing models through decentralized production capabilities. By facilitating distributed manufacturing closer to end markets, microreactors can significantly reduce transportation-related carbon emissions in chemical supply chains. Early adopters report logistics-related emissions reductions of 15-30% through implementation of distributed manufacturing strategies enabled by microreactor technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!